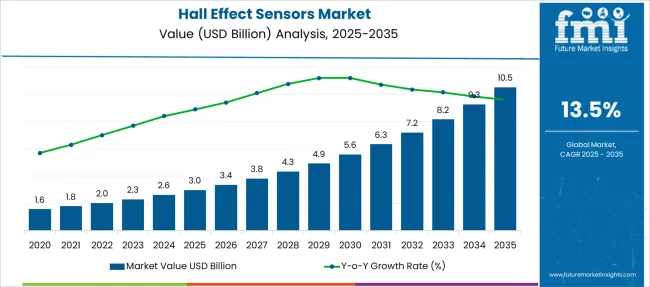

The Hall Effect Sensors Market is estimated to be valued at USD 3.0 billion in 2025 and is projected to reach USD 10.5 billion by 2035, registering a compound annual growth rate (CAGR) of 13.5% over the forecast period.

| Metric | Value |

|---|---|

| Hall Effect Sensors Market Estimated Value in (2025 E) | USD 3.0 billion |

| Hall Effect Sensors Market Forecast Value in (2035 F) | USD 10.5 billion |

| Forecast CAGR (2025 to 2035) | 13.5% |

The hall effect sensors market is experiencing steady growth as industries increasingly require precise magnetic field detection for various applications. Technological advancements have enhanced sensor accuracy and sensitivity while reducing size and power consumption. This has encouraged adoption across automotive, consumer electronics, and industrial sectors.

The rise of automation and smart device integration has further fueled demand for reliable sensing solutions. Material innovations have played a significant role in improving sensor performance and durability.

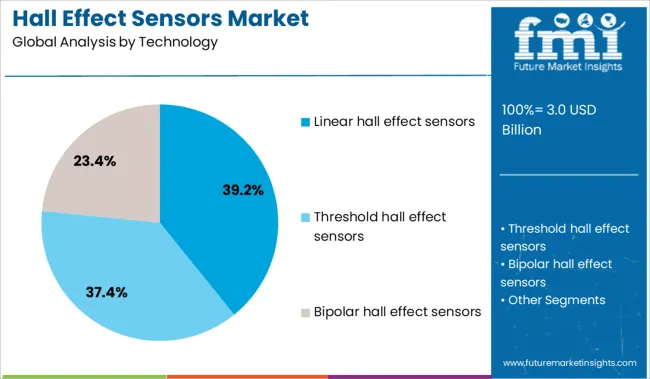

The market outlook remains positive as ongoing developments in sensor technology meet the growing need for accurate and cost-effective detection systems. Growth is expected to be led by linear hall effect sensors due to their wide applicability, indium antimonide as a preferred material for its superior properties, and position sensing as a primary application area.

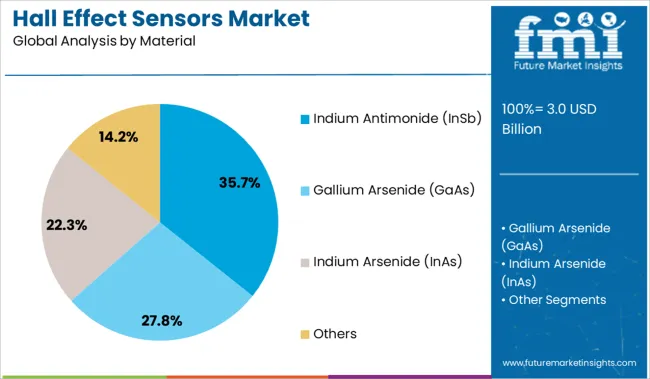

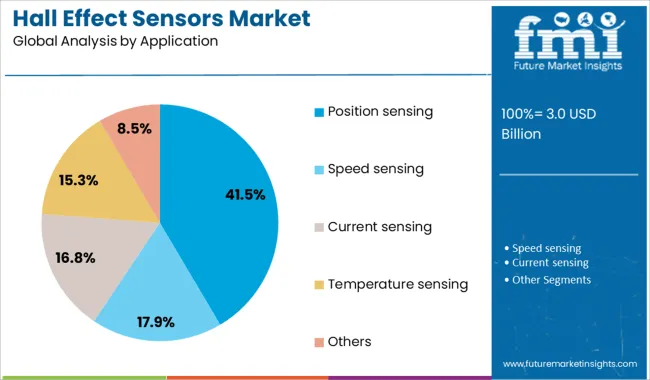

The market is segmented by Technology, Material, Application, and End Use and region. By Technology, the market is divided into Linear hall effect sensors, Threshold hall effect sensors, and Bipolar hall effect sensors. In terms of Material, the market is classified into Indium Antimonide (InSb), Gallium Arsenide (GaAs), Indium Arsenide (InAs), and Others. Based on Application, the market is segmented into Position sensing, Speed sensing, Current sensing, Temperature sensing, and Others. By End Use, the market is divided into Automotive, Consumer electronics, Industrial, Healthcare, Aerospace & defense, Energy & utilities, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The linear hall effect sensors segment is projected to hold 39.2% of the market revenue in 2025, establishing itself as the leading technology type. This segment’s growth is driven by its ability to provide continuous analog output proportional to the magnetic field strength, which is essential for precise measurements. Industries have adopted linear sensors for their versatility in applications such as speed, current, and position sensing.

The high accuracy and reliability of linear hall effect sensors have made them suitable for integration in complex systems requiring fine control.

As the demand for real-time monitoring and automated control increases, linear hall effect sensors are expected to maintain their dominant position.

Indium antimonide is anticipated to account for 35.7% of the hall effect sensors market revenue in 2025, becoming the preferred material. Its high electron mobility enables sensors to operate efficiently at low power and with enhanced sensitivity. The material’s physical and electronic properties allow for the development of miniaturized sensors with fast response times.

Indium antimonide’s performance advantages make it ideal for applications where precision and energy efficiency are critical.

With ongoing research into novel semiconductor materials, indium antimonide remains a top choice for high-performance hall effect sensors.

The position sensing application segment is projected to hold 41.5% of the hall effect sensors market revenue in 2025, reflecting its widespread use. Position sensing requires accurate detection of the location or movement of components, which hall effect sensors provide by measuring magnetic fields with precision. This application is critical in automotive systems such as throttle position monitoring and electronic steering, as well as in industrial automation where equipment positioning affects process quality.

The growth of robotics and smart machinery has further increased reliance on position sensing technologies.

As precision and control become more vital across sectors, position sensing will continue to drive hall effect sensor demand.

Rising demand for robust magnetic field detection in automotive, industrial, and consumer electronics drives growth. Opportunities emerge via miniaturization, IoT integration, and expansion into robotics, renewable energy, and wearables.

Hall effect sensors are increasingly adopted in automotive applications for position sensing, speed detection, and brushless DC motor commutation. As vehicles incorporate more electric powertrains and safety systems, the need for accurate, contactless current and magnetic field measurement grows. In industrial automation, these sensors enable reliable, non-contact feedback in robotics, conveyor systems, and motor control, reducing mechanical wear and improving lifespan. Their immunity to contaminants like dust and oil makes them ideal for harsh environments. Regulatory mandates for automotive safety, including monitoring of anti-lock braking systems, throttle position, and power steering, also fuel demand. Moreover, the trend toward electrified mobility and automated production lines is accelerating Hall sensor deployment as a dependable building block in sensor ecosystems.

Market opportunities center on advanced miniaturization, integration with IoT devices, and entry into emerging segments. As consumer electronics, wearables, and smart appliances proliferate, there is growing demand for small, energy-efficient Hall sensors embedded in compact PCB designs. Integration into IoT-enabled systems permits real-time magnetic field monitoring, predictive maintenance, and enhanced device diagnostics. Renewable energy applications, including wind turbines and solar trackers, also leverage Hall sensors for precise position and current sensing. Additionally, the robotics and drone industries require lightweight, low‑power sensor solutions for navigation and motor control. Partnerships between sensor manufacturers and electronics OEMs to embed Hall sensors in smart devices can unlock new applications. Focus on cost-effective, highly sensitive, and low-power versions could drive broader adoption across fast-growing technology markets.

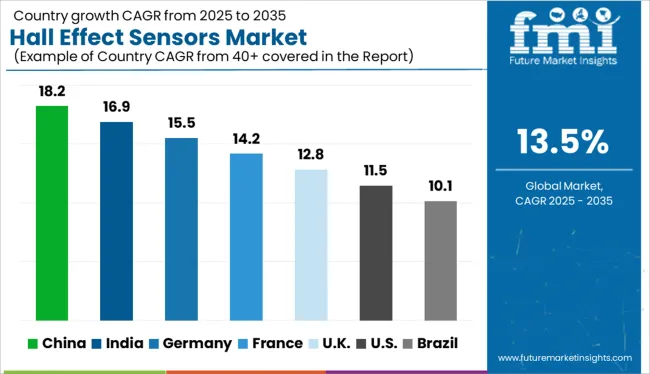

| Country | CAGR |

|---|---|

| India | 16.9% |

| Germany | 15.5% |

| France | 14.2% |

| UK | 12.8% |

| USA | 11.5% |

| Brazil | 10.1% |

The global Hall effect sensors market is projected to grow at a CAGR of 13.5% from 2025 to 2035, driven by increased demand for contactless sensing in automotive, industrial automation, and consumer electronics. China leads with a CAGR of 18.2%, supported by robust EV production, industrial robotics, and domestic sensor fabrication capacity. India follows at 16.9%, fueled by smart manufacturing initiatives and rising adoption in two-wheeler and utility vehicle segments. Germany, at 15.5%, shows strong growth through high-precision applications in automotive safety, power electronics, and motion control. Among OECD countries, the United Kingdom (12.8%) and the United States (11.5%) reflect steady demand driven by integration in ADAS, IoT devices, and motor feedback systems. This report covers detailed analysis of 40+ countries, and the top five countries have been shared as a reference.

Between 2025 and 2035, the Hall effect sensors market across China is projected to grow at a remarkable CAGR of 18.2%, with annual growth fluctuating between 17.5% and 18.8%. Expanding EV manufacturing, rapid industrial automation, and growth in consumer electronics are accelerating sensor deployment across applications. Domestic firms are scaling production of integrated magnetic sensors for battery monitoring, motor control, and proximity sensing. Government-backed smart manufacturing initiatives are fueling demand in robotics, automotive, and renewable energy systems. As the semiconductor sector strengthens, China is positioning itself as both a consumer and global supplier of next-generation Hall sensors.

Hall effect sensors market in India is set to grow at a strong CAGR of 16.9% from 2025 to 2035, with annual gains between 16.2% and 17.5%. This surge is driven by rising demand in electric vehicles, industrial automation, and infrastructure monitoring. Domestic startups and electronics firms are collaborating on sensor innovations designed for compact and cost-sensitive applications. The expansion of EV charging networks and motor controller units is fueling volume requirements across OEMs. With Make-in-India and PLI schemes incentivizing local manufacturing, Hall effect sensors are emerging as essential components in India’s digital and energy-efficient transition.

The Hall effect sensors market in Germany is forecast to grow at a CAGR of 15.5% between 2025 and 2035, with annual growth ranging from 14.9% to 16.1%. Known for its precision engineering and advanced mobility sector, Germany is rapidly embedding Hall sensors in EVs, robotics, and smart automation systems. Automotive Tier-1 suppliers are adopting linear and rotary Hall sensors to optimize electric drivetrain efficiency and battery safety. Smart factory initiatives under Industry 4.0 are also incorporating Hall sensors for real-time position and speed monitoring. Local R&D institutions are enhancing sensor performance for magnetic immunity, temperature resilience, and long-term calibration accuracy.

With a projected CAGR of 12.8% from 2025 to 2035, and year-over-year growth between 12.2% and 13.3%, the Hall effect sensors market in the United Kingdom is expanding rapidly. Electrification in transport, wind energy integration, and smart infrastructure are all driving sensor demand. British engineering firms are leveraging Hall effect technology to develop compact, energy-efficient solutions for embedded systems. Applications in elevators, grid systems, and autonomous platforms are gaining traction. Government-backed clean tech and robotics programs are also creating opportunities for sensor suppliers to participate in innovation-heavy segments.

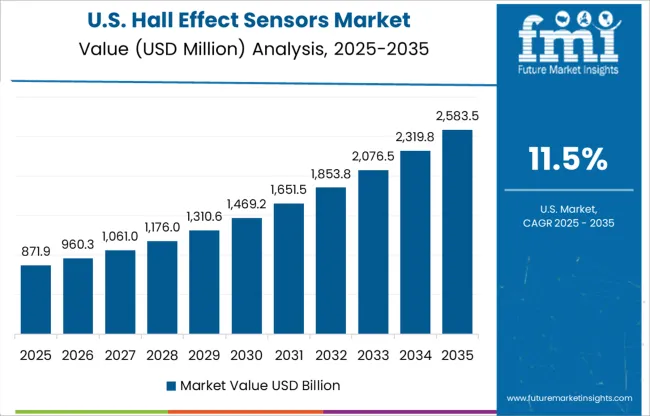

The Hall effect sensors market in the United States is projected to grow at a CAGR of 11.5% between 2025 and 2035, with year-on-year expansion ranging from 10.9% to 12.0%. Growth is supported by strong demand in automotive electrification, aerospace electronics, and industrial safety systems. Sensor suppliers are scaling up production for brushless DC motor applications and advanced driver-assistance systems (ADAS). Innovation is centered around robust, high-temperature-resistant Hall sensors capable of operating in harsh environments. Smart agriculture, HVAC, and robotics are also contributing to steady adoption across multiple verticals.

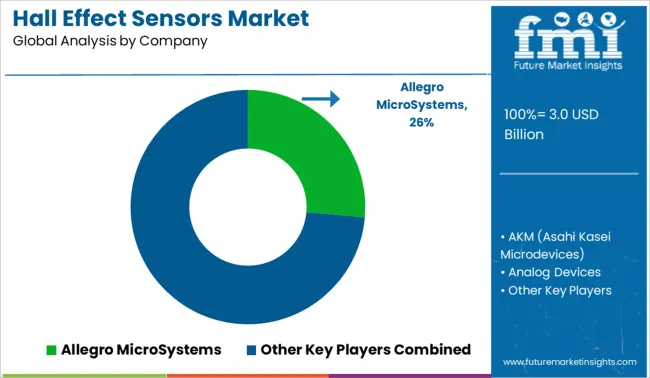

The Hall effect sensors market is moderately consolidated, with a few key players holding significant market shares due to strong technological capabilities and wide industrial adoption. Tier 1 companies like Allegro MicroSystems, AKM (Asahi Kasei Microdevices), and Infineon Technologies dominate through advanced sensor integration, automotive-grade reliability, and extensive product portfolios addressing applications in automotive, consumer electronics, and industrial automation. Tier 2 players such as Analog Devices, TDK Corporation, and Honeywell International focus on precision sensing and magnetic field measurement in high-performance and safety-critical systems. TE Connectivity and others in the Tier 3 segment offer application-specific solutions for niche markets. Market expansion is driven by the growth of EVs, smart devices, and Industry 4.0 automation.

On April 8, 2025, TDK’s Micronas division introduced the HAL 3550 (single‑die) and HAR 3550 (dual‑die) 2D Hall‑effect position sensors—ASIL‑C, ISO 26262 compliant, with analog, PWM, and SENT outputs—for automotive safety applications, as mentioned in Micronas/TDK trade news

| Item | Value |

|---|---|

| Quantitative Units | USD 3.0 Billion |

| Technology | Linear hall effect sensors, Threshold hall effect sensors, and Bipolar hall effect sensors |

| Material | Indium Antimonide (InSb), Gallium Arsenide (GaAs), Indium Arsenide (InAs), and Others |

| Application | Position sensing, Speed sensing, Current sensing, Temperature sensing, and Others |

| End Use | Automotive, Consumer electronics, Industrial, Healthcare, Aerospace & defense, Energy & utilities, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Allegro MicroSystems, AKM (Asahi Kasei Microdevices), Analog Devices, Honeywell International, Infineon Technologies, TDK Corporation, and TE Connectivity |

| Additional Attributes | Dollar sales by sensor type (linear, threshold, bipolar), output type (analog, digital), and end-use sector (automotive, consumer electronics, industrial automation, aerospace, medical devices); regional production and demand shifts driven by EV adoption and Industry 4.0; innovation in miniaturization and sensitivity enhancement; integration with IoT and edge computing platforms; pricing dynamics impacted by semiconductor supply chains; environmental considerations in sensor manufacturing and disposal; and emerging applications in renewable energy systems and robotics. |

The global hall effect sensors market is estimated to be valued at USD 3.0 billion in 2025.

The market size for the hall effect sensors market is projected to reach USD 10.5 billion by 2035.

The hall effect sensors market is expected to grow at a 13.5% CAGR between 2025 and 2035.

The key product types in hall effect sensors market are linear hall effect sensors, threshold hall effect sensors and bipolar hall effect sensors.

In terms of material, indium antimonide (insb) segment to command 35.7% share in the hall effect sensors market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Si-based Hall Effect Sensors Market Size and Share Forecast Outlook 2025 to 2035

Halloysite Market Size and Share Forecast Outlook 2025 to 2035

Hall-Effect Current Sensor Market Size and Share Forecast Outlook 2025 to 2035

Shallow Depth SURF Market Size and Share Forecast Outlook 2025 to 2035

Concert Halls And Theatres Market Size and Share Forecast Outlook 2025 to 2035

Oral Food Challenge Testing Market Analysis Size and Share Forecast Outlook 2025 to 2035

Field-effect Rectifier Diodes Market

Fin Field Effect Transistor (FinFET) Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Sensors Market Analysis by Type, Technology, End User & Region - Forecast from 2025 to 2035

Biosensors Market Trends – Growth & Future Outlook 2025 to 2035

UV Sensors Market Analysis by Type, End User, and Region from 2025 to 2035

Nanosensors Market Size and Share Forecast Outlook 2025 to 2035

VOC Sensors and Monitors Market Analysis - Size, Growth, and Forecast 2025 to 2035

Rain Sensors Market Size and Share Forecast Outlook 2025 to 2035

Skin Sensors Market Size, Growth, and Forecast for 2025 to 2035

Weft Sensors Market - Size, Share, and Forecast Outlook 2025 to 2035

ADAS Sensors Market Growth - Trends & Forecast 2025 to 2035

PM2.5 Sensors for Home Appliances Market Size and Share Forecast Outlook 2025 to 2035

Image Sensors Market Growth – Trends & Forecast through 2034

Chest Sensors Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA