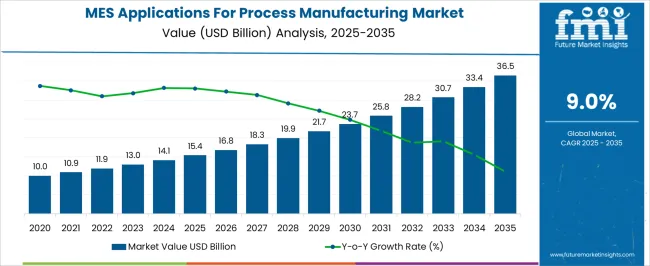

The MES Applications For Process Manufacturing Market is estimated to be valued at USD 15.4 billion in 2025 and is projected to reach USD 36.5 billion by 2035, registering a compound annual growth rate (CAGR) of 9.0% over the forecast period.

| Metric | Value |

|---|---|

| MES Applications For Process Manufacturing Market Estimated Value in (2025 E) | USD 15.4 billion |

| MES Applications For Process Manufacturing Market Forecast Value in (2035 F) | USD 36.5 billion |

| Forecast CAGR (2025 to 2035) | 9.0% |

The MES applications for process manufacturing market is gaining strong momentum as industries increasingly adopt digitized solutions to optimize plant operations, reduce downtime, and enhance traceability across production lines. Manufacturers are prioritizing real time visibility and performance tracking in response to rising regulatory demands, supply chain disruptions, and growing pressure to improve product quality and operational efficiency.

The integration of manufacturing execution systems with enterprise platforms and industrial automation tools is facilitating better decision making, predictive maintenance, and adaptive scheduling. Advances in cloud deployment, IoT integration, and cybersecurity frameworks have further enabled widespread implementation across process intensive sectors.

As manufacturing moves toward smarter, more agile operations, MES applications are emerging as essential infrastructure for achieving consistent quality, resource optimization, and competitive differentiation.

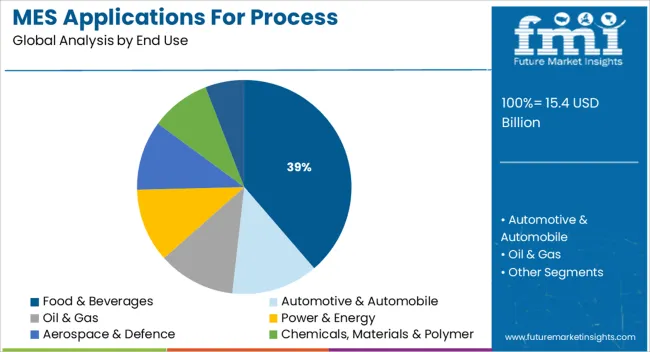

The market is segmented by End Use and region. By End Use, the market is divided into Food & Beverages, Automotive & Automobile, Oil & Gas, Power & Energy, Aerospace & Defence, Chemicals, Materials & Polymer, and Healthcare. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The food and beverages segment is projected to contribute 38.70% of total market revenue by 2025 within the end use category, making it the most dominant segment. This leadership is driven by the sector’s stringent quality control requirements, demand for batch traceability, and regulatory compliance related to food safety standards.

MES applications provide real time monitoring, recipe management, and production data capture that are crucial for minimizing waste and maintaining consistent output quality. The ability to track raw materials from sourcing to final product enables transparency and recall readiness, which are critical in food manufacturing.

Additionally, the rising complexity of consumer preferences and increasing product variety have necessitated flexible and responsive production systems. These dynamics have positioned MES applications as a vital component in ensuring agility, efficiency, and compliance in the food and beverages industry.

MES ensures manufacturing consistency through the production workflow with a focus on floor capabilities. This helps in maximizing the production flexibility and have a larger picture of the process workflow with smaller nuances.

MES applications for process manufacturing improves process execution with clear, detailed definitions of the process. It helps in increasing plant efficiency, integrated planning and inventory management. Another most crucial feature of MES applications for process manufacturing is cost optimization by determining actual, detailed product costs.

This increases profitability of organizations by capturing precise product costs and monitoring true product costs at every level. Manufacturer gets a better idea of how to optimize margins with multiple cost structure models considering the historical costs, inventory valuation, applied resource costs, and batch costs.

MES is the most evolving tool for analysing production batches. MES technology can be applicable to a workflow which has a defined initiation time and end time, further opening up novel opportunities for the expansion of the global MES applications for process manufacturing market.

The most important phase for a manufacturer is the product commercialization wherein management of the product from product conception to commercialization determines success rate. MES applications for process manufacturing also offers enterprise quality management feature.

It aids in achieving the target standards set for a product, product consistency with quality controlled batch processing holds and inspections. MES assists in improving laboratory productivity and augments customer compliance.

Geographically, global MES applications for process manufacturing market is classified into regions viz. North America, Latin America, Western Europe, Eastern Europe, Asia Pacific Excluding Japan (APEJ), Japan, Middle East and Africa (MEA).USA represents the largest region in terms of adoption of MES applications for process manufacturing.

With major industries in USA and Europe adopting MES applications for process manufacturing, the regions are projected to hold more than half the share collectively in the global market by 2029 end.

The key players in global MES applications for process manufacturingmarket are Oracle, Aptean, GENERAL ELECTRIC, Dassault Systèmes, SAP SE, Aspen Technology, Inc., Siemens AG, Rockwell Automation, Inc., Emerson Electric Co. to name a few.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to categories such as market segments, geographies, accessories and applications.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The global MES applications for process manufacturing market is classified on the basis of end use type and region.

The global mes applications for process manufacturing market is estimated to be valued at USD 15.4 billion in 2025.

The market size for the mes applications for process manufacturing market is projected to reach USD 36.5 billion by 2035.

The mes applications for process manufacturing market is expected to grow at a 9.0% CAGR between 2025 and 2035.

The key product types in mes applications for process manufacturing market are food & beverages, automotive & automobile, oil & gas, power & energy, aerospace & defence, chemicals, materials & polymer and healthcare.

In terms of , segment to command 0.0% share in the mes applications for process manufacturing market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Mesquite Flour Market Size and Share Forecast Outlook 2025 to 2035

Mesh Bag Market Size and Share Forecast Outlook 2025 to 2035

Mesh Fabric Market Size and Share Forecast Outlook 2025 to 2035

Mesotherapy Market Size and Share Forecast Outlook 2025 to 2035

Mesh Tarpaulin Sheets Market Size and Share Forecast Outlook 2025 to 2035

Understanding Market Share Trends in Mesh Bags

Mesenteric Penniculitis Treatment Market

Mesh Nebulizer for Kids Market Size and Share Forecast Outlook 2025 to 2035

Emesis Bags Market Size and Share Forecast Outlook 2025 to 2035

Domestic Food Preparation Appliances Market Size and Share Forecast Outlook 2025 to 2035

Games and Puzzles Market is segmented by Type, Licensing, Distribution Channel and Region through 2025 to 2035.

Domestic Booster Pumps Market Growth - Trends, Demand & Innovations 2025 to 2035

A2P Messaging Market Size and Share Forecast Outlook 2025 to 2035

Enzymes Market Size and Share Forecast Outlook 2025 to 2035

Intumescent Coatings Market Size and Share Forecast Outlook 2025 to 2035

Enzymes for Laundry Detergent Market Size and Share Forecast Outlook 2025 to 2035

Enzymes for Water Treatment Market Size and Share Forecast Outlook 2025 to 2035

Exosomes Diagnostic and Therapeutic Market Size and Share Forecast Outlook 2025 to 2035

Foam Mesh Sleeves Market Growth - Demand & Forecast 2025 to 2035

Web3 Messaging Tools Market Report - Growth & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA