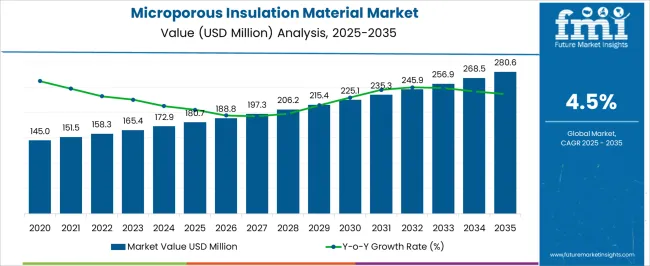

The Microporous Insulation Material Market is estimated to be valued at USD 180.7 million in 2025 and is projected to reach USD 280.6 million by 2035, registering a compound annual growth rate (CAGR) of 4.5% over the forecast period.

| Metric | Value |

|---|---|

| Microporous Insulation Material Market Estimated Value in (2025E) | USD 180.7 million |

| Microporous Insulation Material Market Forecast Value in (2035F) | USD 280.6 million |

| Forecast CAGR (2025 to 2035) | 4.5% |

The microporous insulation material market is gaining considerable traction due to its ability to provide high thermal resistance within minimal thickness, making it a preferred choice in industries requiring space-saving insulation under extreme temperature conditions. The market’s expansion is being shaped by growing energy efficiency mandates, increasing focus on equipment longevity, and the integration of advanced insulation solutions in high-temperature applications.

Significant adoption is being observed in sectors such as power generation, metallurgy, aerospace, and petrochemicals, where thermal management and safety are critical. Additionally, the rising trend of electrification and the transition to renewable energy infrastructure have intensified the demand for durable, lightweight insulation solutions.

Ongoing technological developments in composite microporous structures and silica-based formulations are enabling superior thermal conductivity performance while complying with safety standards. The ability to withstand temperatures exceeding 1000°C without degradation and the material’s compatibility with modern fabrication techniques are expected to reinforce its role in advanced energy systems and industrial thermal protection strategies in the coming years.

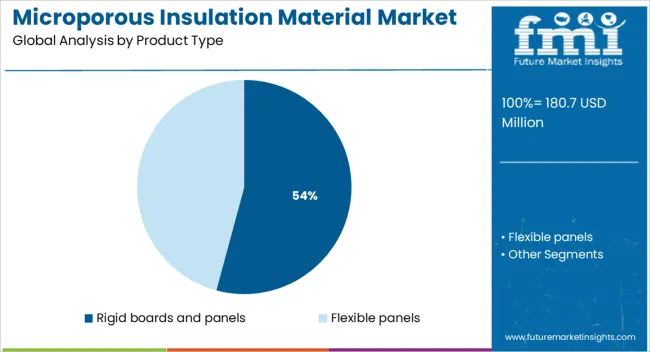

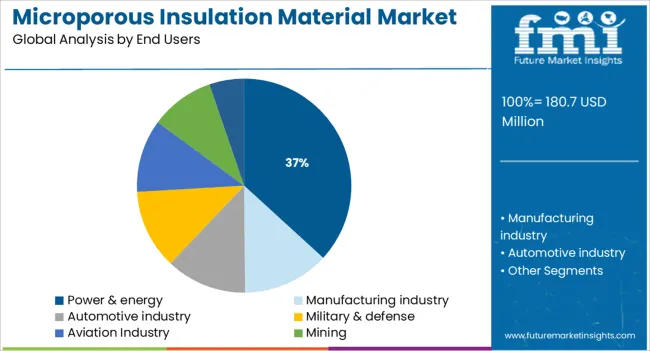

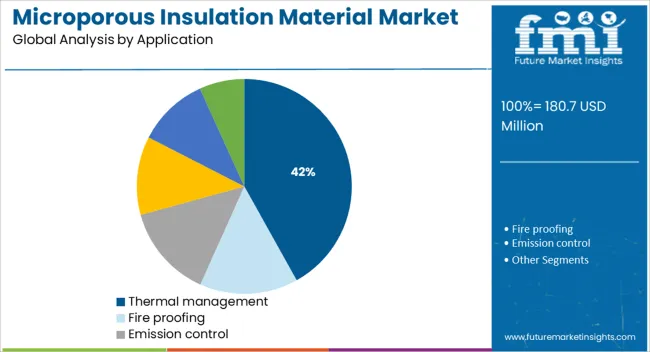

The market is segmented by Product Type, End Users, Application, and Grade and region. By Product Type, the market is divided into Rigid boards and panels and Flexible panels. In terms of End Users, the market is classified into Power & energy, Manufacturing industry, Automotive industry, Military & defense, Aviation Industry, Mining, and Oil & gas. Based on Application, the market is segmented into Thermal management, Fire proofing, Emission control, Piping insulation, Kiln and industrial furnace insulation lining, and Fuel cell and power plant insulation. By Grade, the market is divided into Silica based and Alumina based. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Rigid boards and panels are projected to account for 54.2% of the microporous insulation material market revenue in 2025, making them the dominant product type. This leadership position is supported by their high mechanical strength, dimensional stability, and superior thermal performance in fixed installations. These products are extensively utilized in furnaces, kilns, reformers, and high-temperature vessels where structural integrity and consistent insulation are essential.

Their compatibility with automated installation systems and ease of handling have further contributed to large-scale deployments across industrial environments. Enhanced resistance to thermal shock and minimal shrinkage at elevated temperatures have enabled these materials to maintain insulation performance over extended operational cycles.

The ability to be machined into complex shapes and their suitability for multilayer insulation systems have strengthened their role in thermal containment strategies The growing need for lightweight and compact insulation panels in energy and process industries has further positioned rigid boards and panels as the preferred format in the evolving landscape of thermal engineering.

The power and energy sector is anticipated to hold 36.8% of the microporous insulation material market revenue in 2025, emerging as the leading end-use segment. This dominance is being driven by the increasing emphasis on thermal efficiency, operational safety, and energy conservation across both conventional and renewable power systems. Microporous insulation materials have been integrated into gas turbines, heat recovery steam generators, and boiler linings to minimize heat loss, reduce external casing temperatures, and extend equipment life.

Their low thermal conductivity and compact profile allow significant heat retention while optimizing space in densely packed energy systems. The transition toward cleaner energy production has also accelerated the demand for insulation solutions that meet stringent environmental and efficiency standards.

In concentrated solar power plants and nuclear facilities, the materials are deployed in high-temperature zones where traditional insulation fails to meet performance benchmarks The durability, low emissions, and long lifecycle of microporous insulation make it a strategic component in energy-intensive operations, reinforcing its position within the power and energy landscape.

The thermal management segment is expected to represent 41.9% of the microporous insulation material market revenue in 2025, reflecting its critical role in modern industrial and energy systems. This segment’s growth is supported by the widespread need for temperature control and thermal containment in applications involving high heat flux and rapid thermal cycling. Microporous insulation materials have been increasingly adopted in sectors where precise thermal regulation is essential, such as aerospace, metallurgy, and chemical processing.

Their integration into thermal barriers, protective enclosures, and refractory linings has helped maintain process stability and improve operational efficiency. The capacity to offer consistent thermal performance across wide temperature gradients while reducing heat transfer to adjacent components has made them indispensable in compact systems.

Additionally, their lightweight composition and adaptability to complex geometries allow seamless incorporation into integrated thermal management designs The growing demand for advanced insulation in electric vehicle battery enclosures and fuel cells is further expected to boost this segment, as thermal stability becomes a critical factor in next-generation mobility and clean energy platforms.

The microporous insulation materials are used in applications where space is limited and superior thermal insulation performance is required. Insulation materials are precisely designed to decrease the heat flow by restricting heat conduction, radiation and convection and performs functions like conserving energy by reducing heat loss, increasing operating efficiency of heating, plumbing, steam and various other systems found in industrial and commercial installations.

Microporous insulation material are considered to be very efficient insulation products, they have thermal conductivity value lower than still air. The performance of microporous insulation material depends on their ability to block the three modes of heat transfer they are convention, radiation and conduction.

Microporous insulation material are made up of fibers, silica and other specially developed infrared opacifiers which reduce thermal transport processes by reflection and absorption of radiant heat.

Microporous insulation material are widely used for applications in process piping insulation, furnace lining back-up insulation, heat shields in aerospace and ladle lining solutions for metal products.

Microporous insulation material provides excellent energy conservation and alumina based microporous insulation material provides advanced insulation with ultra-low thermal conductivity.

The factors driving the global microporous insulation material market are the hydrophobic nature, good resistance to flame and weather and excellent thermal performance. The increase in industrialization and infrastructural development has led to increase in global microporous insulation material.

The demand for microporous insulation material in manufacturing industries like glass, cement, iron & steel has led to growth in the global microporous insulation material market.

The preference of light weighted insulating materials over traditional material is another factor pushing the market to grow. The factor restraining the global microporous insulation material in coming years is the expensive manufacturing process

Based on the geographies, the global microporous insulation material market is fragmented into seven key regions- Latin America, North America, Eastern Europe, and Western Europe, Middle East & Africa, Asia-Pacific except Japan and Japan.

Among the regions mentioned above, Western Europe and North America are the largest contributor to the global microporous insulation materials while Asia-Pacific except Japan is expected to have a higher growth rate followed by japan.

Latin America is expected to have a sluggish growth rate due to preference for substitutes. Overall the global microporous insulation material is expected to have a high growth rate owing to increase in the industrialization and infrastructural development.

Some of the market players identified in the global microporous insulation material market includes:

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to categories such as market segments, geographies, type of product and applications.

The global microporous insulation material market has been classified by product type, end users, application and grade.

The global microporous insulation material market is estimated to be valued at USD 180.7 million in 2025.

The market size for the microporous insulation material market is projected to reach USD 280.6 million by 2035.

The microporous insulation material market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in microporous insulation material market are rigid boards and panels and flexible panels.

In terms of end users, power & energy segment to command 36.8% share in the microporous insulation material market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Insulation Tester Market Size and Share Forecast Outlook 2025 to 2035

Insulation Films Market Size and Share Forecast Outlook 2025 to 2035

Insulation Paper Market Size and Share Forecast Outlook 2025 to 2035

Insulation Market Size and Share Forecast Outlook 2025 to 2035

Insulation Coatings Market Size and Share Forecast Outlook 2025 to 2035

Insulation Boards Market Size and Share Forecast Outlook 2025 to 2035

Insulation Testing Instrument Market Size and Share Forecast Outlook 2025 to 2035

OEM Insulation Market Size and Share Forecast Outlook 2025 to 2035

Pipe Insulation Films Market Size and Share Forecast Outlook 2025 to 2035

Thin Insulation Market Size and Share Forecast Outlook 2025 to 2035

Pipe Insulation Market Size and Share Forecast Outlook 2025 to 2035

Cork Insulation Market Size and Share Forecast Outlook 2025 to 2035

Pipe Insulation Products Market Size and Share Forecast Outlook 2025 to 2035

Wool Insulation Market Size and Share Forecast Outlook 2025 to 2035

Cold Insulation Market Growth - Trends & Forecast 2025 to 2035

HVAC Insulation Market Trends & Forecast 2025 to 2035

Market Leaders & Share in the Pipe Insulation Products Industry

Tank Insulation Market Growth – Trends & Forecast 2024-2034

Foam Insulation Market Growth – Trends & Forecast 2024-2034

Wire Insulation & Jacketing Compounds Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA