The North America PET Blow Molder Market is expected to witness significant growth from 2025 to 2035, driven by rising demand for lightweight and sustainable packaging solutions in many industries. These include pharmaceuticals, drinking water bottles, as well as garden tools, container boxes, for example.

Straw machines are very popular in manufacturing drink bottles. Pharmaceutical containers, personal care products, and household goods containers. Silicon machine cleaning packaging bottles, when recycling and environmental concerns are growing increasingly important, big companies are looking hard at PET stretch-blow technology

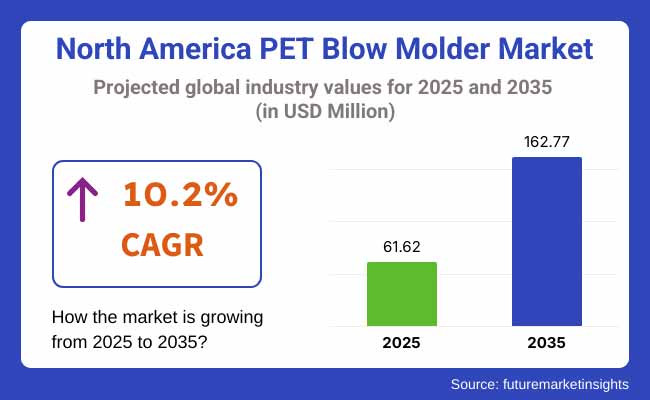

The market is projected to reach USD 162.77 Million by 2035, growing at a CAGR of 10.2% during the forecast period.

The United States is the leading PET blow molding machine manufacturer because that area has a vibrant drink and personal care product industry. To top it all off, large beverage companies have started using PET bottles more and more due to their recyclability and light weight (which saves transportation costs).

Plus, the new federal push for RPET makes the market grow faster still, yet to do so just in line with what people want and need: no more virgin resin means less air pollution! Moreover, advanced blow-molding technologies have been invested in heavily by leading manufacturers in the USA.

Canada's PET blow molder market is growing steadily as consumers become more concerned with eco-friendly packaging and lessening plastic pollution. Bottled water and soft drinks, especially those produced in local bottling plants for local markets, are the biggest users of blow-molded bottles in these elegant new plants.

And as well as expanding their global market shares by exporting more sophisticated machines than other countries do, Canadian manufacturers have been investing in energy-efficient and automated blow molding machines that line up with what the government wants for sustainability.

Mexico is a rising player in the North American PET blow molder market, though. Mexico's expanding manufacturing base means it now also exports more bottled beverages and personal cleansing supplies than previously. With its cost-competitive production environment coupled to favourable trade treaties, foreign investment in blow molding facilities has been on the rise.

Mexican manufacturers are also being induced to invest in advanced PET blow molding technology by rising consumer awareness of sustainability and recycling practices that accompany this. For reasons such as these, which go beyond just satisfying a thirsty local marketplace with other ‘home-grown’ rivals selling at higher prices than imported goods, Mexico's strength in PET containers is growing every year.

Challenge

High Capital Investment and Operational Costs

The North American PET Blow Molder Market must cope with the high level of investment capital required for advanced blow molding equipment and tooling. In addition, the ongoing operating costs such as electric power consumption, machinery maintenance all places a heavy financial burden on small- to medium-sized manufacturers; even more for large ones. Then, it is compelled by legal regulation to be responsible for environmental protection and recycling at the end of this cost structure.

Supply Chain Disruptions and Resin Price Volatility

Supply chains of the North American PET Blow Molder Market face disruption in the physical supply of PET resin, one of its key raw materials. In addition to logistics problems and global fluctuations in crude oil prices, prices of this raw material also fluctuate, making it difficult for manufacturers to predict production costs or profits. Such interruptions can lead to delays in production and an uncertain ability to supply products.

Opportunity

Growing Demand for Sustainable Packaging Solutions

As demand for green, recycled materials continues to increase, so does the potential for growth within the PET Blow Molder Market. Encouraged by consumers and the general trend to stricter legislation from all levels of government worldwide, manufacturers have begun rolling out lightweight bottles using PET and using post-consumer recycled (PCR) materials in manufacturing processes.

Technological Advancements in Blow Molding Machinery

Innovations in blow molding technology, such as the development of energy-saving machinery and the installation of automated systems, are another way to promote operational efficiency and cut production costs. Combining intelligent manufacturing methods with Industry 4.0 solutions will allow manufacturers to use their resources more economically, minimize waste, and satisfy the changing, rigorous demands of consumers.

Market growth should continue in this period from 2025 to 2035, driven by the further application of advanced blow-molding technologies and increased use of recycled polyethylene terephthalate (rPET) and digital manufacturing solutions. In terms of industry trends, the combined result of practices that encourage circular economy use and consumer demand for packaging more protective than canned vegetables will shape future conditions.

Market Shifts: A Comparative Analysis 2020 to 2024 vs. 2025 to 2035

| Market Shift | 2020 to 2024 Trends |

|---|---|

| Regulatory Landscape | Compliance with recycling mandates and packaging waste reduction initiatives |

| Market Demand | Demand driven by the bottled beverages and personal care industries |

| Industry Adoption | Focus on lightweight PET bottles and recyclable packaging solutions |

| Supply Chain and Sourcing | Dependence on traditional PET resin supply chains |

| Market Competition | Presence of regional blow molding manufacturers and multinational packaging firms |

| Market Growth Drivers | Growth is driven by convenience packaging and the expansion of beverage sectors |

| Sustainability and Energy Efficiency | Adoption of energy-efficient blow molding equipment |

| Integration of Digital Innovations | Limited use of digital technologies in production processes |

| Advancements in Manufacturing | Upgrades to semi-automated blow molding machines |

| Market Shift | 2025 to 2035 Projections |

|---|---|

| Regulatory Landscape | Strengthened circular economy regulations and incentives for using post-consumer recycled (PCR) PET materials |

| Market Demand | Increased demand for sustainable and biodegradable PET alternatives |

| Industry Adoption | Broader adoption of smart blow molding technologies and automation |

| Supply Chain and Sourcing | Diversification into rPET and bio-based PET sourcing to mitigate raw material price fluctuations |

| Market Competition | Heightened competition from startups specializing in sustainable packaging solutions |

| Market Growth Drivers | Acceleration due to eco-friendly packaging trends and advancements in production efficiency |

| Sustainability and Energy Efficiency | Transition to carbon-neutral manufacturing facilities and fully recyclable packaging systems |

| Integration of Digital Innovations | Widespread implementation of Industry 4.0 practices, predictive maintenance, and IoT-enabled manufacturing |

| Advancements in Manufacturing | Deployment of fully automated, AI-driven blow molding lines and smart quality control systems |

The United States ’ pet blow molder market is currently undergoing vigorous growth as demand for pet packaging solutions rises among food and beverage producers, in addition to its other applications, the personal care and pharmaceutical sectors. The industry’s shift toward lighter, environmentally-friendly packaging materials is driving the development of this market. Advances made in molding machine technology are also helping to expand the country’s share of global markets.

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 10.0% |

With an increasing number of eager customers and an ever greater weight tilting in favour of environmentally sustainable packaging technologies, the Canadian Market is in stable growth. For food and beverage producers, this is as true as in other industries. In order to do away with plastic packaging altogether, many manufacturers now rely on efficient PET molding systems.

| Country | CAGR (2025 to 2035) |

|---|---|

| Canada | 10.3% |

As the demand for inexpensive and recyclable packaging soars, the PET blow molder market in Mexico is gaining ground. The vigorous growth of the beverage sector--especially bottled water and carbonated drinks--is also a major driving force propelling this market.

| Country | CAGR (2025 to 2035) |

|---|---|

| Mexico | 10.5% |

In the North American PET blow-moulder market, blow-moulder machines take up the largest share. This is because they can create PET bottles, which are lightweight but durable and clear. They are easily used for making such things as beverage bottles and packaging for water containers, cleaners, or personal care products.

Stretch blow molding improves PET bottles' mechanical properties, like tensile strength and resistance to crashing; as such, it makes excellent containers for carbonated drinks and bottled water. Moreover, the technology results in a significant saving of materials--an important concern for manufacturers who are trying to decrease production costs and environmental impact.

The stretch blow molding machine has obtained an upper hand because of the trend to move towards sustainable and recyclable packaging in North America, This is especially true of lager beverage companies: faced with the need for light weighting initiatives, they have preferred the stretch blow molding process. Its ability to make bottles of many shapes and sizes has cemented its dominant position in this market.

In America, the North market is led by the manufacturer's pillar-type PET bottle automatic making machine. The ability of Automatic PET blow molding machines to streamline operations and reduce manual intervention makes they the machines preferred by large-scale manufacturers in industries like food & beverage and personal care. These large machines ensure greater efficiency as well as lower labour costs; they eliminate human error for the end result of higher output and better quality control.

Manufacturers are installing advanced automatic machines that feature smart technologies like IoT integration and predictive maintenance in order to optimize production processes. Since end-users today still place such a heavy emphasis on speed, consistency and cost-effectiveness, it is expected that the automatic segment will continue to be the mainstay of this industry for quite some time to come.

The North American PET blow molder market is growing steadily, driven by increasing demand from the beverage, food, pharmaceutical, and personal care sectors. PET blow molding is favoured due to its lightweight, durability, and recyclability, supporting sustainable packaging trends.

Market Share Analysis by Key Players & Manufacturers

| Company/Organization Name | Estimated Market Share (%) |

|---|---|

| Amcor plc | 14-18% |

| Plastipak Packaging, Inc. | 12-16% |

| Resilux NV | 10-14% |

| ALPLA Group | 9-13% |

| Graham Packaging Company | 7-11% |

| Other Manufacturers | 30-40% |

| Company/Organization Name | Key Offerings/Activities |

|---|---|

| Amcor plc | Molded bottles and containers made from PET (Beverages). For drinks, Beverage, personal care and even healthcare industries are common when creating these kinds of objects today. |

| Plastipak Packaging, Inc. | Packaging made with PET that has been tailored to national food standards fits well into drink boxes. Creamers and house cleaning products are among household goods for which such a high production level matches perfectly. |

| Resilux NV | Food and beverage are currently the main applications of PET preforms for blow moulding bottles. These are also used in pharmaceuticals, cosmetics and many other light industrial products. |

| ALPLA Group | When three men working in a factory in New Jersey decided to open their own cosmetic company, the result was PET bottle blow molding for pharmaceuticals and cosmetics, healthy drinks (bottles) and household products That event began a fading culture that remains undisturbed among the younger generation of Chinese |

| Graham Packaging Company | Reducing The environmental impact of the PET bottle industry by-products. Thereby achieving sustainability. |

Key Market Insights

Amcor plc (14-18%)

Amcor is a major PET blow molding company serving multiple industries such as beverages, personal care, and healthcare.

Plastipak Packaging, Inc. (12-16%)

Plastipak offers highly customizable PET packaging solutions designed for food, beverage, and household applications.

Resilux NV (10-14%)

Resilux focuses on PET preforms and blow molded products tailored to the food and beverage sectors.

ALPLA Group (9-13%)

ALPLA supplies innovative PET blow molding solutions for the pharmaceutical and personal care markets.

Graham Packaging Company (7-11%)

Graham Packaging specializes in sustainable PET blow molded containers, focusing on recyclability and lightweight designs.

Other Key Players (30-40% Combined)

Additional market contributors include:

The overall market size for North America PET Blow Molder market was USD 61.62 Million in 2025.

The North America PET Blow Molder market is expected to reach USD 162.77 Million in 2035.

The North America PET Blow Molder market demand will be driven by increasing food & beverage consumption, pharmaceutical packaging needs, personal care growth, and rising adoption of automatic and stretch molding technologies.

The top 5 countries which drives the development of North America PET Blow Molder market are USA, European Union, Japan, South Korea and UK.

Stretch Blow Molding Machines demand supplier to command significant share over the assessment period.

Table 1: Market Value (US$ Million) Forecast by Region, 2018 to 2033

Table 2: Market Volume (Units) Forecast by Region, 2018 to 2033

Table 3: Market Value (US$ Million) Forecast by Machine Type, 2018 to 2033

Table 4: Market Volume (Units) Forecast by Machine Type, 2018 to 2033

Table 5: Market Value (US$ Million) Forecast by Technology Type, 2018 to 2033

Table 6: Market Volume (Units) Forecast by Technology Type, 2018 to 2033

Table 7: Market Value (US$ Million) Forecast by End Use, 2018 to 2033

Table 8: Market Volume (Units) Forecast by End Use, 2018 to 2033

Table 9: Market Value (US$ Million) Forecast by Country, 2018 to 2033

Table 10: Market Volume (Units) Forecast by Country, 2018 to 2033

Table 11: Market Value (US$ Million) Forecast by Machine Type, 2018 to 2033

Table 12: Market Volume (Units) Forecast by Machine Type, 2018 to 2033

Table 13: Market Value (US$ Million) Forecast by Technology Type, 2018 to 2033

Table 14: Market Volume (Units) Forecast by Technology Type, 2018 to 2033

Table 15: Market Value (US$ Million) Forecast by End Use, 2018 to 2033

Table 16: Market Volume (Units) Forecast by End Use, 2018 to 2033

Figure 1: Market Value (US$ Million) by Machine Type, 2023 to 2033

Figure 2: Market Value (US$ Million) by Technology Type, 2023 to 2033

Figure 3: Market Value (US$ Million) by End Use, 2023 to 2033

Figure 4: Market Value (US$ Million) by Region, 2023 to 2033

Figure 5: Market Value (US$ Million) Analysis by Region, 2018 to 2033

Figure 6: Market Volume (Units) Analysis by Region, 2018 to 2033

Figure 7: Market Value Share (%) and BPS Analysis by Region, 2023 to 2033

Figure 8: Market Y-o-Y Growth (%) Projections by Region, 2023 to 2033

Figure 9: Market Value (US$ Million) Analysis by Machine Type, 2018 to 2033

Figure 10: Market Volume (Units) Analysis by Machine Type, 2018 to 2033

Figure 11: Market Value Share (%) and BPS Analysis by Machine Type, 2023 to 2033

Figure 12: Market Y-o-Y Growth (%) Projections by Machine Type, 2023 to 2033

Figure 13: Market Value (US$ Million) Analysis by Technology Type, 2018 to 2033

Figure 14: Market Volume (Units) Analysis by Technology Type, 2018 to 2033

Figure 15: Market Value Share (%) and BPS Analysis by Technology Type, 2023 to 2033

Figure 16: Market Y-o-Y Growth (%) Projections by Technology Type, 2023 to 2033

Figure 17: Market Value (US$ Million) Analysis by End Use, 2018 to 2033

Figure 18: Market Volume (Units) Analysis by End Use, 2018 to 2033

Figure 19: Market Value Share (%) and BPS Analysis by End Use, 2023 to 2033

Figure 20: Market Y-o-Y Growth (%) Projections by End Use, 2023 to 2033

Figure 21: Market Attractiveness by Machine Type, 2023 to 2033

Figure 22: Market Attractiveness by Technology Type, 2023 to 2033

Figure 23: Market Attractiveness by End Use, 2023 to 2033

Figure 24: Market Attractiveness by Region, 2023 to 2033

Figure 25: Market Value (US$ Million) by Machine Type, 2023 to 2033

Figure 26: Market Value (US$ Million) by Technology Type, 2023 to 2033

Figure 27: Market Value (US$ Million) by End Use, 2023 to 2033

Figure 28: Market Value (US$ Million) by Country, 2023 to 2033

Figure 29: Market Value (US$ Million) Analysis by Country, 2018 to 2033

Figure 30: Market Volume (Units) Analysis by Country, 2018 to 2033

Figure 31: Market Value Share (%) and BPS Analysis by Country, 2023 to 2033

Figure 32: Market Y-o-Y Growth (%) Projections by Country, 2023 to 2033

Figure 33: Market Value (US$ Million) Analysis by Machine Type, 2018 to 2033

Figure 34: Market Volume (Units) Analysis by Machine Type, 2018 to 2033

Figure 35: Market Value Share (%) and BPS Analysis by Machine Type, 2023 to 2033

Figure 36: Market Y-o-Y Growth (%) Projections by Machine Type, 2023 to 2033

Figure 37: Market Value (US$ Million) Analysis by Technology Type, 2018 to 2033

Figure 38: Market Volume (Units) Analysis by Technology Type, 2018 to 2033

Figure 39: Market Value Share (%) and BPS Analysis by Technology Type, 2023 to 2033

Figure 40: Market Y-o-Y Growth (%) Projections by Technology Type, 2023 to 2033

Figure 41: Market Value (US$ Million) Analysis by End Use, 2018 to 2033

Figure 42: Market Volume (Units) Analysis by End Use, 2018 to 2033

Figure 43: Market Value Share (%) and BPS Analysis by End Use, 2023 to 2033

Figure 44: Market Y-o-Y Growth (%) Projections by End Use, 2023 to 2033

Figure 45: Market Attractiveness by Machine Type, 2023 to 2033

Figure 46: Market Attractiveness by Technology Type, 2023 to 2033

Figure 47: Market Attractiveness by End Use, 2023 to 2033

Figure 48: Market Attractiveness by Country, 2023 to 2033

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Northern Blotting Market Size and Share Forecast Outlook 2025 to 2035

Northern Europe Calcium Sulphate Market Size and Share Forecast Outlook 2025 to 2035

North America Boat Trailer Market Size and Share Forecast Outlook 2025 to 2035

North America Cryogenic Label Printer Market Size and Share Forecast Outlook 2025 to 2035

North America Chitosan Market Size and Share Forecast Outlook 2025 to 2035

North America Underground Mining Vehicle Market Size and Share Forecast Outlook 2025 to 2035

North America Bulk Aseptic Packaging Market Size and Share Forecast Outlook 2025 to 2035

North America Licorice Extract Market Size and Share Forecast Outlook 2025 to 2035

North America Par Baked Bread Market Size and Share Forecast Outlook 2025 to 2035

North America Silo Bags Market Size and Share Forecast Outlook 2025 to 2035

North America Fresh Meat Packaging Market Size and Share Forecast Outlook 2025 to 2035

North America Ceramic Barbeque Grill Market Size and Share Forecast Outlook 2025 to 2035

North America Temperature Sensor Market Size and Share Forecast Outlook 2025 to 2035

North American Dietary Supplements Market Size and Share Forecast Outlook 2025 to 2035

North America Head-up Display Market Size and Share Forecast Outlook 2025 to 2035

North America, Europe & Asia Pacific Legal Cannabis Market Size and Share Forecast Outlook 2025 to 2035

North America Ceiling Cassette Market Size and Share Forecast Outlook 2025 to 2035

North America Pressure Regulating Valves Market Size and Share Forecast Outlook 2025 to 2035

North America Flame Retardant Thermoplastics Market Size and Share Forecast Outlook 2025 to 2035

Fire Pit Market Analysis in North America - Growth, Trends and Forecast from 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA