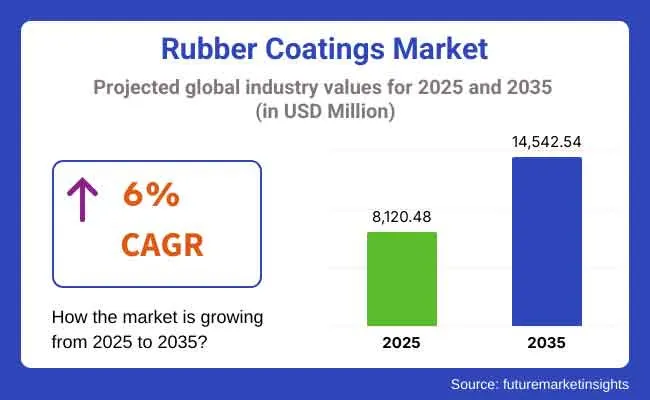

The global rubber coatings market is estimated to be valued at USD 8,120.48 million in 2025 and is projected to reach USD 14,542.54 million by 2035, reflecting a CAGR of 6.0% over the forecast period. Growth is being driven by increasing demand for abrasion-resistant, waterproof, and weather-durable coating solutions across automotive, construction, marine, and industrial applications.

Rubber coatings are being applied to extend the service life of infrastructure, equipment, and consumer goods. These coatings are being utilized to create protective barriers against moisture ingress, corrosion, chemical attack, and environmental degradation. Their elasticity and adhesion to a wide range of substrates are enabling use across concrete, metal, and plastic surfaces.

Industrial sectors are increasingly adopting rubber-based coatings to meet operational standards in corrosive and high-wear environments. According to CoatingsTech Magazine, rubber coatings are being specified in power plants, chemical storage tanks, pipelines, and marine platforms due to their performance under fluctuating environmental conditions.

In the automotive sector, rubberized undercoatings and spray-on solutions are being used to prevent rust, road salt damage, and acoustic transmission. Construction applications are utilizing these coatings for foundation waterproofing, roof sealing, and wall insulation. The demand for coatings that can accommodate structural flexing and temperature variation is supporting further adoption.

Environmental regulations concerning solvent emissions and worker safety are leading manufacturers to develop low-VOC, solvent-free, and water-based rubber coating formulations. Compliance with guidelines set by the USA Environmental Protection Agency and the European Chemicals Agency is influencing formulation chemistry and raw material selection.

Product development efforts are focusing on enhancing tensile strength, UV stability, and chemical resistance through polymer modification and additive blending. Hybrid coatings with polyurethane and silicone-modified rubber compounds are being introduced to meet specific industrial and commercial performance benchmarks.

The market is expected to remain moderately fragmented, with competition centered on product certification, durability, and sustainability claims. Long-term demand is estimated to rise as industries invest in protective surface technologies that reduce maintenance costs, improve lifecycle performance, and meet emerging environmental standards globally.

Silicone rubber is estimated to account for approximately 28% of the global rubber coatings market share in 2025 and is projected to grow at a CAGR of 6.2% through 2035. These coatings are extensively used in high-temperature environments, electrical insulation applications, and sealing surfaces in power generation, aerospace, and electronics. Their resistance to UV radiation, ozone, and weathering also makes them suitable for outdoor and exposed infrastructure, including industrial roofs, cables, and thermal insulation systems.

Manufacturers continue to enhance silicone formulations to support extreme service conditions, compliance with fire-safety norms, and compatibility with composite and metal substrates. With demand increasing across renewable energy and advanced mobility sectors, silicone rubber coatings remain a key driver of high-performance protective materials.

The automotive and transportation segment is projected to hold approximately 33% of the global rubber coatings market share in 2025 and is expected to grow at a CAGR of 6.3% through 2035. Rubber coatings are used extensively in vehicles to prevent corrosion, reduce road noise, and protect engine components from thermal and chemical exposure. Applications include chassis coatings, wheel wells, engine compartments, and electrical housing.

With the shift toward electric vehicles, the demand for lightweight, high-durability rubber coatings that support thermal management and component protection is growing rapidly. Automotive OEMs in North America, Europe, and East Asia continue to adopt advanced rubber formulations to improve vehicle performance and longevity under demanding operational environments. As safety, noise reduction, and energy efficiency become critical in next-gen mobility, the automotive segment remains a primary growth engine for rubber coatings.

Volatility in Raw Material Prices

The rubber coatings market is hindered by volatile raw material prices, especially synthetic rubber as well as petroleum-derived ingredients. The industry is exposed to price fluctuations as manufacturers’ profit margin is affected due to its reliance on raw materials that are derived from crude oil. Moreover, variations in costs are worsened by supply chain disruptions and also geopolitical factors.

Implementing cost-efficient production processes will allow businesses to make sure they remain stable while forging strategic alliances with suppliers to keep their ingredients as stable as possible or exploring bio-based alternatives.

Stringent Environmental Regulations

Rubber coating manufacturers are significantly hampered by tightening government regulations on volatile organic compounds (VOCs) and hazardous emissions. Due to the strong environmental problems of solvent based coatings companies must turn to eco-friendly solutions.

Ongoing investment in R&D to comply with REACH, the EPA, and elsewhere around the world. It follows the trend that manufacturers can be expected to create water based and lower-VOC formulations, along with focusing on clean manufacturing.

Rising Demand for Protective and Industrial Coatings

Emerging applications for high-performance protective coatings are expected across several end-user industries, including automotive, construction, and industrial sectors, which are expected to drive growth during the forecast period. These elasticized coatings provide durability, corrosion resistance, and waterproofing capabilities, which make them favorable for such harsh environmental conditions.

Because infrastructure projects are taking off all over the world and industries look for longer-term solutions in terms of equipment and assets rubber coatings will be adopted. Two-way technologies that allow for the development of new polymer blends and high-resistance formulations will give the company a competitive advantage.

Advancements in Eco-Friendly and Sustainable Coatings

The push towards sustainability is also leading to an increasing demand for environmental friendly rubber coatings. As such, manufacturers are designing bio-based and recyclable coatings that balance performance with lower environmental impact. Trends of moving toward water-based formulations, solvent-free coatings, and biodegradable materials are being energized. Businesses that prioritize sustainable practices such as green chemistry, scaling back their carbon footprint, and driving circular economy initiatives will appeal to consumer and business alike, paving the way for long-term growth.

The rubber coatings market grew in between 2020 to 2024 and the key trends during that period, bubble points (2025 to 2035): The rubber coatings market saw strong growth between 2020 and 2024 due to growing industrial applications, rising demand from the automotive industry, and increasing corrosion resistance.

Yet there were hurdles in the form of rising raw material costs and environmental compliance costs as well as supply chain issues. Manufacturers responded by investing in R&D to find sustainable alternatives and improving the efficiency of production for risk mitigation and profitability.

From 2025 onwards up until 2035, the coating market will see significant shifts, with innovations in nanotechnology-enhanced coatings, self-healing materials, and smart coatings that include embedded sensors for real-time monitoring. By 2026, there will be an increased emphasis on bio-based and recyclable coatings, and digitalization in manufacturing processes will improve production efficiency.

Leading players in the evolving Rubber coatings market will be those that possess a firm grip on advanced material science, regulatory practices, and sustainable business models.

The USA rubber coatings market is projected to expand at a 6% CAGR during the forecast period mainly due to their growing use in automotive, construction and industrial sectors. Market growth is attributed to the need for protective coatings in vehicles, machinery, and infrastructure.

Applications of rubberized coatings possess exceptional corrosion, abrasion, and weather resistance that makes them suitable for various industries. Moreover, increasing focus on sustainability has created eco-friendly, water-based rubber coatings. The market also benefiting from innovations in polymer technology, enhancing the durability and flexibility in coating. A few more growth factors are the considerable presence of key manufacturers and strong infrastructure in the region in terms of distribution networks.

| Country | CAGR (2025 to 2035) |

|---|---|

| USA | 6.2% |

This will make the United Kingdom’s rubber coatings market grow, due to increasing of infrastructure projects and industrial applications. Construction industry’s requirement for weatherproof and durable coatings is in turn driving demand.

The marine and aerospace industries are also experiencing growth with rubber coatings, given their protective properties against saltwater and extreme temperatures. Market trends are being driven by the move to sustain-able and low- VOC coatings (volatile organic compound). Increasing investments towards smart coatings with self-healing properties, and long lasting characteristics are also playing a significant role. An upsurge in the usage of spray-on rubber coverings for do it yourself (Do-It-Yourself) uses additionally augments the market.

| Country | CAGR (2025 to 2035) |

|---|---|

| UK. | 5.8% |

In the European Union, Germany, France and Italy dominate the rubber coatings market due in part to the increasing demand from the automotive and industrial sectors. Based on strict environmental guidelines in EU manufacturers are trying to design the coatings with lower emissions.

One of the main factors is the automotive sector, in which rubber coatings improve vehicle durability and reduce noise. Other applications in the industrial sector are also driving the market dynamics, such as machinery protection, pipe coatings, and electrical insulation. Retail stores and e-commerce platforms are providing easy access to these coatings for consumers, thus aiding the growth of the overall sales.

| Country | CAGR (2025 to 2035) |

|---|---|

| European Union (EU) | 6.1% |

Technological innovations and rising demand from electronics and automotive industries are some factors propelling the Japan rubber coatings market. From transportation, the use of high-performance coatings is expanding across a diverse range of industries such as to be appreciated is the electric vehicle (EV) and semiconductor sectors.

Similarly, the demand for fire-resistant and waterproof coatings in the construction industry is increasing. Japan is one of the countries with significant efforts focused on research and development, which creates advanced coatings with high flexibility, adhesion, and resistance to chemicals. Solutions that are more sustainable, such as bio-based rubber coatings, are also gaining traction due to increasing environmental issues.

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 6.3% |

South Korea rubber coatings market is exhibiting significant growth owing to the growing industrialization and the infrastructure development in the country. Anticipated growth in the shipbuilding and marine sector are also driving demand, as rubber-based coatings can provide corrosion and water damage protection.

As there is an increasing requirement for protective coatings in the country, the presence of top automobile manufacturers is also acting to strengthen the market growth. Smart coatings with self-repair functions are another major trend in South Korea. The growing popularity of government guidelines supporting eco-friendly coatings with a lower environmental footprint is also influencing the development of the market.

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 6.4% |

The rubber coatings market is competitive, with a mix of established players and regional manufacturers offering a variety of solutions for industrial, automotive, and construction applications. Companies focus on enhancing durability, flexibility, and chemical resistance to meet industry-specific needs. Key players are also investing in advanced rubber coating technologies that provide superior performance under harsh conditions. Competition is driven by cost-effectiveness, product differentiation, and the ability to deliver customized solutions.

The overall market size for rubber coatings market was USD 8,120.48 million in 2025.

The rubber coatings market expected to reach USD 14,542.54 million in 2035.

The demand for the rubber coatings market will be driven by increasing applications in automotive and construction industries, rising demand for corrosion and waterproofing solutions, growing use in industrial machinery protection, advancements in eco-friendly and high-performance coatings, and expanding infrastructure development worldwide.

The top 5 countries which drives the development of rubber coatings market are USA, UK, Europe Union, Japan and South Korea.

Material innovations driving market growth to command significant share over the assessment period.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Corrosion Protection Rubber Linings Market 2022 to 2032

Rubber Molding Market Forecast Outlook 2025 to 2035

Rubber Track for Defense and Security Market Size and Share Forecast Outlook 2025 to 2035

Rubber Frame Monitors Market Size and Share Forecast Outlook 2025 to 2035

Rubber Coating Market Size and Share Forecast Outlook 2025 to 2035

Rubber Anti-Tack Agents Market Size and Share Forecast Outlook 2025 to 2035

Rubber to Metal Bonded Articles Market Analysis Size and Share Forecast Outlook 2025 to 2035

Rubber-to-Metal Adhesion Market Analysis - Size, Share, and Forecast Outlook 2025-2035

Rubber Conveyor Belt Market Size, Growth, and Forecast 2025 to 2035

Rubber Testing Equipment Market Growth – Trends & Forecast 2025 to 2035

Rubber Tapes Market Trends - Growth & Forecast 2025 to 2035

Rubber Extruder Market Growth - Trends & Forecast 2025 to 2035

Rubber choppers Market

Gas Scrubber Market Size and Share Forecast Outlook 2025 to 2035

Air Scrubbers Market

Sleeve Rubber Stopper Market Size and Share Forecast Outlook 2025 to 2035

Europe Rubber Derived Unrefined Pyrolysis Oil Market Size and Share Forecast Outlook 2025 to 2035

Sterile Rubber Stopper Market Size and Share Forecast Outlook 2025 to 2035

Natural Rubber Market Size and Share Forecast Outlook 2025 to 2035

Plastic-Rubber Composite Market Trend Analysis Based on Product, Application, and Region 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA