The rubber conveyor belt market is valued at USD 4.21 billion in 2025 and is expected to reach USD 6.28 billion by 2035, growing at a CAGR of 4.1% during the forecast period. Asia Pacific is the most lucrative region, contributing over 50% of global demand in 2025, driven by China and India’s expanding mining, logistics, and infrastructure sectors. Meanwhile, Latin America is projected to be the fastest-growing region between 2025 and 2035, driven by rising commodity exports and logistical investments.

Rising industrial automation and the need for durable, energy-efficient material handling systems are propelling the market. Heavy-duty conveyor belts remain vital in bulk material transport across mining and metal processing operations. Meanwhile, the growth of e-commerce and warehousing is spurring demand for light- and medium-duty belts.

Barriers to growth include fluctuating raw material costs and increasing scrutiny of the rubber manufacturing sector’s environmental impact. However, the adoption of recyclable materials and AI-driven predictive maintenance is gaining traction as key trends.

Looking ahead to 2035, the market is expected to witness a shift toward eco-friendly and smart conveyor belt systems. These innovations will feature sensor-based monitoring, real-time diagnostics, and self-healing capabilities. Sustainability efforts will drive the transition to low-carbon manufacturing and biodegradable rubber compounds. Manufacturers will expand operations in emerging economies, while regulatory pressure in North America and Europe will accelerate demand for energy-efficient belts with longer service lifespans.

| Attributes | Description |

|---|---|

| Estimated Size (2025E) | USD 4.21 billion |

| Projected Value (2035F) | USD 6.28 billion |

| Value-based CAGR (2025 to 2035) | 4.1% |

The market is segmented by Product Type (Heavy Duty, Medium Duty, Light Duty) and End Use (Logistics, Mining, Metal Processing, Manufacturing, Automotive).

Heavy-duty rubber conveyor belts held the largest market share in 2025, driven by their widespread use in mining, metal refining, and bulk material transport. These belts are designed to withstand high impact, abrasion, and load capacity-critical for underground and open-pit mining operations.

Medium-duty belts are widely adopted in warehousing and manufacturing units due to their cost-effectiveness and moderate load capacity. They are expected to grow steadily with the rise of intra-facility automation and packaging activities. Light-duty belts, on the other hand, cater to parcel handling, food processing, and electronics assembly but will see comparatively modest growth due to limited load-bearing capacity and niche applications.

| Product Type | CAGR (2025 to 2035) |

|---|---|

| Heavy Duty | 4.4% |

The logistics sector is expected to be the fastest-growing end-use segment due to soaring demand from e-commerce warehouses, distribution centers, and third-party logistics hubs. These facilities increasingly rely on automated material flow systems, where light and medium-duty rubber conveyor belts offer speed, flexibility, and scalability.

Mining continues to be the dominant end-use segment in 2025, with rubber belts used extensively in ore transportation, coal handling, and crushing circuits. Metal processing and manufacturing industries also represent steady demand streams, driven by consistent infrastructure development and industrial growth. Meanwhile, the automotive sector is turning to conveyor belts for assembly lines and in-plant logistics, supported by rising EV production and smart factory investments.

| End Use Segment | CAGR (2025 to 2035) |

|---|---|

| Logistics | 4.8% |

| 2020 to 2024 | 2025 to 2035 |

|---|---|

| Growth driven by mining, eCommerce, and manufacturing. | Expansion fueled by automation, AI, and smart logistics. |

| Adoption of lightweight, high-durability, and heat-resistant belts. | Shift to IoT-enabled, AI-driven predictive maintenance, and smart conveyor systems. |

| Focus on recyclable and energy-efficient materials. | Demand for biodegradable and low-carbon-footprint rubber belts. |

| Increased use in mining and warehousing. | Growth in automation, robotics, and self-adjusting conveyor belts. |

| Fire-resistant and oil-resistant belts gaining traction. | Stricter safety regulations, advanced compliance, and food-grade materials. |

| Strong demand in Asia-Pacific and North America. | Rapid industrialization in Asia-Pacific and Latin America. |

| Steady segment growth due to industrial expansion. | Increased adoption of smart and eco-friendly conveyor belts. |

Future Market Insights (FMI) conducted a survey among 500 key stakeholders in the rubber conveyor belt industry to assess growth drivers, technological advancements, regulatory challenges, and regional sector variances.

The survey targeted manufacturers, suppliers, logistics operators, and end-users from mining, metal processing, and industrial sectors, providing a comprehensive analysis of emerging trends and strategic priorities.

Primary Concerns

Regional Variance

High Variance in Adoption Rates

Convergent & Divergent Perspectives on ROI

Consensus

Regional Material Preferences

Shared Challenges

Regional Differences

Manufacturers

End-Users

Alignment Among Stakeholders

Regional Differences in Investment Focus

North America

Europe

Asia-Pacific

High Consensus Areas

Key Regional Variances

| Countries/Region | Key Regulations Impacting the Landscape |

|---|---|

| United States | OSHA (Occupational Safety and Health Administration) mandates fire-resistant conveyor belts in mining & industrial sectors; EPA regulations encourage eco-friendly materials. |

| European Union | REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) enforces strict environmental standards; CE marking required for conveyor belts sold in the EU. |

| China | China’s SAC (Standardization Administration of China), National Safety Standards for conveyor belt manufacturing, focusing on flame resistance and durability in heavy industries. |

| India | MoEFCC (Ministry of Environment, Forest and Climate Change), BIS (Bureau of Indian Standards) regulates conveyor belt safety, and CPCB (Central Pollution Control Board) pushes for reduced carbon emissions in production. |

| Australia | MSHA (Mine Safety and Health Administration) enforces flame-retardant belts in mining; strict workplace safety laws for conveyor belt systems. |

| Brazil | ANVISA (National Health Surveillance Agency) requires food-grade belts for the food processing industry; environmental policies promote sustainable rubber production. |

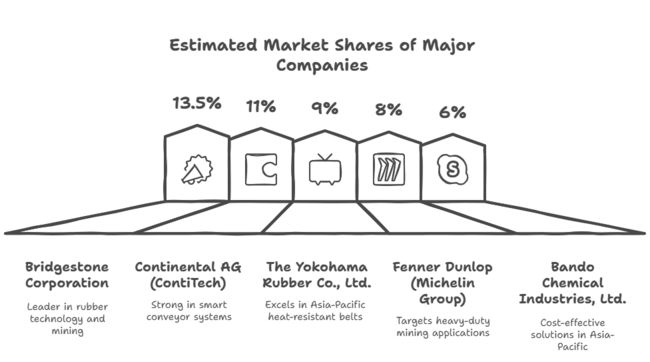

Segment leaders in the industry for rubber conveyor belts are engaging with a mix of price strategies, innovation in technology, strategic alliances, and international growth. Major players are emphasizing affordable production with excellent quality to get price-conscious consumers, especially from developing countries such as India, China, and Latin America.

Companies are diversifying their portfolios by investing in high-end materials, such as heat-resistant, oil-resistant, and eco-friendly rubber belts. The use of IoT-based smart conveyor belts with real-time monitoring features is another critical strategy to meet the increasing demand for automation across industries such as mining, logistics, and manufacturing.

Fenner Dunlop Conveyor Belting Rebranding (January 2024)

ADNOC in Talks to Acquire Covestro A.G. for USD 12.9 Billion

Safety Incident and Legal Actions (March 2025)

The segment for rubber conveyor belts is a type of industrial equipment, and this segment is also closely related to material handling across industries such as mining, manufacturing, logistics, food processing, construction, and eCommerce. It drives demand based on industrial production, infrastructure growth, and global trade trends as a core part of automated material transport.

In shaping segment demand, the most important factor is the economic growth and expansion of the industry. Countries in the world that are undergoing rapid industrialization, like India, China, and Brazil, are accounting for the growing adoption of conveyor belts. Presently, factors like government-supported construction activities across regions, such as North America and the EU, are also driving the demand for highly efficient conveyor systems.

Some commodity price movements also impact the sector, especially in the rubber and mining sectors. Crude prices influence the costs of synthetic rubber production, while changes in steel prices influence the cost of reinforced conveyor belts. Moreover, increasing focus on sustainability and carbon footprint reduction is driving manufacturers to develop environmentally and energy-friendly conveyor belt solutions.

The USA segment for rubber conveyor belts is propelled by its flourishing mining, manufacturing, logistics and automotive sectors. Urbanization and population growth has fueled demand for more automation in warehouses and factories across the country.

The coal and mineral segment remains a key driver, utilising heavy-duty and fire-resistant conveyor belts. Furthermore, environmental regulations encourage the use of energy-efficient and recyclable rubber belts, which reduces carbon footprints.

FMI opines that the United States rubber conveyor belt sales will grow at nearly 2.6% CAGR through 2025 to 2035.

The logistics and automotive sectors have a great impact on the rubber conveyor belt landscape in the United Kingdom. The growing sustainability push around circular economy practices in the country has led to an increased demand for eco-friendly conveyor belts.

Trade policies and supply chain disruptions due to Brexit have made it difficult to procure raw materials. Material manufacturers are localizing production and setting up rubber processing units domestically. Moreover, demand for medium and light duty conveyor belts to increase production efficiency is also increased from process manufacturing and food processing sectors.

FMI projects that the United Kingdom's rubber conveyor belt sales will grow at nearly 2.5% CAGR through 2025 to 2035.

Automotive, metal processing and logistics industries are some of the major driving factors for the rubber conveyor belt segment in France. Renowned automotive companies, including Renault, Peugeot, and Citroën utilize automated assembly lines that depend on medium-duty conveyor belts.

Green industrial policies in the country have further propelled the use of energy-saving and low-carbon conveyor belt systems. Another major trend driving investments in sensor-equipped conveyor belts that is the increasing trend of smart factories. The segment is further bolstered by government incentives for industrial automation and energy efficiency.

FMI opines that the France rubber conveyor belt sales will grow at nearly 2.7% CAGR through 2025 to 2035.

Germany, Europe's largest industrial hub, has strong demand for heavy-duty conveyor belts, driven by its dominant metal processing, mining, and manufacturing industries. Advances in smart conveyor systems that utilize AI with predictive maintenance systems have been and will continue to be driven by the country’s leadership in engineering and automation. Automotive players include Volkswagen, BMW and Daimler and conveyor belts are heavily utilized in the manufacturing of vehicles and assembly of components.

FMI opines that the Germany rubber conveyor belt sales will grow at nearly 2.9% CAGR through 2025 to 2035.

Rubber conveyor belts are used in Italy's manufacturing and food processing sectors to facilitate materials movement. It has a high-quality machinery production and with many medium duty belts working in manufacturing.

The logistics and warehousing industry has experienced a heightened need for automated material handling solutions due to the rise of eCommerce. Workplace safety has been legislated in Italy, resulting in a rise in adoption of fire-resistant and anti-slip conveyor belts across industries.

FMI opines that the Italy rubber conveyor belt sales will grow at nearly 2.6% CAGR through 2025 to 2035.

The advanced manufacturing, electronics, and automotive industries in South Korea drives the rubber conveyor belt industry in the country. Big companies such as Hyundai, Samsung, and LG use conveyor belts as part of their automated assembly lines. As the world leader in robotics and floursihing smart factory technologies, the country also contributes to the advancement of AI-populated conveyor belt systems.

The government’s agenda of eco-friendly manufacturing has fostered innovations to produce conveyor belts. Demand for heavy-duty belts that can withstand harsh environments is also supported by South Korea's strong mining industry.

FMI opines that the South Korea rubber conveyor belt sales will grow at nearly 2.7% CAGR through 2025 to 2035.

Specialized rubber conveyor belts are needed for Japan's high-tech industries and precision manufacturing. Demand for medium and light-duty belts is driven by the country’s automotive and robotics industries, as well as assembly lines and logistics centers.

Japan’s emphasis on sustainability and energy efficiency has spawned durable, high-efficiency rubber materials. Mining, while less significant than other industries in Japan, still depends on heavy-duty conveyor belts to extract resources. Industry-IoT and AI systems for monitoring conveyers are widely implemented to boost operational efficacy.

FMI opines that the Japan rubber conveyor belt sales will grow at nearly 2.6% CAGR through 2025 to 2035.

China accounts for the highest production of rubber conveyor belts, a result of giant industrialization across the mining, manufacturing and logistics sectors. The country’s leadership in coal mining and heavy industries creates a high sector for heat and harsh resistance heavy duty conveyor belts.

Additionally, the thriving eCommerce industry has further stimulated investment in automated logistics centers, supporting light and medium-duty Belt demand. China’s commitment to sustainable practices and reduced emissions has led to use of environmentally friendly materials for conveyor belts.

FMI opines that the China rubber conveyor belt sales will grow at nearly 3.0% CAGR through 2025 to 2035.

The mining and agriculture industries are the leading drivers for the rubber conveyor belt sector in Australia and New Zealand. Australia, a major exporter of iron ore, minerals, and coal has had a robust demand for heavy-duty conveyor belts capable of withstanding extreme conditions. As a result, the country’s increased focus on mine safety regulations have continued to pave the way for the adoption of fire-resistant and self-extinguishing conveyor belt.

New Zealand’s agriculture and food processing industries also drive demand for light-duty belts used in sorting and packaging operations. Intelligent conveyor belt systems with real-time monitoring are being facilitated by automation and sustainability trends.

FMI opines that the Australia & New Zealand rubber conveyor belt sales will grow at nearly 2.8% CAGR through 2025 to 2035.

The rise of industrial automation, e-commerce logistics, and manufacturing will drive growth in the rubber conveyor belt market. The demand for automated material handling systems in warehouses and distribution centers to be a key growth opportunity.

Additionally, the mining and metal processing industries significantly contribute to demand for heavy-duty, heat-resistant, and durable conveyor belts Moreover, the growing demand for sustainable materials presents a lucrative opportunity for manufacturers to develop biodegradable, energy-efficient, and recyclable conveyor belts. Companies can leverage these opportunities by conducting R&D to develop smart conveyor belt solutions that utilize AI, real-time monitoring, and predictive analytics.

It is also vital to expand into high-growth regions, like China, India, and Southeast Asia, where industrialization in these economies is fueling demand. Additionally, the ability to keep pace and even surpass strict environmental policy mandates in regions like Europe and North America will provide companies with a competitive advantage.

Demand is being driven by the rising implementation of automation in several sectors such as mining, logistics, and manufacturing, as well as the requirement for sturdy and energy-efficient material handling systems. Growing eco-friendly and smart conveyor belts also drive the growth.

Mining, metal processing, logistics, automotive, and manufacturing are industries that depend heavily on these belts to transport materials. The growth of e-commerce has also created heightened demand in warehousing and distribution centers.

Emerging technologies like IoT-powered monitoring, AI-driven predictive maintenance, self-healing materials, and energy-efficient innovations will enhance the performance of the belt by minimizing downtime and improving operational efficiency.

To adhere to environmental regulations, manufacturers will see a transition toward recyclable rubber materials, low-carbon production processes, and biodegradable components.

Asia-Pacific is showing substantial growth owing to rapid industrialization, primarily in China and India. Moreover, the demand for automation and regulatory compliance driving growth in the North American and European sector is fueling steady adoption.

Table 1: Global Market Value (US$ Million) Forecast by Region, 2019 to 2034

Table 2: Global Market Volume (Meter) Forecast by Region, 2019 to 2034

Table 3: Global Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 4: Global Market Volume (Meter) Forecast by Material, 2019 to 2034

Table 5: Global Market Value (US$ Million) Forecast by Application, 2019 to 2034

Table 6: Global Market Volume (Meter) Forecast by Application, 2019 to 2034

Table 7: Global Market Value (US$ Million) Forecast by End-use Industry, 2019 to 2034

Table 8: Global Market Volume (Meter) Forecast by End-use Industry, 2019 to 2034

Table 9: North America Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 10: North America Market Volume (Meter) Forecast by Country, 2019 to 2034

Table 11: North America Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 12: North America Market Volume (Meter) Forecast by Material, 2019 to 2034

Table 13: North America Market Value (US$ Million) Forecast by Application, 2019 to 2034

Table 14: North America Market Volume (Meter) Forecast by Application, 2019 to 2034

Table 15: North America Market Value (US$ Million) Forecast by End-use Industry, 2019 to 2034

Table 16: North America Market Volume (Meter) Forecast by End-use Industry, 2019 to 2034

Table 17: Latin America Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 18: Latin America Market Volume (Meter) Forecast by Country, 2019 to 2034

Table 19: Latin America Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 20: Latin America Market Volume (Meter) Forecast by Material, 2019 to 2034

Table 21: Latin America Market Value (US$ Million) Forecast by Application, 2019 to 2034

Table 22: Latin America Market Volume (Meter) Forecast by Application, 2019 to 2034

Table 23: Latin America Market Value (US$ Million) Forecast by End-use Industry, 2019 to 2034

Table 24: Latin America Market Volume (Meter) Forecast by End-use Industry, 2019 to 2034

Table 25: Western Europe Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 26: Western Europe Market Volume (Meter) Forecast by Country, 2019 to 2034

Table 27: Western Europe Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 28: Western Europe Market Volume (Meter) Forecast by Material, 2019 to 2034

Table 29: Western Europe Market Value (US$ Million) Forecast by Application, 2019 to 2034

Table 30: Western Europe Market Volume (Meter) Forecast by Application, 2019 to 2034

Table 31: Western Europe Market Value (US$ Million) Forecast by End-use Industry, 2019 to 2034

Table 32: Western Europe Market Volume (Meter) Forecast by End-use Industry, 2019 to 2034

Table 33: Eastern Europe Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 34: Eastern Europe Market Volume (Meter) Forecast by Country, 2019 to 2034

Table 35: Eastern Europe Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 36: Eastern Europe Market Volume (Meter) Forecast by Material, 2019 to 2034

Table 37: Eastern Europe Market Value (US$ Million) Forecast by Application, 2019 to 2034

Table 38: Eastern Europe Market Volume (Meter) Forecast by Application, 2019 to 2034

Table 39: Eastern Europe Market Value (US$ Million) Forecast by End-use Industry, 2019 to 2034

Table 40: Eastern Europe Market Volume (Meter) Forecast by End-use Industry, 2019 to 2034

Table 41: South Asia and Pacific Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 42: South Asia and Pacific Market Volume (Meter) Forecast by Country, 2019 to 2034

Table 43: South Asia and Pacific Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 44: South Asia and Pacific Market Volume (Meter) Forecast by Material, 2019 to 2034

Table 45: South Asia and Pacific Market Value (US$ Million) Forecast by Application, 2019 to 2034

Table 46: South Asia and Pacific Market Volume (Meter) Forecast by Application, 2019 to 2034

Table 47: South Asia and Pacific Market Value (US$ Million) Forecast by End-use Industry, 2019 to 2034

Table 48: South Asia and Pacific Market Volume (Meter) Forecast by End-use Industry, 2019 to 2034

Table 49: East Asia Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 50: East Asia Market Volume (Meter) Forecast by Country, 2019 to 2034

Table 51: East Asia Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 52: East Asia Market Volume (Meter) Forecast by Material, 2019 to 2034

Table 53: East Asia Market Value (US$ Million) Forecast by Application, 2019 to 2034

Table 54: East Asia Market Volume (Meter) Forecast by Application, 2019 to 2034

Table 55: East Asia Market Value (US$ Million) Forecast by End-use Industry, 2019 to 2034

Table 56: East Asia Market Volume (Meter) Forecast by End-use Industry, 2019 to 2034

Table 57: Middle East and Africa Market Value (US$ Million) Forecast by Country, 2019 to 2034

Table 58: Middle East and Africa Market Volume (Meter) Forecast by Country, 2019 to 2034

Table 59: Middle East and Africa Market Value (US$ Million) Forecast by Material, 2019 to 2034

Table 60: Middle East and Africa Market Volume (Meter) Forecast by Material, 2019 to 2034

Table 61: Middle East and Africa Market Value (US$ Million) Forecast by Application, 2019 to 2034

Table 62: Middle East and Africa Market Volume (Meter) Forecast by Application, 2019 to 2034

Table 63: Middle East and Africa Market Value (US$ Million) Forecast by End-use Industry, 2019 to 2034

Table 64: Middle East and Africa Market Volume (Meter) Forecast by End-use Industry, 2019 to 2034

Figure 1: Global Market Value (US$ Million) by Material, 2024 to 2034

Figure 2: Global Market Value (US$ Million) by Application, 2024 to 2034

Figure 3: Global Market Value (US$ Million) by End-use Industry, 2024 to 2034

Figure 4: Global Market Value (US$ Million) by Region, 2024 to 2034

Figure 5: Global Market Value (US$ Million) Analysis by Region, 2019 to 2034

Figure 6: Global Market Volume (Meter) Analysis by Region, 2019 to 2034

Figure 7: Global Market Value Share (%) and BPS Analysis by Region, 2024 to 2034

Figure 8: Global Market Y-o-Y Growth (%) Projections by Region, 2024 to 2034

Figure 9: Global Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 10: Global Market Volume (Meter) Analysis by Material, 2019 to 2034

Figure 11: Global Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 12: Global Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 13: Global Market Value (US$ Million) Analysis by Application, 2019 to 2034

Figure 14: Global Market Volume (Meter) Analysis by Application, 2019 to 2034

Figure 15: Global Market Value Share (%) and BPS Analysis by Application, 2024 to 2034

Figure 16: Global Market Y-o-Y Growth (%) Projections by Application, 2024 to 2034

Figure 17: Global Market Value (US$ Million) Analysis by End-use Industry, 2019 to 2034

Figure 18: Global Market Volume (Meter) Analysis by End-use Industry, 2019 to 2034

Figure 19: Global Market Value Share (%) and BPS Analysis by End-use Industry, 2024 to 2034

Figure 20: Global Market Y-o-Y Growth (%) Projections by End-use Industry, 2024 to 2034

Figure 21: Global Market Attractiveness by Material, 2024 to 2034

Figure 22: Global Market Attractiveness by Application, 2024 to 2034

Figure 23: Global Market Attractiveness by End-use Industry, 2024 to 2034

Figure 24: Global Market Attractiveness by Region, 2024 to 2034

Figure 25: North America Market Value (US$ Million) by Material, 2024 to 2034

Figure 26: North America Market Value (US$ Million) by Application, 2024 to 2034

Figure 27: North America Market Value (US$ Million) by End-use Industry, 2024 to 2034

Figure 28: North America Market Value (US$ Million) by Country, 2024 to 2034

Figure 29: North America Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 30: North America Market Volume (Meter) Analysis by Country, 2019 to 2034

Figure 31: North America Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 32: North America Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 33: North America Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 34: North America Market Volume (Meter) Analysis by Material, 2019 to 2034

Figure 35: North America Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 36: North America Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 37: North America Market Value (US$ Million) Analysis by Application, 2019 to 2034

Figure 38: North America Market Volume (Meter) Analysis by Application, 2019 to 2034

Figure 39: North America Market Value Share (%) and BPS Analysis by Application, 2024 to 2034

Figure 40: North America Market Y-o-Y Growth (%) Projections by Application, 2024 to 2034

Figure 41: North America Market Value (US$ Million) Analysis by End-use Industry, 2019 to 2034

Figure 42: North America Market Volume (Meter) Analysis by End-use Industry, 2019 to 2034

Figure 43: North America Market Value Share (%) and BPS Analysis by End-use Industry, 2024 to 2034

Figure 44: North America Market Y-o-Y Growth (%) Projections by End-use Industry, 2024 to 2034

Figure 45: North America Market Attractiveness by Material, 2024 to 2034

Figure 46: North America Market Attractiveness by Application, 2024 to 2034

Figure 47: North America Market Attractiveness by End-use Industry, 2024 to 2034

Figure 48: North America Market Attractiveness by Country, 2024 to 2034

Figure 49: Latin America Market Value (US$ Million) by Material, 2024 to 2034

Figure 50: Latin America Market Value (US$ Million) by Application, 2024 to 2034

Figure 51: Latin America Market Value (US$ Million) by End-use Industry, 2024 to 2034

Figure 52: Latin America Market Value (US$ Million) by Country, 2024 to 2034

Figure 53: Latin America Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 54: Latin America Market Volume (Meter) Analysis by Country, 2019 to 2034

Figure 55: Latin America Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 56: Latin America Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 57: Latin America Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 58: Latin America Market Volume (Meter) Analysis by Material, 2019 to 2034

Figure 59: Latin America Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 60: Latin America Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 61: Latin America Market Value (US$ Million) Analysis by Application, 2019 to 2034

Figure 62: Latin America Market Volume (Meter) Analysis by Application, 2019 to 2034

Figure 63: Latin America Market Value Share (%) and BPS Analysis by Application, 2024 to 2034

Figure 64: Latin America Market Y-o-Y Growth (%) Projections by Application, 2024 to 2034

Figure 65: Latin America Market Value (US$ Million) Analysis by End-use Industry, 2019 to 2034

Figure 66: Latin America Market Volume (Meter) Analysis by End-use Industry, 2019 to 2034

Figure 67: Latin America Market Value Share (%) and BPS Analysis by End-use Industry, 2024 to 2034

Figure 68: Latin America Market Y-o-Y Growth (%) Projections by End-use Industry, 2024 to 2034

Figure 69: Latin America Market Attractiveness by Material, 2024 to 2034

Figure 70: Latin America Market Attractiveness by Application, 2024 to 2034

Figure 71: Latin America Market Attractiveness by End-use Industry, 2024 to 2034

Figure 72: Latin America Market Attractiveness by Country, 2024 to 2034

Figure 73: Western Europe Market Value (US$ Million) by Material, 2024 to 2034

Figure 74: Western Europe Market Value (US$ Million) by Application, 2024 to 2034

Figure 75: Western Europe Market Value (US$ Million) by End-use Industry, 2024 to 2034

Figure 76: Western Europe Market Value (US$ Million) by Country, 2024 to 2034

Figure 77: Western Europe Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 78: Western Europe Market Volume (Meter) Analysis by Country, 2019 to 2034

Figure 79: Western Europe Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 80: Western Europe Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 81: Western Europe Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 82: Western Europe Market Volume (Meter) Analysis by Material, 2019 to 2034

Figure 83: Western Europe Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 84: Western Europe Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 85: Western Europe Market Value (US$ Million) Analysis by Application, 2019 to 2034

Figure 86: Western Europe Market Volume (Meter) Analysis by Application, 2019 to 2034

Figure 87: Western Europe Market Value Share (%) and BPS Analysis by Application, 2024 to 2034

Figure 88: Western Europe Market Y-o-Y Growth (%) Projections by Application, 2024 to 2034

Figure 89: Western Europe Market Value (US$ Million) Analysis by End-use Industry, 2019 to 2034

Figure 90: Western Europe Market Volume (Meter) Analysis by End-use Industry, 2019 to 2034

Figure 91: Western Europe Market Value Share (%) and BPS Analysis by End-use Industry, 2024 to 2034

Figure 92: Western Europe Market Y-o-Y Growth (%) Projections by End-use Industry, 2024 to 2034

Figure 93: Western Europe Market Attractiveness by Material, 2024 to 2034

Figure 94: Western Europe Market Attractiveness by Application, 2024 to 2034

Figure 95: Western Europe Market Attractiveness by End-use Industry, 2024 to 2034

Figure 96: Western Europe Market Attractiveness by Country, 2024 to 2034

Figure 97: Eastern Europe Market Value (US$ Million) by Material, 2024 to 2034

Figure 98: Eastern Europe Market Value (US$ Million) by Application, 2024 to 2034

Figure 99: Eastern Europe Market Value (US$ Million) by End-use Industry, 2024 to 2034

Figure 100: Eastern Europe Market Value (US$ Million) by Country, 2024 to 2034

Figure 101: Eastern Europe Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 102: Eastern Europe Market Volume (Meter) Analysis by Country, 2019 to 2034

Figure 103: Eastern Europe Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 104: Eastern Europe Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 105: Eastern Europe Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 106: Eastern Europe Market Volume (Meter) Analysis by Material, 2019 to 2034

Figure 107: Eastern Europe Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 108: Eastern Europe Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 109: Eastern Europe Market Value (US$ Million) Analysis by Application, 2019 to 2034

Figure 110: Eastern Europe Market Volume (Meter) Analysis by Application, 2019 to 2034

Figure 111: Eastern Europe Market Value Share (%) and BPS Analysis by Application, 2024 to 2034

Figure 112: Eastern Europe Market Y-o-Y Growth (%) Projections by Application, 2024 to 2034

Figure 113: Eastern Europe Market Value (US$ Million) Analysis by End-use Industry, 2019 to 2034

Figure 114: Eastern Europe Market Volume (Meter) Analysis by End-use Industry, 2019 to 2034

Figure 115: Eastern Europe Market Value Share (%) and BPS Analysis by End-use Industry, 2024 to 2034

Figure 116: Eastern Europe Market Y-o-Y Growth (%) Projections by End-use Industry, 2024 to 2034

Figure 117: Eastern Europe Market Attractiveness by Material, 2024 to 2034

Figure 118: Eastern Europe Market Attractiveness by Application, 2024 to 2034

Figure 119: Eastern Europe Market Attractiveness by End-use Industry, 2024 to 2034

Figure 120: Eastern Europe Market Attractiveness by Country, 2024 to 2034

Figure 121: South Asia and Pacific Market Value (US$ Million) by Material, 2024 to 2034

Figure 122: South Asia and Pacific Market Value (US$ Million) by Application, 2024 to 2034

Figure 123: South Asia and Pacific Market Value (US$ Million) by End-use Industry, 2024 to 2034

Figure 124: South Asia and Pacific Market Value (US$ Million) by Country, 2024 to 2034

Figure 125: South Asia and Pacific Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 126: South Asia and Pacific Market Volume (Meter) Analysis by Country, 2019 to 2034

Figure 127: South Asia and Pacific Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 128: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 129: South Asia and Pacific Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 130: South Asia and Pacific Market Volume (Meter) Analysis by Material, 2019 to 2034

Figure 131: South Asia and Pacific Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 132: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 133: South Asia and Pacific Market Value (US$ Million) Analysis by Application, 2019 to 2034

Figure 134: South Asia and Pacific Market Volume (Meter) Analysis by Application, 2019 to 2034

Figure 135: South Asia and Pacific Market Value Share (%) and BPS Analysis by Application, 2024 to 2034

Figure 136: South Asia and Pacific Market Y-o-Y Growth (%) Projections by Application, 2024 to 2034

Figure 137: South Asia and Pacific Market Value (US$ Million) Analysis by End-use Industry, 2019 to 2034

Figure 138: South Asia and Pacific Market Volume (Meter) Analysis by End-use Industry, 2019 to 2034

Figure 139: South Asia and Pacific Market Value Share (%) and BPS Analysis by End-use Industry, 2024 to 2034

Figure 140: South Asia and Pacific Market Y-o-Y Growth (%) Projections by End-use Industry, 2024 to 2034

Figure 141: South Asia and Pacific Market Attractiveness by Material, 2024 to 2034

Figure 142: South Asia and Pacific Market Attractiveness by Application, 2024 to 2034

Figure 143: South Asia and Pacific Market Attractiveness by End-use Industry, 2024 to 2034

Figure 144: South Asia and Pacific Market Attractiveness by Country, 2024 to 2034

Figure 145: East Asia Market Value (US$ Million) by Material, 2024 to 2034

Figure 146: East Asia Market Value (US$ Million) by Application, 2024 to 2034

Figure 147: East Asia Market Value (US$ Million) by End-use Industry, 2024 to 2034

Figure 148: East Asia Market Value (US$ Million) by Country, 2024 to 2034

Figure 149: East Asia Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 150: East Asia Market Volume (Meter) Analysis by Country, 2019 to 2034

Figure 151: East Asia Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 152: East Asia Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 153: East Asia Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 154: East Asia Market Volume (Meter) Analysis by Material, 2019 to 2034

Figure 155: East Asia Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 156: East Asia Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 157: East Asia Market Value (US$ Million) Analysis by Application, 2019 to 2034

Figure 158: East Asia Market Volume (Meter) Analysis by Application, 2019 to 2034

Figure 159: East Asia Market Value Share (%) and BPS Analysis by Application, 2024 to 2034

Figure 160: East Asia Market Y-o-Y Growth (%) Projections by Application, 2024 to 2034

Figure 161: East Asia Market Value (US$ Million) Analysis by End-use Industry, 2019 to 2034

Figure 162: East Asia Market Volume (Meter) Analysis by End-use Industry, 2019 to 2034

Figure 163: East Asia Market Value Share (%) and BPS Analysis by End-use Industry, 2024 to 2034

Figure 164: East Asia Market Y-o-Y Growth (%) Projections by End-use Industry, 2024 to 2034

Figure 165: East Asia Market Attractiveness by Material, 2024 to 2034

Figure 166: East Asia Market Attractiveness by Application, 2024 to 2034

Figure 167: East Asia Market Attractiveness by End-use Industry, 2024 to 2034

Figure 168: East Asia Market Attractiveness by Country, 2024 to 2034

Figure 169: Middle East and Africa Market Value (US$ Million) by Material, 2024 to 2034

Figure 170: Middle East and Africa Market Value (US$ Million) by Application, 2024 to 2034

Figure 171: Middle East and Africa Market Value (US$ Million) by End-use Industry, 2024 to 2034

Figure 172: Middle East and Africa Market Value (US$ Million) by Country, 2024 to 2034

Figure 173: Middle East and Africa Market Value (US$ Million) Analysis by Country, 2019 to 2034

Figure 174: Middle East and Africa Market Volume (Meter) Analysis by Country, 2019 to 2034

Figure 175: Middle East and Africa Market Value Share (%) and BPS Analysis by Country, 2024 to 2034

Figure 176: Middle East and Africa Market Y-o-Y Growth (%) Projections by Country, 2024 to 2034

Figure 177: Middle East and Africa Market Value (US$ Million) Analysis by Material, 2019 to 2034

Figure 178: Middle East and Africa Market Volume (Meter) Analysis by Material, 2019 to 2034

Figure 179: Middle East and Africa Market Value Share (%) and BPS Analysis by Material, 2024 to 2034

Figure 180: Middle East and Africa Market Y-o-Y Growth (%) Projections by Material, 2024 to 2034

Figure 181: Middle East and Africa Market Value (US$ Million) Analysis by Application, 2019 to 2034

Figure 182: Middle East and Africa Market Volume (Meter) Analysis by Application, 2019 to 2034

Figure 183: Middle East and Africa Market Value Share (%) and BPS Analysis by Application, 2024 to 2034

Figure 184: Middle East and Africa Market Y-o-Y Growth (%) Projections by Application, 2024 to 2034

Figure 185: Middle East and Africa Market Value (US$ Million) Analysis by End-use Industry, 2019 to 2034

Figure 186: Middle East and Africa Market Volume (Meter) Analysis by End-use Industry, 2019 to 2034

Figure 187: Middle East and Africa Market Value Share (%) and BPS Analysis by End-use Industry, 2024 to 2034

Figure 188: Middle East and Africa Market Y-o-Y Growth (%) Projections by End-use Industry, 2024 to 2034

Figure 189: Middle East and Africa Market Attractiveness by Material, 2024 to 2034

Figure 190: Middle East and Africa Market Attractiveness by Application, 2024 to 2034

Figure 191: Middle East and Africa Market Attractiveness by End-use Industry, 2024 to 2034

Figure 192: Middle East and Africa Market Attractiveness by Country, 2024 to 2034

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Agricultural Food Grade Rubber Conveyor Belt Market Growth - Trends & Forecast 2025 to 2035

Rubber Track for Defense and Security Market Size and Share Forecast Outlook 2025 to 2035

Rubber Frame Monitors Market Size and Share Forecast Outlook 2025 to 2035

Rubber Coating Market Size and Share Forecast Outlook 2025 to 2035

Rubber Anti-Tack Agents Market Size and Share Forecast Outlook 2025 to 2035

Rubber to Metal Bonded Articles Market Analysis Size and Share Forecast Outlook 2025 to 2035

Rubber-to-Metal Adhesion Market Analysis - Size, Share, and Forecast Outlook 2025-2035

Rubber Coatings Market Growth - Trends & Forecast 2025 to 2035

Rubber Testing Equipment Market Growth – Trends & Forecast 2025 to 2035

Rubber Tapes Market Trends - Growth & Forecast 2025 to 2035

Rubber Extruder Market Growth - Trends & Forecast 2025 to 2035

Rubber Molding Market Growth – Trends & Forecast 2024-2034

Rubber choppers Market

Gas Scrubber Market Size and Share Forecast Outlook 2025 to 2035

Air Scrubbers Market

Europe Rubber Derived Unrefined Pyrolysis Oil Market Size and Share Forecast Outlook 2025 to 2035

Sleeve Rubber Stopper Market Growth – Demand & Forecast 2024-2034

Natural Rubber Market Size and Share Forecast Outlook 2025 to 2035

Plastic-Rubber Composite Market Trend Analysis Based on Product, Application, and Region 2025 to 2035

Snap on Rubber Stopper Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA