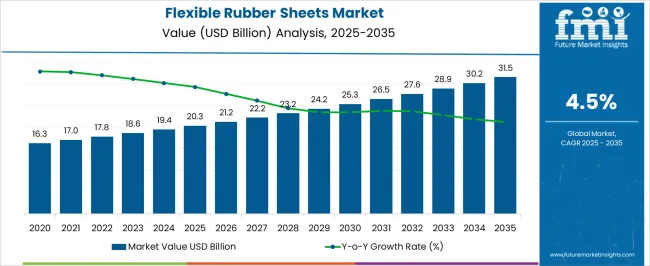

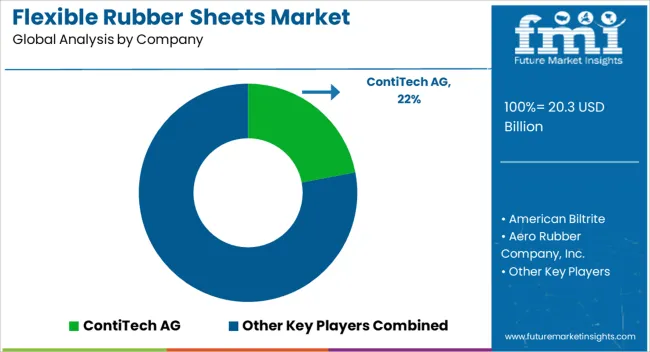

The Flexible Rubber Sheets Market is estimated to be valued at USD 20.3 billion in 2025 and is projected to reach USD 31.5 billion by 2035, registering a compound annual growth rate (CAGR) of 4.5% over the forecast period.

| Metric | Value |

|---|---|

| Flexible Rubber Sheets Market Estimated Value in (2025 E) | USD 20.3 billion |

| Flexible Rubber Sheets Market Forecast Value in (2035 F) | USD 31.5 billion |

| Forecast CAGR (2025 to 2035) | 4.5% |

The Flexible Rubber Sheets market is witnessing steady growth, driven by increasing demand for versatile and durable materials across various industrial and commercial applications. The current market scenario reflects adoption in sectors that require high-performance materials with enhanced resistance to heat, chemicals, and mechanical stress. The growth of the market has been supported by expanding automotive manufacturing, infrastructure development, and industrial automation.

Rubber sheets with flexible properties allow customization in thickness, hardness, and surface finishes, enabling their application in gaskets, seals, vibration dampening, and protective linings. In addition, the shift towards synthetic and composite materials has facilitated improved product performance, longer life cycles, and reduced maintenance costs.

Increasing awareness of workplace safety and regulatory compliance has further fueled adoption, particularly in sectors where mechanical wear and environmental exposure are critical concerns The market is expected to witness future growth opportunities through innovation in high-performance elastomers, sustainable material alternatives, and cost-efficient manufacturing methods, which are anticipated to enhance the utility and adoption of flexible rubber sheets globally.

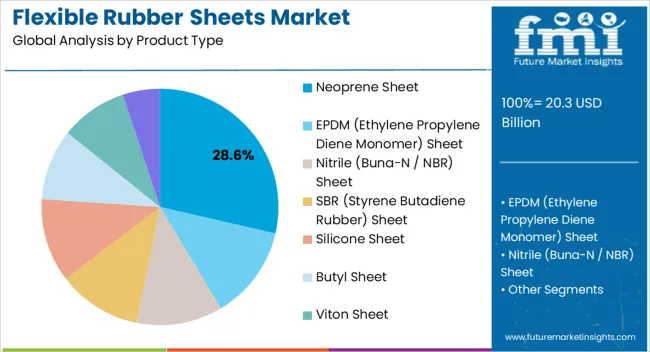

The flexible rubber sheets market is segmented by product type, base material, end-use industry, and geographic regions. By product type, flexible rubber sheets market is divided into Neoprene Sheet, EPDM (Ethylene Propylene Diene Monomer) Sheet, Nitrile (Buna-N / NBR) Sheet, SBR (Styrene Butadiene Rubber) Sheet, Silicone Sheet, Butyl Sheet, Viton Sheet, and Thermoplastic Elastomer Sheet.

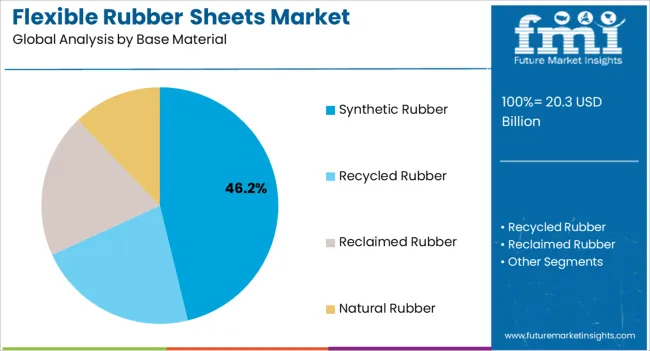

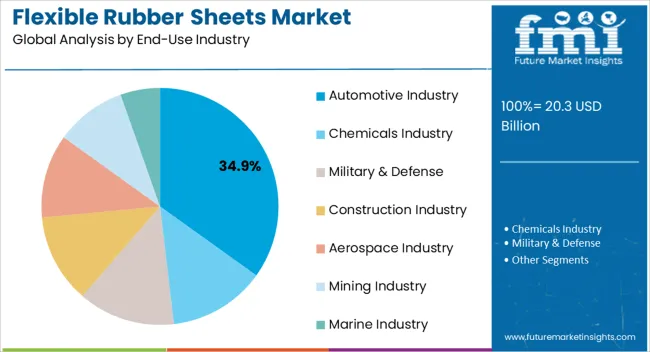

In terms of base material, flexible rubber sheets market is classified into Synthetic Rubber, Recycled Rubber, Reclaimed Rubber, and Natural Rubber. Based on end-use industry, flexible rubber sheets market is segmented into Automotive Industry, Chemicals Industry, Military & Defense, Construction Industry, Aerospace Industry, Mining Industry, and Marine Industry.

Regionally, the flexible rubber sheets industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Neoprene Sheet product type is expected to hold 28.60% of the Flexible Rubber Sheets market revenue share in 2025, making it the leading product type. This segment has grown due to the material’s exceptional resistance to oils, chemicals, and environmental factors, which allows it to be widely adopted in demanding industrial applications.

The flexibility of Neoprene Sheets enables their use in cushioning, sealing, insulation, and protective components where material integrity under stress is critical. The manufacturing and end-use sectors favor Neoprene due to its durability, ease of processing, and compatibility with adhesives and coatings, which enhances installation and performance.

Growth has also been driven by increasing demand in construction, industrial machinery, and transportation sectors where resilience and longevity are key decision factors As industries continue to focus on operational efficiency and cost optimization, Neoprene Sheets are expected to retain market leadership due to their adaptability and long-term value, with continuous innovation in formulations further boosting their application range.

The Synthetic Rubber base material segment is projected to account for 46.20% of the Flexible Rubber Sheets market revenue share in 2025, representing the largest base material category. The growth of this segment has been driven by the superior performance of synthetic rubbers compared with natural alternatives, offering enhanced chemical, heat, and abrasion resistance.

Synthetic rubber allows precise tailoring of mechanical and physical properties to meet the requirements of diverse industries, including automotive, industrial, and construction applications. Adoption has been supported by increasing industrialization and the need for standardized, high-quality materials capable of withstanding challenging operational environments.

Manufacturing processes that facilitate large-scale production with consistent quality have further enabled widespread uptake As global industries continue to prioritize durability, safety, and reliability in material selection, synthetic rubber-based sheets are expected to maintain dominance, with ongoing research into eco-friendly formulations and high-performance variants supporting long-term market expansion.

The Commercial end-use industry segment, represented by the Automotive Industry, is expected to hold 34.90% of the Flexible Rubber Sheets market revenue share in 2025, positioning it as the leading end-use sector. Growth in this segment has been driven by the increasing demand for flexible rubber sheets in vehicle manufacturing and aftermarket applications, including gaskets, seals, vibration dampening components, protective linings, and noise reduction elements.

Adoption has been facilitated by the need for materials that can withstand high mechanical stress, temperature fluctuations, and exposure to oils and chemicals, which are common in automotive environments. The rise of electric vehicles and advanced mobility solutions has created additional opportunities for flexible rubber sheets that provide performance reliability while supporting lightweight and energy-efficient designs.

Furthermore, the global expansion of automotive manufacturing and repair industries has reinforced demand, with manufacturers favoring materials that ensure durability, cost-effectiveness, and compliance with safety standards As vehicle production continues to grow and evolve, the automotive industry is expected to remain the largest contributor to market revenue for flexible rubber sheets.

Flexible rubber sheets are manufactured by processing different types of base materials, such as natural rubber, reclaimed rubber, recycled rubber and synthetic rubber. These sheets find many applications in different industries, such as chemical, automotive, military & defense, construction, aerospace, mining, marine, etc.

Furthermore, depending upon the type of sheet, flexible rubber sheets possess different properties. Some of the commonly used types are neoprene sheets, EPDM (ethylene propylene diene monomer) sheets, nitrile (Buna-N / NBR) sheets, SBR (styrene butadiene rubber) sheets, silicone sheets, butyl sheets, viton sheets, thermoplastic elastomer sheets, etc.

Each type has different beneficial properties, such as high tensile strength, better rebound elasticity, goof flexibility, high tensile strength and corrosion resistance, among others.

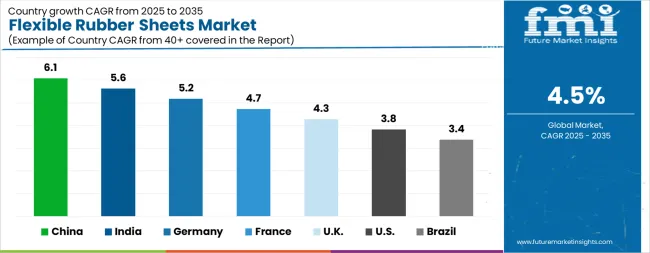

| Country | CAGR |

|---|---|

| China | 6.1% |

| India | 5.6% |

| Germany | 5.2% |

| France | 4.7% |

| UK | 4.3% |

| USA | 3.8% |

| Brazil | 3.4% |

The Flexible Rubber Sheets Market is expected to register a CAGR of 4.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 6.1%, followed by India at 5.6%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 3.4%, yet still underscores a broadly positive trajectory for the global Flexible Rubber Sheets Market.

In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 5.2%. The USA Flexible Rubber Sheets Market is estimated to be valued at USD 7.2 billion in 2025 and is anticipated to reach a valuation of USD 10.4 billion by 2035.

Sales are projected to rise at a CAGR of 3.8% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 1.0 billion and USD 558.2 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 20.3 Billion |

| Product Type | Neoprene Sheet, EPDM (Ethylene Propylene Diene Monomer) Sheet, Nitrile (Buna-N / NBR) Sheet, SBR (Styrene Butadiene Rubber) Sheet, Silicone Sheet, Butyl Sheet, Viton Sheet, and Thermoplastic Elastomer Sheet |

| Base Material | Synthetic Rubber, Recycled Rubber, Reclaimed Rubber, and Natural Rubber |

| End-Use Industry | Automotive Industry, Chemicals Industry, Military & Defense, Construction Industry, Aerospace Industry, Mining Industry, and Marine Industry |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | ContiTech AG, American Biltrite, Aero Rubber Company, Inc., ZENITH RUBBER, Hanna Rubber Company, and West American Rubber Company, LLC |

The global flexible rubber sheets market is estimated to be valued at USD 20.3 billion in 2025.

The market size for the flexible rubber sheets market is projected to reach USD 31.5 billion by 2035.

The flexible rubber sheets market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in flexible rubber sheets market are neoprene sheet, epdm (ethylene propylene diene monomer) sheet, nitrile (buna-n / nbr) sheet, sbr (styrene butadiene rubber) sheet, silicone sheet, butyl sheet, viton sheet and thermoplastic elastomer sheet.

In terms of base material, synthetic rubber segment to command 46.2% share in the flexible rubber sheets market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Flexible Packaging Paper Market Size and Share Forecast Outlook 2025 to 2035

Flexible Plastic Pouch Market Size and Share Forecast Outlook 2025 to 2035

Flexible Plastic Packaging Market Size and Share Forecast Outlook 2025 to 2035

Flexible Printed Circuit Boards Market Size and Share Forecast Outlook 2025 to 2035

Flexible Packaging Machinery Market Size and Share Forecast Outlook 2025 to 2035

Flexible Electronic Market Size and Share Forecast Outlook 2025 to 2035

Flexible Foam Market Size and Share Forecast Outlook 2025 to 2035

Flexible Plastic Packaging Industry Analysis in United States Size and Share Forecast Outlook 2025 to 2035

Flexible Protective Packaging Market Size and Share Forecast Outlook 2025 to 2035

Flexible AC Current Transmission System Market Size and Share Forecast Outlook 2025 to 2035

Flexible End-Load Cartoner Market Size and Share Forecast Outlook 2025 to 2035

Flexible Packaging Market Size and Share Forecast Outlook 2025 to 2035

Flexible Screens Market Size and Share Forecast Outlook 2025 to 2035

Flexible Metallic Conduit Market Size and Share Forecast Outlook 2025 to 2035

Flexible Electrical Conduit Market Size and Share Forecast Outlook 2025 to 2035

Flexible Display Market Size and Share Forecast Outlook 2025 to 2035

Flexible Substrate Market Size and Share Forecast Outlook 2025 to 2035

Flexible Paper Battery Market Size and Share Forecast Outlook 2025 to 2035

Flexible Metallic Tubing Market Size and Share Forecast Outlook 2025 to 2035

Flexible Barrier Films for Electronics Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA