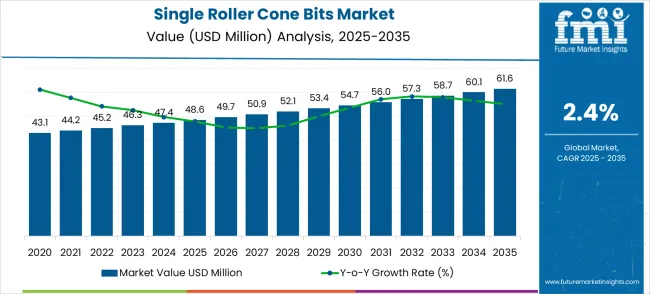

The global single roller cone bits market is projected to grow from USD 49 million in 2025 to approximately USD 62 million by 2035, recording an absolute increase of USD 13.0 million over the forecast period. This translates into a total growth of 26.7%, with the market forecast to expand at a compound annual growth rate (CAGR) of 2.4% between 2025 and 2035. The overall market size is expected to grow by nearly 1.27X during the same period, supported by the steady demand for specialized drilling tools in challenging geological formations and increasing exploration activities in unconventional oil and gas resources requiring precision drilling equipment.

Between 2025 and 2030, the single roller cone bits market is projected to expand from USD 49 million to USD 54.7 million, resulting in a value increase of USD 6.1 million, which represents 47.1% of the total forecast growth for the decade. This phase of growth will be shaped by steady demand for specialized drilling bits in challenging geological conditions, increasing exploration activities in mature oil fields that require enhanced drilling precision, and growing awareness among drilling contractors of the advantages of single-roller cone bits for specific applications. Manufacturers are maintaining their specialized bit production capabilities to meet the ongoing demand for precision drilling tools in unconventional formations and specialized drilling applications.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 49 million |

| Forecast Value in (2035F) | USD 62 million |

| Forecast CAGR (2025 to 2035) | 2.4% |

The single roller cone bits market commands a strong position within the oil and gas drilling market, contributing around 20% of the total market share due to its extensive use in drilling operations. In the mining equipment market, it holds an estimated share of 15%, as these bits are essential in various mining operations. In the construction equipment market, the market share is around 5%, where these bits play a crucial role in drilling for infrastructure projects. The water well drilling market sees a 10% share, given the high demand for reliable drilling tools in water exploration. Within the geotechnical testing equipment market, the single roller cone bits market captures around 8%, demonstrating their vital role in testing soil and rock properties. This collective presence across multiple sectors highlights the importance and adaptability of single roller cone bits in various industries.

The single roller cone bits market is poised for steady growth, projected to increase from USD 49 millionin 2025 to USD 62 million by 2035 at a CAGR of 2.4%, driven by increasing oil and gas exploration activities, rising demand for high-performance drilling tools, and adoption of advanced bearing technologies. By 2035, these pathways collectively represent USD 10–12 million in incremental revenue opportunities.

Pathway A – Oil Well Exploration. Open bearing single roller cone bits are widely used in onshore and offshore oil drilling operations to enhance penetration efficiency and reliability, unlocking USD 3–4 million in near-term revenue.

Pathway B – Well Logging & Precision Applications. Sealed bearing bits are deployed in high-precision well logging and monitoring operations, representing a potential USD 2–3 million opportunity.

Pathway C – Energy Infrastructure Expansion. Growing investments in oil and gas infrastructure across emerging markets create demand for durable, high-performance drilling bits, contributing USD 2–3 million.

Pathway D – Regional Market Growth. Rapid industrialization and energy sector expansion in China, India, and Latin America drive adoption of advanced roller cone bits, adding USD 1–2 million.

Pathway E – Product Innovation & Material Upgrades. Development of wear-resistant alloys, specialized coatings, and high-strength materials provides niche opportunities, expected to add USD 1–2 million.

Pathway F – OEM & Service Network Expansion. Collaborations with drilling contractors, equipment manufacturers, and local distributors enhance market reach and service offerings, offering USD 0.5–1 million in incremental revenue.

Pathway G – Custom & Specialized Applications. Designing bits for complex geological formations, deep wells, and high-temperature environments creates a targeted growth pool of USD 0.5–1 million.

Why is the Single Roller Cone Bits Market Growing?

Market stability is being supported by the continuing need for specialized drilling tools in challenging geological formations and specific drilling applications where single roller cone bits provide unique operational advantages. Modern drilling operations utilize single roller cone bits for specialized applications including reaming operations, pilot hole drilling, and challenging formation drilling where their unique design characteristics provide superior performance compared to conventional multi-cone alternatives. These specialized applications require precise drilling performance and can benefit from the specific geometric and operational characteristics of single roller cone designs.

The specialized nature of drilling applications and specific geological requirements continue driving demand for single roller cone bits from established manufacturers with appropriate technical expertise and proven performance capabilities. Drilling contractors and exploration companies maintain requirements for specialized drilling tools following operational success in specific applications and geological conditions. Technical specifications and drilling performance requirements establish continued demand for specialized equipment that provides operational advantages in particular drilling scenarios and formation characteristics.

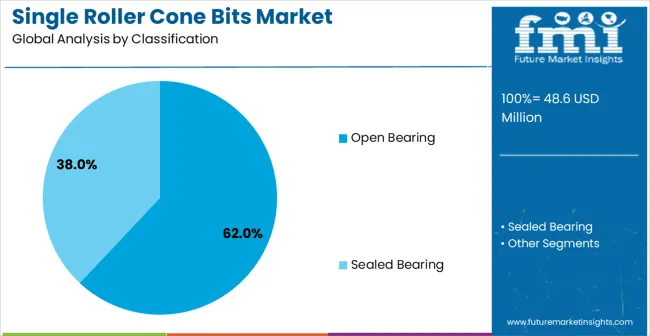

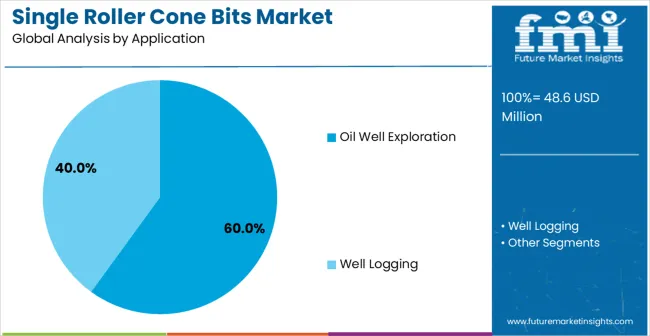

The market is segmented by machine type, end-use applications, and region. By machine type, the market is divided into open bearing and sealed bearing. By end-use application, the market is categorized into oil well exploration and well logging. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

Open bearing single roller cone bits are expected to capture 62% of the market in 2025, driven by their proven performance in specialized drilling applications. These systems offer cost-effective solutions while providing adequate performance in formations that require the unique advantages of single roller cone bits. Their dominance is attributed to their ability to deliver operational efficiency in various drilling scenarios, including exploration and contractor operations. Open bearing designs are favored for their cost-effectiveness and reliable field performance, benefiting from established design approaches and broad availability from specialized manufacturers. This segment is highly valued for its ability to balance performance and cost, making it the preferred choice in many specialized drilling tasks.

The oil well exploration segment is projected to account for 60% of the single roller cone bits market in 2025, securing its position as the dominant application. This leading market share is driven by the crucial role that roller cone bits play in the exploration of new oil and gas reserves. The high demand for drilling efficiency, combined with the increasing need for advanced drilling technologies in deep and complex exploration sites, supports the continued dominance of this segment. As oil companies focus on tapping into new resources and expanding their operations, the demand for high-performance single roller cone bits will remain robust, further reinforcing the growth of this segment over the next decade.

The Single Roller Cone Bits market maintains steady demand due to specialized drilling requirements and continuing recognition of single roller cone advantages in specific applications. However, the market faces challenges including competition from advanced multi-cone bit designs, limited application scope compared to conventional drilling bits, and specialized manufacturing requirements for relatively small market volumes. Technology development efforts and application optimization continue to maintain market viability and performance advantages for specific drilling scenarios.

The ongoing focus on specialized drilling applications is maintaining demand for single roller cone bits at drilling operations, exploration companies, and specialized drilling contractors. Enhanced design optimization and improved manufacturing techniques provide better performance characteristics and extended operational life for specific drilling applications while maintaining the unique advantages of single roller cone designs. These developments are particularly valuable for challenging drilling conditions and specialized applications that benefit from the specific characteristics of single roller cone bit geometry.

Single roller cone bit manufacturers are incorporating improved bearing technologies, advanced materials, and enhanced manufacturing processes that extend bit life and improve drilling performance in challenging conditions. Integration of advanced bearing systems and improved cutting structures enables better performance in specific drilling applications while maintaining the operational advantages that make single roller cone bits suitable for particular drilling scenarios.

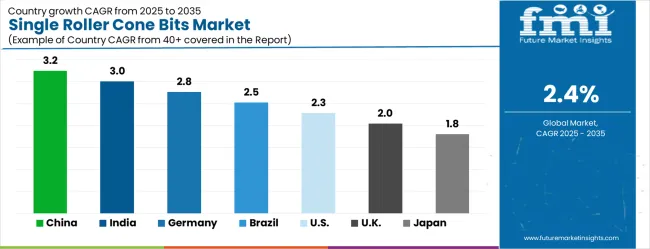

| Country | CAGR (2025-2035) |

|---|---|

| China | 3.2% |

| India | 3.0% |

| Germany | 2.8% |

| Brazil | 2.5% |

| United States | 2.3% |

| United Kingdom | 2.0% |

| Japan | 1.8% |

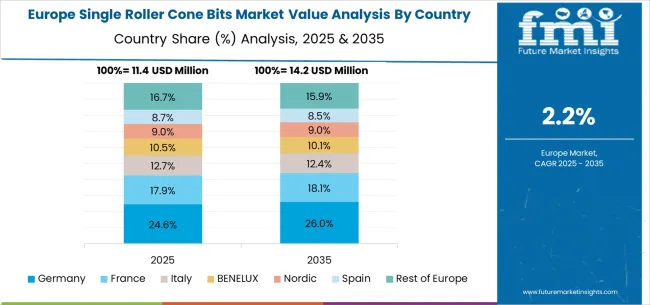

The single roller cone bits market shows moderate growth across key regions, with China leading at a 3.2% CAGR through 2035, driven by continued drilling activities and specialized applications in domestic oil and gas exploration. India follows at 3.0%, supported by ongoing exploration programs and specialized drilling requirements. Germany grows at 2.8%, maintaining focus on precision drilling applications and specialized manufacturing capabilities. Brazil records 2.5%, continuing utilization in specialized drilling operations. The United States shows growth at 2.3%, focusing on niche applications and specialized drilling scenarios. The United Kingdom demonstrates growth at 2.0%, supported by North Sea operations and specialized applications. Japan maintains expansion at 1.8%, driven by specialized drilling requirements and precision applications. Overall, the market reflects steady demand for specialized drilling applications across global drilling operations.

The report covers an in-depth analysis of 40+ countries, the top-performing countries are highlighted below.

The single roller cone bits market in China is projected to grow at a CAGR of 3.2%, driven by the country’s expanding oil and gas sector, as well as its increasing mining activities. China's large-scale infrastructure and energy projects demand durable and high-performance roller cone bits for drilling purposes. The government’s focus on developing the energy industry and improving mining technologies further boosts the market. Additionally, China’s continued investments in the exploration of natural resources, along with increasing demand for improved drilling efficiency, continue to drive the adoption of single roller cone bits.

The single roller cone bits market in India is growing at a CAGR of 3.0%, driven by the country’s burgeoning energy and mining sectors. As India’s oil and gas exploration efforts increase, the demand for reliable and efficient drilling tools such as single roller cone bits rises. Additionally, India’s mining industry, with its growing emphasis on coal and mineral extraction, also contributes to market growth. The government’s push for resource exploration and modernization of drilling operations supports the adoption of these advanced drilling tools.

The single roller cone bits market in Germany is expected to grow at a CAGR of 2.8%, supported by the country’s strong industrial base and active involvement in oil and gas exploration. Germany’s focus on efficient drilling technologies and energy sector advancements contributes to steady market expansion. The mining and geotechnical exploration sectors, which require high-performance drilling tools, continue to drive demand for single roller cone bits. Technological advancements in drilling equipment and efforts to optimize operational efficiency also support the market's growth in Germany.

The single roller cone bits market in Brazil is projected to grow at a CAGR of 2.5%, fueled by the country’s significant oil and gas reserves and growing mining industry. Brazil continues to be a leading player in the Latin American energy sector, driving demand for advanced drilling tools like single roller cone bits. As the country invests in new energy projects and mining ventures, the need for efficient and reliable drilling equipment increases. The focus on improving exploration efficiency and extending the life of drilling equipment supports the market growth.

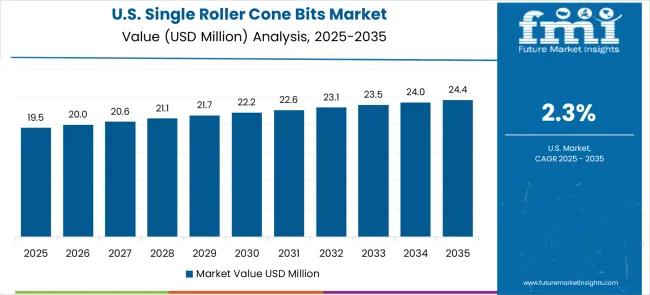

The single roller cone bits market in the United States is expected to grow at a CAGR of 2.3%, driven by the continued demand from the energy sector, particularly oil and gas exploration. As the USA expands its drilling operations, the need for efficient, long-lasting drilling equipment rises. The country’s ongoing investments in resource exploration and the development of oil fields require high-quality drilling tools. Additionally, the shift towards more environmentally conscious extraction methods influences the adoption of technologically advanced single roller cone bits.

The single roller cone bits market in the United Kingdom is projected to grow at a CAGR of 2.0%, driven by the country’s involvement in global oil and gas exploration activities. The need for advanced drilling equipment to maintain efficiency in extraction processes supports market growth. With the country’s energy sector focused on sustainable exploration and extraction, there is an increasing demand for drilling solutions that enhance operational efficiency. The ongoing advancements in drilling technologies further encourage the adoption of roller cone bits.

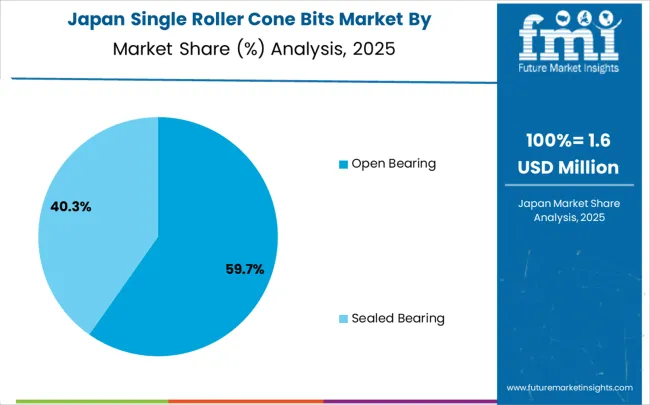

The single roller cone bits market in Japan is expected to grow at a CAGR of 1.8%, primarily driven by the country’s energy exploration and industrial sectors. Japan’s demand for reliable drilling solutions in offshore oil and gas exploration contributes to the adoption of single roller cone bits. Despite moderate growth, Japan’s focus on resource development, technological innovations in drilling equipment, and efforts to enhance drilling operations support market expansion.

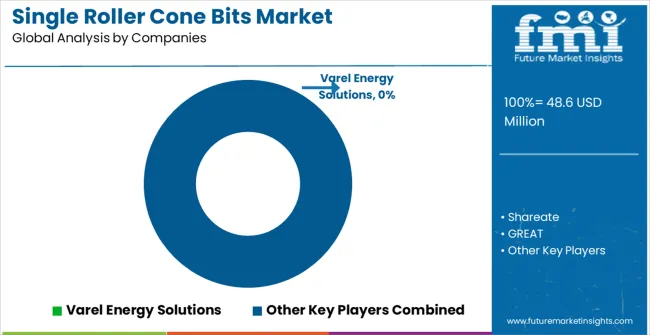

The single roller cone bits market is characterized by specialized manufacturers focusing on niche applications and technical expertise in single roller cone bit design and production. Companies maintain manufacturing capabilities for specialized drilling tools, technical support services, and application expertise to serve continuing demand for single roller cone bits in specific drilling scenarios. Product specialization, technical knowledge, and operational support are essential for maintaining market presence in this specialized drilling tool segment.

Varel Energy Solutions offers specialized single roller cone bits with focus on application expertise, technical support, and proven performance in challenging drilling conditions. Shareate provides drilling bit solutions with emphasis on specialized applications and technical capabilities for specific drilling requirements. GREAT delivers established drilling tools with proven reliability and technical expertise for specialized drilling operations.

TIANJIN LILIN MACHINERY focuses on specialized drilling bit manufacturing with comprehensive technical support and application knowledge. Far Eastern Industry provides drilling tool solutions with emphasis on specialized applications and operational support. Jiangxi Feilong bit manufacturing, KIMDRILL, ROSCHEN, Shanghai Haojiang Drilling Machinery Fittings, Hejian Hengji Drill Bit Manufacturing, Feilong, and Retop offer specialized single roller cone bits, technical expertise, and application support across regional and specialized drilling markets.

| Item | Value |

|---|---|

| Quantitative Units (2025) | USD 49 million |

| Machine Type | Open Bearing and Sealed Bearing |

| End-Use Application | Oil Well Exploration, Well Logging Operations |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, India, Brazil, Australia and 40+ countries |

| Key Companies Profiled | Varel Energy Solutions, Shareate, GREAT, TIANJIN LILIN MACHINERY, Far Eastern Industry, Jiangxi Feilong bit manufacturing, KIMDRILL, ROSCHEN, Shanghai Haojiang Drilling Machinery Fittings, Hejian Hengji Drill Bit Manufacturing, Feilong, Retop |

| Additional Attributes | Dollar sales by machine type, end-use application, and bearing technology, regional demand trends across North America, Europe, and Asia-Pacific, competitive landscape with specialized manufacturers and drilling tool providers, operational preferences for open versus sealed bearing systems, integration with specialized drilling operations and exploration activities |

The global single roller cone bits market is estimated to be valued at USD 48.6 million in 2025.

The market size for the single roller cone bits market is projected to reach USD 61.6 million by 2035.

The single roller cone bits market is expected to grow at a 2.4% CAGR between 2025 and 2035.

The key product types in single roller cone bits market are open bearing and sealed bearing.

In terms of application, oil well exploration segment to command 60.0% share in the single roller cone bits market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Single Air Chamber Hydro-pneumatic Suspension Market Forecast and Outlook 2025 to 2035

Single-channel Frequency Synthesizer Market Size and Share Forecast Outlook 2025 to 2035

Single-axis Drives Market Size and Share Forecast Outlook 2025 to 2035

Single Phase Spot Welder Machine Market Size and Share Forecast Outlook 2025 to 2035

Single Phase Spot Welder Market Size and Share Forecast Outlook 2025 to 2035

Single-use Bioreactors Market Size and Share Forecast Outlook 2025 to 2035

Single Board Computer Market Size and Share Forecast Outlook 2025 to 2035

Single-Serve Packaging Market Size and Share Forecast Outlook 2025 to 2035

Single Phase Recloser Market Size and Share Forecast Outlook 2025 to 2035

Single Phase Portable Conventional Gensets Market Size and Share Forecast Outlook 2025 to 2035

Single Phase Residential Voltage Regulator Market Size and Share Forecast Outlook 2025 to 2035

Single Phase Shunt Reactor Market Size and Share Forecast Outlook 2025 to 2035

Single Phase Air Cooled Home Standby Gensets Market Size and Share Forecast Outlook 2025 to 2035

Single Screw Extruder Market Size and Share Forecast Outlook 2025 to 2035

Single Phase Residential Power Conditioner Market Size and Share Forecast Outlook 2025 to 2035

Single Phase PV Inverter Market Size and Share Forecast Outlook 2025 to 2035

Single Phase Portable Generators Market Size and Share Forecast Outlook 2025 to 2035

Single Core Armored Cable Market Size and Share Forecast Outlook 2025 to 2035

Single Axis Solar Tracker Market Size and Share Forecast Outlook 2025 to 2035

Single Phase Commercial Voltage Regulator Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA