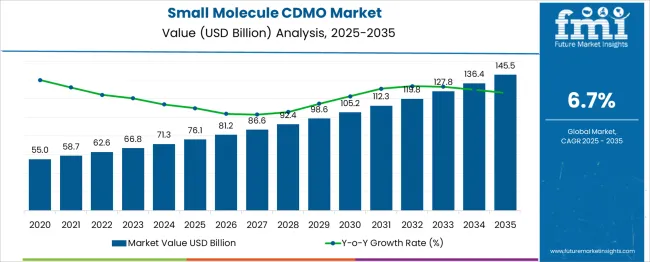

The global small molecule CDMO market is projected to grow from USD 76.1 billion in 2025 to approximately USD 145.5 billion by 2035, recording an absolute increase of USD 69.4 billion over the forecast period. This translates into a total growth of 91.2%, with the market forecast to expand at a compound annual growth rate (CAGR) of 6.7% between 2025 and 2035. The overall market size is expected to grow by nearly 1.9X during the same period, supported by increasing outsourcing trends in pharmaceutical manufacturing, rising demand for specialized manufacturing capabilities, and growing focus on cost optimization and operational efficiency across the pharmaceutical value chain.

Between 2025 and 2030, the small molecule CDMO market is projected to expand from USD 76.1 billion to USD 102.3 billion, resulting in a value increase of USD 26.2 billion, which represents 37.8% of the total forecast growth for the decade. This phase of growth will be shaped by increasing pharmaceutical companies' preference for outsourcing non-core activities, the growing pipeline of small molecule drugs, and the rising demand for specialized manufacturing expertise. Contract development and manufacturing organizations are expanding their capabilities to address the growing demand for comprehensive drug development and manufacturing solutions.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 76.1 billion |

| Forecast Value in (2035F) | USD 145.5 billion |

| Forecast CAGR (2025 to 2035) | 6.7% |

From 2030 to 2035, the market is forecast to grow from USD 102.3 billion to USD 145.5 billion, adding another USD 43.2 billion, which constitutes 62.2% of the overall ten-year expansion. This period is expected to be characterized by consolidation in the CDMO industry, integration of advanced manufacturing technologies, and development of end-to-end service offerings. The growing adoption of continuous manufacturing processes and quality by design principles will drive demand for CDMOs with advanced technical capabilities and regulatory expertise.

Between 2020 and 2025, the small molecule CDMO market experienced significant expansion, driven by pharmaceutical companies' strategic shift toward outsourcing and the need for flexible manufacturing capacity during global health challenges. The market developed as drug manufacturers recognized the value of partnering with specialized CDMOs to accelerate drug development timelines and reduce capital investments. Regulatory harmonization and increasing complexity of drug molecules began focusing the importance of experienced CDMO partners in navigating development and manufacturing challenges.

Market expansion is being supported by the pharmaceutical industry's continued focus on core competencies while outsourcing manufacturing and development activities to specialized partners. Modern pharmaceutical companies are increasingly recognizing the strategic advantages of working with CDMOs that offer comprehensive technical expertise, regulatory knowledge, and flexible manufacturing capacity. The growing complexity of small molecule drugs and stringent regulatory requirements make specialized CDMO services essential for successful drug development and commercialization.

The increasing pressure to reduce drug development costs and timelines is driving demand for integrated CDMO services that span from early-stage development through commercial manufacturing. Pharmaceutical companies benefit from CDMOs' economies of scale, specialized equipment, and expertise in handling complex chemistries and manufacturing processes. The rising number of virtual pharmaceutical companies and small biotech firms without internal manufacturing capabilities is also contributing to increased outsourcing to CDMOs across all stages of drug development.

The market is segmented by product outlook, drug type outlook, application outlook, and region. By product outlook, the market is divided into Active Pharmaceutical Ingredients (API) and Finished Drug Products. Based on drug type outlook, the market is categorized into innovators and generics. In terms of application outlook, the market is segmented into oncology, cardiovascular disease, central nervous system (CNS) conditions, autoimmune/inflammation, and others. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

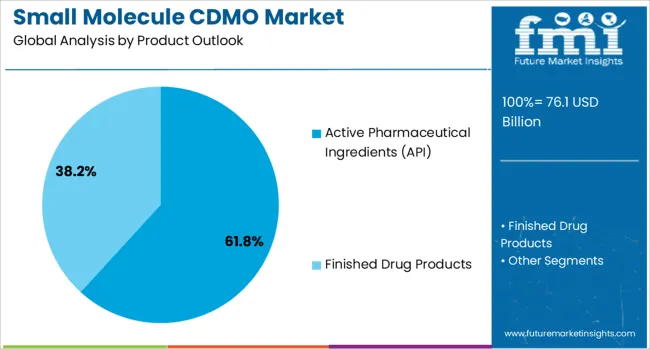

The Active Pharmaceutical Ingredients (API) segment is projected to account for 61.8% of the small molecule CDMO market in 2025, reaffirming its position as the cornerstone of contract manufacturing services. Pharmaceutical companies increasingly rely on specialized CDMOs for API manufacturing due to the complex chemistry, specialized equipment, and regulatory expertise required. The segment benefits from growing demand for both generic and innovative APIs, with CDMOs offering cost-effective solutions while maintaining quality standards.

This dominance reflects the critical nature of API manufacturing in the pharmaceutical value chain and the technical challenges associated with synthesizing complex molecules. CDMOs specializing in API manufacturing provide essential capabilities including process development, scale-up, analytical method development, and regulatory support. With increasing molecular complexity and stringent quality requirements, pharmaceutical companies continue to outsource API manufacturing to experienced partners who can navigate technical and regulatory challenges while ensuring reliable supply chains.

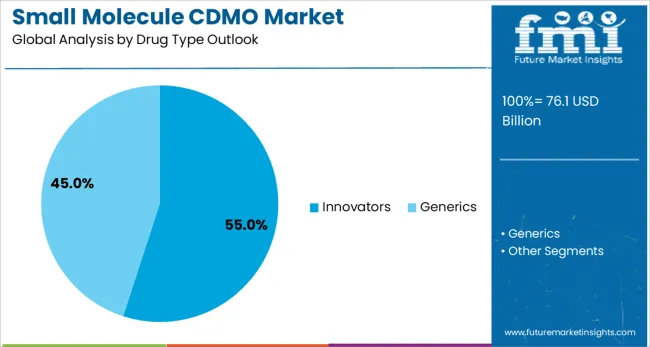

Innovators are projected to represent 55% of small molecule CDMO demand in 2025, underscoring the critical role of contract manufacturing in bringing novel therapeutics to market. Innovative pharmaceutical companies increasingly partner with CDMOs to access specialized capabilities, accelerate development timelines, and manage capacity constraints. The segment benefits from the robust pipeline of new molecular entities and the need for flexible manufacturing solutions during clinical development and early commercialization phases.

The preference for CDMO partnerships among innovators reflects strategic considerations including capital efficiency, risk management, and access to cutting-edge technologies. CDMOs provide valuable expertise in process optimization, analytical development, and regulatory compliance that supports successful drug development. As innovative drug companies focus on discovery and clinical development, partnerships with CDMOs enable efficient resource allocation while maintaining quality and regulatory compliance throughout the development and manufacturing process.

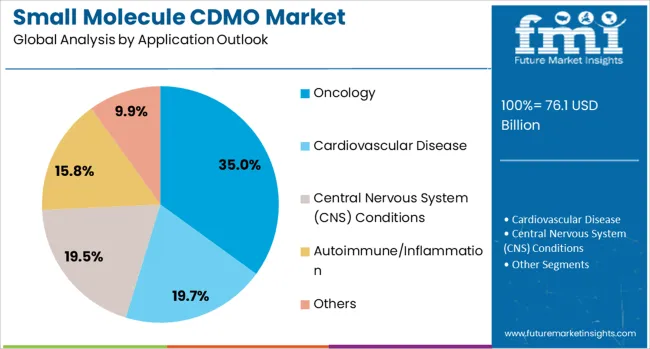

The oncology application is forecasted to contribute 35.0% of the small molecule CDMO market in 2025, reflecting the substantial pipeline of small molecule cancer therapeutics and the specialized manufacturing requirements of oncological drugs. The complexity of oncology APIs, including highly potent compounds and targeted therapies, necessitates specialized containment facilities and handling expertise that many CDMOs have developed. This segment benefits from continuous innovation in cancer treatment and the development of novel small molecule therapies targeting specific cancer pathways.

CDMOs serving the oncology segment must demonstrate capabilities in handling cytotoxic compounds, implementing appropriate containment strategies, and ensuring worker safety while maintaining product quality. The growing prevalence of cancer globally and the expansion of precision medicine approaches continue to drive demand for specialized CDMO services. With oncology remaining a primary focus area for pharmaceutical R&D investment, CDMOs with established oncology expertise and infrastructure are well-positioned to capture growing market opportunities.

The small molecule CDMO market is advancing steadily due to increasing outsourcing trends in pharmaceutical manufacturing and growing demand for specialized technical capabilities. The market faces challenges including capacity constraints, technology transfer complexities, and quality control requirements. Innovation in manufacturing technologies and process optimization continues to influence service offerings and market expansion patterns.

The growing implementation of continuous manufacturing processes is transforming small molecule production efficiency and quality control. CDMOs are investing in flow chemistry, process analytical technology, and real-time monitoring systems to enhance manufacturing capabilities. These advanced technologies enable better process control, reduced production timelines, and improved product quality while supporting regulatory compliance with quality by design principles.

Modern CDMOs are developing comprehensive service portfolios that span from early-stage drug discovery support through commercial manufacturing. This integrated approach provides pharmaceutical companies with single-source solutions that streamline drug development and reduce complexity in vendor management. The trend toward one-stop-shop CDMO services reflects client preferences for simplified project management and seamless technology transfer across development stages.

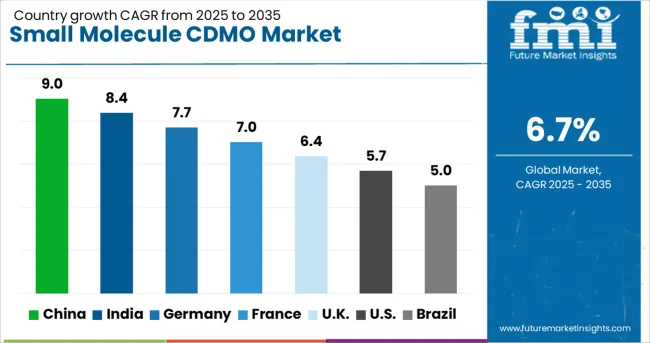

| Country | CAGR (2025-2035) |

|---|---|

| China | 9.0% |

| India | 8.4% |

| Germany | 7.7% |

| France | 7.0% |

| UK | 6.4% |

| USA | 5.7% |

| Brazil | 5.0% |

The small molecule CDMO market is experiencing varied growth globally, with China leading at a 9.0% CAGR through 2035, driven by expanding manufacturing capabilities, cost advantages, and government support for pharmaceutical manufacturing. India follows at 8.4%, supported by established generic drug manufacturing expertise and growing investments in quality infrastructure. Germany shows robust growth at 7.7%, focusing technical excellence and regulatory compliance. France records 7.0%, focusing on specialized manufacturing capabilities. The UK demonstrates 6.4% growth, leveraging its pharmaceutical innovation ecosystem. The USA shows 5.7% growth, maintaining leadership in innovative drug manufacturing.

The report covers an in-depth analysis of 40+ countries; seven top-performing countries are highlighted below.

Revenue from small molecule CDMO services in China is projected to exhibit strong growth with a CAGR of 9.0% through 2035, driven by substantial investments in pharmaceutical manufacturing infrastructure and technical capabilities. The country's cost-competitive manufacturing environment combined with improving quality standards is attracting global pharmaceutical companies seeking reliable CDMO partners. Chinese CDMOs are expanding their service offerings beyond basic manufacturing to include integrated drug development services.

Revenue from small molecule CDMO services in India is expanding at a CAGR of 8.4%, supported by the country's established position in generic drug manufacturing and growing capabilities in innovative drug development. Indian CDMOs benefit from strong chemistry expertise, cost advantages, and improving regulatory compliance standards. The industry is evolving from volume-based manufacturing toward specialized, high-value services.

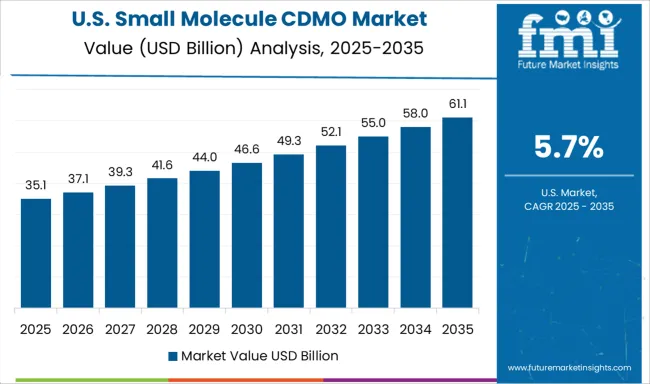

Demand for small molecule CDMO services in the USA is projected to grow at a CAGR of 5.7%, supported by the country's leadership in pharmaceutical innovation and stringent quality requirements. American CDMOs excel in handling complex molecules, providing integrated development services, and supporting innovative drug development programs. The market benefits from proximity to major pharmaceutical companies and access to advanced technologies.

Revenue from small molecule CDMO services in Germany is projected to grow at a CAGR of 7.7% through 2035, driven by the country's strong chemical and pharmaceutical manufacturing heritage. German CDMOs are recognized for technical excellence, process optimization capabilities, and adherence to highest quality standards. The market benefits from skilled workforce, advanced infrastructure, and strategic location within Europe.

Revenue from small molecule CDMO services in France is projected to grow at a CAGR of 7.0% through 2035, supported by government initiatives promoting pharmaceutical manufacturing and biotechnology innovation. French CDMOs offer specialized capabilities in complex chemistry, controlled substances, and advanced drug delivery systems.

Revenue from small molecule CDMO services in the UK is projected to grow at a CAGR of 6.4% through 2035, supported by the country's strong life sciences sector and favorable regulatory environment. British CDMOs benefit from access to pharmaceutical innovation clusters and skilled scientific workforce.

Revenue from small molecule CDMO services in Brazil is projected to grow at a CAGR of 5.0% through 2035, supported by the growing domestic pharmaceutical market and increasing manufacturing capabilities. Brazilian CDMOs are developing expertise in serving both local and regional markets with cost-effective solutions.

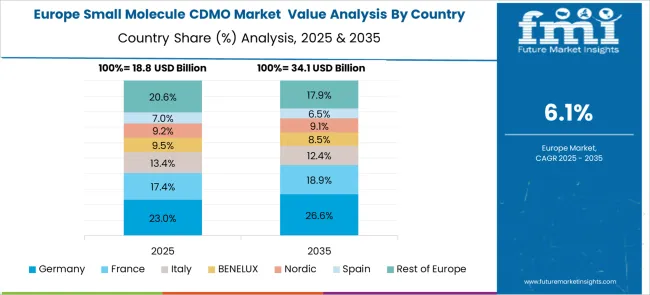

The small molecule CDMO market in Europe demonstrates established infrastructure across major economies with Germany showing strong presence through its advanced chemical manufacturing capabilities and extensive pharmaceutical industry expertise, supported by CDMOs leveraging technical excellence to provide comprehensive drug development and manufacturing services that meet stringent regulatory requirements. France represents a significant market driven by its pharmaceutical manufacturing heritage and government support for biotechnology innovation, with companies investing in specialized capabilities for complex small molecule manufacturing and advanced drug delivery systems.

The UK exhibits considerable growth through its strong regulatory framework and established pharmaceutical ecosystem, with CDMOs benefiting from access to skilled workforce and proximity to major pharmaceutical companies requiring flexible manufacturing solutions. Italy and Spain show expanding capabilities in generic drug manufacturing and API production, particularly in serving both European and global markets with cost-effective manufacturing solutions. Switzerland contributes through its concentration of innovative pharmaceutical companies and high-value manufacturing expertise, while Nordic countries display growing specialization in niche therapeutic areas. Eastern European markets demonstrate increasing competitiveness through cost advantages and expanding technical capabilities across diverse manufacturing requirements.

The small molecule CDMO market is characterized by competition among global contract manufacturers, regional specialists, and emerging service providers. Companies are investing in advanced manufacturing technologies, capacity expansion, integrated service offerings, and strategic partnerships to deliver comprehensive drug development and manufacturing solutions. Technical capabilities, regulatory compliance, and operational excellence are central to strengthening service portfolios and market presence.

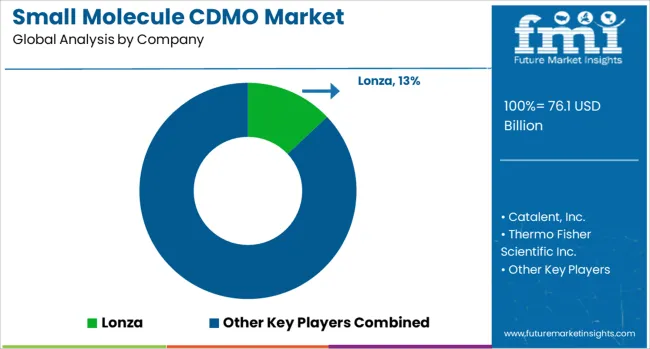

Lonza, Switzerland-based, leads the market with 13.0% global value share, offering comprehensive small molecule services from development through commercial manufacturing with focus on complex APIs and drug products. Catalent, Inc., USA, provides integrated solutions spanning drug development, delivery technologies, and commercial supply with extensive global manufacturing network. Thermo Fisher Scientific Inc., USA, delivers end-to-end CDMO services leveraging scientific expertise and advanced technologies. Cambrex Corporation, USA, specializes in small molecule APIs with particular strength in complex chemistry and controlled substances.

Bellen Chemistry, China, focuses on cost-effective API manufacturing with growing capabilities in innovative drug development support. Siegfried Holding AG, Switzerland, provides integrated drug substance and drug product manufacturing with focuses on quality and reliability. Recipharm AB, Sweden, offers comprehensive CDMO services with strong presence in European markets. Eurofins Scientific, Luxembourg, combines analytical services with CDMO capabilities for integrated solutions. Aurigene Pharmaceutical Services Ltd., India, leverages chemistry expertise for both generic and innovative drug manufacturing. CordenPharma International, Europe, provides platform technologies and specialized manufacturing capabilities across multiple sites.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 76.1 billion |

| Product Outlook | Active Pharmaceutical Ingredients (API), Finished Drug Products |

| Drug Type Outlook | Innovators, Generics |

| Application Outlook | Oncology, Cardiovascular Disease, Central Nervous System (CNS) Conditions, Autoimmune/Inflammation, Others |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, India, Brazil, Australia and 40+ countries |

| Key Companies Profiled | Lonza, Catalent Inc., Thermo Fisher Scientific Inc., Cambrex Corporation, Bellen Chemistry, Siegfried Holding AG, Recipharm AB, Eurofins Scientific, Aurigene Pharmaceutical Services Ltd., and CordenPharma International |

| Additional Attributes | Dollar sales by service type and scale of operation, regional capacity distribution, competitive landscape, client preferences for integrated versus specialized services, technology adoption trends including continuous manufacturing, process analytical technology, and digitalization initiatives in CDMO operations |

The global small molecule CDMO market is estimated to be valued at USD 76.1 billion in 2025.

The market size for the small molecule CDMO market is projected to reach USD 145.5 billion by 2035.

The small molecule CDMO market is expected to grow at a 6.7% CAGR between 2025 and 2035.

The key product types in small molecule CDMO market are active pharmaceutical ingredients (api) and finished drug products.

In terms of drug type outlook, innovators segment to command 55.0% share in the small molecule CDMO market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Small Molecule CMO/CDMO Market Size and Share Forecast Outlook 2025 to 2035

Small Molecule Innovator CDMO Market Size and Share Forecast Outlook 2025 to 2035

Small Molecule Brominated Flame Retardants Market Size and Share Forecast Outlook 2025 to 2035

Small Molecule-Drug Conjugates Market Size and Share Forecast Outlook 2025 to 2035

Small Molecule Inhibitors Market Analysis – Size, Share, and Forecast Outlook 2025 to 2035

Small Molecule API Market Analysis - Size, Share & Forecast 2025 to 2035

Small-Molecule Injectable Market Analysis - Trends, Growth & Forecast 2025 to 2035

RNA-Targeted Small Molecules Market – Trends & Forecast 2024-2034

Small Form Factor (SFF) Connectors Market Size and Share Forecast Outlook 2025 to 2035

Small Satellite Market Size and Share Forecast Outlook 2025 to 2035

Small Marine Engine Market Forecast Outlook 2025 to 2035

Small Gas Engine Market Size and Share Forecast Outlook 2025 to 2035

Small Animal Metabolic Monitoring System Market Size and Share Forecast Outlook 2025 to 2035

Small Animal Running Wheel System Market Size and Share Forecast Outlook 2025 to 2035

Small Caliber Ammunition Market Size and Share Forecast Outlook 2025 to 2035

Small Boats Market Size and Share Forecast Outlook 2025 to 2035

Small Capacity Electrolyzer Market Size and Share Forecast Outlook 2025 to 2035

Small Animal Imaging (In Vivo) Market Size and Share Forecast Outlook 2025 to 2035

Small Cell Lung Cancer (SCLC) Treatment Market Size and Share Forecast Outlook 2025 to 2035

Small Cell Network Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA