The soft touch lamination film market is experiencing consistent growth, driven by increasing demand for premium packaging and enhanced product aesthetics across multiple end-use sectors. Brand owners and converters have emphasized the tactile appeal and visual sophistication offered by soft touch films, making them a preferred choice for luxury packaging, cosmetics, electronics, and high-end publications.

Press releases and packaging trade publications have underlined how soft touch lamination adds a velvety finish and anti-scuff properties that elevate perceived product value while ensuring durability. Advances in extrusion and coating technologies have improved film performance and compatibility with digital and offset printing processes.

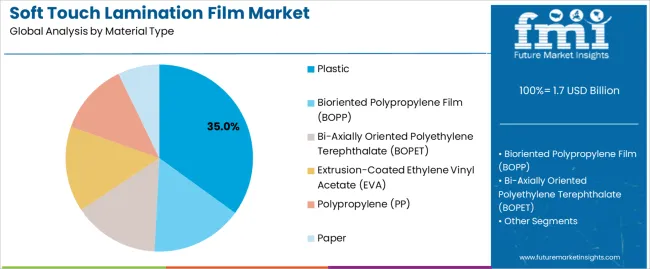

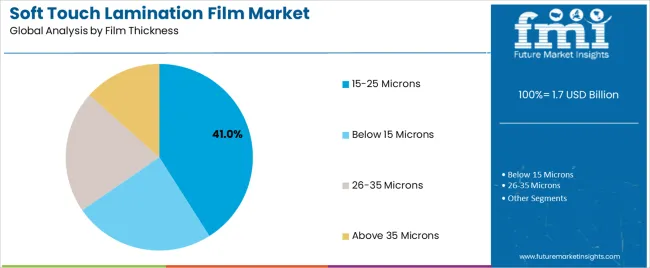

Additionally, growing consumer preference for visually appealing and tactile packaging has contributed to a surge in the adoption of soft touch films, particularly in retail and promotional materials. Future market expansion is expected to be fueled by innovations in sustainable plastic films, growing adoption in developing markets, and increased usage in short-run customized packaging. Segmental leadership is currently defined by Plastic materials, One-Side Lamination Films, and 15–25 Micron thickness formats due to their adaptability, cost-effectiveness, and production efficiency.

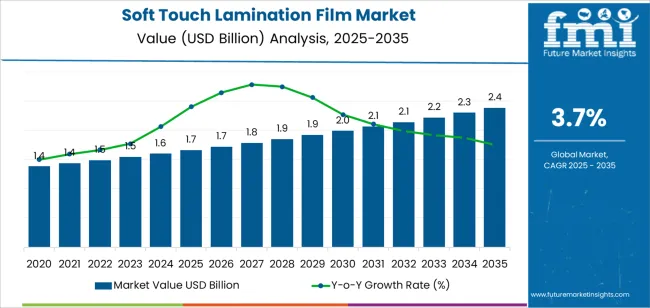

| Metric | Value |

|---|---|

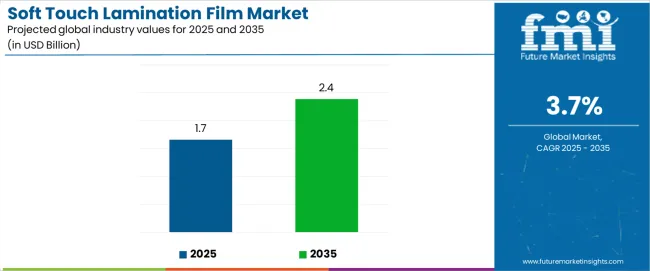

| Soft Touch Lamination Film Market Estimated Value in (2025 E) | USD 1.7 billion |

| Soft Touch Lamination Film Market Forecast Value in (2035 F) | USD 2.4 billion |

| Forecast CAGR (2025 to 2035) | 3.7% |

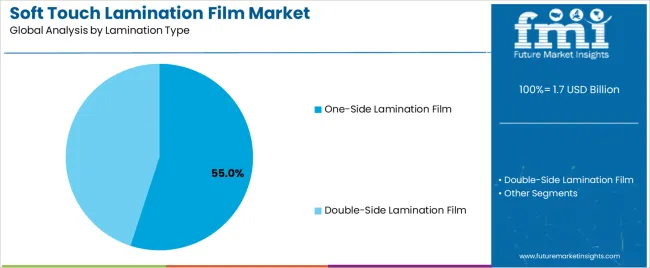

The market is segmented by Material Type, Lamination Type, Film Thickness, Coating Type, and End Use and region. By Material Type, the market is divided into Plastic, Bioriented Polypropylene Film (BOPP), Bi-Axially Oriented Polyethylene Terephthalate (BOPET), Extrusion‑Coated Ethylene Vinyl Acetate (EVA), Polypropylene (PP), and Paper. In terms of Lamination Type, the market is classified into One-Side Lamination Film and Double-Side Lamination Film. Based on Film Thickness, the market is segmented into 15‑25 Microns, Below 15 Microns, 26‑35 Microns, and Above 35 Microns. By Coating Type, the market is divided into Water-Based and Solvent-Based. By End Use, the market is segmented into Premium Prints, Presentation / Book Covers, Dust Jackets, Pocket Folders, Gift Bags, Corporate Brochures, Electronic Packaging, Luxury Folding Cartons, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Plastic segment is projected to account for 35.00% of the soft touch lamination film market revenue in 2025, maintaining its leadership among material types. Growth of this segment has been driven by the flexibility, durability, and processing ease associated with plastic-based substrates, particularly BOPP and PET.

Manufacturers have favored plastic materials for their superior compatibility with soft touch coatings and consistent performance across high-speed lamination lines. Additionally, plastic films have demonstrated better resistance to moisture, abrasion, and temperature fluctuations, making them suitable for a wide range of packaging and print applications.

Technical datasheets and converter feedback have highlighted the ability of plastic-based soft touch films to retain smoothness and clarity post-lamination, even under high-pressure applications. With ongoing innovation in recyclable and bio-based plastics, the segment is expected to maintain its momentum by aligning with both performance expectations and sustainability trends in the packaging industry.

The One-Side Lamination Film segment is projected to hold 55.0% of the soft touch lamination film market revenue in 2025, reinforcing its dominance among lamination types. This growth has been supported by the segment’s utility in applications requiring one exposed decorative surface, such as premium packaging boxes, book covers, and promotional cards.

One-side films have enabled printers and converters to reduce material costs while achieving desired tactile and visual effects on the presentation surface. Production efficiency has also contributed to their popularity, as single-sided lamination is typically faster and more cost-effective in standard workflows.

Converter specifications and industry feedback have pointed to widespread adoption of these films in projects where only one side needs enhancement or protection. Additionally, one-side lamination is compatible with post-laminate embellishments like foil stamping and spot UV, further enhancing its appeal in the design and packaging ecosystem. As demand for visually differentiated consumer goods grows, this segment is expected to retain its commanding share.

The 15–25 Microns segment is projected to contribute 41.0% of the soft touch lamination film market revenue in 2025, establishing itself as the preferred film thickness range. Growth in this segment has been driven by its ideal balance between flexibility, durability, and premium surface feel.

Industry standards have identified 15–25 micron films as optimal for maintaining a smooth matte finish while providing adequate protection during handling and transportation. This thickness range has shown excellent adaptability across various substrates and printing techniques, making it suitable for short-run digital jobs as well as high-volume offset printing.

Packaging converters and print service providers have favored this segment due to its ease of application and consistent results in both sheet-fed and roll-fed operations. Furthermore, this thickness range offers favorable economics by minimizing film consumption without compromising on sensory or functional properties. As the market continues to value efficient lamination without sacrificing aesthetic quality, the 15–25 Microns segment is expected to remain the thickness standard across diverse end-use applications.

The table beneath shows the predicted CAGR for the worldwide soft touch lamination film market across multiple semi-annual periods from 2025 to 2035. The business is foreseen to develop at a marginal rate of 3.5% in the second half (H2) of the same decade after surging at a CAGR of 3.9% in the first half (H1) of the decade from 2025 to 2035.

| Particular | Value CAGR |

|---|---|

| H1 | 3.9% (2025 to 2035) |

| H2 | 3.5% (2025 to 2035) |

| H1 | 3.4% (2025 to 2035) |

| H2 | 3.8% (2025 to 2035) |

Moving forward, from H1 2025 to H2 2035, the CAGR is anticipated to fall slightly to 3.4% in the first half and stay relatively stable at 3.8% in the second half. The market value retained by 40 BPS in the first half, but remained constant at 40 BPS in the second half.

Budding Demand for Soft Touch Lamination Film for the Luxury Packaging

The soft touch lamination film market is experiencing emerging growth within the packaging industry, especially in the realm of premium and luxury goods. Esteemed companies such as Estée Lauder in the cosmetics sector and Diageo in the spirits industry are harnessing the potential of these films to enhance their brand perception.

The tactile, velvety finish delivers a sense of opulence that immediately captures the attention of consumers amidst a sea of competing products on store shelves. In addition to enhancing aesthetics, these films also offer practical benefits.

Leading brands such as Nestlé, known for their Nespresso coffee pods, employ flexible packaging films due to their robustness and capability to safeguard products from moisture, grease, and scratches. Additionally, the market is enhanced by the potential for customization of these films.

Tech companies like Apple, recognized for their premium iPhone packaging, can integrate logos, designs, or even embossing to craft unique packaging that reflects their brand identity. As sustainability continues to be a focal point, manufacturers are working on developing environmentally friendly alternatives.

The global packaging leader, Huhtamaki, exemplifies the potential of soft touch films crafted from recycled or renewable materials, catering to the preferences of environmentally conscious consumers and brands.

This harmonious blend of visual appeal, functionality, adaptability, and eco-friendliness is propelling the soft touch lamination film market forward, indicating sustained expansion potential.

Escalating Trend of Sustainability Upsurge Brand’s Market Reach

The soft touch lamination film industry is currently undergoing a significant transition towards the use of environmentally friendly materials, largely spurred by the escalating focus on sustainability.

With consumers showing an increasing awareness of environmental issues, brands are proactively embracing eco-friendly packaging solutions. There is a growing interest in bioplastics, which are derived from renewable sources such as plant starches, signifying a noticeable shift in consumer and industry preferences.

For instance, The TIPA Corporation, a prominent film manufacturer, provides environmentally friendly soft touch films made from bio-based materials for renowned brands such as Seventh Generation, known for its eco-friendly cleaning products. The brands offer recyclable soft touch lamination films as another sustainable alternative.

Along with that, Avery Dennison, a global leader in labeling and packaging materials, provides bioplastic and recyclable films tailored to the needs of environmentally responsible companies such as The Body Shop, renowned for its ethical beauty products.

Such a strategic shift towards sustainable materials underscores the soft touch lamination film market's dedication to fostering innovation and environmental stewardship, ensuring its continued significance in a world increasingly attuned to sustainability.

Expensive Production of Colorful Packaging Curbs Soft Touch Lamination Market Growth

The soft touch lamination film market, despite its undeniable advantages, faces challenges that need to be addressed to ensure sustained growth. A key drawback is the potential for muted colors. The luxurious matte finish can sometimes diminish the vibrancy of richly colored printed pieces.

This necessitates careful design considerations, ensuring the final product retains its visual impact. The cost factor can be a hurdle, particularly for companies in emerging economies. The premium price point associated with soft touch lamination may limit its widespread adoption by budget-conscious firms.

Due to its scratchiness, which necessitates cautious handling and storage, the soft touch lamination film market confronts difficulties. For optimal utilization, designers and printers need to possess a certain knowledge.

Cost-effective solutions with better color accuracy and scratch resistance should be the manufacturers' main priorities. Educational programs may provide printers and designers the expertise they need to realize the possibilities of such opulent packaging options.

During the historical period from 2020 to 2025, the global soft touch lamination film industry maintained a solid CAGR of 3.2%. The industry's growth trajectory was evident as it witnessed an increase in value from USD 1.4 billion in 2020 to USD 1.7 billion in 2025.

The growing consumer demand for premium packaging solutions predominantly fueled this growth. The projected period is estimated to witness further expansion driven by consumers' preference for high-quality packaging.

The market had a substantial drop in 2024 because of the Covid-19 epidemic. In addition to causing the temporary closure of many companies that are important end consumers of the items in the market, the pandemic also disrupted international commerce and transportation, which had adverse repercussions on the soft touch lamination film industry.

The global epidemic greatly influenced business priorities in the soft touch lamination film sector. Prior to the pandemic, luxury aesthetics could have been the only priority, but in the aftermath, cost-effectiveness rose to the top of the priority list for many businesses.

Such a shift in emphasis fueled the desire for less expensive soft touch lamination film solutions. In response, producers created more reasonably priced substitutes, guaranteeing that a greater variety of brands could still enjoy the opulent sensation of a soft touch.

Fortunately, the global economic climate also played a role in this market adaptation. International trade experienced a rapid recovery in 2024 and 2025, facilitating the movement of materials and finished products at a more efficient pace.

Such swift recovery, coupled with the introduction of cost-effective film options, allowed the soft touch lamination film market to helm the challenges of the pandemic and position itself for continued growth.

Developments in manufacturing procedures have led to a significant revolution in the soft touch lamination film industry. Substantial advancements in research and development have resulted in an expansion of these films' capabilities. The introduction of unique finishes is one noteworthy area of innovation.

Companies such as Amcor, a significant player in the global packaging industry, have created soft touch films with antimicrobial qualities. These films are especially appropriate for food or medicine packaging that must adhere to strict hygienic guidelines.

In a comparable manner, companies such as Bemis, renowned for their proficiency in flexible packaging solutions, have created UV-resistant films to address the needs of items susceptible to solar harm. These developments not only improve packaging's aesthetic appeal but also expand its practical potential.

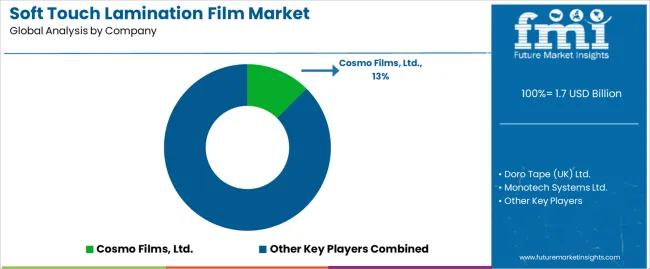

A substantial fraction of the global market share is held by Tier 1 enterprises. These industry leaders specialize in producing and reconditioning products in a variety of packaging styles, and they have a large product range and high production capability.

They have a huge customer base and a wide geographic reach. Avery Dennison Corporation, Amcor Limited, and Dow Chemical Co. are notable Tier 1 firms that fulfill regulatory criteria and provide a wide range of series.

Tier 2 firms are mid-size players who are distinguished by a significant presence internationally and industry understanding. DUNMORE Corporation, Taghleef Industries SLU, Flex film Limited, and Cosmo Films, Ltd. are among the enterprises that are well-established in particular regions and can benefit from acquiring cutting-edge technology and a broader global footprint.

Small businesses mostly catering to local or regional requirements are referred to as Tier 3. Compared to their structured rivals, these businesses require a greater degree of formalization and comprehensive structure because of their perceived need for more organization and requirement for a wider geographic reach.

This group includes up-and-coming businesses including Jet Technologies, Monotech Systems Ltd., and Doro Tape (UK) Ltd. To meet the demands of the local market, these enterprises need to expand their geographic reach.

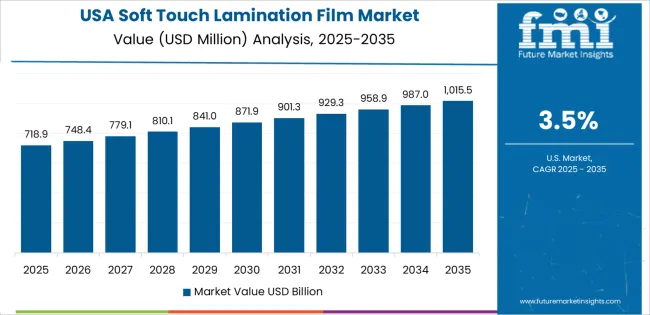

The soft touch lamination film market analysis for various countries is included in the section below. It is projected that the United States is anticipated to continue to lead North America at a CAGR of 2.1% until 2035. By 2035, the Asia Pacific market is envisioned to grow at a CAGR of 5.8% in India, followed by the market in China with a CAGR of 4.9%.

| Countries | Value CAGR (2025 to 2035) |

|---|---|

| United States | 2.1% |

| Canada | 1.3% |

| Spain | 2.6% |

| United Kingdom | 1.7% |

| China | 4.9% |

| India | 5.8% |

The soft touch lamination film sector in the United States is anticipated to report a CAGR of 2.1% from 2025 to 2035. As of right now, it has the most market share in North America, and this is anticipated to keep happening throughout the projection period.

The need for high-end experiences among Americans is fueling the growth of soft-touch lamination films. A growing number of consumers are lured to luxury goods with elegant packaging, such as Apple's sleek iPhone boxes with their distinctive velvety texture. This is not only an electronics fad.

In the United States, Brands like Estée Lauder are using soft-touch films to enhance the perceived value of their high-end cosmetic packaging. Demand is also being fueled by the growth of business brochures that emphasize tactile encounters. These marketing materials are made more elegant and professional by the soft-touch lamination.

Understanding the shift, leading package manufacturers such as Avery Dennison are always coming up with new film textures and finishes to meet the changing demands of brands in the United States and their more discriminating clientele.

India’s soft touch lamination film industry is anticipated to register a CAGR of 5.8% by 2035. As the food and beverage manufacturers in India develop demand for soft touch lamination for the production of food boxes and containers.

Indian food and beverage businesses are increasingly adopting soft touch lamination as a packaging technique. This involves creating a velvety texture on luxury chocolate boxes from brands such as Cadbury, owned by Mondelez, and premium tea tins from Lipton, owned by PepsiCo.

The incorporation of soft touch lamination enhances the perceived value of the product and contributes to a more memorable brand experience.

Such a technique adds a tactile dimension that is absent in standard packaging, making it a compelling choice for companies looking to differentiate themselves in the competitive retail environment of India.

China is projected to highlight a CAGR of 4.9% from 2025 to 2035, developing novel improvements in the soft touch lamination film sector. Burgeoning e-commerce companies such as Alibaba are developing novel packaging designs that integrate soft touch laminations for premium packaging, which are supposed to be exported outside China.

The need for soft-touch lamination films has increased because of China's industrial sector's explosive expansion. Instead of concentrating solely on the functioning of their products, manufacturers are increasingly trying to improve the way they seem.

Soft-touch films are used to give the packaging of modern products a luxurious feel, as companies like Xiaomi and Huawei have realized the importance of premium packaging. Soft-touch lamination is becoming popular not just for electronics but also for high-end appliances.

Haier and other manufacturers are using this technique to create a more upscale look. This trend is in line with the rising demand in China from consumers for high quality, aesthetically pleasing items.

The section contains information about the leading segments in the soft touch lamination industry. By material, the polypropylene segment is estimated to acquire a market share of 39.2% in 2025. Additionally, based on the thickness of the film, around 37.4% of the market prefers films with 0.1 to 0.5 mm thickness.

| Material | Polypropylene (PP) |

|---|---|

| Value Share (2025) | 39.2% |

Polypropylene (PP) reigns supreme in the soft touch lamination film market, capturing nearly 39.2% of revenue in 2025. This dominance stems from its ability to deliver the smooth, velvety texture that consumers crave. Nevertheless, Polypropylene's value extends beyond aesthetics in the market.

Manufacturers are constantly innovating, leveraging PP's versatility to create unique designs and cater to a wider consumer base. Expect to see a surge in novel PP-based soft touch films with exciting textures, finishes, and potentially even integrated functionalities, further solidifying PP's position as the leading material in this rapidly growing market.

| Thickness | 0.1 to 0.5 mm |

|---|---|

| Value Share (2025) | 37.4% |

Brands are incorporating soft touch lamination films into their designs, leading to a surge in demand for thin films between 0.1 and 0.5 millimeters thick. These films, projected to capture a 37.4% revenue share in 2025, offer aesthetics and functionality, allowing manufacturers to create innovative container designs with intricate shapes and details.

Thin films are revolutionizing packaging design by creating visually striking chocolate boxes with a velvety texture. This is driven by consumer preference for a soft touch experience, leading to increased demand for thin lamination films.

As brands differentiate themselves, innovative and captivating packaging designs are expected to emerge due to the versatility of thin, soft-touch lamination films.

The soft touch lamination film market is witnessing a two-pronged approach from key players. Established industry leaders are prioritizing research and development to stay ahead of the curve. Such a strategy translates into cutting-edge products with improved features.

Soft touch films with enhanced durability, superior scratch resistance, or even embedded functionalities like anti-microbial properties. By constantly innovating, leading companies aim to solidify their market position and cater to the evolving needs of brands.

Meanwhile, emerging companies are taking a collaborative approach. They are strategically collaborating with local and regional firms to augment their geographic reach.

Such a procedure allows them to leverage local expertise and distribution networks, facilitating the introduction of new soft touch lamination film options to previously untapped markets.

This sort of dual strategy, which eventually benefits both brands and consumers, is fostering a dynamic and competitive soft touch lamination film market: innovation from established companies and market development through partnership.

Recent Industry Developments in Soft Touch Lamination Film Market:

In terms of material, the industry is divided into Polypropylene (PP), Polyvinyl Chloride (PVC), Polyester (PET), Polyamide (PA), Polyethylene (PE), and other materials such as EVA, and EVOH.

In terms of thickness, the industry is segregated into upto 0.1 mm, 0.1 to 0.5 mm, 0.5 to 1.0 mm, and above 1.0 mm.

End use industries of the sector are packaging, printing and publication.

Key countries of North America, Latin America, Europe, East Asia, South Asia, Middle East and Africa (MEA), and Oceania have been covered in the report.

The global soft touch lamination film market is estimated to be valued at USD 1.7 billion in 2025.

The market size for the soft touch lamination film market is projected to reach USD 2.4 billion by 2035.

The soft touch lamination film market is expected to grow at a 3.7% CAGR between 2025 and 2035.

The key product types in soft touch lamination film market are plastic, bioriented polypropylene film (bopp), bi-axially oriented polyethylene terephthalate (bopet), extrusion‑coated ethylene vinyl acetate (eva), polypropylene (pp) and paper.

In terms of lamination type, one-side lamination film segment to command 55.0% share in the soft touch lamination film market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Software Defined Vehicle Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Networking (SDN) And Network Function Virtualization (NFV) Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Perimeter (SDP) Market Size and Share Forecast Outlook 2025 to 2035

Soft Ferrite Core Market Size and Share Forecast Outlook 2025 to 2035

Soft Gripper Market Size and Share Forecast Outlook 2025 to 2035

Software-Defined Wide Area Network SD-WAN Market Size and Share Forecast Outlook 2025 to 2035

Soft Magnetic Composite Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Softwood Veneer and Plywood Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Radio (SDR) Market Size and Share Forecast Outlook 2025 to 2035

Software License Management (SLM) Market Size and Share Forecast Outlook 2025 to 2035

Soft Wall Military Shelter Market Size and Share Forecast Outlook 2025 to 2035

Software-Defined Networking SDN Market Size and Share Forecast Outlook 2025 to 2035

Soft Drinks Packaging Market Size and Share Forecast Outlook 2025 to 2035

Software-Defined Anything (SDx) Market Size and Share Forecast Outlook 2025 to 2035

Software-Defined Data Center Market Size and Share Forecast Outlook 2025 to 2035

Software Containers Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Application And Infrastructure Market Size and Share Forecast Outlook 2025 to 2035

Software Defined Networking Market Size and Share Forecast Outlook 2025 to 2035

Software-Defined Camera (SDC) Market Size and Share Forecast Outlook 2025 to 2035

Softgel Capsules Market Overview - Growth & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA