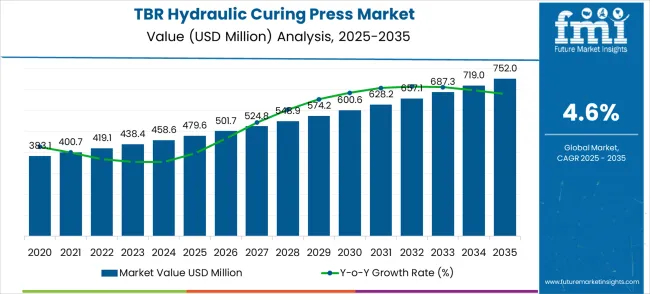

The global TBR hydraulic curing press market is projected to grow from USD 479.6 million in 2025 to approximately USD 752.0 million by 2035, recording an absolute increase of USD 272.4 million over the forecast period. This translates into a total growth of 56.8%, with the market forecast to expand at a CAGR of 4.6% between 2025 and 2035. The overall market size is expected to grow by nearly 1.57X during the same period, supported by the rising demand for advanced tire manufacturing equipment and increasing adoption of automated curing technologies.

| TBR Hydraulic Curing Press Market | Value |

|---|---|

| Market Value (2025) | USD 479.6 million |

| Market Forecast Value (2035) | USD 752.0 million |

| Market Forecast CAGR | 4.6% |

Between 2025 and 2030, the TBR hydraulic curing press market is anticipated to expand from USD 479.6 million to USD 601.8 million, resulting in a value increase of USD 122.2 million, which represents 44.9% of the total forecast growth for the decade. This phase of growth will be shaped by rising penetration of advanced hydraulic curing technologies in tire manufacturing facilities, increasing demand for high-precision tire production equipment, and growing adoption of automated manufacturing processes. Equipment manufacturers are expanding their hydraulic curing press capabilities to address the growing complexity of modern tire production requirements and stringent quality standards.

From 2030 to 2035, the market is forecast to grow from USD 601.8 million to USD 752.0 million, adding another USD 150.2 million, which constitutes 55.1% of the overall ten-year expansion. This period is expected to be characterized by expansion of intelligent hydraulic control systems, development of enhanced energy efficiency features, and advancement of Industry 4.0 integration capabilities. The growing adoption of larger tire manufacturing facilities and specialized TBR tire production will drive demand for more sophisticated hydraulic curing press solutions and advanced automation technologies.

Market expansion is being supported by the rapid increase in commercial vehicle production worldwide and the corresponding need for efficient tire manufacturing equipment that provides superior curing performance and operational reliability. Modern tire manufacturing facilities rely on consistent tire quality and production efficiency to ensure optimal performance including commercial trucks, buses, and industrial vehicles. Even minor curing inefficiencies can require comprehensive production protocol adjustments to maintain optimal manufacturing standards and product quality.

The growing complexity of tire manufacturing requirements and increasing demand for high-performance TBR tires are driving demand for hydraulic curing press equipment from certified manufacturers with appropriate technical capabilities and proven expertise. Tire manufacturing companies are increasingly requiring documented curing efficiency and equipment reliability to maintain production quality and cost effectiveness. Industry specifications and quality standards are establishing standardized tire curing procedures that require specialized hydraulic technologies and trained operators.

The automotive industry's shift toward heavy-duty commercial vehicles and the expansion of logistics and transportation sectors are creating demand for TBR tires, consequently driving the need for advanced curing press equipment. The stringent safety and quality regulations in the automotive sector are compelling tire manufacturers to invest in precision hydraulic curing systems that ensure consistent tire performance and durability.

The TBR Hydraulic Curing Press market is entering a new phase of growth, driven by demand for precision tire manufacturing, commercial vehicle expansion, and evolving quality and efficiency standards. By 2035, these pathways together can unlock USD 180-220 million in incremental revenue opportunities beyond baseline growth.

Pathway A -- Advanced Framework Style Technology Leadership The Framework Style segment already holds the largest share due to its superior structural stability and production capacity. Expanding automation capabilities, precision control systems, and modular design options can consolidate market leadership. Opportunity pool: USD 50-65 million.

Pathway B -- Commercial Vehicle Tire Manufacturing Excellence. Commercial Vehicle Tires account for the majority of demand. Growing commercial vehicle production, especially in emerging economies, will drive higher adoption of advanced hydraulic curing systems for premium tire manufacturing. Opportunity pool: USD 40-55 million.

Pathway C -- Smart Manufacturing and Industry 4.0 Integration.In advanced manufacturing facilities, IoT-enabled, automated curing systems with predictive maintenance and quality monitoring capabilities are being adopted. Equipment tailored for smart factories can capture significant growth. Opportunity pool: USD 25-35 million.

Pathway D -- Emerging Market Expansion and Localization Asia-Pacific, Latin America, and the Middle East present growing demand due to rising automotive manufacturing and commercial vehicle production. Targeting local manufacturing partnerships and cost-effective solutions will accelerate adoption. Opportunity pool: USD 20-30 million.

Pathway E -- Energy Efficiency and Compliance With stricter energy efficiency regulations and requirements, there is an opportunity to promote energy-efficient hydraulic systems and eco-friendly curing technologies. Opportunity pool: USD 15-20 million.

Pathway F -- Premium Precision and Quality Features Curing presses with advanced temperature control, pressure monitoring, and quality assurance systems offer premium positioning for high-end tire manufacturers and automotive suppliers. Opportunity pool: USD 12-18 million.

Pathway G -- Service, Maintenance & Aftermarket Support. Recurring revenue from spare parts, maintenance contracts, technical support services, and equipment upgrades creates a long-term revenue stream for manufacturers. Opportunity pool: USD 10-15 million.

Pathway H -- Customization and Application-Specific Solutions Specialized curing press configurations for specific tire types, sizes, and manufacturing requirements can command premium pricing and strengthen customer relationships. Opportunity pool: USD 8-12 million.

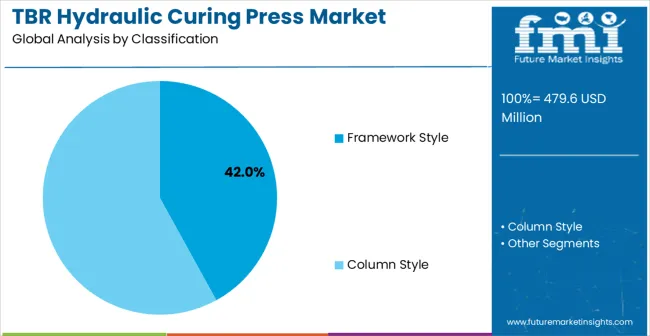

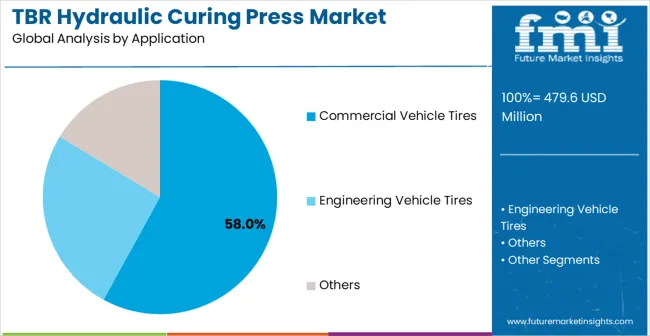

The market is segmented by machine type, application, and region. By machine type, the market is divided into Framework Style, Column Style, and others. Based on application, the market is categorized into Commercial Vehicle Tires, Engineering Vehicle Tires, and others. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

In 2025, the Framework Style TBR hydraulic curing press segment is projected to capture around 42% of the total market share, making it the leading machine type category. This dominance is largely driven by the widespread adoption of framework-based curing systems that offer superior structural stability and precise pressure distribution, catering to high-volume tire production requirements. The Framework Style design is particularly favored for its ability to deliver consistent curing performance across various tire sizes while maintaining operational efficiency and reducing maintenance requirements.

Large-scale tire manufacturing facilities, commercial tire producers, and automotive suppliers increasingly prefer this design, as it meets demanding production schedules without imposing excessive operational costs or complex maintenance procedures. The availability of well-established product lines, along with comprehensive automation options and technical support from leading manufacturers, further reinforces the segment's market position. This machine type benefits from consistent demand across regions, as it is considered the most reliable solution for high-volume TBR tire production facilities of varying scales.

The combination of structural integrity, performance consistency, and automation compatibility makes Framework Style hydraulic curing presses a preferred choice for manufacturers seeking reliable, high-capacity tire production solutions, ensuring their continued dominance in the commercial tire manufacturing equipment market.

The Commercial Vehicle Tires segment is expected to represent 58% of TBR hydraulic curing press demand in 2025, highlighting its position as the most significant application sector. This dominance stems from the unique requirements of commercial vehicle tire production, where consistent quality, durability, and performance are critical to vehicle safety and operational efficiency. Commercial vehicle tires must endure extreme operating conditions, heavy loads, and extended service intervals, requiring precise curing processes that can only be achieved through advanced hydraulic curing systems.

The segment benefits from the global expansion of logistics, e-commerce, and transportation industries, which continue to drive demand for commercial vehicles and consequently their tires. As commercial vehicle manufacturers emphasize improved safety standards and operational efficiency, the demand for high-quality TBR tires produced using advanced hydraulic curing technology continues to rise. The segment also benefits from increasing government regulations regarding commercial vehicle safety and emissions, which indirectly drive demand for premium tire quality that requires sophisticated manufacturing equipment.

With commercial vehicle fleets investing in operational efficiency and safety compliance, hydraulic curing presses offer a crucial solution for manufacturing tires that meet stringent performance requirements. The growth of organized transportation companies, coupled with increased focus on tire quality and safety standards, ensures that Commercial Vehicle Tires will remain the largest and most stable demand driver for TBR hydraulic curing presses throughout the forecast period.

The TBR Hydraulic Curing Press market is advancing steadily due to increasing commercial vehicle production and growing recognition of hydraulic curing advantages over conventional tire manufacturing methods. However, the market faces challenges including higher initial equipment costs compared to traditional curing systems, need for specialized technical expertise for operation and maintenance, and varying quality standards across different geographic regions. Technology advancement efforts and automation integration programs continue to influence equipment development and market adoption patterns.

The growing development of advanced hydraulic control systems is enabling higher precision curing processes with improved temperature and pressure control characteristics. Enhanced hydraulic technologies and optimized control algorithms provide superior tire quality while maintaining energy efficiency and production consistency. These technologies are particularly valuable for large-scale tire manufacturers who require reliable equipment performance that can support extensive production operations with consistent results across multiple tire specifications.

Modern TBR hydraulic curing press manufacturers are incorporating advanced automation features and IoT connectivity that enhance production efficiency and equipment monitoring capabilities. Integration of predictive maintenance systems and real-time quality monitoring enables superior production management and comprehensive process optimization. Advanced equipment features support operation in diverse manufacturing environments while meeting various quality requirements and production specifications, facilitating seamless integration with existing manufacturing systems.

| Country | CAGR (2025-2035) |

|---|---|

| China | 6.2% |

| India | 5.8% |

| Germany | 5.3% |

| Brazil | 4.8% |

| United States | 4.4% |

| United Kingdom | 3.9% |

| Japan | 3.5% |

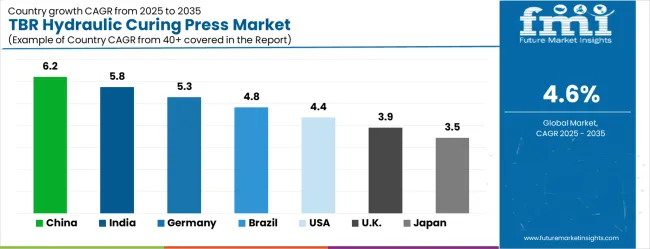

The TBR hydraulic curing press market is growing rapidly, with China leading at a 6.2% CAGR through 2035, driven by massive commercial vehicle production and increasing adoption of advanced tire manufacturing equipment. India follows at 5.8%, supported by expanding automotive manufacturing infrastructure and growing demand for commercial vehicle tires. Germany grows steadily at 5.3%, integrating hydraulic curing technology into its established automotive manufacturing ecosystem. Brazil records 4.8%, emphasizing manufacturing modernization and automotive industry expansion. The United States shows solid growth at 4.4%, focusing on technology advancement and operational efficiency in tire manufacturing. The United Kingdom demonstrates steady progress at 3.9%, maintaining established automotive manufacturing applications. Japan records 3.5% growth, concentrating on technological innovation and precision manufacturing excellence.

The report covers an in-depth analysis of 40+ countries, top-performing countries are highlighted below.

Revenue from TBR hydraulic curing presses in China is projected to exhibit the highest growth rate with a CAGR of 6.2% through 2035, driven by the country's position as the world's largest automotive manufacturing hub and increasing demand for advanced tire production equipment. China's massive commercial vehicle production and expanding tire manufacturing capacity are creating unprecedented demand for sophisticated hydraulic curing systems. Major equipment manufacturers are establishing comprehensive manufacturing and service networks to support the growing requirements of tire producers and automotive manufacturers across key industrial regions.

The country's Belt and Road Initiative and domestic infrastructure development projects are significantly boosting commercial vehicle demand, subsequently driving tire manufacturing requirements. China's tire production industry, which accounts for approximately 45% of global tire output, is undergoing rapid technological transformation to meet both domestic and international quality standards. Leading Chinese tire manufacturers are investing heavily in automated production lines that incorporate state-of-the-art hydraulic curing systems to maintain competitive advantages in global markets.

Government initiatives supporting automotive manufacturing modernization and technology advancement are facilitating adoption of advanced hydraulic curing equipment that enhances production efficiency and quality standards throughout the industry. Industrial development programs are promoting the integration of cutting-edge manufacturing technologies, including automated hydraulic curing systems that meet international quality standards while supporting domestic production capabilities. The Made in China 2025 strategy specifically targets advanced manufacturing equipment, creating favorable policies for hydraulic curing press adoption across tire manufacturing facilities.

Revenue from TBR hydraulic curing presses in India is expanding at a CAGR of 5.8%, supported by rapid automotive industry growth and increasing investment in modern tire manufacturing facilities. The country's expanding commercial vehicle production and rising demand for quality tires are driving adoption of advanced hydraulic curing technologies. Automotive manufacturers and tire producers are gradually implementing state-of-the-art curing equipment to meet growing domestic demand and export requirements.

India's commercial vehicle market is experiencing robust growth driven by infrastructure development projects, e-commerce expansion, and government initiatives such as the National Infrastructure Pipeline and Make in India program. The country's tire manufacturing sector is witnessing significant capacity expansion, with major domestic and international players establishing new production facilities equipped with advanced hydraulic curing systems. The growing emphasis on tire quality and safety standards, particularly for commercial vehicles operating in challenging road conditions, is compelling manufacturers to invest in precision curing equipment.

Industrial modernization programs and foreign investment in automotive manufacturing are creating opportunities for equipment suppliers that can support diverse production requirements and technical specifications. Professional training initiatives and technology transfer programs are building technical expertise among manufacturing personnel, enabling effective utilization of hydraulic curing technology that meets international standards and quality requirements. The government's Production Linked Incentive (PLI) scheme for automotive components is further accelerating technology adoption in tire manufacturing facilities.

Demand for TBR hydraulic curing presses in Germany is projected to grow at a CAGR of 5.3%, supported by the country's emphasis on precision manufacturing and technological innovation in automotive production. German automotive manufacturers are implementing advanced hydraulic curing systems that meet stringent quality requirements and performance specifications. The market is characterized by focus on technological excellence, operational efficiency, and compliance with comprehensive manufacturing standards.

Germany's position as Europe's automotive manufacturing powerhouse, home to global leaders like Mercedes-Benz, BMW, and Volkswagen, creates substantial demand for high-quality commercial vehicle tires and consequently advanced curing equipment. The country's Industry 4.0 initiative is driving widespread adoption of smart manufacturing technologies, including IoT-enabled hydraulic curing systems that offer real-time monitoring and predictive maintenance capabilities. German tire manufacturers are increasingly focusing on manufacturing processes, leading to demand for energy-efficient hydraulic curing systems that reduce environmental impact while maintaining superior product quality.

Automotive industry investments are prioritizing cutting-edge hydraulic technology that demonstrates superior precision and reliability while meeting German engineering and quality standards. Professional certification programs ensure comprehensive technical expertise among equipment operators, enabling specialized tire manufacturing capabilities that support diverse automotive applications and international export requirements. The country's strong focus on research and development is fostering innovation in hydraulic curing technologies, with universities and industry collaborating on next-generation systems.

Revenue from TBR hydraulic curing presses in Brazil is growing at a CAGR of 4.8%, driven by expanding automotive manufacturing and growing recognition of advanced curing equipment advantages. The country's developing tire manufacturing sector is gradually integrating professional-grade hydraulic curing equipment to enhance production capacity and product quality. Automotive manufacturers and tire producers are investing in hydraulic curing technology to address growing domestic market demand and international competitiveness requirements.

Brazil's strategic position as Latin America's largest automotive market and manufacturing hub is driving significant investments in tire production capabilities. The country's commercial vehicle sector is experiencing growth due to agricultural expansion, mining activities, and infrastructure development projects, creating demand for high-quality TBR tires. Major international tire manufacturers have established production facilities in Brazil to serve both domestic and export markets, necessitating investment in advanced hydraulic curing systems to meet global quality standards.

Manufacturing modernization initiatives are facilitating adoption of advanced hydraulic technologies that support comprehensive tire production capabilities across industrial regions. Professional development programs are enhancing technical capabilities among manufacturing personnel, enabling effective hydraulic curing system operation that meets evolving industry standards and production requirements. The government's automotive sector development policies are encouraging technology transfer and local manufacturing capabilities, creating favorable conditions for hydraulic curing press market growth.

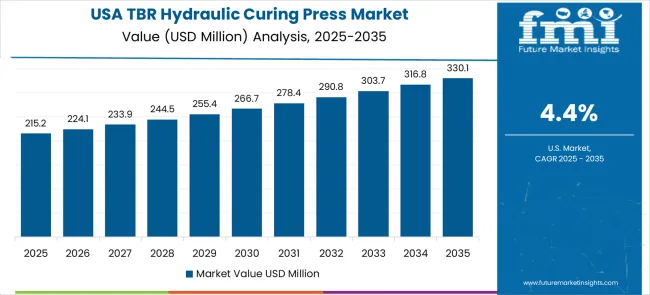

Demand for TBR hydraulic curing presses in the USA is expanding at a CAGR of 4.4%, driven by established automotive manufacturing industries and growing emphasis on production efficiency enhancement. Large tire manufacturers and automotive suppliers are implementing comprehensive hydraulic curing capabilities to serve diverse commercial vehicle requirements. The market benefits from established equipment distribution networks and professional training programs that support various automotive manufacturing applications.

The United States' mature commercial vehicle market is characterized by stringent safety regulations and performance standards, driving demand for high-quality TBR tires produced using advanced curing technologies. Major tire manufacturers in the USA are investing in next-generation hydraulic curing systems that incorporate predictive maintenance, energy efficiency, and quality monitoring capabilities. The country's focus on reshoring manufacturing capabilities and reducing supply chain dependencies is encouraging domestic tire production, creating additional demand for sophisticated curing equipment.

Automotive manufacturing leadership is enabling standardized equipment utilization across multiple production facilities, providing consistent quality standards and comprehensive operational coverage throughout regional markets. Professional development and certification programs are building specialized technical expertise among equipment operators, enabling effective hydraulic curing utilization that supports evolving automotive industry requirements. The integration of Industry 4.0 technologies and smart manufacturing practices is driving adoption of advanced hydraulic curing systems with enhanced automation and monitoring capabilities.

Demand for TBR hydraulic curing presses in the UK is projected to grow at a CAGR of 3.9%, supported by established automotive sectors and growing emphasis on manufacturing precision capabilities. British automotive manufacturers and tire producers are implementing hydraulic curing equipment that meets industry quality standards and operational requirements. The market benefits from established manufacturing infrastructure and comprehensive training programs for technical professionals.

The United Kingdom's automotive industry, despite Brexit-related challenges, continues to maintain high manufacturing standards and technological innovation in tire production. British tire manufacturers are focusing on premium quality products for both domestic and European markets, necessitating investment in advanced hydraulic curing systems that can deliver consistent performance and quality. The country's commitment to net-zero emissions is driving demand for energy-efficient manufacturing equipment, including hydraulic curing systems with reduced environmental impact.

Automotive industry investments are prioritizing advanced hydraulic equipment that supports diverse manufacturing applications while maintaining established quality and operational standards. Professional development programs are building technical expertise among manufacturing personnel, enabling specialized hydraulic curing operation capabilities that meet evolving industry requirements and quality standards. The UK's strong engineering heritage and focus on advanced manufacturing technologies are fostering innovation in hydraulic curing systems, with emphasis on automation and digital integration capabilities.

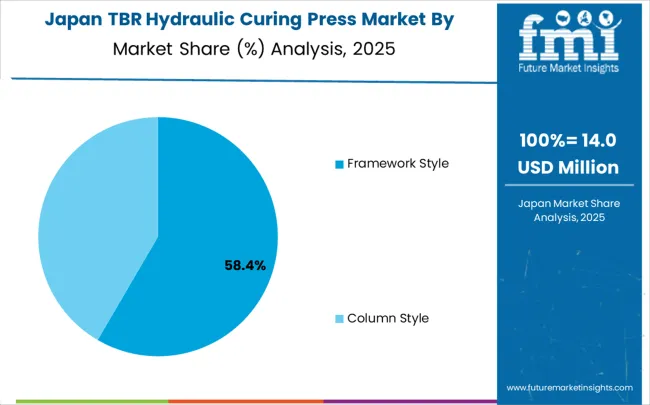

Revenue from TBR hydraulic curing presses in Japan is growing at a CAGR of 3.5%, driven by the country's focus on manufacturing technology innovation and quality enhancement applications. Japanese automotive manufacturers are implementing advanced hydraulic curing systems that demonstrate superior precision and operational efficiency. The market is characterized by emphasis on technological excellence, quality assurance, and integration with established automotive manufacturing workflows.

Japan's renowned automotive industry, home to global leaders like Toyota, Honda, and Nissan, maintains exceptionally high standards for component quality, including tires for commercial vehicles. The country's lean manufacturing philosophy and continuous improvement culture are driving adoption of hydraulic curing systems that maximize efficiency while minimizing waste and defects. Japanese manufacturers are pioneering the integration of artificial intelligence and machine learning technologies in hydraulic curing processes to achieve unprecedented levels of precision and consistency.

Technology industry investments are prioritizing innovative curing solutions that combine advanced hydraulic technology with precision engineering while maintaining Japanese quality and reliability standards. Professional development programs are ensuring comprehensive technical expertise among equipment operators, enabling specialized tire manufacturing capabilities that support diverse automotive applications and export requirements. The country's Society 5.0 initiative is promoting digital transformation in manufacturing, leading to increased adoption of smart hydraulic curing systems with advanced monitoring and control capabilities.

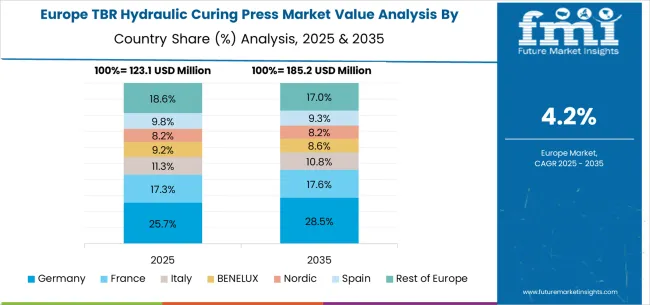

The European TBR (Truck and Bus Radial) hydraulic curing press market is projected to witness steady growth, driven by stringent environmental regulations, increasing adoption of advanced tire manufacturing technologies, and rising demand for durable commercial tires. In 2025, the market is estimated at approximately USD 1.27 billion, with Germany dominating the region with a 41.2% share. Germany’s leadership is attributed to its robust automotive industry, stringent environmental standards, and emphasis on technological innovation in tire production. The United Kingdom follows with a 19.4% share, supported by fleet optimization initiatives and stringent requirements in transportation, which drive the need for precision tire manufacturing. France holds 15.1% of the market, benefiting from investments in logistics infrastructure and environmental compliance that require advanced curing press technologies. Italy and Spain together account for 16.7% of regional demand, fueled by the expansion of commercial transportation and growing adoption of tire management practices. The remaining 7.6% is contributed by Nordic countries, the BENELUX region, and Eastern European nations, where specialized fleet applications and increasing commercial transport operations support market growth.

The TBR Hydraulic Curing Press market is defined by competition among specialized equipment manufacturers, automotive suppliers, and tire production solution providers. Companies are investing in advanced hydraulic system development, equipment precision optimization, automation integration, and comprehensive service capabilities to deliver reliable, efficient, and cost-effective tire curing solutions. Strategic partnerships, technological innovation, and market expansion are central to strengthening product portfolios and market presence.

VMI Group offers comprehensive hydraulic curing press solutions with established manufacturing expertise and industrial-grade equipment capabilities. Larsen & Toubro provides specialized heavy engineering equipment with a focus on precision manufacturing and operational reliability. Harburger Eisenwerke AG delivers advanced hydraulic systems with emphasis on German engineering excellence and technical innovation. Hebert specializes in tire manufacturing equipment with advanced hydraulic technology integration and automation capabilities.

DOUBLE STAR TIRE offers integrated tire manufacturing solutions with comprehensive hydraulic curing capabilities. Guilin Rubber Machinery provides specialized rubber processing equipment with a focus on performance optimization and reliability. SAFERUN GROUP, Mesnac, Greatoo Intelligent, ARP Technologies, and Qingdao FANGYUANDA Rubber Machinery offer specialized manufacturing expertise, equipment innovation, and comprehensive product development across global and regional market segments.

| Item | Value |

|---|---|

| Quantitative Units | USD 479.6 million |

| Machine Type | Framework Style, Column Style |

| Application | Commercial Vehicle Tires, Engineering Vehicle Tires, Others |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Country Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | VMI Group, Larsen & Toubro, Harburger Eisenwerke AG, Hebert, DOUBLE STAR TIRE, Guilin Rubber Machinery, SAFERUN GROUP, Mesnac, Greatoo Intelligent, ARP Technologies, Qingdao FANGYUANDA Rubber Machinery |

| Additional Attributes | Dollar sales by machine type and application segment, regional demand trends across major markets, competitive landscape with established equipment manufacturers and emerging technology providers, customer preferences for different curing press configurations and automation levels, integration with tire manufacturing systems and quality control protocols, innovations in hydraulic control efficiency and precision technologies, and adoption of Industry 4.0 features with enhanced monitoring capabilities for improved production workflows. |

The global TBR hydraulic curing press market is estimated to be valued at USD 479.6 million in 2025.

The market size for the TBR hydraulic curing press market is projected to reach USD 752.0 million by 2035.

The TBR hydraulic curing press market is expected to grow at a 4.6% CAGR between 2025 and 2035.

The key product types in TBR hydraulic curing press market are framework style and column style.

In terms of application, commercial vehicle tires segment to command 58.0% share in the TBR hydraulic curing press market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Hydraulic Anchor Drilling Vehicle for Mining Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Gear Pumps Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Recloser Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Lifting Mobile Light Tower Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Fracturing Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Power Unit Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Lifting Light Tower Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Squeeze Chute Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Cylinder Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Filters Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Dosing Pump Market Size and Share Forecast Outlook 2025 to 2035

Hydraulic Fluids Market Analysis - Size, Share, and Forecast 2025 to 2035

Hydraulic Fluids & Process Oil Market Size 2025 to 2035

Hydraulic Pumps Market Growth & Outlook 2025 to 2035

Hydraulic Intensifiers Market Growth – Trends & Forecast 2025 to 2035

Hydraulic Spreader Market

Hydraulic Demolition Machine And Breaker Market

Hydraulic Cab Tilt System Market

Electrohydraulic Pump Market Insights by Type, End Use, Application, and Region through 2035

Railway Hydraulic Damper Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA