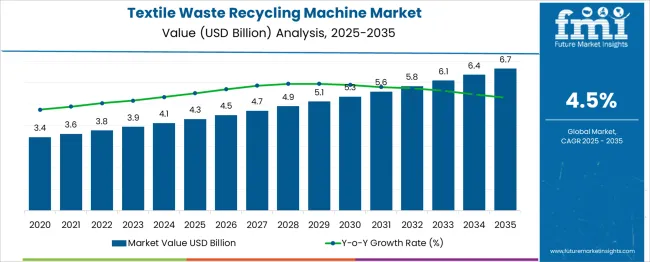

The Textile Waste Recycling Machine Market is estimated to be valued at USD 4.3 billion in 2025 and is projected to reach USD 6.7 billion by 2035, registering a compound annual growth rate (CAGR) of 4.5% over the forecast period. The textile waste recycling machine market is projected to generate an incremental gain of USD 1 billion over the first five years, which represents 48.2% of the total incremental growth over the 10-year forecast period. This early-phase growth is driven by increasing demand for sustainable and efficient textile waste recycling solutions due to rising environmental concerns and regulatory pressures.

The market will benefit from growing textile waste volumes and the adoption of recycling technologies in the garment, automotive, and packaging industries. The second half (2030–2035) will contribute USD 1.1 billion, representing 51.8% of the total growth, reflecting continued adoption as recycling technologies become more efficient and widely implemented across the textile industry. Annual increments average USD 0.2 billion per year in the first phase, while the later years will see stronger growth due to increasing investments in green technologies, automation, and the circular economy. Manufacturers focusing on high-efficiency systems, cost-effectiveness, and scalability will capture the largest share of this USD 2.1 billion growth opportunity.

| Metric | Value |

|---|---|

| Textile Waste Recycling Machine Market Estimated Value in (2025 E) | USD 4.3 billion |

| Textile Waste Recycling Machine Market Forecast Value in (2035 F) | USD 6.7 billion |

| Forecast CAGR (2025 to 2035) | 4.5% |

Governments and regulatory bodies worldwide have been enforcing stricter mandates to reduce landfill waste and promote recycling, which has accelerated investments in machinery capable of processing post-consumer and post-industrial textile waste.

Technological advancements in recycling methods, including mechanical and chemical processes, have improved material recovery rates and product quality, making recycled fibers more competitive with virgin materials. The rising cost of raw materials and increasing consumer demand for eco-friendly textiles have further driven the need for automated and efficient recycling solutions.

Furthermore, integration of Industry 4.0 technologies, such as IoT-enabled monitoring and AI-based process optimization, is enhancing operational efficiency and reducing downtime. These trends are expected to continue shaping the market’s future, with growing opportunities in emerging economies that seek to expand textile recycling capacities and adopt sustainable production models.

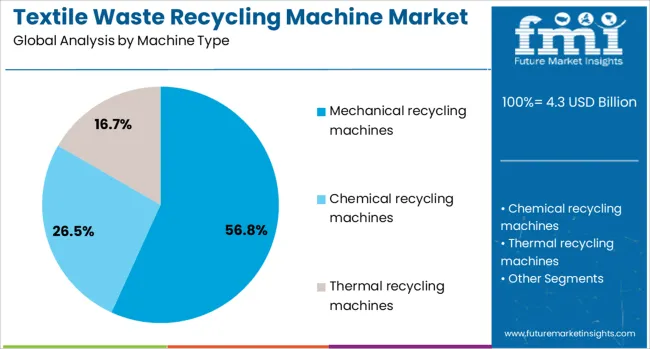

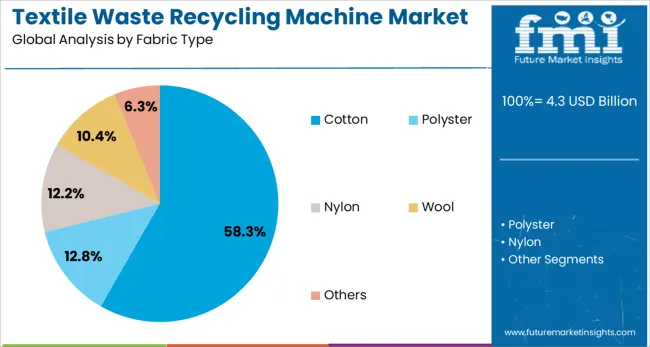

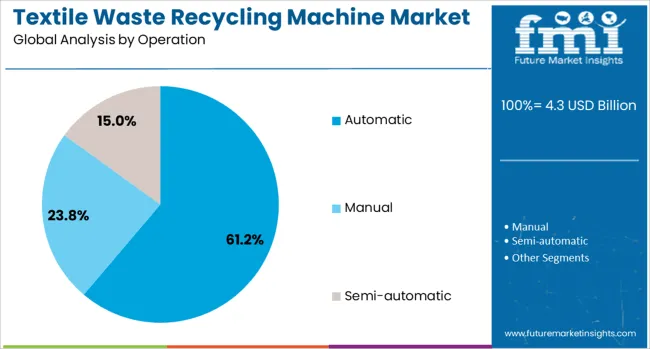

The textile waste recycling machine market is segmented by machine type, fabric type, operation, capacity, application, and geographic region. By machine type, the textile waste recycling machine market is divided into Mechanical recycling machines, Chemical recycling machines, and thermal recycling machines. In terms of fabric type, the textile waste recycling machine market is classified into Cotton, Polyester, Nylon, Wool, and others. Based on the operation of the textile waste recycling machine, the market is segmented into Automatic, Manual, and Semi-automatic. By capacity, the textile waste recycling machine market is segmented into Up to 2,000 kg/h, Up to 1,000 kg/h, Up to 3000 kg/hAbove 3000 kg/h. By application of the textile waste recycling machine market is segmented into Fiber-to-fiber recycling, Non-fiber applications, Apparel manufacturing, Home textilesTechnical textiles. Regionally, the textile waste recycling machine industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

Mechanical recycling machines are expected to account for 56.8% of the textile waste recycling machine market revenue share by 2025, reflecting their dominant position in the industry. This leadership is attributed to the relative cost-effectiveness and operational simplicity of mechanical processes, which allow for large-scale shredding, sorting, and fiber regeneration.

The segment has been favored due to its ability to process a wide variety of fabric wastes, particularly cotton blends and natural fibers, with minimal chemical use, reducing environmental impact. Improvements in machine design have enabled better fiber length retention and reduced contamination, enhancing the quality of recycled yarns.

Additionally, the compatibility of mechanical systems with automated workflows and integration into existing textile manufacturing lines has supported their widespread adoption. These factors combined have contributed to the steady growth and sustained demand for mechanical recycling machines in textile waste management.

The cotton fabric segment is projected to account for 58.3% of the textile waste recycling machine market revenue share in 2025, highlighting its critical role in recycling operations. Cotton waste constitutes a significant portion of global textile discards due to its widespread use and relatively high biodegradability.

The recyclability of cotton fibers through mechanical means has been enhanced by advancements in fiber cleaning and sorting technologies that preserve fiber integrity. This has allowed recycled cotton to be reintroduced into the manufacturing cycle as sustainable raw material alternatives.

Additionally, the environmental benefits of recycling cotton, including reduced water and energy consumption compared to virgin cotton production, have reinforced its preference among manufacturers and sustainability advocates. The cotton segment’s prominence is further supported by the rising demand for organic and recycled cotton textiles in the fashion and home furnishing industries.

Automatic operation machines are expected to capture 61.2% of the revenue share in the textile waste recycling machine market by 2025, driven by the need for higher efficiency, consistency, and reduced labor costs. Automation has enabled continuous processing and real-time monitoring of recycling operations, minimizing errors and optimizing throughput.

The integration of sensors and control systems allows for precise adjustment of machine parameters, which improves fiber quality and reduces material wastage. Automatic machines also facilitate easier maintenance and quicker changeovers between fabric types, supporting flexible production schedules.

These capabilities have made automatic recycling machines preferable for large-scale industrial applications where operational efficiency and product consistency are paramount. Increasing adoption of automation aligns with the broader industry trend towards smart manufacturing and digital transformation.

The textile waste recycling machine market is driven by increasing demand for efficient waste management solutions and recycling technologies in the textile industry. Opportunities in the circular economy and sustainability initiatives are shaping market growth, while trends toward automation and smart recycling are gaining momentum. However, high initial investment and operational costs remain significant barriers. By 2025, addressing these challenges through cost-effective, automated, and scalable solutions will be crucial for ensuring continued market expansion and broad adoption.

The textile waste recycling machine market is growing due to the increasing demand for efficient waste management solutions in the textile industry. With the rising volume of textile waste generated globally, the need for machines that can efficiently recycle fabrics and materials is growing. These machines help reduce landfill waste and recover valuable fibers, offering significant environmental and economic benefits. By 2025, the market is expected to continue benefiting from this demand for better waste management in textile production.

Opportunities in the textile waste recycling machine market are expanding with the rise of the circular economy and recycling initiatives. Companies in the textile industry are adopting more sustainable practices, including the recycling of waste materials into new products. These initiatives are gaining traction as brands seek to minimize environmental impact and meet consumer demand for eco-friendly products. By 2025, increased focus on sustainability and the adoption of circular economy practices will drive the demand for textile waste recycling machines.

Emerging trends in the textile waste recycling machine market include the growing adoption of automation and smart recycling technologies. Automated machines that enhance efficiency and reduce labor costs are becoming more common in textile recycling operations. Smart recycling machines equipped with sensors and AI for sorting, processing, and tracking waste materials are gaining traction. By 2025, these technologies are expected to dominate the market, improving processing speed, reducing errors, and enhancing overall operational efficiency.

Despite growth, challenges related to high initial investment and operational costs persist in the textile waste recycling machine market. The cost of purchasing and maintaining advanced recycling machinery can be prohibitive, especially for small and medium-sized enterprises. Additionally, specialized machinery and skilled labor are required to operate and maintain these systems efficiently, which adds to overall expenses. By 2025, overcoming these challenges through cost-effective solutions and accessible financing options will be crucial to broadening market adoption.

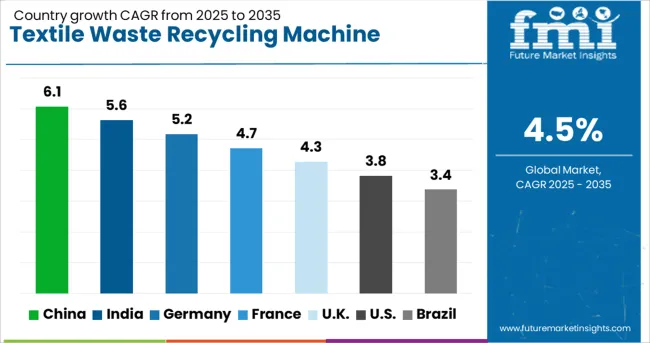

| Country | CAGR |

|---|---|

| China | 6.1% |

| India | 5.6% |

| Germany | 5.2% |

| France | 4.7% |

| UK | 4.3% |

| USA | 3.8% |

| Brazil | 3.4% |

The global textile waste recycling machine market is projected to grow at a 4.5% CAGR from 2025 to 2035. China leads with a growth rate of 6.1%, followed by India at 5.6%, and France at 4.7%. The United Kingdom records a growth rate of 4.3%, while the United States shows the slowest growth at 3.8%. These differences in growth rates are influenced by factors such as increasing demand for sustainable textile production, government regulations on waste management, and the rising adoption of recycling technologies in the textile industry. Emerging markets like China and India are witnessing higher growth due to rapid industrialization, urbanization, and increasing awareness of environmental concerns, while more mature markets like the USA and the UK experience steady growth driven by existing waste management policies and the need for sustainable textile manufacturing practices. This report includes insights on 40+ countries; the top markets are shown here for reference.

The textile waste recycling machine market in China is growing at a strong pace, with a projected CAGR of 6.1%. China’s rapidly expanding textile industry, combined with increasing concerns about waste management and sustainability, is driving significant demand for textile waste recycling machines. The country’s focus on circular economy principles, along with government policies aimed at reducing textile waste, further accelerates market growth. Additionally, China’s rising textile production, along with the growing adoption of eco-friendly manufacturing practices in the fashion and apparel sectors, contributes to the increasing demand for efficient recycling technologies.

The textile waste recycling machine market in India is projected to grow at a CAGR of 5.6%. India’s growing textile manufacturing industry, coupled with increasing environmental awareness and government support for sustainable practices, is driving the demand for textile waste recycling machines. As the country continues to focus on reducing textile waste and improving recycling efficiency, the adoption of advanced recycling technologies is increasing. Additionally, the rising focus on reducing textile pollution, particularly in the apparel industry, along with government initiatives to promote recycling and waste management, further fuels the market growth.

The textile waste recycling machine market in France is projected to grow at a CAGR of 4.7%. France’s well-established textile industry, combined with the country’s strong emphasis on sustainability and waste reduction, is supporting steady demand for textile waste recycling machines. The increasing need for eco-friendly recycling solutions in the apparel and textile manufacturing sectors is contributing to market growth. Furthermore, France’s regulatory frameworks and government policies aimed at reducing textile waste and promoting the circular economy are driving the adoption of advanced recycling technologies.

The textile waste recycling machine market in the United Kingdom is projected to grow at a CAGR of 4.3%. The UK’s growing focus on sustainability and circular economy principles, combined with its expanding textile industry, continues to drive demand for textile waste recycling machines. The country’s emphasis on reducing textile waste, improving recycling rates, and supporting eco-friendly manufacturing practices ensures steady market growth. Additionally, the growing interest in sustainable fashion and eco-conscious consumer behavior contributes to the adoption of textile waste recycling technologies.

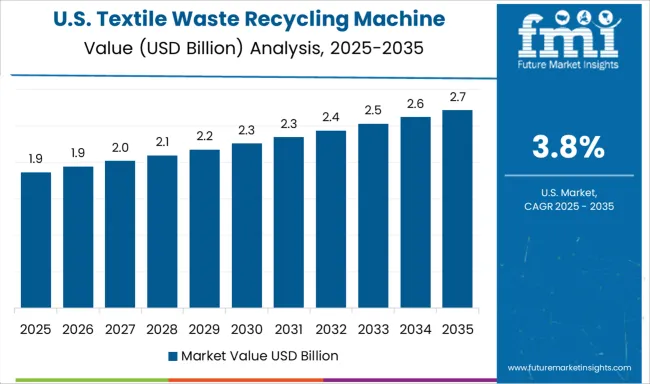

The textile waste recycling machine market in the United States is expected to grow at a CAGR of 3.8%. Despite being a mature market, the USA continues to see steady demand for textile waste recycling machines driven by the need to improve recycling efficiency and reduce textile waste. The growing focus on sustainability and waste management in the apparel industry, along with increasing regulatory pressure to adopt recycling technologies, supports the continued growth of the market. However, the growth rate in the USA is slower compared to emerging economies due to market maturity and the saturation of existing recycling technologies.

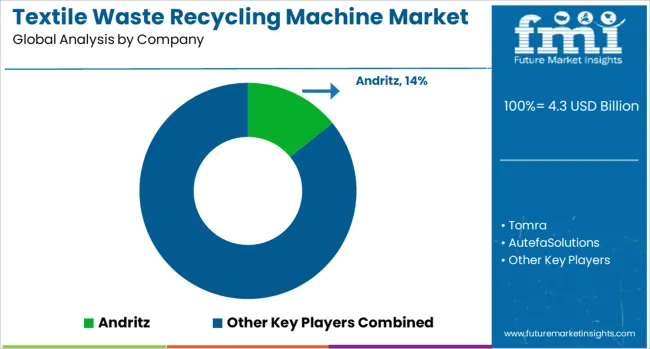

The textile waste recycling machine market is increasingly defined by players that integrate technological innovation with end-to-end process solutions, rather than just machine manufacturing. Andritz maintains a leadership position by offering modular recycling lines that combine fiber sorting, shredding, and refining with automation analytics, enabling clients to achieve high material recovery rates while minimizing operational costs. Tomra and Autefa Solutions leverage sensor-based sorting and smart separation systems, positioning themselves as solution partners for large-scale textile recyclers who demand precision and scalability. Rieter differentiates through the integration of recycling machinery with fiber processing systems, emphasizing seamless adoption in spinning and nonwoven production units.

Emerging players, including Dell’Orco and Villani, Larochr Group, and Ecotex Group, focus on localized and specialized recycling operations, offering compact and energy-efficient units capable of processing mixed or hard-to-recycle fabrics. Collaborative strategies, such as co-development agreements with textile manufacturers and participation in circular economy consortia, allow these companies to embed their machinery into broader sustainability workflows, creating high switching costs for clients. Regulatory pressures on waste management accelerate market growth, the fashion industry's initiatives for traceability, and the rising demand for recycled fibers in premium textiles. Future competitive dynamics will hinge on innovation in automated sorting algorithms, material recovery optimization, and integration with digital monitoring systems to maximize both efficiency and environmental impact.

| Item | Value |

|---|---|

| Quantitative Units | USD 4.3 Billion |

| Machine Type | Mechanical recycling machines, Chemical recycling machines, and Thermal recycling machines |

| Fabric Type | Cotton, Polyster, Nylon, Wool, and Others |

| Operation | Automatic, Manual, and Semi-automatic |

| Capacity | Up to 2,000 kg/h, Up to 1,000 kg/h, Up to 3000 kg/h, and Above 3000 kg/h |

| Application | Fiber-to-fiber recycling, Non-fiber applications, Apparel manufacturing, Home textiles, and Technical textiles |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Andritz, Tomra, AutefaSolutions, Rieter, Dell'orcoandvillani, LarochrGroup, ShaanxiHuanxinTextileMachine, EcotexGroup, SavioMacchineTessili, mrindustries, Loptex, multipromachine, HSNMachinery, SNSurgicare, and WatercareSoftenersLtd. |

| Additional Attributes | Dollar sales by machine type and application, demand dynamics across textile, automotive, and packaging sectors, regional trends in textile waste recycling adoption, innovation in fiber recovery and eco-friendly processing technologies, impact of regulatory standards on sustainability and waste reduction, and emerging use cases in circular economy and sustainable fashion. |

The global textile waste recycling machine market is estimated to be valued at USD 4.3 billion in 2025.

The market size for the textile waste recycling machine market is projected to reach USD 6.7 billion by 2035.

The textile waste recycling machine market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in textile waste recycling machine market are mechanical recycling machines, chemical recycling machines and thermal recycling machines.

In terms of fabric type, cotton segment to command 58.3% share in the textile waste recycling machine market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Waste Recycling Services Market by Application, Product Type, and Region - Growth, Trends, and Forecast 2025 to 2035

Textile Machine Lubricants Market Size and Share Forecast Outlook 2025 to 2035

Textile Recycling Market Analysis by Material, Source, Process, and Region: Forecast for 2025 and 2035

Waste Wood Recycling Market Size and Share Forecast Outlook 2025 to 2035

Recycling Equipment And Machinery Market Size and Share Forecast Outlook 2025 to 2035

Packaging Waste Recycling Market Growth and Insights 2025 to 2035

Food Waste Composting Machine Market Size and Share Forecast Outlook 2025 to 2035

Waste Heat Power Generation Boiler Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Kraft Paper Market Forecast and Outlook 2025 to 2035

Machine Condition Monitoring Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Asia Pacific Forecast Outlook 2025 to 2035

Machine Vision Camera Market Size and Share Forecast Outlook 2025 to 2035

Waste-derived Pyrolysis Oil Market Size and Share Forecast Outlook 2025 to 2035

Wastewater Heavy Metal Treatment Agent Market Size and Share Forecast Outlook 2025 to 2035

Machine Tool Oils Market Size and Share Forecast Outlook 2025 to 2035

Waste Management Carbon Credit Market Size and Share Forecast Outlook 2025 to 2035

Textile Coatings Market Size and Share Forecast Outlook 2025 to 2035

Machine Vision System And Services Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Western Europe Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA