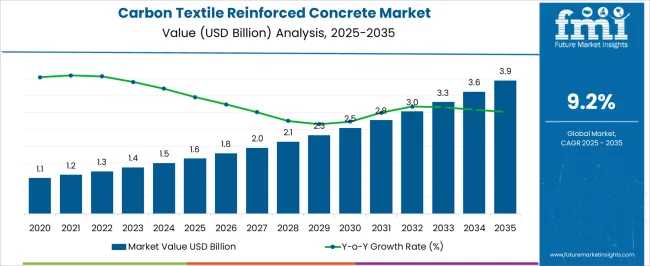

The carbon textile reinforced concrete market is projected to grow from USD 1.6 billion in 2025 to USD 3.9 billion by 2035, at a CAGR of 9.2 percent. In 2025, the market size stands at USD 1.6 billion and rises gradually to USD 1.8 billion in 2026 as adoption of advanced, sustainable construction materials gathers pace. By 2027, the market reaches USD 2.0 billion, expanding further to USD 2.3 billion in 2028 and USD 2.5 billion in 2029 as infrastructure projects increasingly integrate this material. Growth accelerates in the early 2030s, with the market valued at USD 2.8 billion in 2030 and USD 3.0 billion in 2032. Continued emphasis on durability, corrosion resistance, and sustainability drives acceptance, and by 2035 the market achieves USD 3.9 billion, reflecting its position as a key material in the global construction industry.

| Metric | Value |

|---|---|

| Carbon Textile Reinforced Concrete Market Estimated Value in (2025 E) | USD 1.6 billion |

| Carbon Textile Reinforced Concrete Market Forecast Value in (2035 F) | USD 3.9 billion |

| Forecast CAGR (2025 to 2035) | 9.2% |

The carbon textile reinforced concrete market is gaining strong traction due to the growing need for advanced, high-performance construction materials that offer durability without added structural weight. As traditional steel reinforcements face challenges such as corrosion and heavy maintenance costs, carbon-based textiles are being adopted for their superior tensile strength, chemical resistance, and lightweight profile.

Increased focus on infrastructure longevity, seismic resilience, and sustainable urban development has driven research and deployment of non-metallic reinforcement alternatives across high-rise buildings, bridges, and precast components. Government support for green construction practices and rising investments in rehabilitation of aging infrastructure have further strengthened the market’s momentum.

Technological advancements in textile weaving patterns, pre-impregnation methods, and composite layering are also enhancing application flexibility and reducing installation time In the coming years, the integration of smart sensing capabilities and carbon capture compatibility into carbon textile composites is expected to create new functional value, reinforcing the market’s potential across diverse civil engineering domains.

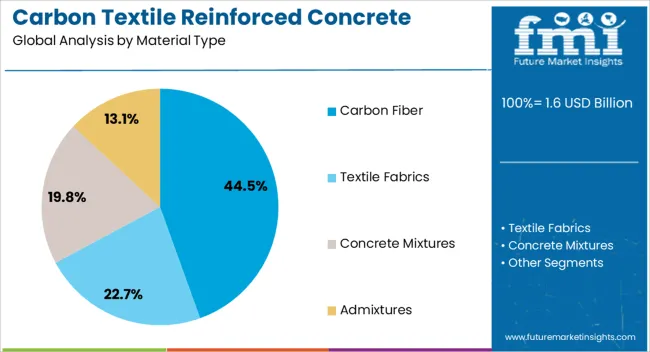

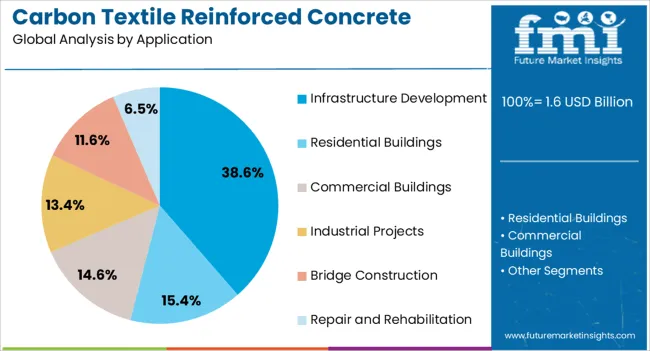

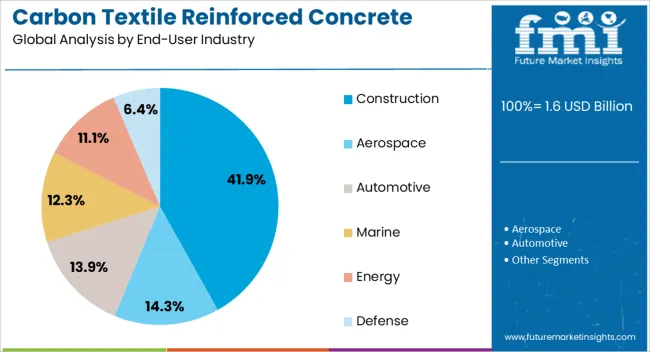

The carbon textile reinforced concrete market is segmented by material type, application, end-user industry, fiber orientation, manufacturing technique, and geographic regions. By material type, carbon textile reinforced concrete market is divided into Carbon Fiber, Textile Fabrics, Concrete Mixtures, and Admixtures. In terms of application, carbon textile reinforced concrete market is classified into Infrastructure Development, Residential Buildings, Commercial Buildings, Industrial Projects, Bridge Construction, and Repair and Rehabilitation. Based on end-user industry, carbon textile reinforced concrete market is segmented into Construction, Aerospace, Automotive, Marine, Energy, and Defense. By fiber orientation, carbon textile reinforced concrete market is segmented into Unidirectional, Bidirectional, and Multidirectional. By manufacturing technique, carbon textile reinforced concrete market is segmented into Prepreg Lay-Up, Hand Lay-Up, Filament Winding, Resin Transfer Molding (RTM), and Vacuum Infusion. Regionally, the carbon textile reinforced concrete industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The carbon fiber segment is projected to hold 44.5% of the overall revenue share in the carbon textile reinforced concrete market in 2025, making it the most dominant material type. The prominence of carbon fiber can be attributed to its exceptional mechanical properties, including high tensile strength and superior fatigue resistance, which make it ideal for long-lasting structural applications. Its resistance to corrosion and environmental degradation has positioned it as a preferred material in construction settings where conventional steel reinforcements underperform over time.

The lightweight nature of carbon fiber has enabled its use in load-sensitive structures without compromising on strength or safety. Additionally, ongoing innovations in fiber processing and cost optimization have made carbon fibers increasingly accessible for commercial-scale construction projects.

Integration into prefabricated panels and compatibility with thin concrete layers have also enhanced its use in retrofitting and seismic strengthening These attributes, combined with its long lifecycle and low maintenance requirements, continue to drive the segment’s growth in global infrastructure projects.

The infrastructure development application segment is expected to account for 38.6% of the revenue share in the carbon textile reinforced concrete market in 2025, highlighting its critical role in driving demand. The segment’s leading position is being supported by a global emphasis on building resilient and sustainable infrastructure that can withstand climatic and environmental challenges.

Carbon textile reinforced concrete is increasingly being used in bridges, tunnels, highway structures, and public transit systems due to its enhanced strength-to-weight ratio and resistance to corrosion, which reduces maintenance frequency and extends service life. The ability to cast thin concrete elements using textile reinforcements allows for design flexibility and faster installation, both of which are essential in time-sensitive infrastructure projects.

Additionally, the reduced material consumption associated with this technology aligns with sustainability mandates and resource efficiency goals As public and private sector investments in smart infrastructure and urban connectivity rise, the demand for carbon textile solutions in critical infrastructure is expected to grow steadily.

The construction end-user industry segment is projected to represent 41.9% of the carbon textile reinforced concrete market revenue share in 2025, making it the most significant contributor by end use. The segment's dominance is being driven by widespread deployment of carbon textile materials in commercial buildings, residential complexes, and industrial facilities. Their use in precast concrete components, facades, and reinforcement of slabs and walls has been promoted by the need for high strength-to-weight ratios, aesthetic flexibility, and durability in modern construction.

The shift toward lightweight construction solutions and the growing preference for long-lasting, low-maintenance materials have accelerated the use of carbon textiles in urban real estate developments. Additionally, compliance with green building certifications and energy-efficient construction practices has further encouraged adoption.

The ability to integrate carbon textiles into digitally fabricated molds and 3D construction workflows has positioned this technology as a critical enabler of the next-generation construction ecosystem As urbanization continues to rise, the construction sector is expected to remain the largest end user of carbon textile reinforced concrete.

The carbon textile reinforced concrete (CTRC) market is seeing significant growth, driven by the increasing demand for durable and high-performance construction materials. CTRC uses carbon fiber textiles as an alternative to traditional steel reinforcement, offering advantages such as higher tensile strength, corrosion resistance, and lighter weight. These features make it suitable for use in harsh environments, such as coastal areas and structures exposed to moisture. The market growth is further supported by ongoing advancements in concrete technology and textile engineering, which are making CTRC solutions more cost-effective and efficient. As the construction industry looks for materials with enhanced durability and longevity, CTRC is positioned to replace conventional reinforced concrete in several applications.

The carbon textile reinforced concrete market is growing due to several key factors. One of the primary drivers is the increasing demand for more durable construction materials. CTRC's resistance to corrosion extends the lifespan of structures, reducing the need for frequent repairs and maintenance. Additionally, the lightweight nature of CTRC makes transportation and handling easier, leading to cost savings during construction. Its versatility also allows for application across a variety of sectors, including infrastructure, residential, and commercial buildings. Moreover, improvements in the performance and affordability of carbon fiber textiles, driven by ongoing research and technological advancements, are further driving the adoption of CTRC in construction projects.

Despite the growth potential of the carbon textile reinforced concrete market, several challenges remain. One of the main barriers is the higher cost of carbon fiber textiles compared to traditional steel reinforcement, which can make CTRC less affordable for certain projects. Additionally, the lack of established industry standards and regulations for CTRC may slow its widespread adoption in mainstream construction practices. The manufacturing processes for CTRC also require specialized equipment and expertise, which can increase production costs and limit scalability. Furthermore, more extensive field studies are required to validate the long-term performance of CTRC in various environmental conditions, creating the need for additional research and testing.

The carbon textile reinforced concrete market presents numerous opportunities for growth and innovation. One opportunity lies in the development of hybrid reinforcement materials that combine carbon fiber with other materials to improve performance and reduce costs. Collaborations between construction companies, material suppliers, and research institutions can help develop standardized guidelines for CTRC applications, which could lead to broader adoption. The growing need for infrastructure renovation and rehabilitation, especially in regions with aging buildings, offers substantial market potential for CTRC. Furthermore, expanding the use of CTRC in new markets and applications could drive significant growth as the material proves its capabilities in various industries.

Advances in digital construction technologies, such as Building Information Modeling (BIM) and 3D printing, are streamlining the design and integration of CTRC into construction projects. The development of smart materials that respond to environmental changes, such as those incorporating sensors, is enhancing the functionality of CTRC in real-time applications. Additionally, the use of recycled carbon fibers in CTRC is gaining interest, offering cost-effective alternatives while maintaining performance standards. The increasing focus on reducing material waste and improving efficiency in construction methods will likely drive the adoption of CTRC in a wide range of structural applications. These trends point to a promising future for CTRC in modern infrastructure.

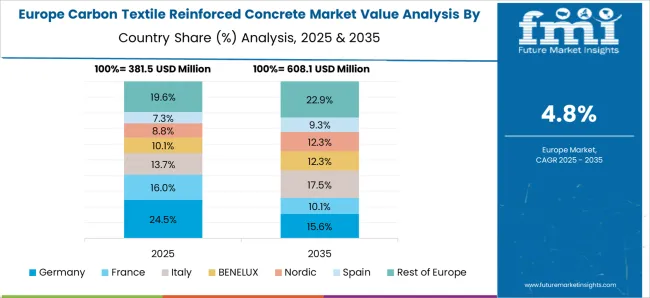

The global carbon textile reinforced concrete market is projected to grow at a CAGR of 9.2% from 2025 to 2035. China leads with a growth rate of 12.4%, followed by India at 11.5%, and Germany at 10.6%. The United Kingdom and the United States show more moderate growth rates of 8.7% and 7.8%, respectively. This growth is driven by the rising demand for sustainable, durable, and lightweight construction materials across various sectors, including residential, commercial, and infrastructure projects. Emerging markets are seeing faster growth due to rapid urbanization and industrialization, while developed markets focus on green construction solutions. The analysis spans over 40+ countries, with the leading markets shown below.

China is projected to lead the global carbon textile reinforced concrete market, growing at a CAGR of 12.4% from 2025 to 2035. The country's rapid urbanization and growing demand for infrastructure development are key factors driving the adoption of innovative construction materials like carbon textile reinforced concrete. As China continues to expand its commercial, industrial, and residential infrastructure, the demand for durable, lightweight, and high-performance concrete solutions is expected to increase. The construction industry’s shift towards sustainability and advanced building materials is further boosting market growth. With government investments in infrastructure projects and initiatives supporting the adoption of eco-friendly materials, China is poised to remain a dominant player in the carbon textile reinforced concrete market.

The carbon textile reinforced concrete market in India is expected to grow at a CAGR of 11.5% from 2025 to 2035. The country’s expanding construction industry, coupled with the rise in infrastructure projects across urban and rural areas, is a key driver of demand for high-performance concrete solutions. India’s increasing focus on building durable and sustainable infrastructure, along with growing awareness of the benefits of carbon textile reinforcement in construction, is propelling the market forward. The government's initiatives to boost the construction and housing sector, coupled with rising demand for green building solutions, will continue to fuel growth in the carbon textile reinforced concrete market.

Demand for carbon textile reinforced concrete in Germany is projected to grow at a steady pace, with a CAGR of 10.6% from 2025 to 2035. The country’s strong presence in the construction sector and the growing demand for high-performance building materials are driving the market. The ongoing development of large infrastructure projects, such as bridges, tunnels, and highways, is expected to increase the use of carbon textile reinforced concrete. As Germany continues to invest in new construction technologies and large-scale projects, the market for these advanced materials is set for steady growth.

The carbon textile reinforced concrete market in the United Kingdom is projected to grow at a CAGR of 8.7% from 2025 to 2035. The UK construction sector’s increasing adoption of advanced materials in infrastructure, housing, and commercial projects is driving market demand. The ongoing upgrades to transportation networks and public buildings are creating a steady demand for carbon textile reinforced concrete. As industries focus on improving the durability and longevity of infrastructure, the market for these advanced materials is expected to expand further, offering opportunities for both domestic and international players.

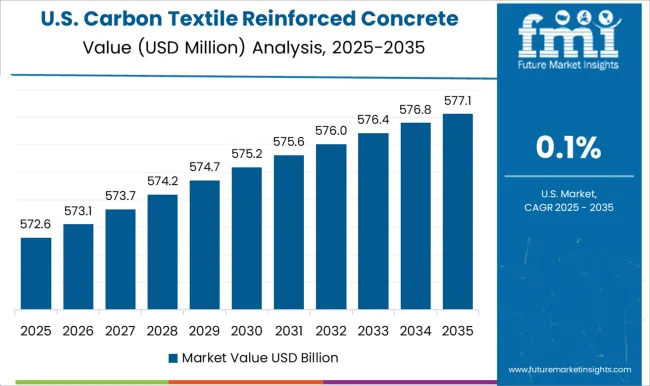

The carbon textile reinforced concrete market in the United States is projected to grow at a CAGR of 7.8% from 2025 to 2035. The country’s focus on enhancing infrastructure in urban, commercial, and industrial sectors is a key driver of market growth. The growing demand for durable and lightweight building materials in large-scale projects, including bridges, tunnels, and highways, is increasing the adoption of carbon textile reinforced concrete. As the USA continues to invest in infrastructure renewal and development, the market for these high-performance materials is expected to grow steadily.

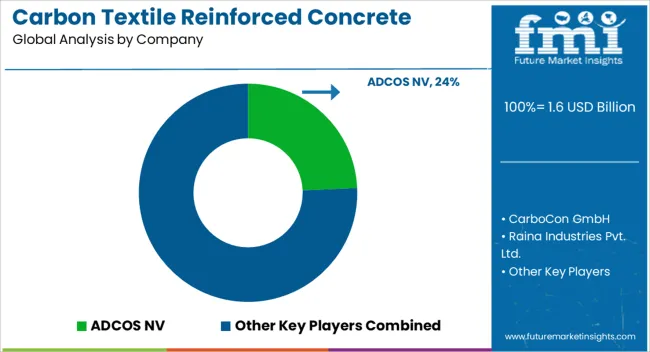

The carbon textile reinforced concrete market is led by key players who offer innovative solutions for sustainable and high-performance building materials. ADCOS NV specializes in integrating textile materials with concrete to improve strength and reduce weight. CarboCon GmbH focuses on carbon textile solutions for infrastructure projects, ensuring durability and corrosion resistance. Raina Industries Pvt. Ltd. tailors cost-effective products to regional construction needs, boosting adoption in India. Solidian GmbH is known for its versatile textile-reinforced concrete, used in applications like facades and structural elements. Tradecc provides lightweight and durable solutions, addressing industry demands for high-performance materials. Hering Architectural Concrete integrates textile-reinforced concrete in prefabricated concrete elements, focusing on energy efficiency.

These companies distinguish themselves by enhancing concrete with carbon textiles, offering stronger, lighter, and more durable alternatives to traditional steel reinforcements. Some, like Raina Industries, emphasize regional customization, while others focus on sustainability and long-term performance, appealing to eco-conscious markets. Partnerships with construction firms and developers help these players extend their reach and offer tailored solutions.

With growing demand in telecom, data centers, and cloud services, the carbon textile reinforced concrete market is seeing increased investment in 5G infrastructure, broadband expansion, and data centers. Regional growth is particularly strong in Asia-Pacific, North America, and Europe, with significant contributions from the construction and infrastructure sectors.

| Item | Value |

|---|---|

| Quantitative Units | USD Billion |

| Material Type | Carbon Fiber, Textile Fabrics, Concrete Mixtures, and Admixtures |

| Application | Infrastructure Development, Residential Buildings, Commercial Buildings, Industrial Projects, Bridge Construction, and Repair and Rehabilitation |

| End-User Industry | Construction, Aerospace, Automotive, Marine, Energy, and Defense |

| Fiber Orientation | Unidirectional, Bidirectional, and Multidirectional |

| Manufacturing Technique | Prepreg Lay-Up, Hand Lay-Up, Filament Winding, Resin Transfer Molding (RTM), and Vacuum Infusion |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | ADCOS NV, CarboCon GmbH, Raina Industries Pvt. Ltd., Solidian GmbH, Tradecc, and Hering Architectural Concrete |

| Additional Attributes | Dollar sales by product type (carbon fiber, optical transceivers, optical amplifiers) and end-use segments (telecom, data centers, enterprise networks, cloud services). Demand dynamics are driven by the increasing need for high-performance, sustainable construction materials, and investments in infrastructure projects. Regional trends show strong growth in Asia-Pacific, North America, and Europe, fueled by expanding construction projects, infrastructure development, and the adoption of eco-friendly building solutions. |

The global carbon textile reinforced concrete market is estimated to be valued at USD 1.6 billion in 2025.

The market size for the carbon textile reinforced concrete market is projected to reach USD 3.9 billion by 2035.

The carbon textile reinforced concrete market is expected to grow at a 9.2% CAGR between 2025 and 2035.

The key product types in carbon textile reinforced concrete market are carbon fiber, textile fabrics, concrete mixtures and admixtures.

In terms of application, infrastructure development segment to command 38.6% share in the carbon textile reinforced concrete market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Carbon Fiber Reinforced Plastic Market Size and Share Forecast Outlook 2025 to 2035

Carbon Capture and Sequestration Market Forecast Outlook 2025 to 2035

Carbon Dioxide Incubators Market Size and Share Forecast Outlook 2025 to 2035

Carbon Enhanced Lead Acid Battery Market Size and Share Forecast Outlook 2025 to 2035

Carbon-negative Cement Market Size and Share Forecast Outlook 2025 to 2035

Concrete Epoxy Repair Market Size and Share Forecast Outlook 2025 to 2035

Carbon Tetrabromide Market Size and Share Forecast Outlook 2025 to 2035

Carbon Steel Market Size and Share Forecast Outlook 2025 to 2035

Carbon Brush Market Size and Share Forecast Outlook 2025 to 2035

Carbon Offset Platform Market Size and Share Forecast Outlook 2025 to 2035

Concrete Fiber Market Size and Share Forecast Outlook 2025 to 2035

Carbon Tapes Market Size and Share Forecast Outlook 2025 to 2035

Textile Coatings Market Size and Share Forecast Outlook 2025 to 2035

Carbon-Free Waste Gas Abatement System Market Size and Share Forecast Outlook 2025 to 2035

Carbon Labeled Packaged Meal Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Carbon Fiber Bike Wheelset Market Size and Share Forecast Outlook 2025 to 2035

Carbon Dioxide Lasers Market Size and Share Forecast Outlook 2025 to 2035

Carbon-negative Packaging Market Size and Share Forecast Outlook 2025 to 2035

Carbon Fiber Construction Repair Market Size and Share Forecast Outlook 2025 to 2035

Concrete Densification and Polishing Material Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA