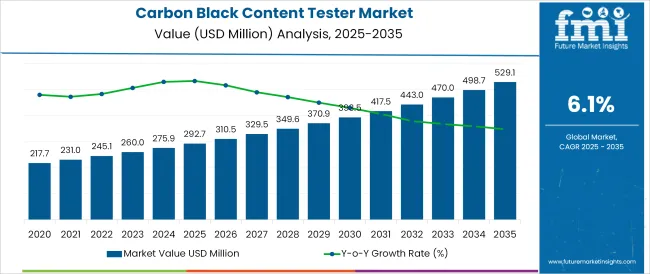

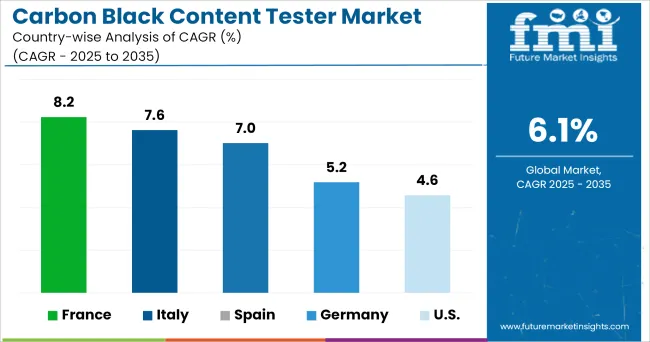

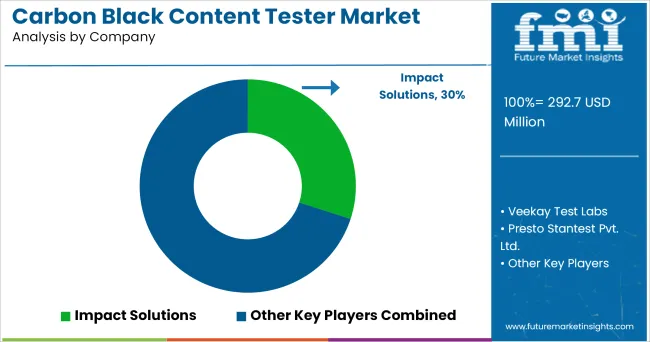

The Carbon Black Content Tester Market is estimated to be valued at USD 292.7 million in 2025 and is projected to reach USD 529.1 million by 2035, registering a compound annual growth rate (CAGR) of 6.1% over the forecast period.

The carbon black content tester market is gaining momentum as industries increasingly emphasize material quality control, regulatory compliance, and process optimization. Rising demand for reliable testing equipment in plastics and rubber manufacturing has reinforced the role of precise carbon black measurement in ensuring product durability, UV resistance, and mechanical strength.

Industry journals and corporate disclosures underline how advancements in automation, digital interfaces, and enhanced temperature control systems have improved testing accuracy and throughput. Future growth is expected to be fueled by expanding polymer production, stricter international quality standards, and growing awareness of product performance attributes linked to carbon black dispersion.

The trend toward laboratory modernization and in-line quality monitoring is also paving the way for broader adoption, with manufacturers focusing on user-friendly designs and multi-sample capabilities to meet diverse end-user needs efficiently.

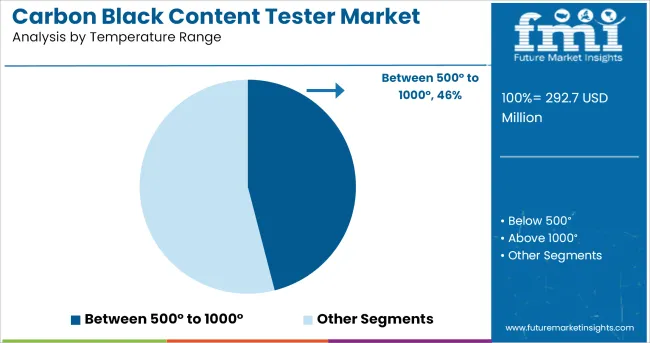

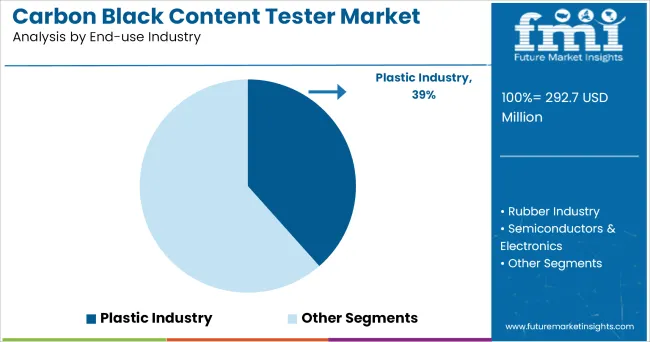

The market is segmented by Temperature Range and End-use Industry and region. By Temperature Range, the market is divided into Between 500° to 1000°, Below 500°, and Above 1000°. In terms of End-use Industry, the market is classified into Plastic Industry, Rubber Industry, Semiconductors & Electronics, Electrical Goods & Components, General Manufacturing, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

When segmented by temperature range, equipment operating between 500° to 1000° is projected to hold 46.0% of the total market revenue in 2025, establishing itself as the leading temperature range segment. This dominance has been driven by its suitability for effectively decomposing polymer matrices while preserving carbon black integrity for accurate quantification.

Industry technical bulletins and laboratory best-practice guidelines indicate that this temperature range is optimal for achieving reliable and repeatable test results, meeting both ISO and ASTM standards. Manufacturers have been incorporating precise thermal controls, uniform heating zones, and safety enhancements within this range to improve operator confidence and minimize measurement errors.

The operational flexibility provided by this range has also enabled wider adoption across different polymer types, contributing to its significant market share. Its alignment with established testing protocols and compatibility with a majority of plastic and rubber formulations has reinforced its leadership in laboratory and production environments.

Segmented by end-use industry, the plastic industry is expected to account for 38.5% of the carbon black content tester market revenue in 2025, maintaining its position as the leading industry segment. This leadership has been underpinned by the plastics sector’s critical need to ensure uniform carbon black dispersion for achieving desired material properties, such as tensile strength, UV resistance, and aesthetic appeal.

Company sustainability reports and industry association publications have noted that increased production of pipes, films, automotive parts, and consumer goods has heightened the emphasis on stringent quality control processes. The plastic industry’s ongoing investments in laboratory infrastructure and compliance with evolving regulatory norms regarding material consistency and environmental performance have also driven the adoption of advanced testing equipment.

The ability of these testers to provide reliable, standardized measurements has enabled manufacturers to enhance product quality, reduce rejects, and maintain competitive differentiation, securing the plastic industry’s dominant role in market adoption.

Evolving end-user demand for to ascertain the quality and strength of plastics components continues to drive demand for the market. Plastic Sector continue to be a lucrative avenue for Carbon Black Content Tester manufacturers.

The testing machine is widely used in PET & Preform, and plastic products manufacturing industries to determine the quality and strength of plastics, therefor this sector is crucial for Carbon Black Content Tester market demand generation.

The growing rubber industry especially synthetic rubber and related elastomeric grades is also a strong factor in fortifying the market growth. The product is the most widely used cost-effective reinforcing filler used in elastic compounds, especially tires. This increased demand for carbon black is anticipated to create lucrative growth for the carbon black content tester market.

However, issues related with the recyclability of black plastic is anticipated to have negative impact on the market growth.

The steady demand from consumer goods production and sales will bail out the recessionary effect created due to the pandemic.

This test equipment is used in plastic industry for testing the amount of carbon black in the component or say plastic materials and with increasing strict regulation from governments for better quality products, the market is anticipated gain momentum.

North America market is dominated by the USA., both in terms of utilization as well as generation. The demand for plastics and tires in North America has increased. In addition, consistent recovery of ongoing plastic and rubber sector will assist the carbon black content tester market in future.

Plastics manufactured from carbon black are lightweight and in this way offer reduce carbon emission and fuel utilization.

This region is one of the most attractive market for investment owing to high demand for carbon black.

For instance, in February 2020, Cancarb Ltd., a key manufacturer of carbon black in the Canadian region, announced investing USD 40.1 million to expand its thermal carbon black production capacity by adding a sixth production unit at its facility in Medicine Hat. As the carbon black and carbon black content tester market is set to grow synchronously, therefore this investments will prove to be very optimistic of the market.

Asia-Pacific dominated the market and is anticipated to grow with an attractive growth rate. Demand for the product has seen a noteworthy increment from this region, including China, India, and Japan. Measures embraced by governments, especially in India, such as import duties to boost domestic production is expected to create growth opportunities.

The adoption of carbon black by the tire segment within the automobile industry has gone up due to a rise in domestic tire production after the imposition of anti-dumping duty on tire imports from China by Indian Government. This accelerated carbon black content tester growth in the region.

Some of the leading manufacturers and suppliers of Carbon Black Content Tester include

Many leading manufacturers and suppliers are directly contacted by end users for the procurement. Leading players have their own authorized suppliers.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments.

The report also maps the qualitative impact of various market factors on market segments and geographies.

The global carbon black content tester market is estimated to be valued at USD 292.7 million in 2025.

The market size for the carbon black content tester market is projected to reach USD 529.1 million by 2035.

The carbon black content tester market is expected to grow at a 6.1% CAGR between 2025 and 2035.

The key product types in carbon black content tester market are between 500° to 1000°, below 500° and above 1000°.

In terms of end-use industry, plastic industry segment to command 38.5% share in the carbon black content tester market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Carbon Capture and Sequestration Market Forecast Outlook 2025 to 2035

Carbon Dioxide Incubators Market Size and Share Forecast Outlook 2025 to 2035

Carbon Enhanced Lead Acid Battery Market Size and Share Forecast Outlook 2025 to 2035

Carbon-negative Cement Market Size and Share Forecast Outlook 2025 to 2035

Carbon Tetrabromide Market Size and Share Forecast Outlook 2025 to 2035

Carbon Steel Market Size and Share Forecast Outlook 2025 to 2035

Carbon Brush Market Size and Share Forecast Outlook 2025 to 2035

Carbon Offset Platform Market Size and Share Forecast Outlook 2025 to 2035

Carbon Tapes Market Size and Share Forecast Outlook 2025 to 2035

Carbon-Free Waste Gas Abatement System Market Size and Share Forecast Outlook 2025 to 2035

Carbon Labeled Packaged Meal Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Carbon Fiber Bike Wheelset Market Size and Share Forecast Outlook 2025 to 2035

Carbon Dioxide Lasers Market Size and Share Forecast Outlook 2025 to 2035

Carbon-negative Packaging Market Size and Share Forecast Outlook 2025 to 2035

Carbon Fiber Construction Repair Market Size and Share Forecast Outlook 2025 to 2035

Carbon Credit Market Size and Share Forecast Outlook 2025 to 2035

Carbon-Dioxide Synthesis Cosmetics Market Size and Share Forecast Outlook 2025 to 2035

Carbon-Neutral Skincare Ingredients Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Carbonate Market Size and Share Forecast Outlook 2025 to 2035

Carbon Fiber Reinforced Plastic Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA