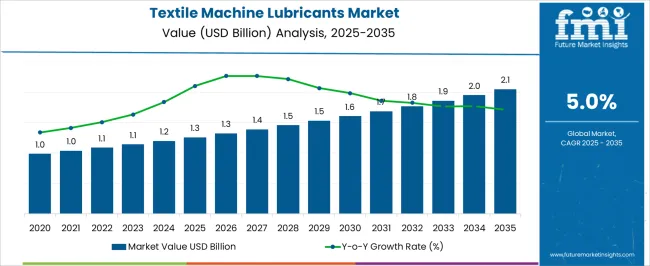

The Textile Machine Lubricants Market is estimated to be valued at USD 1.3 billion in 2025 and is projected to reach USD 2.1 billion by 2035, registering a compound annual growth rate (CAGR) of 5.0% over the forecast period.

| Metric | Value |

|---|---|

| Textile Machine Lubricants Market Estimated Value in (2025 E) | USD 1.3 billion |

| Textile Machine Lubricants Market Forecast Value in (2035 F) | USD 2.1 billion |

| Forecast CAGR (2025 to 2035) | 5.0% |

The Textile Machine Lubricants Market is experiencing steady expansion as textile manufacturers increasingly adopt advanced lubrication solutions to ensure efficiency and reliability in production processes. The current market dynamics are being shaped by the growing demand for higher productivity, reduced downtime, and extended machine lifecycles. Rising emphasis on precision engineering in spinning, weaving, knitting, and finishing machines has reinforced the need for lubricants that minimize friction, heat generation, and wear under continuous operation.

The market is also being influenced by strict quality standards in textile output, where smooth machine functioning is directly linked to fabric quality and consistency. Growing textile exports from emerging economies and modernization of textile facilities in developed regions are further supporting adoption.

The future outlook highlights strong opportunities in eco-friendly and high-performance lubricant formulations, with bio-based and synthetic blends expected to gain traction As manufacturers look for sustainable, cost-efficient, and reliable solutions, the role of specialized textile machine lubricants is anticipated to strengthen considerably over the coming decade.

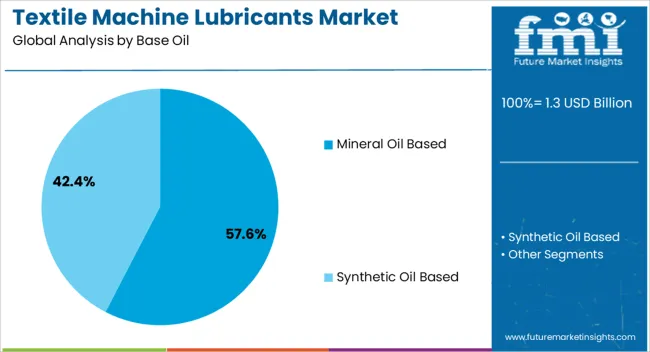

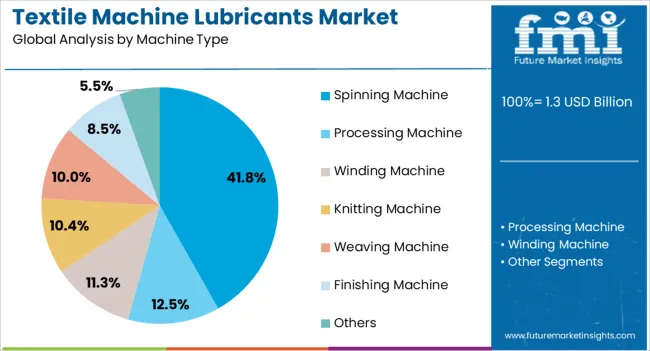

The textile machine lubricants market is segmented by base oil, machine type, and geographic regions. By base oil, textile machine lubricants market is divided into Mineral Oil Based and Synthetic Oil Based. In terms of machine type, textile machine lubricants market is classified into Spinning Machine, Processing Machine, Winding Machine, Knitting Machine, Weaving Machine, Finishing Machine, and Others. Regionally, the textile machine lubricants industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Mineral Oil Based category is projected to hold 57.60% of the Textile Machine Lubricants Market revenue in 2025, making it the leading segment in terms of base oil. This strong position is being supported by its widespread use across textile machinery due to cost-effectiveness, wide availability, and proven performance in reducing friction and wear.

The dominance of mineral oil based lubricants is also associated with their compatibility with a wide range of machines operating under varied temperature and load conditions. Their ability to provide stable viscosity and consistent lubrication has enabled their continued preference in spinning, weaving, and knitting operations.

The segment’s growth has further been reinforced by established supply chains and the relatively lower price point compared to synthetic or bio-based alternatives, which makes them favorable for cost-sensitive textile manufacturers While sustainable alternatives are gaining attention, mineral oil based lubricants continue to dominate owing to their affordability, established reliability, and broad acceptance across both small and large-scale textile manufacturing units.

The Spinning Machine category is expected to account for 41.80% of the Textile Machine Lubricants Market revenue in 2025, establishing it as the largest machine type segment. This dominance is being attributed to the high reliance on spinning operations in the textile industry, where efficiency and continuous operation directly impact overall production output. Lubricants play a vital role in spinning machines by minimizing friction in spindles, bearings, and gears, which are subjected to high-speed operations.

The segment’s growth has been reinforced by the increasing adoption of advanced spinning technologies that require reliable lubrication to maintain precision and avoid downtime. Demand has further been driven by textile manufacturers seeking higher yarn quality and reduced machine maintenance costs, which are supported through effective lubrication practices.

As global demand for textiles continues to rise, spinning operations remain central to production, ensuring sustained adoption of lubricants in this category The ability of lubricants to extend machine life, reduce operational failures, and support continuous high-volume production has positioned spinning machines as the key driver within the machine type segment.

Textile machine lubricants have been an integral part of effective functioning of textile machinery. The textile machine lubricants have enabled today's modern textile machines to operate at higher speeds while maintaining the product quality. Textile machine lubricants have potentially increased the runtime of the equipments, thereby reducing the maintenance requirements. The use of textile machine lubricants also reduces the risk of unplanned down time.

The textile machines are subject to high stress. The external conditions such as humidity and increased temperatures also act as challenges for textile machine lubricants. The textile machine lubricants are used in order to reduce the noise and vibration in spinning and knitting machines, among others. Textile machine lubricants aid a smooth operation and decrease the risk of rust formation in the equipment.

The manufacturers of textile machine lubricants are noted to offer products serving a range of temperatures and are chemically resistant. The textile machine lubricants are desired to be non – staining to the fabric produced in an event of accidental leak. The textile machine lubricants should also be easily washable without affecting the product quality.

The textile industry is capital-intensive and reduction in maintenance activity can result in significant amount of savings. Hence, the textile machine lubricants are widely demanded. Moreover, the textile industry is growing at a rapid pace and the evolution in fashion trends pushes the manufacturers to set up advanced textile mills while also expanding the production capacity of existing ones.

Given the shift from labor intensive manufacturing processes, the textile industry is highly relying on machine operated and automated textile production which requires pertinent scope of lubrication for its components at regular intervals. This in turn proves to drive the textile machine lubricants market. Given the penetration of automation in textile industry, it will further augment the growth of textile machine lubricants market.

The players operating in the textile machine lubricants market are observed to be involved in research and development activities in order to attain product differentiation. Being a versatile industry, a single lubricant cannot serve the various textile machine requirements and there seems to be even more growth potential for the textile machine lubricants market players.

Some textile machine equipment manufacturers are noted to produce and supply textile machine lubricants as a part of after sales and services. Such kind of vertical integration acts as a very imperative feature of the overall textile machine lubricants market.

The Asia Pacific textile machine lubricants market is estimated to account for a significant share due to the presence of several SME and large scale textile manufacturing enterprises in the region. The North America textile machine lubricants market follows APAC.

This is largely due to the preference of textile manufacturers towards efficient and uninterrupted production. Europe also holds a vital position in the textile machine lubricants market and the region sees a high density of manufacturers. The Middle East & Africa textile machine lubricants market is estimated to gain significant traction during the forecast period owing to investments in textile mills. The Latin America textile machine lubricants market is anticipated to grow marginally during the forecast period as the countries are dependent on importing textile from countries such as USA and China.

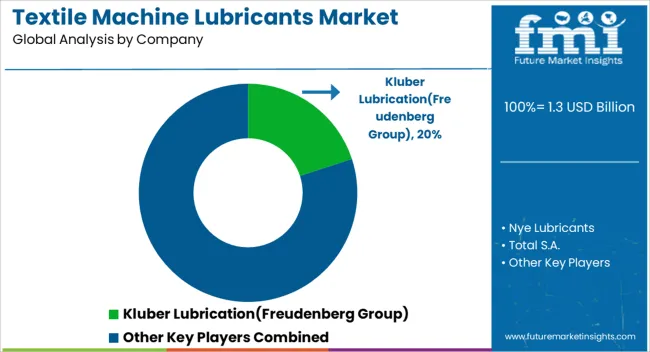

Some of the market participants in the global textile machine lubricants market identified across the value chain include Nye Lubricants, Inc., Total S.A., Klüber Lubrication, The Chemours Company, BENJN R. VICKERS & SONS LTD., BRÜCKNER Trockentechnik GmbH & Co. KG, Eni S.p.A., Matrix Specialty Lubricants B.V., CARL BECHEM GMBH, Eldons Lubricants Industry

The research report on textile machine lubricants presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data and statistically supported and industry-validated market data and contains projections using a suitable set of assumptions and methodologies. The textile machine lubricants research report provides analysis and information according to market segments such as geographies, application and industry.

The textile machine lubricants report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

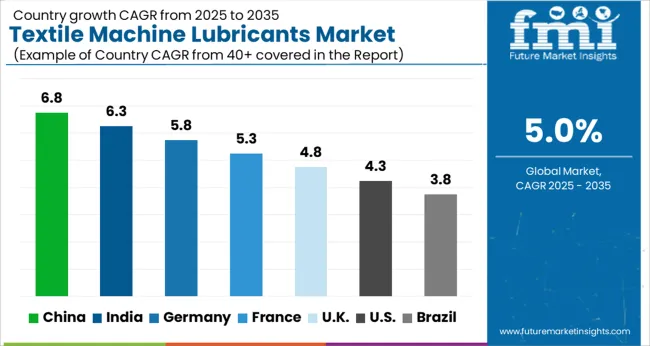

| Country | CAGR |

|---|---|

| China | 6.8% |

| India | 6.3% |

| Germany | 5.8% |

| France | 5.3% |

| UK | 4.8% |

| USA | 4.3% |

| Brazil | 3.8% |

The Textile Machine Lubricants Market is expected to register a CAGR of 5.0% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 6.8%, followed by India at 6.3%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 3.8%, yet still underscores a broadly positive trajectory for the global Textile Machine Lubricants Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 5.8%. The USA Textile Machine Lubricants Market is estimated to be valued at USD 471.7 million in 2025 and is anticipated to reach a valuation of USD 715.3 million by 2035. Sales are projected to rise at a CAGR of 4.3% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 57.6 million and USD 36.8 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.3 Billion |

| Base Oil | Mineral Oil Based and Synthetic Oil Based |

| Machine Type | Spinning Machine, Processing Machine, Winding Machine, Knitting Machine, Weaving Machine, Finishing Machine, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Kluber Lubrication(Freudenberg Group), Nye Lubricants, Total S.A., The Chemours Company, Vickers Oils, Bruckner Textile Machinery, Eni Oil Products, Matrix Specialty Lubricants, Carl Bechem GmbH, Eldons Lubricants Industry, Caltex, and MORESCO Corporation |

The global textile machine lubricants market is estimated to be valued at USD 1.3 billion in 2025.

The market size for the textile machine lubricants market is projected to reach USD 2.1 billion by 2035.

The textile machine lubricants market is expected to grow at a 5.0% CAGR between 2025 and 2035.

The key product types in textile machine lubricants market are mineral oil based and synthetic oil based.

In terms of machine type, spinning machine segment to command 41.8% share in the textile machine lubricants market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Textile Coatings Market Size and Share Forecast Outlook 2025 to 2035

Textile Based pH Controllers Market Size and Share Forecast Outlook 2025 to 2035

Textile Transfer Paper Market Size and Share Forecast Outlook 2025 to 2035

Textile Colorant Market – Trends & Forecast 2025 to 2035

Textile Recycling Market Analysis by Material, Source, Process, and Region: Forecast for 2025 and 2035

Textile Flooring Market Trends & Growth 2025 to 2035

Textile Tester Market Growth – Trends & Forecast 2025 to 2035

Textile Colors Market Growth - Trends & Forecast 2025 to 2035

Textile Testing, Inspection, and Certification (TIC) Market Insights - Growth & Forecast 2025 to 2035

Textile Staples Market Size & Trends 2025 to 2035

Textile Auxiliaries Market Trends 2024-2034

Textile Printing Ink Market

Textile Waste Recycling Machine Market Size and Share Forecast Outlook 2025 to 2035

Geotextile Tube Market Growth – Trends & Forecast 2024-2034

Agri Textiles Market Size and Share Forecast Outlook 2025 to 2035

Asia Textile Chemicals Market Size and Share Forecast Outlook 2025 to 2035

Agro textiles Market

Carbon Textile Reinforced Concrete Market Size and Share Forecast Outlook 2025 to 2035

Ceramic Textile Market Size and Share Forecast Outlook 2025 to 2035

Digital Textile Printing Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA