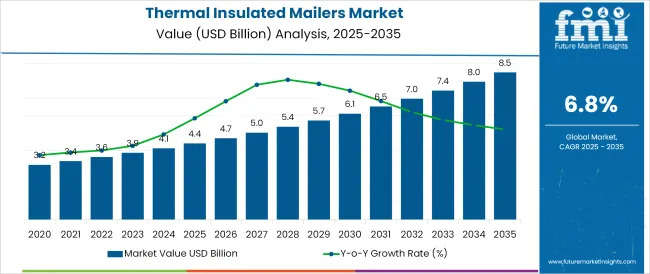

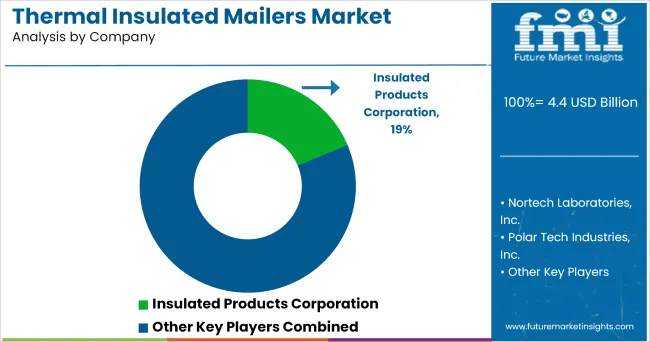

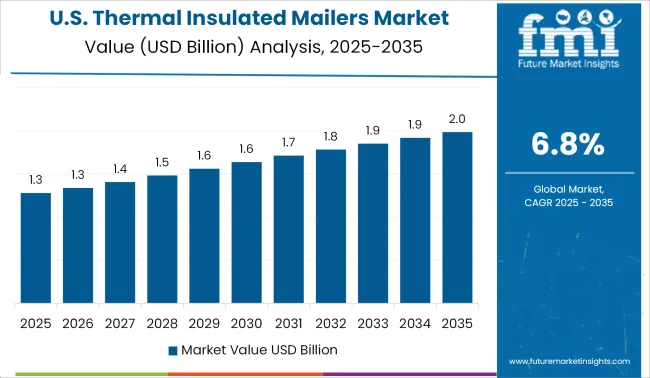

The Thermal Insulated Mailers Market is estimated to be valued at USD 4.4 billion in 2025 and is projected to reach USD 8.5 billion by 2035, registering a compound annual growth rate (CAGR) of 6.8% over the forecast period.

The thermal insulated mailers market is witnessing substantial expansion, propelled by surging demand for temperature-sensitive packaging across food, pharmaceutical, and e-commerce sectors. The rise of online grocery and direct-to-consumer cold chain delivery has intensified the need for packaging that maintains thermal integrity without compromising on durability or cost-efficiency. Advancements in insulation materials, reflective films, and leak-resistant linings have enhanced the functional performance of mailers while reducing weight and shipping costs.

Regulatory emphasis on pharmaceutical cold chain compliance and food safety standards is also contributing to adoption. Sustainability concerns are encouraging innovation in recyclable and reusable formats, prompting manufacturers to develop eco-responsible yet high-performance solutions.

Additionally, the shift toward automation in warehouse and distribution systems has increased demand for mailers compatible with high-speed sealing and labelling technologies. As demand rises for reliable, efficient, and compliant thermal packaging, thermal insulated mailers are emerging as a vital enabler of modern logistics and temperature-controlled commerce.

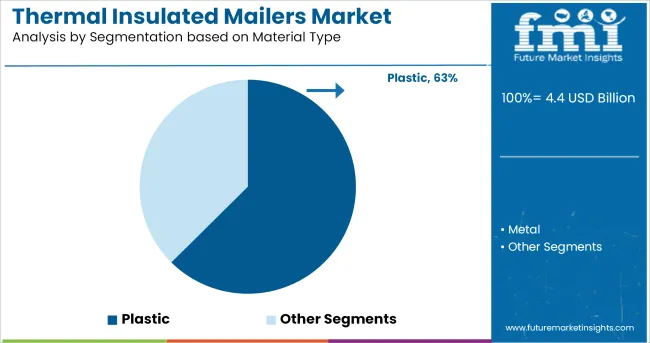

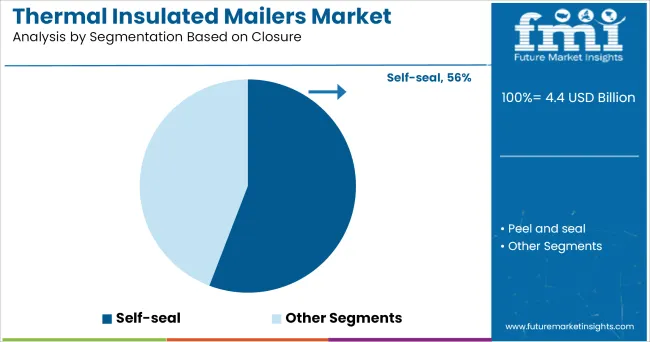

The market is segmented by Segmentation based on Material Type, Segmentation Based on Closure, and Segmentation Based on End Use and region. By Segmentation based on Material Type, the market is divided into Plastic and Metal. In terms of Segmentation Based on Closure, the market is classified into Self-seal and Peel and seal.

Based on Segmentation Based on End Use, the market is segmented into Manufacturing & Warehousing, Pharmaceuticals, Automotive & Allied Industries, Cosmetics & Personal Care, Electrical & Electronics, Food & Beverages, Others (Agriculture & Healthcare), Shipping & Logistics, and E-commerce. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

It is observed that plastic-based mailers hold 62.50% of total market revenue, making this material type the most dominant in the segment. This prevalence is due to plastic’s inherent thermal insulation properties, lightweight composition, and superior flexibility during transport. Plastic mailers offer greater resistance to moisture, puncture, and tearing, which are critical in maintaining the integrity of perishable or temperature-sensitive products during extended transit.

Their adaptability to a variety of closure systems and compatibility with automated packing lines have further elevated their utility in high-volume shipping operations. Additionally, plastic materials allow for enhanced customization through metallized layers and foam linings, contributing to extended cold retention.

Despite rising environmental scrutiny, the ability to recycle certain plastic composites and their cost-effectiveness in large-scale operations have maintained their leadership within the material category.

The self-seal sub-segment is estimated to capture 55.80% of market revenue, positioning it as the leading closure type. This dominance is driven by the need for operational efficiency and tamper-evident security in high-throughput shipping environments. Self-sealing mailers minimize the time and labour associated with manual taping or heat sealing, making them highly preferred in e-commerce fulfilment centres and distribution warehouses.

The consistent closure integrity offered by pressure-sensitive adhesives ensures reliable insulation during transit, which is especially critical for temperature-controlled shipments. Additionally, self-seal closures support hygiene compliance by reducing handling and exposure, particularly in pharmaceutical and food-grade applications.

Their compatibility with automated packing systems has further reinforced their widespread use, enabling fast, secure, and scalable packaging solutions that align with supply chain performance benchmarks.

It has been noted that manufacturing and warehousing applications comprise 19.30% of overall market share, ranking this end-use segment among the most significant contributors. This is attributed to the increasing need for internal cold chain logistics and thermal protection of temperature-sensitive components during inter-facility transport. In industrial settings, thermal mailers are used to safeguard adhesives, chemicals, and electronics that require stable temperature conditions to preserve quality and efficacy.

Warehousing operations benefit from mailers that reduce spoilage and eliminate the need for more costly refrigeration systems during short-term storage or transit. Moreover, the growing emphasis on supply chain continuity and damage prevention has prompted greater adoption of insulated packaging solutions that are lightweight, durable, and efficient.

As industries seek to optimize their packaging strategies under tightening compliance and operational efficiency goals, this end-use segment continues to gain traction in the thermal insulated mailers market.

The packaging industry has undergone several path-breaking innovations, the most advanced packaging solution is temperature-controlled packaging. Thermal insulated mailers are a globally accepted form of temperature controlled packaging for transportation of temperature-sensitive goods such as seafood, meat, meals and many pharmaceutical items.

Thermal insulated mailers are made up of using plastic air bubble film along with protective aluminium foil having cotton pad layers to save goods from outer temperature fluctuations. Due to increasing consumer trends of choosing frozen eatable items over canned foods, the thermal insulated mailers market is expected to record a sharp growth over the forecasted period.

The thermal insulated mailers are lightweight packaging solution for safely packaging high-value goods such as temperature-controlled drugs & medicines. Various sizes and customization of thermal insulated mailers are manufactured to solve the logistical and quality problems faced by the shipping and logistics industry.

The features like easy storage and tamper-proof packaging of such temperature-controlled mailers make them unique and save products from any kind of malpractices while shipping. Thermal insulated mailers are sustainable, as it’s made from recyclable materials.

Thermal insulated mailers are made up of non-biodegradable plastics and pollutant materials. Also, the cotton pads and aluminium foil used as insulation in thermal insulated mailers have an expensive recycling process. All these factors are going to have a negative impact on the growth of the global thermal insulated mailers market.

The demand for temperature-controlled packaging used to transport small sized items in shorter distances is growing in the food and pharmaceutical industry in all parts of the world.

The introduction of thermally insulated mailers with different levels of thickness & paddings in the mailers for various applications to control the temperature of natural & organic types of cosmetics and medicines. The cost of cold chain logistics can be reduced significantly by the usage of thermal insulated mailers that do not require cold storages and refrigerators.

The thermally insulated mailer market is expected to expand rapidly in China, as a result of rapid industrialization due to cheaper raw materials used in thermally insulated mailers. Also, the rising demand for seafood, meat and food items from one part of the country to another growing the demand for thermally insulated mailers for even the smallest of quantities of goods to be shipped.

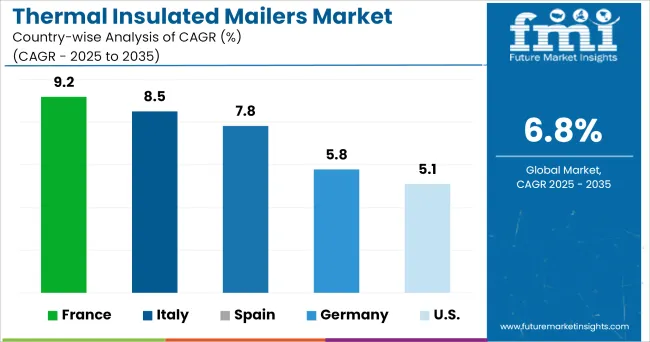

The booming pharmaceutical industry along with the innovation-driven chemical industry ensures the growth of the thermally insulated mailers market in France over the forecasted period. The development of temperature-sensitive drugs & medicines, also the demand for tamper-proof packaging of the same will contribute as a growth factor to the thermally insulated mailer market in France.

Usage of thermally insulated mailers in packaging food and beverages for the soldiers of the USA army to protect them and to maintain freshness. The rising demand for frozen fruits & vegetables along with frozen meat and meat products are exponentially driving the demand for temperature-controlled packaging solutions for shorter distances in small quantities. All the above-mentioned factors are direct growth indicators of the thermally insulated mailer market.

The global thermal insulated mailers market is estimated to be valued at USD 4.4 billion in 2025.

The market size for the thermal insulated mailers market is projected to reach USD 8.5 billion by 2035.

The thermal insulated mailers market is expected to grow at a 6.8% CAGR between 2025 and 2035.

The key product types in thermal insulated mailers market are plastic and metal.

In terms of segmentation based on closure, self-seal segment to command 55.8% share in the thermal insulated mailers market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Thermal Impulse Sealers Market Size and Share Forecast Outlook 2025 to 2035

Thermal Insulation Materials for Optical Fibers Market Size and Share Forecast Outlook 2025 to 2035

Thermal Inkjet Printer Market Size and Share Forecast Outlook 2025 to 2035

Thermal Insulation Material Market Size and Share Forecast Outlook 2025 to 2035

Thermal-Wet Gas Abatement System Market Size and Share Forecast Outlook 2025 to 2035

Thermal Spray Service Market Size and Share Forecast Outlook 2025 to 2035

Thermal Management Materials for EV Batteries Market Size and Share Forecast Outlook 2025 to 2035

Thermal Barrier Coatings Market Size and Share Forecast Outlook 2025 to 2035

Thermal Energy Harvesting Market Size and Share Forecast Outlook 2025 to 2035

Thermally Stable Antiscalant Market Size and Share Forecast Outlook 2025 to 2035

Thermal Spa and Wellness Market Size and Share Forecast Outlook 2025 to 2035

Thermal Mixing Valves Market Size and Share Forecast Outlook 2025 to 2035

Thermal Inkjet Inks Market Size and Share Forecast Outlook 2025 to 2035

Thermal Liner Market Analysis Size and Share Forecast Outlook 2025 to 2035

Thermal Interface Material Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Thermal Insulation Coating Market Size and Share Forecast Outlook 2025 to 2035

Thermal Spray Equipment Market Size and Share Forecast Outlook 2025 to 2035

Thermal Spring Market Size and Share Forecast Outlook 2025 to 2035

Thermal Printing Market Analysis - Size, Share & Forecast 2025 to 2035

Thermal Transfer Roll Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA