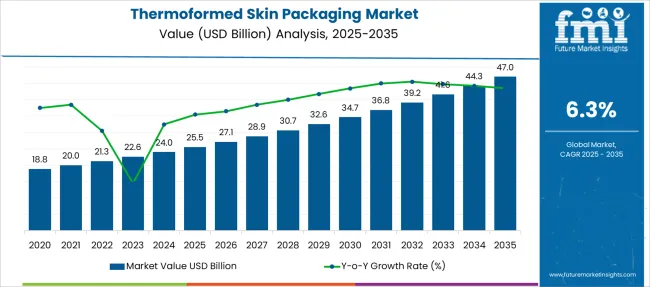

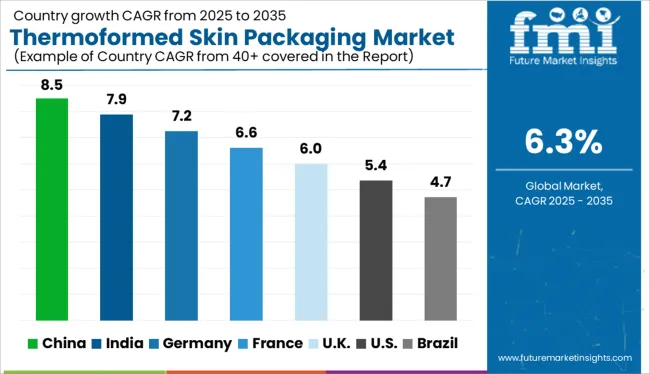

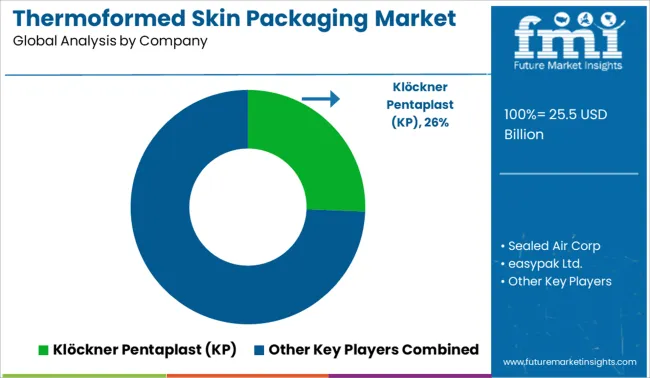

The Thermoformed Skin Packaging Market is estimated to be valued at USD 25.5 billion in 2025 and is projected to reach USD 47.0 billion by 2035, registering a compound annual growth rate (CAGR) of 6.3% over the forecast period.

| Metric | Value |

|---|---|

| Thermoformed Skin Packaging Market Estimated Value in (2025 E) | USD 25.5 billion |

| Thermoformed Skin Packaging Market Forecast Value in (2035 F) | USD 47.0 billion |

| Forecast CAGR (2025 to 2035) | 6.3% |

The thermoformed skin packaging market is experiencing consistent growth driven by the global shift toward sustainable, shelf stable, and tamper evident packaging solutions. Rising consumer demand for extended shelf life products and improved visual appeal is encouraging adoption across perishable goods categories.

The vacuum sealing technology used in thermoformed skin packaging enhances product protection while maintaining freshness, making it ideal for temperature sensitive and high quality food items. In addition, advancements in recyclable and mono material films are aligning with environmental regulations and corporate sustainability goals.

Food manufacturers and retailers are increasingly investing in skin packaging to minimize food waste, reduce secondary packaging, and enhance consumer confidence in product hygiene. With growing demand for secure and visually appealing product presentation, especially in fresh food categories, the market is expected to see strong expansion across multiple regions and applications.

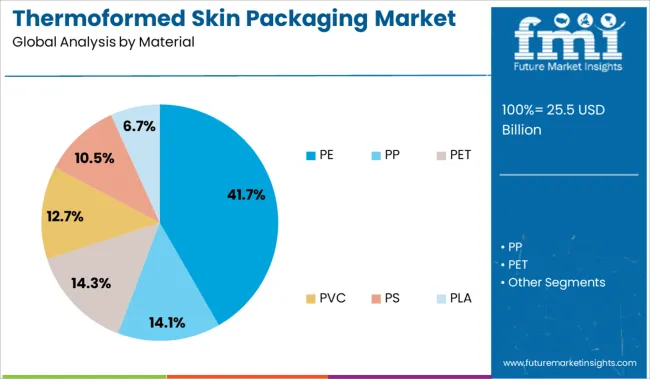

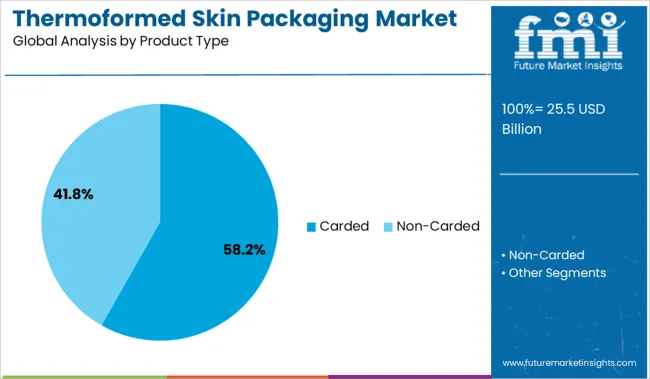

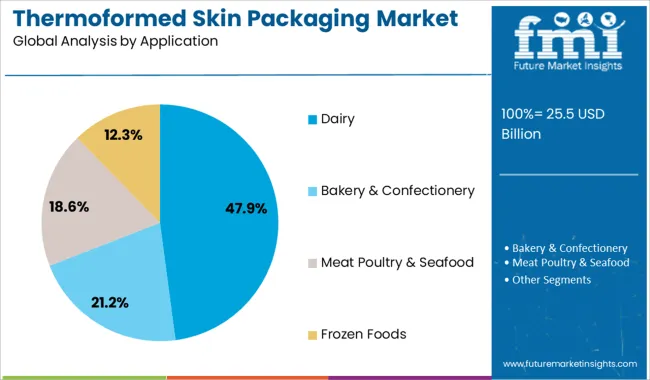

The market is segmented by Material, Product Type, and Application and region. By Material, the market is divided into PE, PP, PET, PVC, PS, and PLA. In terms of Product Type, the market is classified into Carded and Non-Carded. Based on Application, the market is segmented into Dairy, Bakery & Confectionery, Meat Poultry & Seafood, and Frozen Foods. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The PE material segment is anticipated to account for 41.70% of total revenue by 2025, making it the dominant material type in the market. This is primarily due to its cost effectiveness, thermoformability, and compatibility with vacuum sealing technologies.

PE films offer excellent moisture barrier properties and strong sealing integrity, making them highly suitable for applications requiring prolonged shelf life. Their recyclability and ease of sourcing have also contributed to their widespread adoption, particularly among food processors looking to meet regulatory and environmental compliance.

With manufacturers shifting toward lightweight, sustainable, and food grade materials, PE continues to lead the material segment.

The carded product type segment is projected to hold 58.20% of total market revenue by 2025 within the product type category. This prominence is attributed to its superior display capabilities, product protection features, and compatibility with automated packaging lines.

Carded skin packaging provides excellent product visibility while maintaining vacuum sealed freshness, making it popular for retail ready packaging across fresh produce, meats, and specialty food items. The rigid backing material enhances structural integrity and branding potential, supporting both marketing and operational needs.

As demand grows for packaging formats that balance functionality, aesthetics, and sustainability, carded packaging is being increasingly favored across the supply chain.

The dairy application segment is expected to contribute 47.90% of total market revenue by 2025, making it the leading end use segment. This growth is driven by the sector’s high sensitivity to product freshness, hygiene, and extended shelf life.

Thermoformed skin packaging offers dairy producers an effective method for preserving product integrity while reducing spoilage and contamination risks. It also supports portion control and tamper resistance, which are critical for consumer trust and regulatory compliance.

As the dairy industry expands its product offerings into premium and specialty formats, the adoption of visually appealing and protective packaging formats like skin packaging is becoming a preferred strategy, thereby consolidating its leadership in application use.

The global thermoformed skin packaging market expanded at a CAGR of 5.8% during the historic period and reached USD 25.5 billion in 2025.

The thermoforming industry is rapidly increasing because of its numeric value, giving profitable business results, this type of packaging is light in weight, flexible, completely moisture free, and keeps food fresh and odor-free for a longer period, it is majorly used in the food industry sector to maintain the nutrient level of the food and exceeding the shelf life to the packed food, taking care of food spoilage, thermoformed packaging avoid the exposure from the environment which is harmful to food which is packed.

The fast-growing packaging industry is now taking care of the environment also along with profitable results and customer satisfaction. thermoformed skin packaging is a step ahead to solving the environmental problem, this drives the demand for the thermoformed skin packaging market.

Thermoformed skin packaging is used in bakery applications for dough preparations and for shipping bakery products to retail outlets. It can withstand the heat cycle of dishwashers offering cost savings to bakery operators as it is used for dough preparations and can be cleaned and reused for shipping baked products to retail outlets while also fulfilling the display functions as a packaging solution.

Thermoformed packaging made using PP material has high heat resistance, allowing a longer packaging life span. Thermoformed skin packaging has various benefits over other packaging formats. Thermoformed skin packaging removes all air from packed food which reduces bacterial growth. It prevents food spoilage and leakage. It extended food shelf life.

Transportation is an important aspect of food service. Thermoformed skin packaging provides Convenient storage and transportation. These factors will create a positive outlook for the thermoformed skin packaging market.

Based on the material segment, the polyethylene material segment is anticipated to hold around 29.3% of the market value share during the forecast period.

Polyethylene has the characteristic to work as a natural barrier to moisture and oxygen transmission. For long period using polyethylene material to maintain the freshness of the product, are frivolous therefore, they are easy to use in packaging. The effect and scratch-proof character will result positively. Easy production of PE and now recyclable gives an extra advantage using plastic in the packaging industry, PE manufacturing also has reduced carbon dioxide radiation, solid waste generation, and pollution. PE can be reusable and easy to carry store, and clean.

The Meat, Poultry & Seafood industry is expected to expand 1.7x market share from 2025 to 2035. The manufacturer focuses on the quality of the food product as the penetration of water and moisture should not affect the food product. The product can be prevented through thermoformed skin packaging.

The protection is required for the safety of the product, by looking at the temperature and humidity conditions, and where a product is likely to be exposed in the supply chain or while consumption. It is essential to specify the regions and their climatic conditions for packaging a product.

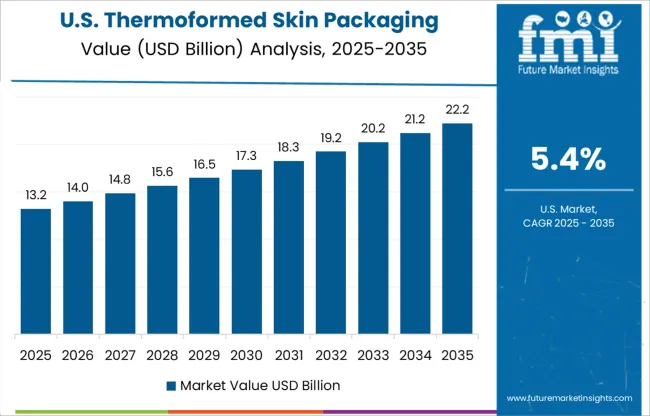

The USA is estimated to hold a major portion of the North American thermoformed skin packaging market during the forecast period.

According to the American Frozen Food Institute (AFFI), in 2024 the sales of frozen foods increased by 21%. Also, it states that around 39% of the shoppers were core frozen food shoppers in 2024. The increasing sales of frozen food in the countries of America bolster the demand for thermoformed skin packaging market.

India’s thermoformed skin packaging market is anticipated to grow at 7.0% from 2025 to 2035. According to the Agricultural & Proceed Food Products Export Development Authority (APEDA), India has exported 462.58 proceed meat worth USD 24 Million from the year 2024 to 2025. These factors will create growth opportunities for thermoformed skin packaging market

The major players in the global thermoformed packaging market are trying to focus on expanding their production capacity by investing in their existing facilities to cater to the growing demand for the thermoformed skin packaging market. Also, the key players are focusing on developing sustainable and innovative products to meet the demand for sustainable packaging. Some of the recent developments by the players are:-

| Attribute | Details |

|---|---|

| Growth Rate | CAGR of 6.3% from 2025 to 2035 |

| Base Year for Estimation | 2025 |

| Historical Data | 2020 to 2024 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in USD Billion, Volume in Tons, and CAG from 2025 to 2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, Growth Factors, Trends, and Pricing Analysis |

| Segments Covered | Material, Product, Application, Region |

| Regions Covered | North America; Latin America; Europe; East Asia; South Asia; Oceania; Middle East and Africa |

| Key Countries Covered | The USA, Canada, Mexico, Brazil, Germany, United Kingdom, France, Italy, Spain, Russia, China, Japan, India, GCC countries, Australia |

| Key Companies Profiled | Klöckner Pentaplast (KP); Sealed Air Corp; easypak Ltd.; DMD 2000 Ltd.; Clondalkin Group; DRADER Manufacturing Industries Ltd.; SouthPack, Vinpac Innovations; Berry Global Group; Schur Flexibles Holding GesmbH; Winpak Ltd; Amcor PLC; Plastissimo Film Co., Ltd. |

| Customization & Pricing | Available upon Request |

The global thermoformed skin packaging market is estimated to be valued at USD 25.5 billion in 2025.

The market size for the thermoformed skin packaging market is projected to reach USD 47.0 billion by 2035.

The thermoformed skin packaging market is expected to grow at a 6.3% CAGR between 2025 and 2035.

The key product types in thermoformed skin packaging market are pe, pp, pet, pvc, ps and pla.

In terms of product type, carded segment to command 58.2% share in the thermoformed skin packaging market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Thermoformed Containers Market Size and Share Forecast Outlook 2025 to 2035

Thermoformed Tray Market Size and Share Forecast Outlook 2025 to 2035

Thermoformed Plastics Market Size and Share Forecast Outlook 2025 to 2035

Thermoformed Tubs Market Trend Analysis Based on Material, Shape, End-Users and Regions through 2025 to 2035

Market Share Distribution Among Thermoformed Tubs Manufacturers

Market Share Breakdown of Thermoformed Tray Market

Thermoformed Lids Market

Vacuum Thermoformed Packaging Market Size and Share Forecast Outlook 2025 to 2035

Key Companies & Market Share in the Vacuum Thermoformed Packaging Sector

Skin Lightening Product Market Size and Share Forecast Outlook 2025 to 2035

Skincare Supplement Market Size and Share Forecast Outlook 2025 to 2035

Skin Tightening Device Market Size and Share Forecast Outlook 2025 to 2035

Skincare Oil Market Size and Share Forecast Outlook 2025 to 2035

Skin-Barrier Strengthening Phospholipids Market Size and Share Forecast Outlook 2025 to 2035

Skin Toner Market Size and Share Forecast Outlook 2025 to 2035

Skin Cancer Detection Devices Market Size and Share Forecast Outlook 2025 to 2035

Skincare Nutritional Serum Market Size and Share Forecast Outlook 2025 to 2035

Skincare Products Market Size and Share Forecast Outlook 2025 to 2035

Skin Sensors Market Size, Growth, and Forecast for 2025 to 2035

Skin Grafting System Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA