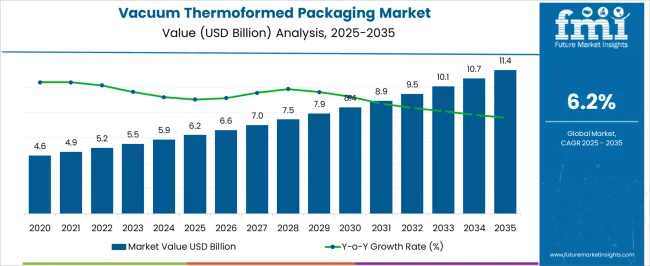

The Vacuum Thermoformed Packaging Market is estimated to be valued at USD 6.2 billion in 2025 and is projected to reach USD 11.4 billion by 2035, registering a compound annual growth rate (CAGR) of 6.2% over the forecast period.

| Metric | Value |

|---|---|

| Vacuum Thermoformed Packaging Market Estimated Value in (2025 E) | USD 6.2 billion |

| Vacuum Thermoformed Packaging Market Forecast Value in (2035 F) | USD 11.4 billion |

| Forecast CAGR (2025 to 2035) | 6.2% |

The vacuum thermoformed packaging market is witnessing a steady rise in adoption, supported by the expanding need for sustainable, cost-efficient, and highly customizable packaging solutions. Industries are increasingly leaning toward thermoformed formats due to their material efficiency, design flexibility, and faster production cycles compared to traditional molding methods.

The market is further bolstered by growing regulatory pressure to reduce plastic waste and increase recyclability, which has prompted manufacturers to innovate with recyclable and biocompatible polymers. In food and healthcare sectors, the demand for product protection, extended shelf life, and enhanced visual appeal has led to a shift toward transparent and form-fitting packaging, all of which are well-addressed by vacuum thermoforming.

Continuous investments in automation and cleanroom-compatible machinery have enabled producers to meet rising hygiene standards and output demands Going forward, the integration of post-consumer recycled content, along with advancements in barrier technology and digital tooling, is expected to drive broader adoption across global markets.

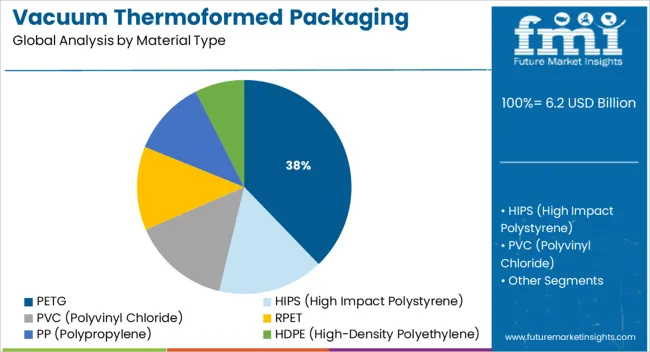

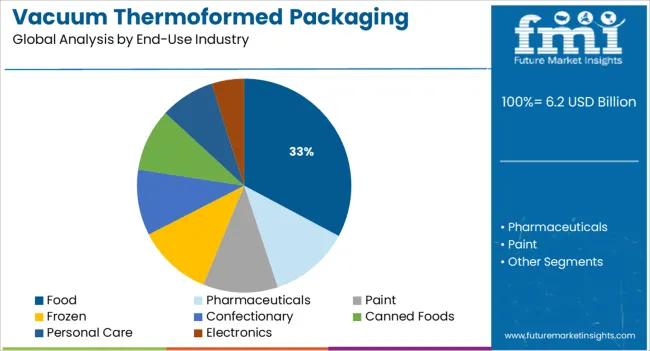

The market is segmented by Material Type and End-Use Industry and region. By Material Type, the market is divided into PETG, HIPS (High Impact Polystyrene), PVC (Polyvinyl Chloride), RPET, PP (Polypropylene), and HDPE (High-Density Polyethylene). In terms of End-Use Industry, the market is classified into Food, Pharmaceuticals, Paint, Frozen, Confectionary, Canned Foods, Personal Care, and Electronics. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The PETG material segment is projected to hold 37.8% of the total revenue share in the vacuum thermoformed packaging market in 2025, making it the leading material type. This dominance is attributed to PETG's excellent clarity, formability, and impact resistance, which make it ideal for creating visually appealing and protective packaging. Its ability to maintain structural integrity under various thermoforming conditions has supported its adoption in both shallow and deep draw applications.

The compatibility of PETG with food contact standards and sterilization protocols has enhanced its use in sectors demanding high safety standards. Its recyclability and lower carbon footprint compared to other plastics have aligned well with the growing emphasis on sustainability.

Additionally, the material's versatility in supporting intricate design features and its compatibility with a range of sealing methods have expanded its utility in product categories requiring tamper-evidence and extended shelf appeal As material innovation progresses, PETG is expected to remain a preferred choice for manufacturers seeking performance and sustainability.

The food end-use industry segment is anticipated to account for 32.8% of the vacuum thermoformed packaging market's total revenue share in 2025, reflecting its prominent role in driving demand. This growth is being driven by the sector’s focus on extending product shelf life, ensuring contamination-free storage, and enhancing consumer convenience through tamper-proof and microwave-safe packaging.

Vacuum thermoforming has gained traction in the food industry for its ability to produce lightweight, stackable, and visually transparent packaging that facilitates effective product presentation and portion control. The segment has benefited from the demand for ready-to-eat meals, dairy products, and meat packaging where customized cavity designs improve space utilization and reduce material wastage.

Compliance with global food safety standards, along with increasing retail shelf competition, has further reinforced the adoption of thermoformed formats The technology’s suitability for modified atmosphere packaging and barrier film integration has solidified its position within the food industry, where both preservation and presentation are critical to consumer satisfaction.

Plastics have become a vital part of packaging in today’s world. Plastics are finding a major portion of the packaging industry. Thermoforming is a process in which a sheet of plastic is heated made flexible then fabricated and shaped in required shape to make it usable.

The sheet, or film when referring to thinner gauges and certain material types, is heated in an oven to a high-enough temperature and is stretched into or onto a mold and cooled to a finished shape.

The various factors that drive the Vacuum Thermoformed Packaging are that it is vital in compact packaging. Vacuum Thermoformed Packaging helps in maintaining the stability and protection of the products. The increasing demands from food manufacturers, such as the application for packaging that can be used to store fresh as well as processed food can be met.

Vaccum Thermoformed Packaging is highly used in packaging due to their flexibility and durability. It aids the growing automation and demand due to ease of preparation, indirectly drives the global Vacuum Thermoformed Packaging market for efficient manufacturing and shipping of electronic components.

The consumers are more inclined towards quick and safe intake of food ingredients/chemicals, which ultimately aids in driving the global Vacuum Thermoformed Packaging market. In the present scenario, in Vacuum Thermoformed Packaging market governments have laid down many rules and regulations in reference to the material used.

These developments act as a major restraint on the growth of the global Vacuum Thermoformed Packaging products market over the forecast period. Also, during thermoforming, it is difficult to attain precise wall thickness symmetrically over the complete product, thereby affecting the quality standards of the product to a large extent.

This technical difficulty leads to manufacturers looking for a substitute to vacuumed thermoformed packaging products, thereby acting as a restraint to the global Vacuum Thermoformed Packaging market.

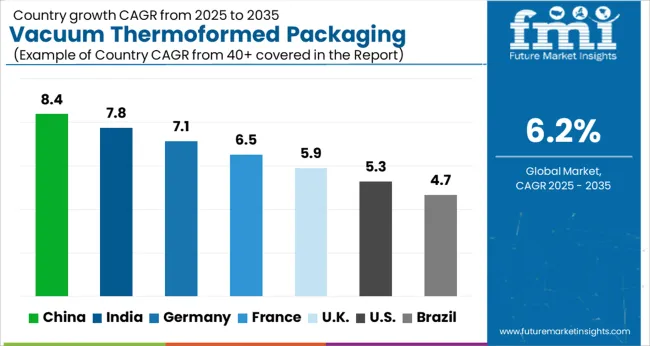

The global vacuum thermoformed market is divided into seven regions, namely North America, Latin America, Asia Pacific excluding Japan (APEJ), Western Europe, Eastern Europe, Japan and the Middle East and Africa (MEA). Globally, the food industry is performing in a fast evolving manner where food manufacturers and suppliers are evolving, and work closely to meets the huge variety of demands from consumers.

The vaccum thermoformed packaging market in North America is in its maturity phase. The Asia Pacific Vacuum Thermoformed Packaging market is expected to grow at significant CAGR during the forecast period, due to the growing end-use industry such as pharmaceutical food and personal care.

With the increasing disposable income and consumerism, Asia Pacific and the Middle East region stand ahead regarding the demand for vacuum thermoformed trays. As a result, Vacuum Thermoformed Packaging market will witness a significant rise in CAGR through the forecasted period through our forecasted period.

Europe and North America are also witnessing a steady however slower growth through the forecasted period. The consumers’ demands are changing in the region which is influenced by the growing retailers offering attractive and likewise innovative sale formats.

The retailers’ now-a-days keep first-hand knowledge on demands and purchase habits of the consumers which they transfer to the upper stream of manufacturers in the supply chain. This information from retailers to the manufacturers call for the demand of vaccum thermoformed packaging, since it is a packaging material for manufacturers.

Thus, the vaccum thermoformed packaging manufacturer has to strategize their business through consumer insights and responses, the regional shift in the eating habits and penetration of modernizing food products such as fast food, demand for technology etc.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain.

The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

The prominent players in the Vacuum Thermoformed Packaging market are:

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to categories such as market segments, geographies, types, technology and applications.

The global vacuum thermoformed packaging market is estimated to be valued at USD 6.2 billion in 2025.

The market size for the vacuum thermoformed packaging market is projected to reach USD 11.4 billion by 2035.

The vacuum thermoformed packaging market is expected to grow at a 6.2% CAGR between 2025 and 2035.

The key product types in vacuum thermoformed packaging market are petg, hips (high impact polystyrene), pvc (polyvinyl chloride), rpet, pp (polypropylene) and hdpe (high-density polyethylene).

In terms of end-use industry, food segment to command 32.8% share in the vacuum thermoformed packaging market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Key Companies & Market Share in the Vacuum Thermoformed Packaging Sector

Vacuum Heat Shrink Film Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Products for Emergency Services Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Fiber Feedthrough Flanges Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Tension Rolls Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Self-priming Mobile Pumping Station Market Size and Share Forecast Outlook 2025 to 2035

Vacuum-Refill Units Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Vacuum Leak Detectors Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Insulation Panels Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Pressure Encapsulated Transformer Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Insulated Medium Voltage Switchgear Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Rated Motors Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Concentrators Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Insulated Low Voltage Commercial Switchgear Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Pressure Impregnated (VPI) Transformer Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Insulated Pipe Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Therapy Devices Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Pressure Swing Adsorption Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Grease Market Size and Share Forecast Outlook 2025 to 2035

Vacuum Truck Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA