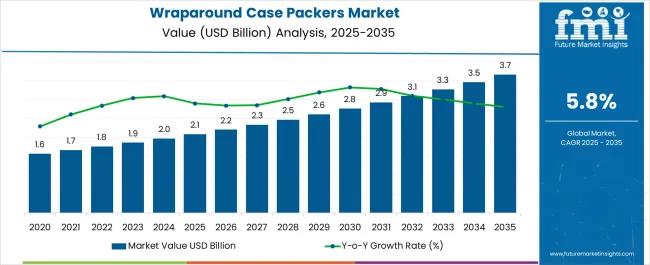

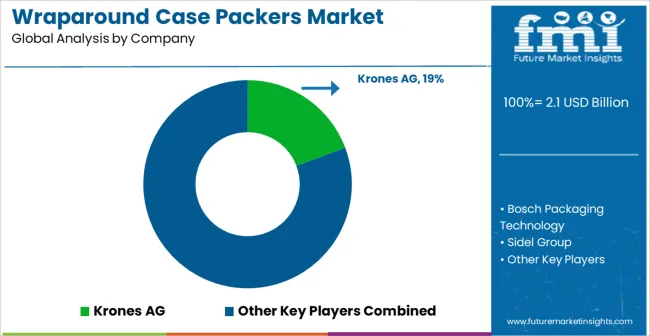

The Wraparound Case Packers Market is estimated to be valued at USD 2.1 billion in 2025 and is projected to reach USD 3.7 billion by 2035, registering a compound annual growth rate (CAGR) of 5.8% over the forecast period.

| Metric | Value |

|---|---|

| Wraparound Case Packers Market Estimated Value in (2025 E) | USD 2.1 billion |

| Wraparound Case Packers Market Forecast Value in (2035 F) | USD 3.7 billion |

| Forecast CAGR (2025 to 2035) | 5.8% |

The Wraparound Case Packers market is witnessing robust growth as industries increasingly demand efficient, reliable, and space-saving secondary packaging solutions. These machines are widely used in food and beverages, personal care, pharmaceuticals, and household goods, where product safety, cost efficiency, and shelf-ready presentation are essential. Demand is being supported by manufacturers seeking automation to enhance productivity, reduce labor costs, and ensure consistent packaging quality.

Advancements in robotics, servo-driven systems, and intelligent controls are further shaping the adoption of wraparound case packers, enabling precise handling of a wide range of products and case sizes. Sustainability trends are also influencing market expansion, as wraparound packaging designs typically require less corrugated material compared to traditional case styles, reducing waste and packaging costs.

The growing need for high-speed, flexible equipment that can be easily integrated into automated production lines is reinforcing adoption across large-scale operations As consumer product companies continue to scale operations and expand product portfolios, the Wraparound Case Packers market is expected to maintain steady growth, with innovation and customization driving competitiveness and adoption worldwide.

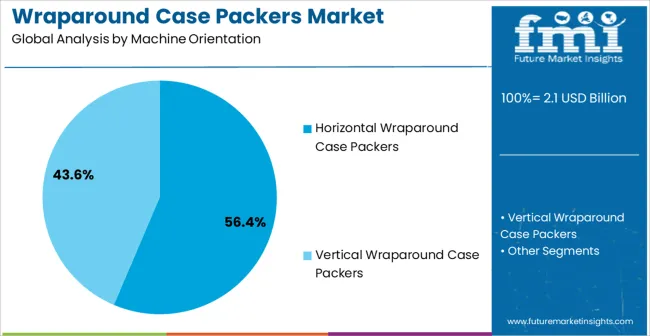

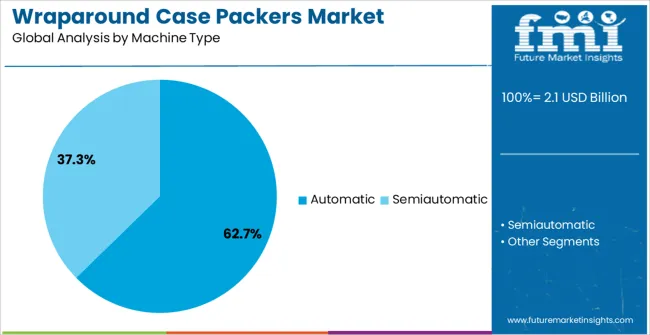

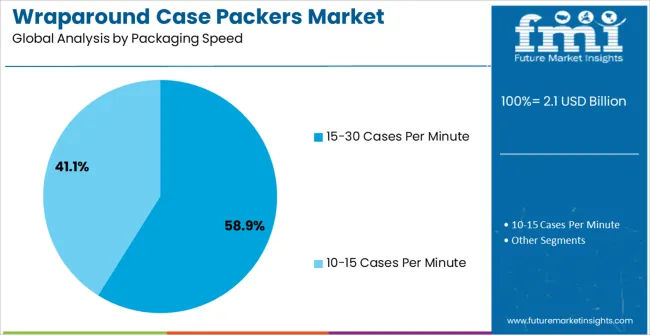

The wraparound case packers market is segmented by machine orientation, machine type, packaging speed, and geographic regions. By machine orientation, wraparound case packers market is divided into Horizontal Wraparound Case Packers and Vertical Wraparound Case Packers. In terms of machine type, wraparound case packers market is classified into Automatic and Semiautomatic. Based on packaging speed, wraparound case packers market is segmented into 15-30 Cases Per Minute and 10-15 Cases Per Minute. Regionally, the wraparound case packers industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The horizontal wraparound case packers orientation segment is projected to hold 56.4% of the market revenue in 2025, making it the dominant orientation type. This strong share is being driven by the versatility and efficiency of horizontal configurations in handling a wide variety of product types and packaging formats. Horizontal machines are widely adopted across food and beverage, consumer goods, and household product industries due to their ability to streamline operations while delivering consistent case quality.

Their design allows for improved product stability, uniform case loading, and adaptability to packaging line layouts, making them a preferred choice for high-volume manufacturers. The ability to integrate with robotic pick-and-place systems and advanced control mechanisms enhances flexibility and production throughput.

Additionally, horizontal wraparound case packers are recognized for their space efficiency, which is a critical factor in modern production facilities As industries continue to demand scalable, cost-effective, and durable packaging solutions, horizontal wraparound case packers are expected to sustain their leadership position, supported by innovation in automation and improved system integration capabilities.

The automatic machine type segment is anticipated to account for 62.7% of the market revenue in 2025, making it the leading machine type. This dominance is being fueled by the rapid adoption of automated systems across industries seeking to improve operational efficiency and reduce reliance on manual labor. Automatic wraparound case packers are widely preferred for their ability to deliver consistent performance, faster packaging speeds, and minimal error rates.

Integration of smart sensors, servo motors, and advanced software controls has significantly enhanced the performance and flexibility of automatic machines. These systems enable quick changeovers, remote diagnostics, and adaptive control, aligning with manufacturers’ need for efficiency in high-volume environments. The automatic segment also benefits from cost savings over time due to reduced downtime, optimized material usage, and lower operational errors.

Growing emphasis on smart factories and Industry 4.0 is further driving investment in automation, making automatic wraparound case packers a critical element of advanced packaging lines As manufacturers continue to prioritize speed, precision, and scalability, automatic machines are expected to retain their leadership role in the market.

The 15–30 cases per minute packaging speed segment is expected to capture 58.9% of the market revenue in 2025, positioning it as the leading speed category. This growth is being driven by its suitability for medium to large-scale operations where a balance between speed, efficiency, and flexibility is essential. Machines within this speed range offer manufacturers the advantage of handling significant throughput while maintaining consistent packaging quality.

The ability to adapt to varying product dimensions and packaging requirements makes this segment particularly attractive for industries with diverse product portfolios, including beverages, household items, and personal care goods. Additionally, machines in this speed category offer cost-effectiveness compared to higher-speed alternatives, making them a preferred choice for mid-sized enterprises and expanding production facilities.

Advancements in control systems and modular machine designs are enhancing reliability and ease of maintenance, further driving adoption As companies focus on optimizing packaging line efficiency without incurring excessive costs, the 15–30 cases per minute category is expected to remain the most sought-after speed segment in the wraparound case packers market.

Rising Establishment of Manufacturing and Industrial units will boost the demand for wraparound case packers in APEJ

Over the past ten years, more machinery for packing has been used. Standard RSCs (Regular Slotted Cartons) are no longer used because wraparound case packers are known to save considerable amounts of money. Despite utilizing pre-made boxes, wraparound case packers drape a die-cut cardboard layer around the items.

RSCs feature flaps that overlap one another on all four sides. In RSCs, the case is typically bigger than what is required to fit the product. Wraparound case packers provide tighter wraparound cases with reduced material use since it is not required to load and put assembly within the case during packaging.

The wraparound case packer is capable of handling wraparound harness-type case blanks, tray blanks, and case blanks. These packers provide strong packing boxes with exceptional stacking and distributing strength while significantly reducing corrugated overlap. Whenever corrugated packaging is used, the cardboard is cut and folded. By minimizing unnecessary overlaps, this wrapping uses less material than a typical RSC.

All of these characteristics are anticipated to increase manufacturers' preference for wraparound case packers throughout the projection period. Additionally, wraparound case packers can be modified to a customer's specifications.

There are wraparound case packers that can pack cases at a speed of almost 10 to 30 cases every minute. To meet a variety of needs, wraparound case packers are available as both vertical and horizontal machines.

The global market for wraparound case packers is anticipated to expand due to expanding industrial and commercial sectors. Additionally, the wraparound case packer reduces the amount of material required to build cases, in contrast to typical slotted containers.

This factor is anticipated to grow the market for wraparound case packers throughout the forecasted time frame. The popularity of wraparound case packers has surged since they are a quicker and more efficient packing method in production units than RSCs. The cost may restrict the growth of the worldwide wraparound case packers market during the forecast period.

Over the projection period, the APEJ region is anticipated to lead the demand for wraparound case packers as a result of increasing industrial and manufacturing facilities in countries like India and China. The market for machines, particularly in China, is expanding quickly as a result of increased manufacturer rivalry, which will accelerate the market growth of wraparound case packers.

The use of packaging machinery has increased over the past decade. Nowadays wraparound case packers are used in place of regular RSCs (Regular Slotted Cartons), as they are known to result in significant cost savings. In wraparound case packers, a die cut cardboard sheet is folded around the products despite using pre made cartons.

RSCs have flaps on all sides that overlap each other. In RSCs, case is generally larger in size than what is needed to accommodate the product. In wraparound case packers, it is not necessary to place and load assemblies inside the case during process of packaging, which results in tighter wraparound case that leads to less material usage for the formation of cases.

Wraparound case packer is capable of handling the wraparound tray blank, harness style case blank, and case blank. All these features are expected to increase preference for wraparound case packers, among manufacturers, over the forecast period. In addition, wraparound case packers are customizable according to the requirement of customer.

It provides higher operational speed and minimal clearance between case and products. Wraparound case packers come with speed of up to 10 cases per minute to 30 cases per minute. Wraparound case packers are available in horizontal and vertical machine types to meet various industrial demands. Therefore, the market outlook for wraparound case packers are likely to remain largely positive, over the forecast period.

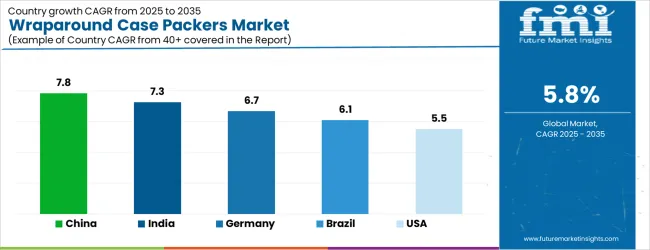

| Country | CAGR |

|---|---|

| China | 7.8% |

| India | 7.3% |

| Germany | 6.7% |

| Brazil | 6.1% |

| USA | 5.5% |

| UK | 4.9% |

| Japan | 4.4% |

The Wraparound Case Packers Market is expected to register a CAGR of 5.8% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 7.8%, followed by India at 7.3%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 4.4%, yet still underscores a broadly positive trajectory for the global Wraparound Case Packers Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 6.7%. The USA Wraparound Case Packers Market is estimated to be valued at USD 762.2 million in 2025 and is anticipated to reach a valuation of USD 762.2 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 97.1 million and USD 70.8 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 2.1 Billion |

| Machine Orientation | Horizontal Wraparound Case Packers and Vertical Wraparound Case Packers |

| Machine Type | Automatic and Semiautomatic |

| Packaging Speed | 15-30 Cases Per Minute and 10-15 Cases Per Minute |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Krones AG, Bosch Packaging Technology, Sidel Group, Douglas Machine Inc., Bradman Lake Group, Massman Automation Designs, LLC, PMI Cartoning, Inc., JLS Automation, Delkor Systems, Inc., Standard-Knapp, Inc., Aetna Group (Robopac), Marchesini Group S.p.A., Cama Group, and Tetra Pak International S.A. |

The global wraparound case packers market is estimated to be valued at USD 2.1 billion in 2025.

The market size for the wraparound case packers market is projected to reach USD 3.7 billion by 2035.

The wraparound case packers market is expected to grow at a 5.8% CAGR between 2025 and 2035.

The key product types in wraparound case packers market are horizontal wraparound case packers and vertical wraparound case packers.

In terms of machine type, automatic segment to command 62.7% share in the wraparound case packers market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Case and Box Handling Robots Market Size and Share Forecast Outlook 2025 to 2035

Case Management Software (CMS) Market Size and Share Forecast Outlook 2025 to 2035

Casein Market Analysis - Size, Share, and Forecast 2025 to 2035

Case Coders Market Size and Share Forecast Outlook 2025 to 2035

Case Closures and Sealers Market Analysis - Size and Share Forecast Outlook 2025 to 2035

Case Material Market Size and Share Forecast Outlook 2025 to 2035

Casein Hydrolysate Market Size, Growth, and Forecast for 2025 to 2035

Case Erectors Market by Automation Type from 2025 to 2035

Case Packing Machines Market from 2025 to 2035

Casein Peptone Market Report – Growth & Industry Trends 2025 to 2035

Competitive Breakdown of Case Erectors Providers

Market Share Breakdown of Case Coders Industry

Leading Providers & Market Share in Case Material Industry

Casein Glycomacropeptide Market

Slipcases Market Size and Share Forecast Outlook 2025 to 2035

Crank Case Ventilation Valve Market Size and Share Forecast Outlook 2025 to 2035

Watch Case Market Trends & Growth Forecast 2024-2034

Sodium Caseinate Market Size and Share Forecast Outlook 2025 to 2035

Mobile cases and covers market Size, Share & Forecast 2025 to 2035

Bakery Cases Market Analysis – Trends, Growth & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA