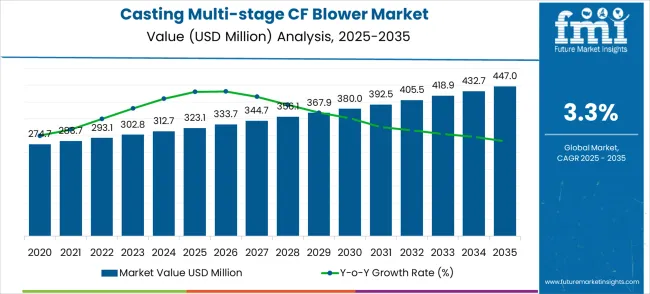

The global casting multi-stage centrifugal blower market is projected to grow from USD 323.1 million in 2025 to approximately USD 447 million by 2035, recording an absolute increase of USD 123.9 million over the forecast period. This translates into a total growth of 38.3%, with the market forecast to expand at a CAGR of 3.3% between 2025 and 2035. The overall market size is expected to grow by nearly 1.38X during the same period, supported by increasing industrial automation and growing demand for energy-efficient blower systems across various industrial applications.

Between 2025 and 2030, the casting multi-stage centrifugal blower market is projected to expand from USD 323.1 million to USD 378.5 million, resulting in a value increase of USD 55.4 million, which represents 44.7% of the total forecast growth for the decade. This phase of growth will be shaped by rising industrial automation across manufacturing sectors, increasing demand for energy-efficient ventilation systems, and growing adoption of advanced blower technologies in wastewater treatment facilities. Industrial manufacturers are investing in high-performance blower systems to improve operational efficiency and reduce energy consumption.

From 2030 to 2035, the market is forecast to grow from USD 378.5 million to USD 447.0 million, adding another USD 68.5 million, which constitutes 55.3% of the overall ten-year expansion. This period is expected to be characterized by the expansion of mining operations in developing countries, the integration of smart monitoring technologies in blower systems, and the development of specialized blower configurations for chemical processing applications. The growing focus on environmentally self-sufficient solutions will drive demand for oil-free and energy-efficient centrifugal blower solutions across multiple industrial sectors.

Between 2020 and 2025, the casting multi-stage centrifugal blower market experienced steady expansion, driven by increasing industrialization in emerging economies and growing awareness of energy-efficient blower technologies. The market developed as industrial facilities recognized the need for reliable and durable blower systems to support critical manufacturing processes. Environmental regulations and energy efficiency mandates began influencing procurement decisions toward advanced centrifugal blower technologies.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 323.1 million |

| Market Forecast Value (2035) | USD 447 million |

| Forecast CAGR (2025–2035) | 3.3% |

The casting multi-stage centrifugal blower market has been recognized as a crucial segment within industrial airflow and ventilation systems, providing efficient and reliable air movement for diverse applications. Within the industrial blower market, this segment accounts for nearly 12.1% share, reflecting its preference in high-pressure, multi-stage operations. In the HVAC equipment market, the contribution is around 10.4%, driven by demand for controlled airflow in large-scale heating, ventilation, and cooling systems. The manufacturing equipment market records approximately 11.3% share, as these blowers support production lines requiring precise air handling and material movement. Within process industries, the share is about 9.7%, with applications in chemical, pharmaceutical, and food processing where controlled airflow is critical. The air handling systems market contributes 8.9%, highlighting the role of multi-stage centrifugal blowers in ensuring operational efficiency and reliability. Combined, these parent markets amount to 52.4%, underlining the significant position of casting multi-stage centrifugal blowers across interrelated industrial segments. The market has been regarded as instrumental in enhancing process performance, reducing energy losses, and supporting complex industrial operations where air management is a key factor.

Market expansion is being supported by the rapid industrialization across developing economies and the corresponding need for reliable ventilation and material handling systems in manufacturing facilities. Modern industrial operations require precise airflow control and pressure management to ensure optimal production conditions and worker safety. The superior durability and performance characteristics of casting multi-stage centrifugal blowers make them essential components in demanding industrial environments where continuous operation is critical.

The growing emphasis on energy efficiency and environmental compliance is driving demand for advanced blower technologies from certified manufacturers with proven track records of reliability and performance. Industrial operators are increasingly investing in high-quality blower systems that offer lower operational costs and reduced maintenance requirements over extended service periods. Regulatory requirements and industry standards are establishing performance benchmarks that favor precision-engineered centrifugal blower solutions with advanced control capabilities.

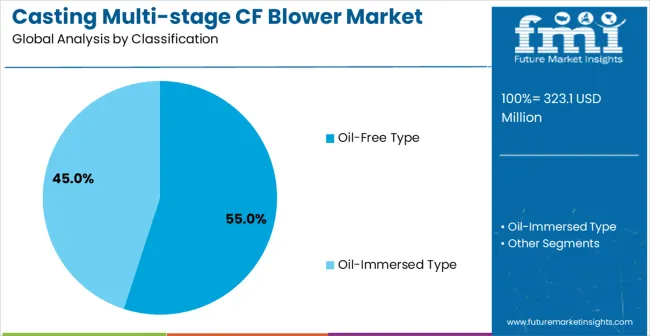

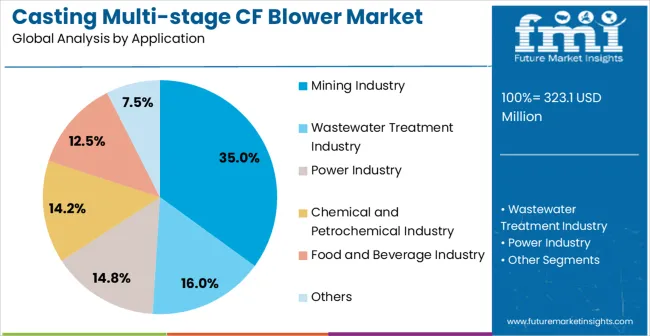

The market is segmented by product type, application, and region. By compressor type, the market is divided into oil-free type and oil-immersed type configurations. Based on application, the market is categorized into mining industry, wastewater treatment industry, power industry, chemical and petrochemical industry, food and beverage industry, and others. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

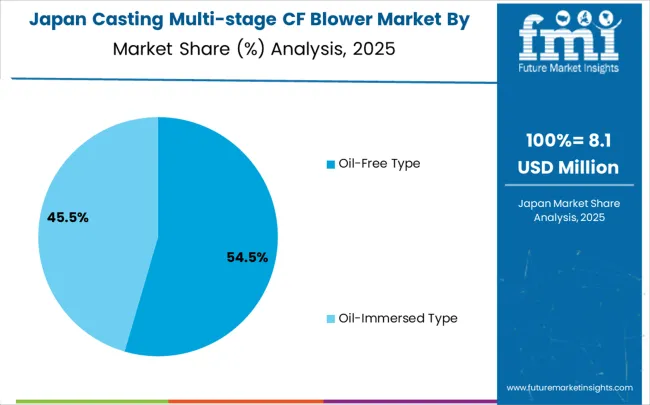

Oil-free type configurations are projected to account for 55% of the casting multi-stage centrifugal blower market in 2025. This leading share is supported by the increasing demand for contamination-free airflow in sensitive industrial applications and growing environmental regulations requiring clean air handling systems. Oil-free blowers provide superior air quality and eliminate the risk of oil contamination in critical processes, making them the preferred choice for food processing, pharmaceutical manufacturing, and clean room applications. The segment benefits from technological advancements that have improved the reliability and efficiency of oil-free bearing systems while reducing maintenance requirements.

Modern oil-free centrifugal blowers incorporate advanced magnetic bearings, air bearings, and sophisticated sealing technologies that eliminate the need for traditional oil lubrication systems. These innovations have significantly improved operational efficiency while reducing total cost of ownership through lower maintenance intervals and elimination of oil replacement costs. The pharmaceutical and biotechnology sectors particularly drive demand for oil-free solutions, as these industries require absolute air purity to maintain product integrity and comply with stringent regulatory standards.

The food and beverage industry increasingly adopts oil-free blowers to prevent contamination risks and meet international food safety certifications. Environmental consciousness and conscious initiatives further accelerate market adoption, as oil-free systems eliminate oil disposal requirements and reduce environmental impact.

Mining industry applications are expected to represent 35% of casting multi-stage centrifugal blower demand in 2025. This dominant share reflects the critical role of ventilation systems in underground mining operations and the need for robust blower equipment capable of operating in harsh environmental conditions. Mining facilities require powerful and reliable blowers for air circulation, dust control, and material pneumatic conveying systems. The segment benefits from ongoing expansion of mining operations in developing countries and increasing safety regulations requiring enhanced ventilation systems in mining facilities.

Underground mining operations demand exceptional blower performance to ensure adequate air circulation for worker safety and operational efficiency. These applications require blowers capable of handling high static pressures, corrosive environments, and continuous operation in extreme temperature conditions. The growing emphasis on mining safety regulations, particularly in coal mines and metal extraction facilities, drives consistent demand for high-performance ventilation equipment. Emerging markets in Africa, South America, and Asia-Pacific regions contribute significantly to market growth as mining companies invest in modern equipment to improve operational safety and efficiency.

The trend toward automation and digitization in mining operations creates opportunities for smart blower systems equipped with monitoring capabilities and predictive maintenance features. The segment also benefits from increasing copper, lithium, and rare earth metal mining activities driven by renewable energy infrastructure development.

The casting multi-stage centrifugal blower market is advancing steadily due to increasing industrial automation and growing recognition of energy-efficient blower system importance. However, the market faces challenges including high initial equipment costs, need for specialized maintenance expertise, and varying performance requirements across different industrial applications. Standardization efforts and certification programs continue to influence equipment quality and market development patterns.

The growing deployment of IoT-enabled monitoring systems and digital control interfaces is enabling real-time performance optimization and predictive maintenance capabilities in centrifugal blower installations. Smart sensors and automated control systems provide continuous monitoring of operating parameters while optimizing energy consumption and extending equipment service life. These technologies are particularly valuable for large industrial facilities that require reliable blower performance and minimal unplanned downtime.

Modern blower manufacturers are incorporating advanced design technologies and materials that improve energy efficiency while reducing environmental impact through lower emissions and noise levels. Integration of variable frequency drives and advanced impeller designs enables precise flow control and significant energy savings compared to traditional fixed-speed systems. Advanced materials and manufacturing techniques also support development of more durable and corrosion-resistant blower components for demanding industrial environments.

| Country | CAGR (2025–2035) |

|---|---|

| China | 4.5% |

| India | 4.1% |

| Germany | 3.8% |

| Brazil | 3.5% |

| United States | 3.1% |

| United Kingdom | 2.8% |

| Japan | 2.5% |

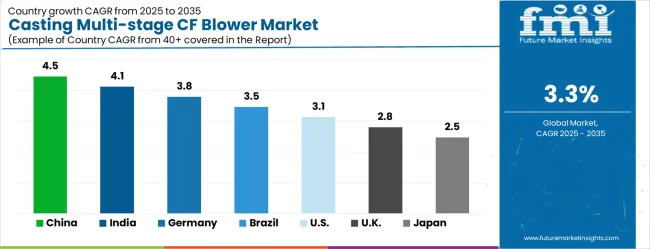

The casting multi-stage centrifugal blower market is growing rapidly, with China leading at a 4.5% CAGR through 2035, driven by massive industrial expansion, infrastructure development, and manufacturing sector growth. India follows at 4.1%, supported by rising industrialization in mining and chemical sectors and increasing investments in wastewater treatment facilities. Germany records strong growth at 3.8%, emphasizing precision engineering, quality standards, and advanced manufacturing capabilities. Brazil grows steadily at 3.5%, integrating blower systems into expanding mining operations and industrial facilities. The United States shows moderate growth at 3.1%, focusing on equipment upgrades and energy efficiency improvements. The United Kingdom maintains steady expansion at 2.8%, supported by industrial modernization programs. Japan demonstrates stable growth at 2.5%, emphasizing technological innovation and manufacturing excellence. The report covers an in-depth analysis of 40+ countries; seven top-performing countries are highlighted below.

The casting multi-stage centrifugal blower market in China is growing at a CAGR of 4.5%, driven by rapid industrialization and increasing adoption in chemical, power generation, and manufacturing sectors. Demand for energy-efficient and reliable ventilation solutions in industrial plants and infrastructure projects supports market expansion. Chinese manufacturers are investing in optimizing blower design, improving airflow efficiency, and extending operational life. The country’s focus on enhancing industrial productivity, coupled with government initiatives in energy-efficient manufacturing, continues to fuel the adoption of multi-stage centrifugal blowers in various industrial applications.

The casting multi-stage centrifugal blower market in India is projected to grow at a CAGR of 4.1%, supported by expanding industrial facilities, power plants, and chemical processing units. Indian industries are increasingly adopting multi-stage centrifugal blowers to improve air circulation, process efficiency, and operational reliability. Investments in modern manufacturing practices and energy-efficient solutions further contribute to market growth. The rising demand for industrial ventilation and the government’s focus on enhancing energy productivity are driving the adoption of advanced centrifugal blower systems in India.

The casting multi-stage centrifugal blower market in Germany is growing at a CAGR of 3.8%, driven by demand from the country’s manufacturing, chemical, and energy sectors. German industries focus on integrating high-performance, reliable, and energy-efficient blower solutions to optimize operations and reduce operational costs. Investments in industrial automation, airflow management, and conscious production practices further support the adoption of centrifugal blowers. Germany’s strong industrial base and emphasis on quality and precision engineering continue to contribute to the steady growth of the market.

The casting multi-stage centrifugal blower market in Brazil is projected to grow at a CAGR of 3.5%, driven by the expansion of industrial sectors such as manufacturing, chemical processing, and energy generation. Brazil’s focus on improving operational efficiency and energy management in industrial plants fuels the adoption of multi-stage centrifugal blowers. Investments in modern industrial systems, enhanced ventilation solutions, and industrial infrastructure development further support market growth. The country’s emphasis on industrial modernization and increased production capacity contributes to the steady demand for centrifugal blowers.

The casting multi-stage centrifugal blower market in the United States is expanding at a CAGR of 3.1%, with demand driven by manufacturing, chemical, and power generation industries. USA companies are increasingly implementing multi-stage centrifugal blowers to improve airflow efficiency, reliability, and industrial productivity. Investments in energy-efficient and conscious manufacturing solutions, coupled with the adoption of advanced industrial systems, continue to drive market growth. The USA market focuses on performance optimization and operational longevity, ensuring steady adoption across industrial applications

Manufacturing and power generation industries drive blower demand in the USA

The casting multi-stage centrifugal blower market in the United Kingdom is growing at a CAGR of 2.8%, supported by industrial ventilation demand in manufacturing, chemical, and energy sectors. UK industries are adopting multi-stage centrifugal blowers to improve air handling efficiency, process reliability, and operational sustainability. Investments in modern manufacturing infrastructure and industrial optimization projects further contribute to market growth. The country’s emphasis on industrial modernization and performance standards continues to support steady adoption of centrifugal blower solutions.

The casting multi-stage centrifugal blower market in Japan is expanding at a CAGR of 2.5%, with adoption driven by manufacturing, chemical processing, and energy sectors. Japanese industries prioritize operational efficiency, reliability, and energy management, contributing to the demand for high-performance multi-stage centrifugal blowers. Investments in modern industrial systems, airflow optimization, and conscious production practices further support market growth. Although growth is slower compared to emerging markets, Japan’s emphasis on precision engineering and industrial optimization ensures continued adoption of centrifugal blower solutions.

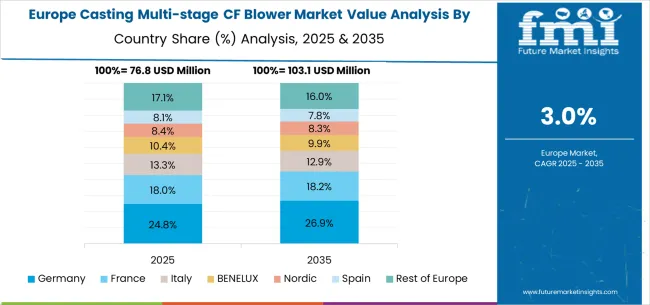

The casting multi-stage centrifugal blower market in Europe is projected to grow from USD 87.2 million in 2025 to USD 118.6 million by 2035, registering a CAGR of 3.1% over the forecast period. Germany is expected to maintain its leadership with a 28.5% share in 2025, supported by its strong manufacturing base and advanced industrial infrastructure. The United Kingdom follows with 18.2% market share, driven by ongoing industrial modernization and wastewater treatment facility upgrades. France holds 15.8% of the European market, benefiting from chemical industry expansion and power generation investments. Italy and Spain collectively represent 22.1% of regional demand, with growing focus on mining and food processing applications. The Rest of Europe region accounts for 15.4% of the market, supported by industrial development in Eastern European countries and Nordic manufacturing sectors.

The casting multi-stage centrifugal blower market is defined by competition among established industrial equipment manufacturers, specialized blower companies, and regional engineering firms. Companies are investing in advanced manufacturing technologies, product innovation, standardized quality systems, and technical support capabilities to deliver reliable, efficient, and cost-effective blower solutions. Strategic partnerships, technological advancement, and geographic expansion are central to strengthening product portfolios and market presence.

Continental Industrie, operating globally, offers comprehensive centrifugal blower solutions with focus on precision engineering, reliability, and technical support services. Atlas Copco, multinational, provides advanced blower systems with emphasis on energy efficiency and digital integration capabilities. Mooers Products, USA-based, delivers specialized blower solutions for industrial applications with focus on performance and durability. Gardner Denver offers comprehensive blower technologies with standardized procedures and global service support.

Air Control Industries provides industrial blower systems with emphasis on custom solutions and technical expertise. Spencer Turbine delivers specialized centrifugal blower equipment with focus on high-performance applications. Hibon offers comprehensive blower solutions for demanding industrial environments. Howden provides advanced blower systems with global manufacturing and service capabilities.

Shree Udyog, Hoffman & Lamson, Lone Star, Everest Blowers, Universal Blower Pac, DOMEL D.O.O., Elmo Rietschle, MAPRO International, Shandong Dacheng Machinery Technology, Atlantic Blowers, ZHANG GU, Greatall, and SONGJIANGGROUP offer specialized blower expertise, regional manufacturing capabilities, and technical support across global and regional networks.

The casting multi-stage centrifugal blower market underpins industrial automation, mining safety, wastewater treatment efficiency, and conscious production. With energy-efficiency mandates, stricter environmental compliance, and demand for contamination-free airflow, the sector must balance cost competitiveness, performance reliability, and digital integration. Coordinated contributions from governments, industry bodies, OEMs/technology integrators, suppliers, and investors will accelerate the transition toward energy-smart, digitally monitored, and environmentally compliant blower systems.

| Item | Value |

|---|---|

| Quantitative Units | USD 323.1 million |

| Classification Type | Oil-Free Type, Oil-Immersed Type |

| Application | Mining Industry, Wastewater Treatment Industry, Power Industry, Chemical and Petrochemical Industry, Food and Beverage Industry, Others |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Germany, India, China, United Kingdom, Japan, Brazil, and other 40+ countries |

| Key Companies Profiled | Continental Industrie, Atlas Copco, Mooers Products, Gardner Denver, Air Control Industries, Spencer Turbine, Hibon, Howden, Shree Udyog, Hoffman & Lamson, Lone Star, Everest Blowers Pvt Ltd, Universal Blower Pac, DOMEL D.O.O., Elmo Rietschle, MAPRO International S.p.A., Shandong Dacheng Machinery Technology, Atlantic Blowers, ZHANG GU, Greatall, SONGJIANGGROUP |

| Additional Attributes | Dollar sales by classification type and application, regional demand trends across North America, Europe, and Asia-Pacific, competitive landscape with established manufacturers and emerging suppliers, buyer preferences for energy-efficient versus conventional systems, integration with digital monitoring and control technologies, innovations in materials and manufacturing processes for enhanced durability and performance, and adoption of smart blower solutions with embedded sensors and remote monitoring capabilities for improved operational efficiency. |

The global casting multi-stage centrifugal blower market is estimated to be valued at USD 323.1 million in 2025.

The market size for the casting multi-stage centrifugal blower market is projected to reach USD 447.0 million by 2035.

The casting multi-stage centrifugal blower market is expected to grow at a 3.3% CAGR between 2025 and 2035.

The key product types in casting multi-stage centrifugal blower market are oil-free type and oil-immersed type.

In terms of application, mining industry segment to command 35.0% share in the casting multi-stage centrifugal blower market in 2025.

Explore Similar Insights

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA