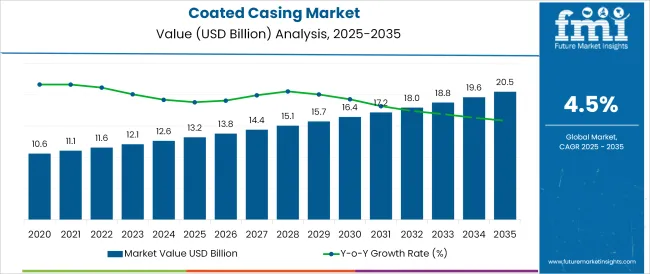

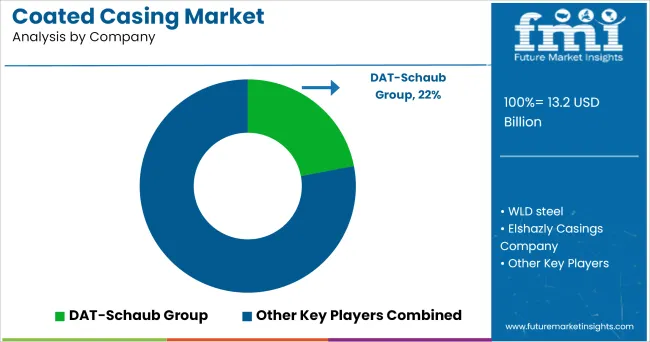

The Coated Casing Market is estimated to be valued at USD 13.2 billion in 2025 and is projected to reach USD 20.5 billion by 2035, registering a compound annual growth rate (CAGR) of 4.5% over the forecast period.

The coated casing market is witnessing sustained growth as industries prioritize durability, operational efficiency, and compliance with stringent environmental and safety standards. Adoption has been accelerated by rising demand for corrosion-resistant solutions in critical infrastructure, energy, and manufacturing applications.

Companies are increasingly integrating coated casings into their operations to minimize maintenance costs and extend service life under harsh environmental conditions. Technological advancements in coating materials and application methods are enhancing performance attributes such as wear resistance, thermal stability, and chemical resilience.

Future growth is expected to be driven by regulatory mandates promoting sustainable construction and energy efficiency, alongside ongoing investments in industrial modernization and infrastructure expansion. These drivers, coupled with innovations in eco-friendly coatings and automated application technologies, are paving the way for greater market penetration and long-term relevance.

The market is segmented by Method, Type, Material Type, and Application and region. By Method, the market is divided into Artificial Casing and Traditional Casing. In terms of Type, the market is classified into Production casing, Surface casing, Intermediate casing, and Drilling casing. Based on Material Type, the market is segmented into Coated Steel, Painted Steel, Real parchment, Protein coated woven fabric, Hardened protein, Woven fabric, and Plastic coated woven fabric.

By Application, the market is divided into Oil and Gas Industries, Food and Beverage, Chemical Industries, Cosmetic Industries, Maritime industries, and Others. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

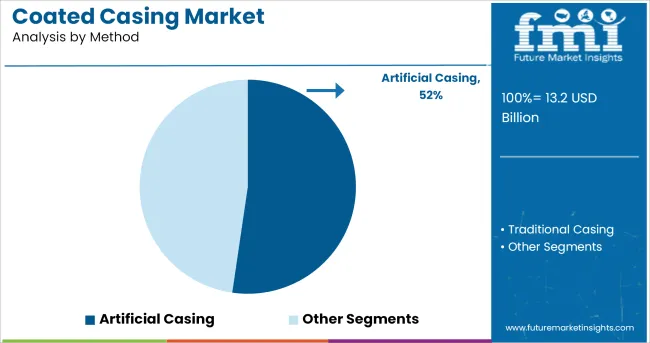

When segmented by method, artificial casing is projected to account for 52.3% of the market revenue in 2025, making it the leading method segment. This dominance is attributed to its superior uniformity, customizable properties, and scalability compared to natural alternatives.

Artificial casings have been preferred for their ability to deliver consistent performance across large-scale operations, particularly in environments where precise specifications and reliability are critical. Manufacturing processes have evolved to support higher throughput and tighter quality control, reinforcing the segment’s appeal among industrial users.

Enhanced resistance to environmental factors and lower susceptibility to defects have also supported the shift toward artificial casings. Furthermore, the ability to tailor coatings and substrates to specific operational needs has strengthened their position as the method of choice in high-demand applications.

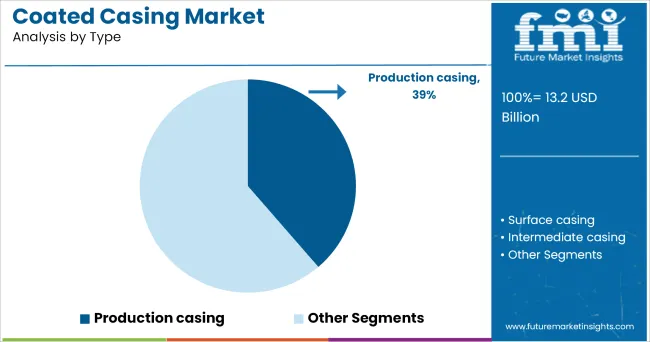

In terms of type, production casing is expected to hold 38.7% of the market revenue in 2025, establishing itself as the leading type segment. This leadership has been supported by its indispensable role in safeguarding wellbore integrity and ensuring operational safety in energy extraction and industrial drilling operations.

The segment has benefited from ongoing investments in energy projects and the growing emphasis on reducing downtime through enhanced reliability. Coated production casings have been increasingly adopted due to their ability to withstand corrosive and abrasive conditions while maintaining structural integrity.

Improvements in coating technologies have further increased their longevity and performance, minimizing maintenance requirements and operational risks. The critical nature of production casing in maintaining process efficiency and complying with safety regulations has solidified its dominant market position.

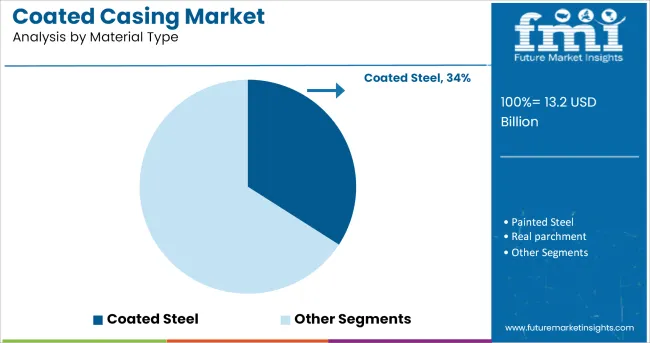

When segmented by material type, coated steel is anticipated to capture 34.1% of the market revenue in 2025, positioning it as the leading material segment. This prominence is reinforced by the material’s inherent strength, cost-effectiveness, and adaptability to diverse industrial needs.

Coated steel has been increasingly favored for its ability to deliver superior protection against corrosion, mechanical wear, and chemical exposure while retaining high load-bearing capacity. Advances in coating formulations and application techniques have enhanced its durability and performance, making it a reliable choice for demanding environments.

The availability of various coating options tailored to specific operational requirements has further expanded its adoption. Additionally, the balance of affordability, recyclability, and robust performance has positioned coated steel as the preferred material type across multiple sectors, supporting its continued dominance in the market.

The coated casing is the technique used to increase the bonding between the two matters. This technology is massively utilized in food & beverage industry to maintain the flavours of preserved foods as well as in electronic industries to protect the items from damage.

The increase in the population is elevating the dependence of people on various goods resulting to increase the demand for product as rising cost of the economic balance in the lifestyle of people changes.

Coated casing increases the shelf life of products such as pipeline and other electronic goods by preventing them from corrosion while the utilization in the food and beverage industries is done to maintain the taste and flavours.

The increasing usability of products due to rapid swelling prices of various commodities has propelled the manufacturers to come with various innovative ideas to make the coated casing material have a longer life.

Demand would undoubtedly be accelerated by expected developments in end-use industries, resulting in rapid penetration. The market is expected to open up vast potential opportunities as a result of the aforementioned primary features.

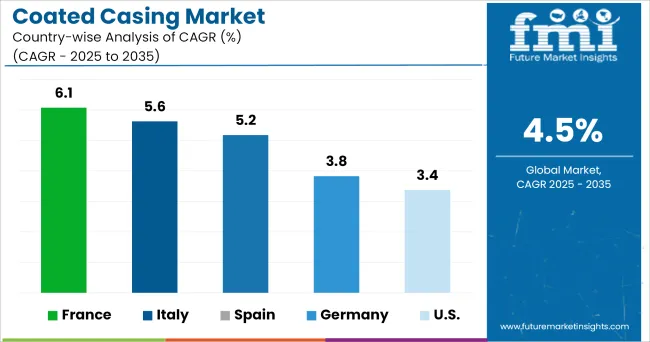

In the report of “Global Coated Casing Market,” the prominent region included are North America, Latin America, Europe, South Asia & Oceania and the Middle East and Africa.

Europe is the leading player in the industry due to the high demand for sausages in the region. Germany is the foremost consumer of meat sausages. According to the Federal Ministry of Food and Agriculture, there in total per capita consumption of meat includes 57.3% of pork which needs to be transformed into sausages, as a result, increasing the demand for coating.

Following Europe is East Asia and North America due to rising in the construction facility and being the major industrialized region. The USA in North America is the major industrialized country as 26% of the population is directly or indirectly involved in manufacturing activities.

While in East Asia there is a high demand for meat and meat products also the country is the foremost exporter of various animal goods which has directly boosted the dependency on the coated casing.

South Asia and the Middle East and Asia are expected to gain the market share due to the robust spending on development and raising the economic level of the country.

During the projected period, Latin America is expected to grow at a slow pace and account for a tiny portion of the global market.

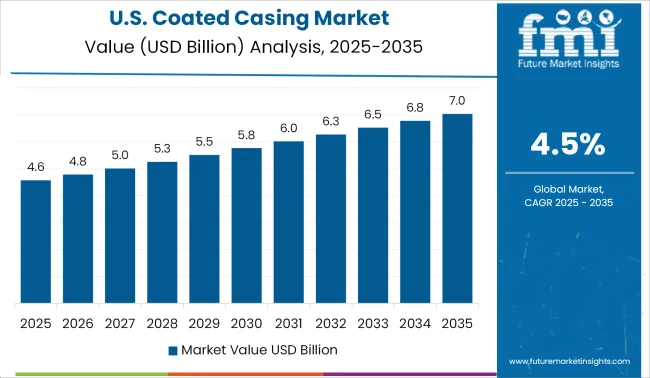

USA and China are the developed countries having elevated standards of living and higher disposable income because of expanding meat consumption and spending trends, the coated casing industry in the United States and China is likely to grow.

China is the global leader in the production of chemicals so the demand for the coated casing is high in the region for the prevention of pipelines from corrosion and get purified chemicals without impurities.

The prominent players of coated casing are

Some of the leading supplier for the market are

There are lot of players in the market. Players are aggressively pursuing a substantial portion of the market, utilising both organic and inorganic expansion strategies. Alliances, acquisitions, and a steady expansion of their global internet sales and distribution network were the main goals.

The global coated casing market is estimated to be valued at USD 13.2 billion in 2025.

The market size for the coated casing market is projected to reach USD 20.5 billion by 2035.

The coated casing market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in coated casing market are artificial casing and traditional casing.

In terms of type, production casing segment to command 38.7% share in the coated casing market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Spice Coated Casing Market Analysis - Size, Share & Forecast 2025 to 2035

Demand for Spice Coated Casing in EU Size and Share Forecast Outlook 2025 to 2035

Coated Label Market Size and Share Forecast Outlook 2025 to 2035

Coated Fabrics Market Size and Share Forecast Outlook 2025 to 2035

coated-paper-packaging-box-market-market-value-analysis

Coated Recycled Boxboard Market Size and Share Forecast Outlook 2025 to 2035

Coated Recycled Paperboard Market Size and Share Forecast Outlook 2025 to 2035

Coated Fabrics for Defense Market 2025 to 2035

Market Share Breakdown of Coated Recycled Boxboard Manufacturers

Competitive Landscape of Coated Recycled Paperboard Providers

Coated White Board Paper Market

Coated Sack Kraft Paper Market

Coated Duplex Board Market

Uncoated Fine Papers Market Size and Share Forecast Outlook 2025 to 2035

Uncoated White Top Testliner Market Size and Share Forecast Outlook 2025 to 2035

Uncoated Fine Paper Market Size and Share Forecast Outlook 2025 to 2035

Uncoated Paper Market Trends- Growth & Industry Outlook 2025 to 2035

AR Coated Film Glass Market Size and Share Forecast Outlook 2025 to 2035

PE Coated Sack Kraft Paper Market Size and Share Forecast Outlook 2025 to 2035

Market Share Insights of PE Coated Sack Kraft Paper Providers

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA