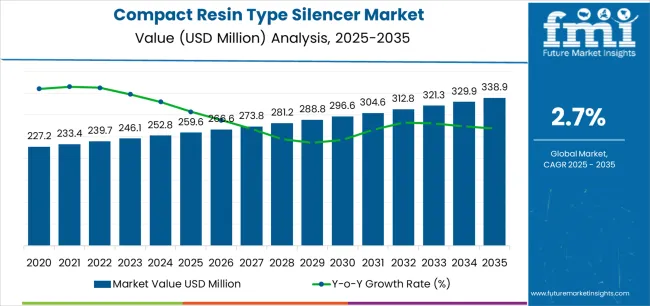

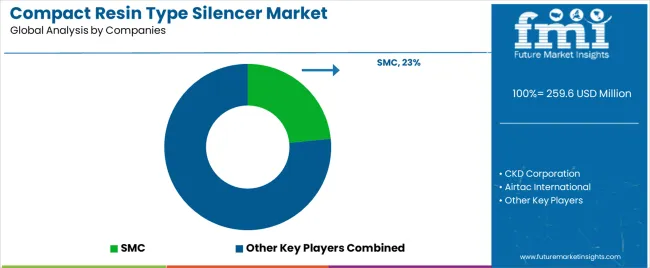

The global compact resin type silencer market is projected to grow from USD 259.6 million in 2025 to approximately USD 338.8 million by 2035, recording an absolute increase of USD 79.2 million over the forecast period. This translates into a total growth of 30.5%, with the market forecast to expand at a CAGR of 2.7% between 2025 and 2035. The overall market size is expected to grow by 1.3X during the same period, supported by expanding industrial automation applications, increasing pneumatic system installations across manufacturing facilities, and growing demand for noise reduction solutions in compressed air systems.

The steady market expansion reflects the essential role of resin-based silencing technology in maintaining operational compliance and worker safety across industrial applications. Manufacturing facilities worldwide are increasingly adopting compact resin type silencers to meet noise regulations while maintaining pneumatic system efficiency, with advanced polymer formulations and precision molding techniques creating enhanced performance characteristics for diverse operating environments including high-temperature applications, corrosive atmospheres, and demanding manufacturing conditions.

Production capabilities are advancing through specialized polymer processing technologies and automated manufacturing systems that enable consistent quality control while reducing production costs. Leading manufacturers are investing in advanced molding equipment and resin compound development to create silencer products that deliver superior noise attenuation, extended service life, and reliable performance under varying pressure conditions. Industrial equipment suppliers and pneumatic system specialists are expanding their compact resin silencer offerings to address specific application requirements across automotive manufacturing, food processing, electronics assembly, and general industrial applications.

Quality standards continue evolving as applications demand higher durability specifications and consistent performance under extreme operating conditions including temperature variations, chemical exposure, and prolonged service cycles. Industry certification programs and testing protocols ensure reliable product performance while supporting market confidence in resin-based silencing technology adoption across critical manufacturing processes and regulated industrial environments. Compliance requirements for industrial noise control and worker safety applications are driving investments in comprehensive quality assurance systems and validation procedures throughout the manufacturing supply chain.

International manufacturing coordination is supporting market development as major industrial projects require standardized silencing solutions across multiple production facilities. Global manufacturing companies are establishing unified specifications for pneumatic noise control that influence worldwide procurement standards and create opportunities for specialized silencer manufacturers. Industrial engineering firms are forming partnerships with pneumatic component suppliers to develop application-specific silencing solutions tailored to emerging automation requirements and industrial equipment specifications.

Investment patterns are shifting toward integrated system solutions as manufacturing facilities seek comprehensive pneumatic noise control systems that combine compact design with advanced material performance and maintenance-friendly characteristics. Industrial companies are implementing standardized silencer specifications across their facilities, while equipment manufacturers are incorporating advanced resin silencer technology into their pneumatic system designs to ensure noise compliance and operational efficiency. This trend toward standardization and performance optimization is reshaping competitive dynamics across the industrial pneumatic components value chain.

Market maturation is evident in the emergence of specialized application segments that demand unique material characteristics and performance specifications. Food processing applications require FDA-approved resin formulations and sanitary design features under strict hygiene requirements, while automotive manufacturing systems need silencers that maintain performance during high-cycle operations and provide consistent noise attenuation in automated assembly environments. These specialized requirements are driving innovation in polymer chemistry, molding technologies, and integration methodologies that extend beyond traditional pneumatic noise control applications.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 259.6 million |

| Market Forecast Value (2035) | USD 338.8 million |

| Forecast CAGR (2025-2035) | 2.7% |

| INDUSTRIAL AUTOMATION EXPANSION | NOISE REGULATION COMPLIANCE | MANUFACTURING EFFICIENCY |

|---|---|---|

| Pneumatic System Growth -- Manufacturing automation requiring specialized silencing solutions for compressed air systems, pneumatic actuators, and robotic applications with enhanced noise control performance for industrial facility compliance and worker safety requirements. | Workplace Safety Standards -- Industrial noise regulations and occupational health requirements driving adoption of effective silencing solutions for pneumatic equipment installations requiring certified noise reduction performance and regulatory compliance documentation. | Production Optimization -- Manufacturing facility improvements implementing pneumatic silencing technology for operational efficiency, reduced maintenance requirements, and enhanced equipment longevity while maintaining productive work environments and quality standards. |

| Automation Technology -- Industrial equipment advancement requiring integrated silencing components for automated manufacturing systems, assembly line operations, and material handling applications with superior noise attenuation and reliability characteristics. | Environmental Compliance -- Industrial facility standards requiring comprehensive noise control solutions for manufacturing operations, equipment installations, and facility expansions with documented performance and certification requirements. | Equipment Integration -- Manufacturing system optimization requiring specialized silencing components for pneumatic equipment, process automation, and facility infrastructure with enhanced performance and standardized specifications. |

| System Integration -- Pneumatic component suppliers implementing comprehensive silencing solutions for industrial automation projects, manufacturing system installations, and equipment upgrades with specialized design characteristics and performance specifications. | Regulatory Requirements -- Industrial safety standards and noise control regulations requiring certified silencing performance for manufacturing facilities, equipment operations, and worker protection with comprehensive compliance documentation and testing validation. | Cost Effectiveness -- Manufacturing cost reduction initiatives requiring durable silencing solutions for pneumatic systems, equipment maintenance optimization, and facility operational efficiency with proven performance and reliability characteristics. |

| Category | Segments / Values |

|---|---|

| By Type | Male Threaded Silencers; Push-in Fitting Silencers; Female Threaded Silencers; Barbed Connection Silencers; Others |

| By Application | Industrial Automation; Manufacturing Facilities; Pneumatic Systems; Food Processing Equipment; Automotive Assembly; Others |

| By End-User | Manufacturing Companies; Industrial Equipment Suppliers; Pneumatic Component Distributors; System Integrators; Others |

| By Material | Standard Resin; High-Temperature Resin; Chemical Resistant Resin; FDA-Approved Resin; Others |

| By Pressure Range | Low Pressure (0-5 Bar); Medium Pressure (5-10 Bar); High Pressure (10+ Bar); Others |

| By Region | North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

| Segment | 2025-2035 Outlook |

|---|---|

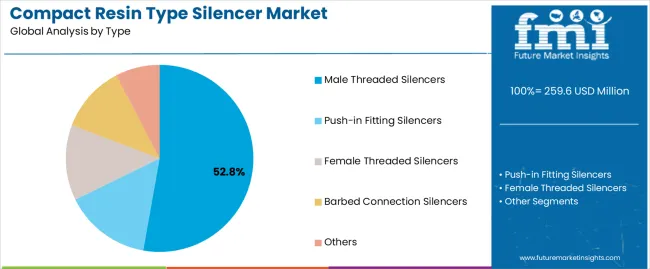

| Male Threaded Silencers | Leader in 2025 with 52.8% market share; standard connection method for pneumatic equipment and industrial applications requiring reliable threading interface and consistent sealing performance. Widely adopted across manufacturing facilities and automation systems. Momentum: strong growth across industrial automation and pneumatic system segments. Watchouts: competition from push-in fitting alternatives in modern pneumatic applications. |

| Push-in Fitting Silencers | Growing segment with 28.4% share, favored for modern pneumatic installations and automated manufacturing systems requiring quick connection capabilities and maintenance efficiency. Momentum: exceptional growth in advanced manufacturing and automation applications. Watchouts: higher initial costs compared to traditional threaded solutions in cost-sensitive applications. |

| Female Threaded Silencers | Specialized segment serving applications requiring internal threading connections for specific equipment configurations and space-constrained installations. Momentum: steady growth in specialized industrial applications and custom pneumatic system designs. Watchouts: limited application scope compared to male threaded alternatives. |

| Others | Includes barbed connection silencers and specialty connection types for unique application requirements. Momentum: selective growth in specialized manufacturing and custom pneumatic system applications. |

| Segment | 2025-2035 Outlook |

|---|---|

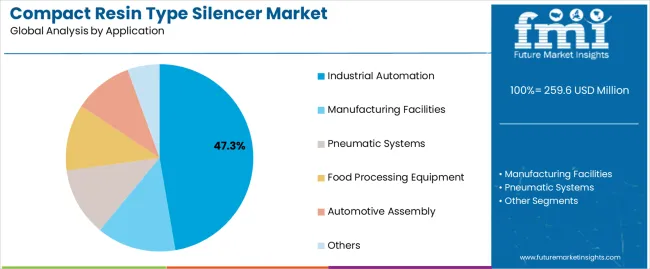

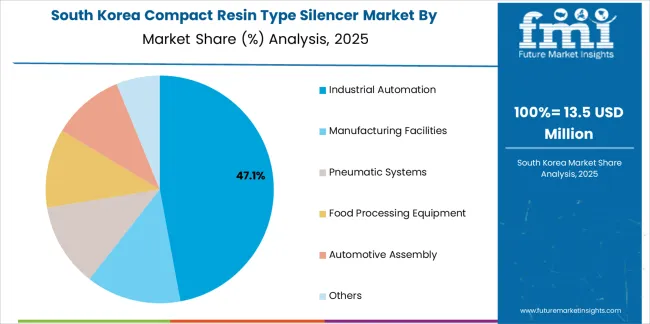

| Industrial Automation | Largest application segment in 2025 at 47.3% share, driven by manufacturing automation expansion and pneumatic system installations requiring effective noise control for robotic applications, assembly systems, and material handling equipment. Momentum: robust growth from factory automation advancement and industrial digitalization initiatives. Watchouts: pressure for cost reduction and standardization in competitive automation markets. |

| Manufacturing Facilities | Critical segment representing 31.6% share, experiencing steady growth from facility expansion and equipment modernization requiring noise compliance solutions for general manufacturing operations. Momentum: consistent growth as manufacturing facilities upgrade pneumatic systems and improve workplace environments. Watchouts: budget constraints and procurement standardization requirements in traditional manufacturing sectors. |

| Pneumatic Systems | Growing segment at 14.2% share for specialized pneumatic applications, compressed air systems, and industrial equipment requiring dedicated silencing solutions. Momentum: moderate growth from pneumatic system expansion and industrial infrastructure development. Watchouts: technical complexity and application-specific requirements limiting broad market adoption. |

| Others | Includes food processing equipment, automotive assembly, and emerging industrial applications. Momentum: diverse growth opportunities across multiple industrial sectors and specialized applications. |

| End-User | Status & Outlook (2025-2035) |

|---|---|

| Manufacturing Companies | Dominant end-user in 2025 with 68.2% share for direct pneumatic system installations and facility noise control requirements. Provides operational efficiency, regulatory compliance, and worker safety improvements for industrial operations. Momentum: steady growth driven by manufacturing expansion and automation investment. Watchouts: cost pressure and procurement standardization requirements across multiple facility locations. |

| Industrial Equipment Suppliers | Technical end-user serving original equipment manufacturer applications and integrated pneumatic system solutions requiring certified silencing performance and reliability specifications. Momentum: moderate growth as equipment suppliers enhance noise control offerings and system integration capabilities. Watchouts: competitive pressure and performance specification requirements in diverse industrial applications. |

| Pneumatic Component Distributors | Distribution end-user for aftermarket applications and replacement requirements serving industrial maintenance and system upgrade projects. Momentum: consistent growth as industrial facilities maintain and upgrade existing pneumatic installations. Watchouts: inventory management challenges and technical support requirements for diverse application segments. |

| Others | Includes system integrators, specialty contractors, and emerging industrial end-user categories. Momentum: selective growth opportunities in specialized applications and emerging industrial sectors. |

| KEY TRENDS | DRIVERS | RESTRAINTS |

|---|---|---|

| Material Innovation -- Advanced resin formulations and polymer technology delivering enhanced durability, temperature resistance, and chemical compatibility for demanding industrial applications with improved performance characteristics and extended service life. | Manufacturing Automation Growth across industrial facilities and production systems creating substantial demand for pneumatic silencing solutions supporting automated equipment, robotic applications, and assembly line operations requiring effective noise control and regulatory compliance. | Cost Sensitivity in industrial procurement and budget constraints limiting adoption of premium silencing solutions across cost-conscious manufacturing facilities and competitive industrial applications with restricted capital equipment budgets. |

| System Integration -- Expanding integration with pneumatic control systems, automated manufacturing equipment, and industrial IoT platforms enabling comprehensive noise monitoring, maintenance optimization, and performance tracking capabilities. | Noise Regulation Compliance -- Industrial safety standards and occupational health requirements driving adoption of certified silencing technology for manufacturing facilities, equipment installations, and worker protection applications requiring documented noise reduction performance and regulatory validation. | Market Fragmentation -- Diverse industrial applications, equipment specifications, and regional requirements creating complexity for suppliers developing standardized silencing solutions across multiple manufacturing sectors and international markets. |

| Digital Manufacturing -- Integration with Industry 4.0 initiatives and smart manufacturing systems enabling predictive maintenance, performance monitoring, and automated silencing system optimization for enhanced operational efficiency and reliability. | Equipment Modernization -- Industrial facility upgrades and pneumatic system enhancements requiring specialized silencing components for improved operational efficiency, reduced maintenance costs, and enhanced workplace environments with superior noise control performance. | Technical Complexity -- Application-specific requirements, installation procedures, and performance validation affecting deployment timelines and operational capabilities for industrial facilities lacking specialized pneumatic system expertise and maintenance capabilities. |

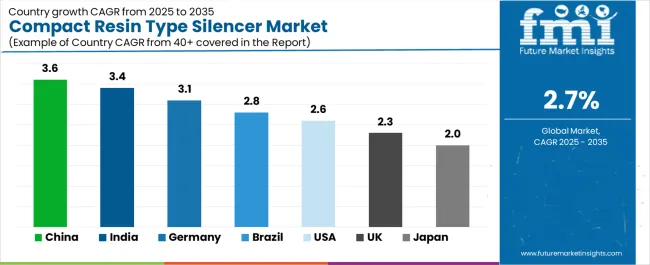

| Country | CAGR (2025-2035) |

|---|---|

| China | 3.6% |

| India | 3.4% |

| Germany | 3.1% |

| Brazil | 2.8% |

| USA | 2.6% |

| UK | 2.3% |

| Japan | 2.0% |

Revenue from compact resin type silencers in China is projected to exhibit steady growth with a CAGR of 3.6% from 2025 to 2035, driven by extensive manufacturing modernization programs and comprehensive industrial automation initiatives. These initiatives are creating substantial opportunities for silencing technology suppliers across pneumatic system installations, factory automation projects, and industrial facility development sectors.

The country's ambitious manufacturing upgrade programs, including national industrial digitalization initiatives and automated production facility expansion, are creating consistent demand for specialized pneumatic silencing systems. Major manufacturing companies and industrial equipment suppliers, including Shanghai Electric, Sany Group, and specialized pneumatic component manufacturers, are establishing comprehensive silencing solution programs to support large-scale industrial production and advanced manufacturing technology applications.

Revenue from compact resin type silencers in India is projected to grow at a CAGR of 3.4% from 2025 to 2035, supported by extensive manufacturing industry development programs and comprehensive industrial infrastructure modernization initiatives. These initiatives are creating demand for pneumatic silencing solutions across diverse manufacturing facility and automation system application segments. The country's growing industrial manufacturing capabilities and expanding automation infrastructure are driving demand for silencing components that provide exceptional reliability while supporting advanced manufacturing system requirements. Industrial companies and manufacturing facilities are investing in pneumatic silencing technology to support growing production demand and industrial automation advancement requirements.

Demand for compact resin type silencers in Germany is projected to grow at a CAGR of 3.1% from 2025 to 2035, supported by the country's leadership in industrial engineering technology and advanced manufacturing systems requiring sophisticated pneumatic silencing solutions for precision manufacturing and industrial automation applications. German manufacturing operators are implementing cutting-edge silencing platforms that support advanced operational capabilities, precision performance, and comprehensive quality monitoring protocols. The market is characterized by a focus on engineering excellence, technology innovation, and compliance with stringent industrial safety and performance standards.

Revenue from compact resin type silencers in Brazil is projected to grow at a CAGR of 2.8% from 2025 to 2035, driven by industrial infrastructure development programs and increasing manufacturing capabilities. These factors are creating opportunities for silencing suppliers serving both industrial manufacturers and specialized equipment contractors. The country's expanding manufacturing sector and growing industrial infrastructure are creating demand for silencing components that support diverse manufacturing requirements while maintaining performance standards. Industrial companies and manufacturing facilities are developing technology strategies to support operational efficiency and system reliability advancement.

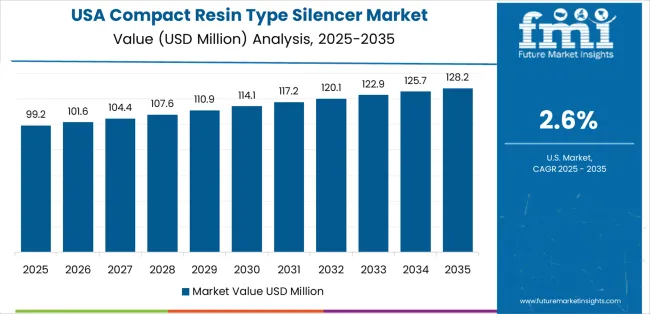

Demand for compact resin type silencers in the United States is projected to grow at a CAGR of 2.6% from 2025 to 2035, driven by advanced manufacturing technology innovation and specialized industrial applications supporting precision manufacturing and comprehensive automation technology applications. The country's established manufacturing technology tradition, including major industrial equipment manufacturers and automation facilities, is creating demand for high-performance pneumatic silencing components that support operational advancement and safety standards. Manufacturers and industrial system suppliers are maintaining comprehensive development capabilities to support diverse manufacturing and automation requirements.

Revenue from compact resin type silencers in the United Kingdom is projected to grow at a CAGR of 2.3% from 2025 to 2035, supported by manufacturing technology heritage and established industrial engineering communities. These factors are driving demand for premium pneumatic silencing solutions across traditional manufacturing systems and specialized industrial automation applications. The country's rich industrial engineering heritage, including major manufacturing companies and established industrial system capabilities, is creating demand for silencing components that support both legacy system advancement and modern manufacturing applications.

Demand for compact resin type silencers in Japan is projected to grow at a CAGR of 2.0% from 2025 to 2035, driven by precision manufacturing technology tradition and established industrial leadership. These factors are supporting both domestic manufacturing system markets and export-oriented component production. Japanese companies maintain sophisticated pneumatic silencing development capabilities, with established manufacturers continuing to lead in silencing technology and industrial equipment standards.

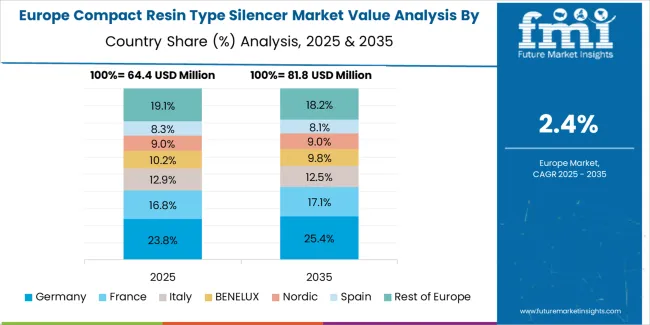

European compact resin type silencer operations are increasingly concentrated between German engineering excellence and specialized manufacturing across multiple countries. German facilities dominate high-performance pneumatic silencing production for precision manufacturing and industrial automation applications, leveraging cutting-edge manufacturing technologies and strict quality protocols that command price premiums in global markets. British manufacturing technology operators maintain leadership in industrial system innovation and pneumatic silencing method development, with organizations like specialized engineering companies and university research centers driving technical specifications that suppliers must meet to access major industrial contracts.

Eastern European operations in Czech Republic and Poland are capturing specialized production contracts through precision manufacturing expertise and EU compliance standards, particularly in component fabrication and assembly technologies for industrial applications. These facilities increasingly serve as development partners for Western European manufacturing programs while building their own industrial technology expertise.

The regulatory environment presents both opportunities and constraints. European industrial safety framework requirements create quality standards that favor established European manufacturers and industrial system operators while ensuring consistent performance specifications for critical manufacturing infrastructure and safety applications. Brexit has created complexity for UK manufacturing collaboration with EU programs, driving opportunities for direct relationships between British operators and international pneumatic silencing suppliers.

Technology collaboration accelerates as manufacturing companies seek technology advancement to support major industrial modernization milestones and automation development timelines. Vertical integration increases, with major industrial system operators acquiring specialized manufacturing capabilities to secure component supplies and quality control for critical manufacturing programs. Smaller industrial contractors face pressure to specialize in niche applications or risk displacement by larger, more comprehensive operations serving mainstream manufacturing and automation requirements.

South Korean compact resin type silencer operations reflect the country's advanced manufacturing technology capabilities and export-oriented industrial development model. Major industrial system operators including Samsung Engineering and technology companies drive component procurement strategies for their manufacturing facilities, establishing direct relationships with specialized pneumatic silencing suppliers to secure consistent quality and performance for their industrial development programs and advanced manufacturing technology systems targeting both domestic infrastructure and international collaboration projects.

The Korean market demonstrates particular strength in integrating pneumatic silencing technologies into automated manufacturing platforms and advanced industrial system configurations, with engineering teams developing solutions that bridge traditional manufacturing silencing applications and next-generation industrial systems. This integration approach creates demand for specific performance specifications that differ from conventional applications, requiring suppliers to adapt silencing capabilities and system coordination characteristics.

Regulatory frameworks emphasize industrial safety and manufacturing system reliability, with Korean industrial standards often exceeding international requirements for pneumatic silencing systems. This creates barriers for standard component suppliers but benefits established manufacturers who can demonstrate industrial-grade performance capabilities. The regulatory environment particularly favors suppliers with Korean manufacturing system qualification and comprehensive testing documentation systems.

Supply chain excellence remains critical given Korea's manufacturing focus and international collaboration dynamics. Industrial system operators increasingly pursue development partnerships with suppliers in Japan, Germany, and specialized manufacturers to ensure access to cutting-edge pneumatic silencing technologies while managing infrastructure risks. Investment in industrial infrastructure supports performance advancement during extended manufacturing development cycles.

SMC leads the market with 23.4% share owing to its comprehensive pneumatic component portfolio and established industrial automation relationships, which manufacturers use to implement integrated silencing solutions across diverse pneumatic applications. Profit pools are consolidating upstream in advanced material development and downstream in application-specific solutions for industrial automation, manufacturing facility integration, and specialized pneumatic markets where performance reliability, installation simplicity, and consistent noise attenuation command substantial premiums. Value is migrating from basic silencing component production to specification-driven, application-ready pneumatic systems where material expertise, precision manufacturing, and reliable integration capabilities create competitive advantages.

Several archetypes define market leadership: established Japanese component companies defending share through comprehensive pneumatic system development and proven industrial automation support; German industrial suppliers leveraging manufacturing excellence and engineering capabilities; American technology leaders with automation expertise and precision manufacturing heritage; and emerging Asian manufacturers pursuing cost-effective production while developing advanced material capabilities.

Switching costs - system integration, equipment compatibility validation, industrial certification - provide stability for established suppliers, while technological advancement requirements and specialized application growth create opportunities for innovative component manufacturers. Consolidation continues as companies seek manufacturing scale; direct industrial partnerships grow for specialized applications while traditional pneumatic distribution remains relationship-driven. Focus areas: secure premium manufacturing and industrial automation market positions with application-specific performance specifications and technical collaboration; develop pneumatic silencing technology and advanced manufacturing capabilities; explore specialized applications including food processing and automotive assembly requirements.

| Stakeholder Type | Primary Advantage | Repeatable Plays |

|---|---|---|

| Japanese Component Leaders | Comprehensive pneumatic expertise; proven industrial integration; established manufacturer relationships | Precision manufacturing; technical innovation; industrial certification support |

| German Industrial Suppliers | Manufacturing excellence; comprehensive automation development programs; established customer partnerships | Engineering collaboration focus; integrated solutions; technical consultation |

| American Technology Leaders | Automation system expertise; precision technology leadership; trusted by major manufacturing programs | Industrial partnerships; application-specific specifications; automation infrastructure collaboration |

| Emerging Asian Producers | Manufacturing efficiency; competitive pricing; rapid technology development | Production scaling; technology advancement; market entry strategies |

| Industrial Distributors | Technical distribution networks; manufacturing service relationships | Industrial expertise; inventory management; technical support services |

| Item | Value |

|---|---|

| Quantitative Units | USD 259.6 million |

| Type Segments | Male Threaded Silencers; Push-in Fitting Silencers; Female Threaded Silencers; Barbed Connection Silencers; Others |

| Applications | Industrial Automation; Manufacturing Facilities; Pneumatic Systems; Food Processing Equipment; Automotive Assembly; Others |

| End-Users | Manufacturing Companies; Industrial Equipment Suppliers; Pneumatic Component Distributors; System Integrators; Others |

| Material Segments | Standard Resin; High-Temperature Resin; Chemical Resistant Resin; FDA-Approved Resin; Others |

| Pressure Ranges | Low Pressure (0-5 Bar); Medium Pressure (5-10 Bar); High Pressure (10+ Bar); Others |

| Regions Covered | North America; Latin America; Europe; Asia Pacific; Middle East & Africa |

| Key Countries | China; India; Germany; Brazil; United States; United Kingdom; Japan (+35 additional countries) |

| Key Companies Profiled | SMC; CKD Corporation; Airtac International; Festo; Parker Hannifin; Norgren; Camozzi; Mindman Industrial; Tameson; Koganei; CEJN; Legris; Pneumax; Metal Work; Aventics; Bürkert; Emerson; IMI Precision Engineering |

| Additional Attributes | Dollar sales by type and application; Regional demand trends (NA, EU, APAC); Competitive landscape; Manufacturing vs. aftermarket adoption patterns; Industrial automation and pneumatic system integration; Advanced material innovations driving performance enhancement, installation reliability, and industrial safety excellence |

The global compact resin type silencer market is estimated to be valued at USD 259.6 million in 2025.

The market size for the compact resin type silencer market is projected to reach USD 338.9 million by 2035.

The compact resin type silencer market is expected to grow at a 2.7% CAGR between 2025 and 2035.

The key product types in compact resin type silencer market are male threaded silencers, push-in fitting silencers, female threaded silencers, barbed connection silencers and others.

In terms of application, industrial automation segment to command 47.3% share in the compact resin type silencer market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Compact Loader Market Size and Share Forecast Outlook 2025 to 2035

Compact Construction Equipment Market Size and Share Forecast Outlook 2025 to 2035

Compact Wheel Loaders Market Size and Share Forecast Outlook 2025 to 2035

Compact Recloser Replacement Market Size and Share Forecast Outlook 2025 to 2035

Compact Pick-up Trucks Market Size and Share Forecast Outlook 2025 to 2035

Compact Track and Multi-Terrain Loader Market Size and Share Forecast Outlook 2025 to 2035

Compacted Graphite Iron Market Size and Share Forecast Outlook 2025 to 2035

Compact Utility Vehicles Market Growth - Trends & Forecast 2025 to 2035

Compaction Machines Market Growth - Trends & Forecast 2025 to 2035

Compact Power Equipment Rental Market Growth - Trends & Forecast 2025 to 2035

Examining Market Share Trends in Compact Construction Equipment

Compact E-Scooter Market Growth - Trends & Forecast 2024 to 2034

Compact Road Sweepers Market

Compaction equipment Market

USA Compact Construction Equipment Market Trends – Growth, Demand & Forecast 2025–2035

Self-Compacting Concrete Market Size and Share Forecast Outlook 2025 to 2035

Japan Compact Construction Equipment Market Insights – Demand, Size & Industry Trends 2025–2035

ASEAN Compact Construction Equipment Market Analysis – Size, Share & Forecast 2025–2035

Canada Compact Wheel Loader Industry Analysis Size and Share Forecast Outlook 2025 to 2035

Refuse Compactor Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA