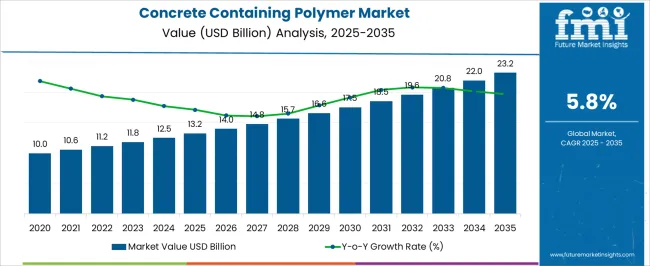

The Concrete Containing Polymer Market is estimated to be valued at USD 13.2 billion in 2025 and is projected to reach USD 23.2 billion by 2035, registering a compound annual growth rate (CAGR) of 5.8% over the forecast period.

| Metric | Value |

|---|---|

| Concrete Containing Polymer Market Estimated Value in (2025 E) | USD 13.2 billion |

| Concrete Containing Polymer Market Forecast Value in (2035 F) | USD 23.2 billion |

| Forecast CAGR (2025 to 2035) | 5.8% |

The Concrete Containing Polymer market is experiencing consistent expansion, supported by the growing need for advanced construction materials that deliver higher strength, durability, and environmental resistance compared to traditional concrete. In 2025, demand is being influenced by increasing urbanization, large-scale infrastructure upgrades, and the emphasis on sustainable building practices.

Concrete formulations enhanced with polymers are being widely adopted due to their superior bonding properties, resistance to chemical attacks, and reduced permeability, which collectively enhance structural longevity. This transition is aligning with global trends where construction stakeholders are prioritizing materials that reduce lifecycle costs while supporting long-term performance in diverse environmental conditions.

Future growth prospects are expected to be reinforced by expanding applications across industrial flooring, repair of aging infrastructure, and the adoption of innovative polymers that improve thermal and mechanical properties As governments and private players continue to invest heavily in resilient infrastructure, concrete containing polymer is anticipated to remain integral in modern construction practices with strong demand growth projected across multiple end-use categories.

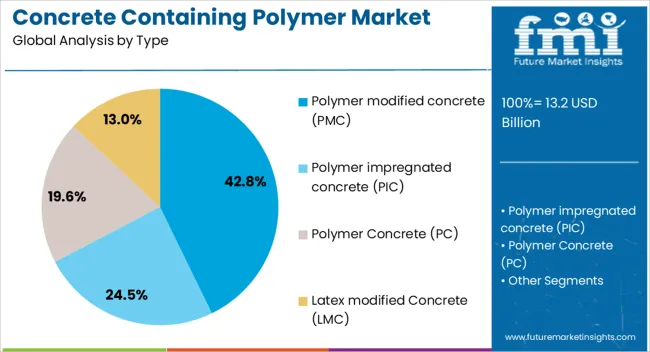

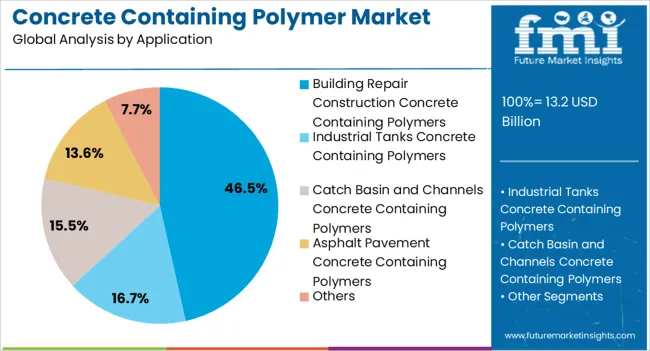

The concrete containing polymer market is segmented by type, application, and geographic regions. By type, concrete containing polymer market is divided into Polymer modified concrete (PMC), Polymer impregnated concrete (PIC), Polymer Concrete (PC), and Latex modified Concrete (LMC). In terms of application, concrete containing polymer market is classified into Building Repair Construction Concrete Containing Polymers, Industrial Tanks Concrete Containing Polymers, Catch Basin and Channels Concrete Containing Polymers, Asphalt Pavement Concrete Containing Polymers, and Others. Regionally, the concrete containing polymer industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Polymer Modified Concrete type is estimated to hold 42.80% of the overall Concrete Containing Polymer market revenue share in 2025, making it the leading segment by type. This dominance is being driven by its superior performance characteristics, including enhanced adhesion, reduced cracking, and improved resistance to harsh weather conditions.

The use of polymer additives in traditional concrete formulations has enabled a balance between cost-effectiveness and structural reliability, which is essential in high-demand applications such as bridges, pavements, and marine structures. The increased adoption of polymer modified concrete is also attributed to its compatibility with both new construction and repair works, providing versatility that appeals to contractors and engineers.

With growing attention on minimizing maintenance costs and extending the lifespan of critical infrastructure, PMC has been preferred for its ability to perform under variable load and environmental stresses Its scalability and suitability for diverse climatic regions have further reinforced its position, ensuring continued expansion within both developed and emerging construction markets.

The Building Repair Construction application segment is projected to capture 46.50% of the total Concrete Containing Polymer market revenue share in 2025, making it the dominant application area. The leadership of this segment is being attributed to the rising demand for cost-efficient and durable repair materials as global infrastructure ages and requires rehabilitation. Concrete containing polymers has been widely applied in repair works due to its rapid curing time, enhanced bonding with existing substrates, and improved resistance against chemical penetration and mechanical wear.

These characteristics have made it a material of choice for extending the service life of existing structures without complete reconstruction. The growing focus on sustainability in construction has also encouraged the use of polymer-based repair materials, as they help reduce material wastage and prolong asset performance.

Increasing investments in urban renewal projects, combined with regulatory emphasis on maintaining structural safety, are expected to accelerate adoption This trajectory positions building repair construction as a critical driver of market growth over the forecast period.

Concrete containing polymers were introduced in late 1950s and had become a popular choice by 1970s for precast components, thin overlays & floors and repair. The use of concrete containing polymers has been overseen by the Committee 548 of the American Concrete Institute since 1971. Owing to its unique properties, such as fast curing, strength, resistance to chemical attack, etc., concrete containing polymers find numerous applications in specialized domains.

These days, bars in steel are getting replaced by fibers reinforced concrete, which is also referred to as FRC. Concrete containing polymers are a more viable option for construction materials as they exhibit excellent performance.

Investment is civil construction, such as roads, bridges, drainage infrastructure, desalination plants and nuclear power plants, is the key driver spurring the demand in the concrete containing polymer market. Moreover, increase in demand for ecofriendly concrete will create trending opportunities for concrete containing polymers manufacturers. Concrete containing polymers in overall due to advanced physical characteristics, ease of sculpting and custom design as well as economical over its counterparts makes it a preferred choice for procurers of construction materials.

Most of the manufacturers are either expanding their production capacity or launching new products in the concrete containing polymer market. For instance, Organic Kimya (Istanbul), in 2025, announced its plan to increase the manufacturing volume for redispersible polymer powder by adding a second spray dryer at its Tuzla site (Bosnia). Similarly, Hexion launched a new redispersible polymer powder under the brand name Axilat HP 8530. Also, Dudick Inc. launched a concrete containing polymer which could be used for truck unloading pads, precast trenches and sumps, chemical processing flooring, tank piers and curbing.

Growing demand from end-use applications, such as industrial tanks, catch basin, asphalt pavements, repair construction, etc. are spurring the demand for concrete containing polymers. Moreover, high demand for environment-friendly materials will also drive the demand in the concrete containing polymers market. However, the high cost of this material might hamper the growth of the concrete containing polymers market during the forecast period.

Also, the slowdown in the construction industry in some regions is a major challenge for the concrete containing polymers market.

Within the modern building material and construction industry, the use of polymers is increasing with every passing day. Polymer modified concrete (PMC) is a polymer that is used in cement. The polymer impregnated concrete (PIC), is treated using polymerization and soaking. In Polymer concrete (PC), the binder is the polymer that replaces the cement paste. These days, concrete containing polymers are being widely used in bridges and floor overlays.

Concrete containing polymers can also be used in radiation shielding. For shield design, gamma & neutrons are the main types of nuclear radiation to be considered. Also, concrete containing polymers find usage in repair and coverage. Polymers have improved chemical and mechanical configuration of concrete. Concrete containing polymers offers is more compressive, has higher tensile strength, offers good durability and reduces corrosion and permeability of concrete.

Some of the market participants/vendors identified across the value chain of the Concrete Containing Polymers market are:

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

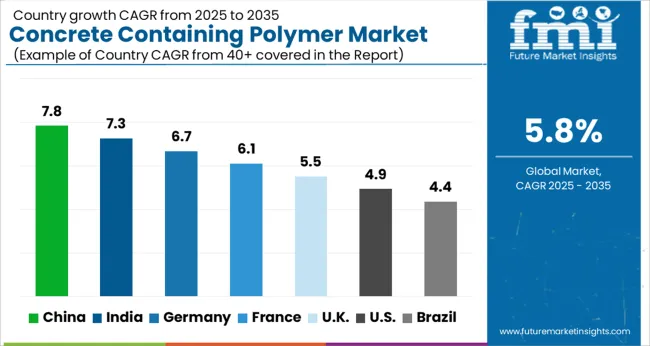

| Countries | CAGR |

|---|---|

| China | 7.8% |

| India | 7.3% |

| Germany | 6.7% |

| France | 6.1% |

| UK | 5.5% |

| USA | 4.9% |

| Brazil | 4.4% |

The Concrete Containing Polymer Market is expected to register a CAGR of 5.8% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 7.8%, followed by India at 7.3%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 4.4%, yet still underscores a broadly positive trajectory for the global Concrete Containing Polymer Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 6.7%. The USA Concrete Containing Polymer Market is estimated to be valued at USD 4.7 billion in 2025 and is anticipated to reach a valuation of USD 7.5 billion by 2035. Sales are projected to rise at a CAGR of 4.9% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 713.9 million and USD 377.2 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 13.2 Billion |

| Type | Polymer modified concrete (PMC), Polymer impregnated concrete (PIC), Polymer Concrete (PC), and Latex modified Concrete (LMC) |

| Application | Building Repair Construction Concrete Containing Polymers, Industrial Tanks Concrete Containing Polymers, Catch Basin and Channels Concrete Containing Polymers, Asphalt Pavement Concrete Containing Polymers, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

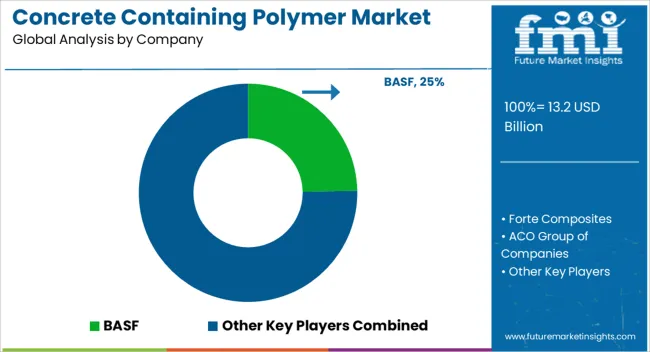

| Key Companies Profiled | BASF, Forte Composites, ACO Group of Companies, Bechtel Corporation, Forte Composites, Kwik Bond Polymers, ULMA Architectural Solutions, Bouygues, Wacker Chemie, Interplastic, and Italcementi |

The global concrete containing polymer market is estimated to be valued at USD 13.2 billion in 2025.

The market size for the concrete containing polymer market is projected to reach USD 23.2 billion by 2035.

The concrete containing polymer market is expected to grow at a 5.8% CAGR between 2025 and 2035.

The key product types in concrete containing polymer market are polymer modified concrete (pmc), polymer impregnated concrete (pic), polymer concrete (pc) and latex modified concrete (lmc).

In terms of application, building repair construction concrete containing polymers segment to command 46.5% share in the concrete containing polymer market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Polymer Concrete Market Growth 2024-2034

Polymer Mixing Unit Market Size and Share Forecast Outlook 2025 to 2035

Polymeric Brominated Flame Retardants Market Size and Share Forecast Outlook 2025 to 2035

Polymer-based Prefilled Syringe Market Size and Share Forecast Outlook 2025 to 2035

Polymer Modified Bitumen Market Forecast and Outlook 2025 to 2035

Concrete Epoxy Repair Market Size and Share Forecast Outlook 2025 to 2035

Polymer Stabilizers Market Size and Share Forecast Outlook 2025 to 2035

Polymeric Adsorbents Market Size and Share Forecast Outlook 2025 to 2035

Polymerization Initiator Market Size and Share Forecast Outlook 2025 to 2035

Concrete Fiber Market Size and Share Forecast Outlook 2025 to 2035

Polymer Processing Aid (PPA) Market Size and Share Forecast Outlook 2025 to 2035

Polymer Feed System Market Size and Share Forecast Outlook 2025 to 2035

Polymer Bearings Market Size and Share Forecast Outlook 2025 to 2035

Polymer Surge Arrester Market Size and Share Forecast Outlook 2025 to 2035

Polymer Nanomembrane Market Size and Share Forecast Outlook 2025 to 2035

Concrete Densification and Polishing Material Market Size and Share Forecast Outlook 2025 to 2035

Polymeric Sand Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Concrete Surface Retarders Market Size and Share Forecast Outlook 2025 to 2035

Concrete Densifier Market Size and Share Forecast Outlook 2025 to 2035

Polymer Binders Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA