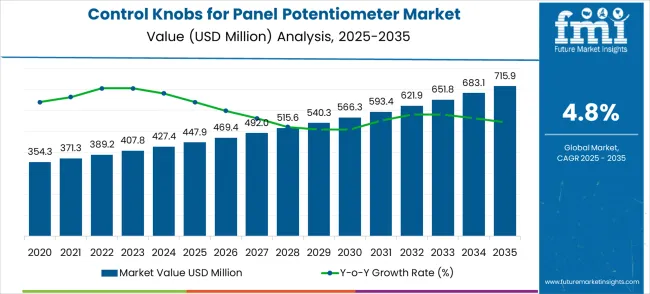

The control knobs for panel potentiometer market is projected to expand from USD 447.9 million in 2025 to USD 715.9 million by 2035, recording a CAGR of 4.8%. These knobs are essential components in a wide range of equipment, offering precise manual adjustment for functions such as volume, tuning, and calibration. Their role spans electronics, professional audio, household appliances, and industrial control systems, which ensures steady long-term demand. The market’s progression reflects the growing integration of control interfaces across devices and the continued need for tactile adjustment in equipment design. Over the forecast period, the segment evolves from niche adoption to full-scale incorporation, ultimately maturing into a highly competitive and consolidated industry.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 448 million |

| Forecast Value in (2035F) | USD 716 million |

| Forecast CAGR (2025 to 2035) | 5% |

The early adoption phase (2020–2024) set the foundation for market expansion, as control knobs for panel potentiometers were primarily integrated into specialized electronics, industrial machines, and select consumer products. During this period, demand grew steadily but was concentrated in markets where precision control was essential. By 2025, the market reached USD 447.9 million, transitioning into the scaling phase. This marked a shift from selective usage to broader adoption, with manufacturers increasingly incorporating these knobs into standard designs. Production capacity, distribution networks, and global supply chains strengthened, ensuring availability across multiple industries.

Between 2025 and 2030, the market experiences its scaling phase, where wider integration drives consistent growth across consumer electronics, professional equipment, and industrial applications. Market value builds steadily as panel potentiometer knobs become common across diverse systems requiring reliable user control. By 2030, they are recognized as standard components across product categories. From 2030 to 2035, the consolidation phase emerges, with the market projected to reach USD 715.9 million. Leading players focus on refining product portfolios, enhancing cost efficiencies, and securing long-term partnerships with device manufacturers. This results in a mature, competitive market, with steady CAGR-driven growth ensuring stability and widespread global adoption.

Market expansion is being supported by the increasing adoption of industrial automation systems worldwide and the corresponding need for reliable control interfaces that ensure precise operation and user safety. Modern manufacturing facilities require sophisticated control systems with durable, ergonomic interfaces that maintain performance across extended operational periods. Control knobs provide essential human-machine interface functionality while ensuring precise adjustment capabilities necessary for optimal equipment performance and process control accuracy.

The growing emphasis on workplace safety and ergonomic design is driving demand for high-quality control knobs that reduce operator fatigue and improve operational accuracy. Industrial equipment manufacturers increasingly specify premium control components that provide tactile feedback, durability under harsh operating conditions, and resistance to environmental factors including temperature variations, moisture, and chemical exposure. The expanding medical device manufacturing sector creates additional demand for specialized control knobs that meet stringent regulatory requirements and provide reliable performance in critical healthcare applications.

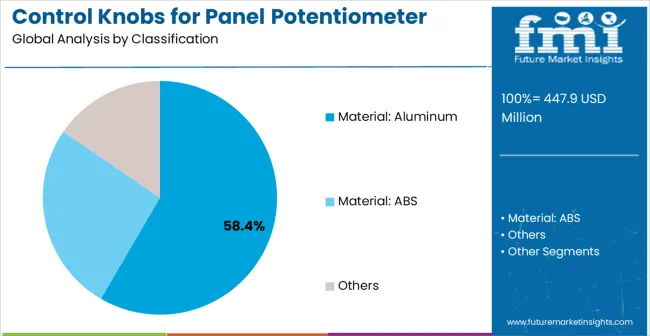

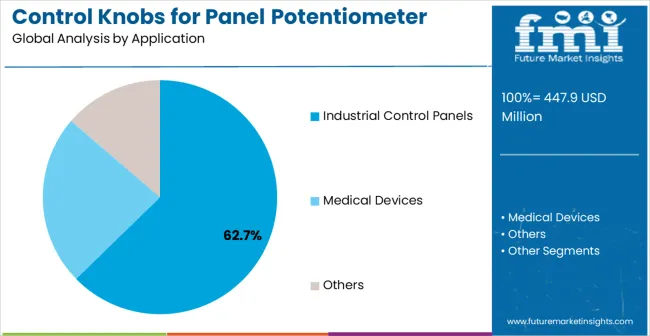

The market is segmented by material type, end-use application, design configuration, manufacturing process, and region. By material type, the market is divided into aluminum, ABS, and others. Based on end-use application, the market is categorized into industrial control panels, medical devices, and others. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

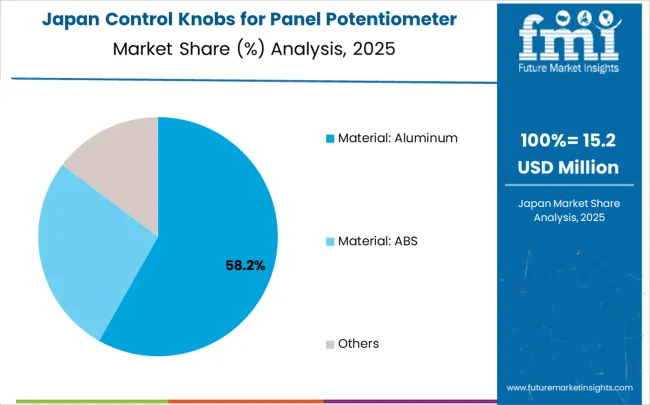

Aluminum control knobs are projected to account for 58.4% of the control knobs for panel potentiometer market in 2025. This leading share is supported by aluminum's superior durability characteristics, excellent heat dissipation properties, and resistance to corrosion that make it ideal for demanding industrial applications. Aluminum knobs provide precise tactile feedback while maintaining dimensional stability across temperature variations and mechanical stress conditions commonly encountered in industrial environments. The material's lightweight properties combined with exceptional strength enable optimal ergonomic design while ensuring long-term operational reliability.

Aluminum's machining characteristics allow for precise manufacturing tolerances and surface finish quality that meet demanding industrial specifications. The material supports various finishing options including anodizing, painting, and laser etching that provide aesthetic appeal and functional identification features. Aluminum knobs demonstrate superior performance in environments with temperature fluctuations, humidity variations, and exposure to cleaning chemicals or industrial fluids that would degrade alternative materials over time.

Industrial control panels are expected to represent 62.7% of control knobs for panel potentiometer demand in 2025. This dominant share reflects the widespread use of control panels across manufacturing industries including process control, machinery operation, and production line management where precise parameter adjustment and system monitoring are essential operational requirements. Industrial control panels require robust, reliable control knobs that withstand frequent operation while providing accurate adjustment capabilities for critical process parameters.

The segment benefits from increasing industrial automation adoption and growing emphasis on process optimization that requires sophisticated control interfaces for monitoring and adjusting equipment parameters. Modern industrial facilities rely on control panels for coordinating complex manufacturing processes where precise control knob operation directly impacts product quality, operational efficiency, and worker safety. Advanced control panels incorporate multiple knobs for adjusting temperature, pressure, speed, and other critical parameters requiring durable, ergonomic interface components.

The control knobs for panel potentiometer market is advancing steadily due to increasing industrial automation adoption and growing emphasis on ergonomic design in control interfaces across manufacturing and medical applications. However, the market faces challenges including material cost volatility affecting production expenses, competition from digital control interfaces and touchscreen technologies, and stringent regulatory requirements for medical and safety-critical applications. Innovation in materials science and manufacturing processes continues to influence product development and market expansion patterns across diverse industrial sectors.

Growing adoption of Industry 4.0 technologies is driving demand for sophisticated control interfaces that integrate with automated manufacturing systems while providing reliable human-machine interaction capabilities. Smart manufacturing facilities require control knobs that maintain traditional operational benefits while supporting digital integration through position sensing and feedback systems. Advanced control knobs incorporate sensors and connectivity features that enable remote monitoring and predictive maintenance while preserving tactile control advantages that operators prefer for critical adjustments and emergency procedures.

Modern control knob manufacturers are incorporating advanced materials including engineered plastics, metal alloys, and composite materials that provide enhanced performance characteristics for demanding applications. Advanced manufacturing techniques including precision machining, injection molding, and additive manufacturing enable complex geometries and integrated features that improve functionality while reducing production costs. These technological improvements support customization capabilities for specialized applications while maintaining cost-effectiveness for standard configurations, enabling broader market penetration across diverse industrial sectors.

Control interface design increasingly emphasizes ergonomic characteristics and user experience optimization that reduce operator fatigue while improving operational accuracy and safety. Modern control knobs incorporate features including textured surfaces, optimized grip dimensions, and visual indicators that enhance usability across extended operational periods. Ergonomic improvements support productivity enhancement and workplace safety initiatives while addressing aging workforce demographics that require interfaces accommodating reduced dexterity and strength. Advanced design features include customizable tactile feedback, position indication systems, and safety lockout mechanisms that prevent accidental adjustment during critical operations.

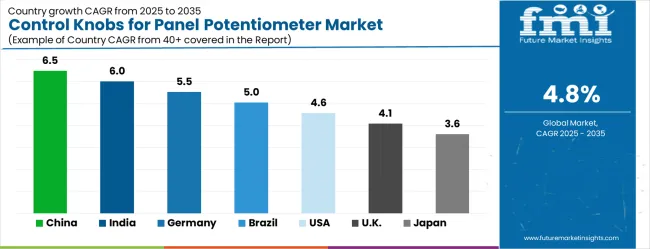

| Country | CAGR (2025-2035) |

|---|---|

| China | 6.5% |

| India | 6.0% |

| Germany | 5.5% |

| Brazil | 5.0% |

| USA | 4.6% |

| UK | 4.1% |

| Japan | 3.6% |

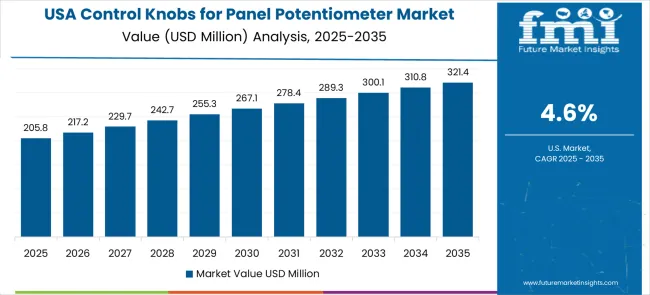

The control knobs for panel potentiometer market is experiencing steady growth globally, with China leading at a 6.5% CAGR through 2035, driven by massive industrial expansion, manufacturing modernization, and increasing automation adoption across diverse industrial sectors. India follows at 6.0%, supported by growing manufacturing industry, infrastructure development, and increasing adoption of industrial automation technologies. Germany shows consistent growth at 5.5%, emphasizing precision engineering and advanced manufacturing capabilities. Brazil records 5.0%, driven by industrial modernization and equipment manufacturing growth. The United States demonstrates 4.6% growth through established industrial markets and technological advancement. The United Kingdom and Japan show mature market characteristics with 4.1% and 3.6% growth respectively, focusing on specialized applications and quality improvements.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

The control knob market for panel potentiometer applications in China is projected to exhibit the highest growth rate, with a CAGR of 6.5% through 2035, driven by massive industrial expansion, manufacturing modernization programs, and increasing adoption of automation technologies across diverse industrial sectors. The country's expanding manufacturing base and growing emphasis on production efficiency create significant demand for reliable control interface components. Major industrial development projects in manufacturing hubs including Guangdong, Jiangsu, and Shandong provinces require sophisticated control systems with durable, precise control knobs for equipment operation and process control applications.

Government initiatives promoting manufacturing upgrade and industrial modernization are driving adoption of advanced control systems that require high-quality interface components. The country's leadership in manufacturing automation and smart factory development creates sustained demand for reliable control knobs that support precise equipment operation and process optimization. China's growing focus on quality manufacturing and export competitiveness further supports market expansion for premium control components that meet international standards.

Revenue from control knobs for panel potentiometer applications in India is projected to expand at a CAGR of 6.0%, supported by growing manufacturing industry, infrastructure development projects, and increasing adoption of industrial automation technologies across major industrial centers. The country's expanding industrial base and government initiatives supporting manufacturing development create significant opportunities for control interface components. Major development projects in manufacturing hubs including Maharashtra, Gujarat, and Tamil Nadu require sophisticated control systems for equipment operation and process management applications.

Government programs promoting industrial development and automation adoption are driving demand for reliable control interface components that support modern manufacturing practices. The construction of new manufacturing facilities and upgrade of existing industrial infrastructure create sustained demand for quality control knobs that ensure optimal equipment performance. India's growing focus on manufacturing quality and productivity improvement further supports market expansion for advanced control components that meet evolving industrial requirements.

The control knob market for panel potentiometer applications in Germany is projected to grow at a CAGR of 5.5%, supported by the country's leadership in precision engineering, advanced manufacturing technologies, and comprehensive quality standards that prioritize reliable control interface components. German industrial practices consistently demand high-quality components that meet rigorous performance specifications and provide long-term reliability. The market benefits from established supply chains, advanced manufacturing capabilities, and strong demand from automotive, machinery, and process industries that require sophisticated control systems.

The country's emphasis on engineering excellence and manufacturing precision creates competitive advantages for advanced control knobs that incorporate innovative design features and superior material performance. German manufacturers and industrial equipment suppliers prioritize components that provide proven performance, regulatory compliance, and long-term value through reduced maintenance requirements and extended service life. The industrial sector's commitment to continuous improvement and technological advancement supports sustained demand for premium control interface components.

The control knob market for panel potentiometer applications in Brazil is projected to grow at a CAGR of 5.0%, driven by industrial development initiatives, manufacturing sector expansion, and increasing adoption of automation technologies across major industrial regions. The country's growing industrial base and modernization programs create opportunities for advanced control interface components that support improved operational efficiency. Major development projects in industrial centers including São Paulo, Rio de Janeiro, and Minas Gerais require sophisticated control systems for equipment operation and process management applications.

The industrial sector's gradual adoption of automation technologies and quality improvement initiatives supports demand for reliable control components that ensure consistent equipment performance. Brazil's growing focus on manufacturing competitiveness and export market development creates opportunities for premium control knobs that meet international quality standards while supporting local industrial development objectives. The expansion of industrial infrastructure and equipment modernization programs further supports market growth for advanced control interface components.

The control knob market for panel potentiometer applications in the United States is projected to expand at a CAGR of 4.6%, driven by advanced manufacturing initiatives, technological innovation programs, and established industrial infrastructure that requires sophisticated control interface solutions. American manufacturing practices emphasize quality, reliability, and technological advancement, creating sustained demand for premium control components that meet demanding performance requirements. The market benefits from comprehensive distribution networks, advanced manufacturing capabilities, and strong demand from aerospace, medical device, and industrial equipment sectors that prioritize component quality and performance.

The industrial sector's focus on productivity improvement and operational efficiency creates opportunities for advanced control knobs that provide enhanced functionality and reliability. Advanced manufacturing initiatives including reshoring programs and smart factory development support demand for sophisticated control interface components that enable precise equipment operation and process optimization. The emphasis on workplace safety and ergonomic design further drives adoption of premium control knobs that improve operator experience and reduce safety risks.

Demand for control knobs for panel potentiometer applications in the UK is projected to grow at a CAGR of 4.1%, supported by established manufacturing standards, emphasis on precision applications, and comprehensive quality requirements across industrial and medical sectors. British industrial practices prioritize components that provide reliable performance, regulatory compliance, and long-term value through durability and consistent operation. The market benefits from established supply chains, technical expertise, and strong demand from specialized applications that require high-quality control interface solutions.

The industrial sector's commitment to quality and precision creates demand for control components that demonstrate proven performance and meet stringent specifications. Manufacturing facilities and equipment suppliers consistently specify premium control knobs that provide optimal user experience while ensuring reliable operation across demanding applications. The focus on innovation and technological advancement supports adoption of advanced control interface technologies that enhance operational capabilities.

The control knob market for panel potentiometer applications in Japan is projected to grow at a CAGR of 3.6% through 2035, driven by the country's emphasis on precision manufacturing, advanced technology integration, and stringent quality standards that consistently demand high-performance control interface components. Japanese manufacturing practices prioritize components that provide exceptional reliability, precise operation, and long-term durability for critical industrial applications. The market reflects mature industrial infrastructure and established requirements for control components that meet demanding performance specifications across diverse sectors.

The country's leadership in manufacturing technology and quality control creates competitive advantages for developing advanced control knobs that incorporate innovative materials, precise manufacturing processes, and superior performance characteristics. Japanese industrial facilities and equipment manufacturers consistently specify components that provide proven performance, quality assurance, and long-term value through reduced maintenance requirements and extended operational life.

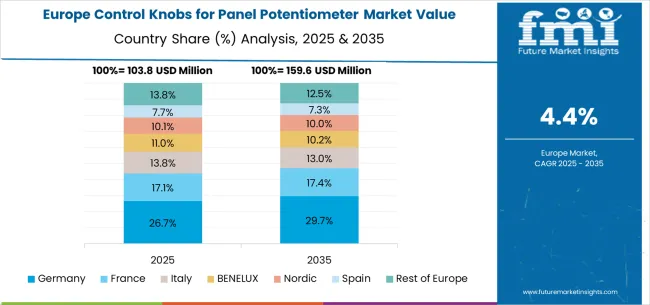

The control knobs for panel potentiometer market in Europe demonstrates mature development across established industrial economies, with Germany commanding approximately 34.2% of regional market share through its advanced manufacturing sector and comprehensive industrial automation infrastructure spanning automotive, machinery, and process industries. The country benefits from extensive engineering expertise, precision manufacturing capabilities, and strong demand from industrial equipment manufacturers requiring high-quality control components. The United Kingdom follows with 25% regional share, supported by diverse industrial applications including medical device manufacturing, test equipment production, and process control systems.

France maintains 18.7% of the European market through its advanced industrial sectors including aerospace, automotive, and pharmaceutical manufacturing that require precision control interfaces. Italy contributes 12.9% market share with its machinery manufacturing sector and industrial equipment production requiring reliable control components. Spain accounts for 9.4% regional share with expanding industrial automation and manufacturing modernization initiatives creating demand for advanced control interfaces across various sectors.

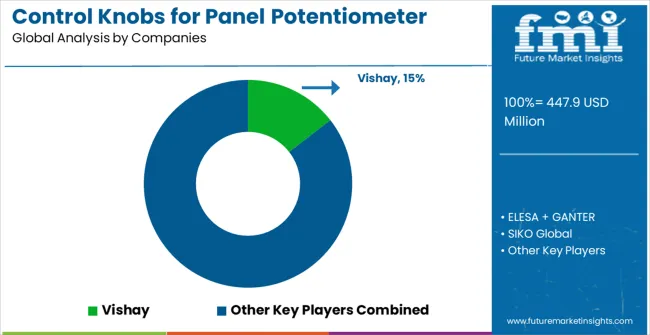

The control knobs for panel potentiometer market is characterized by competition among established component manufacturers, industrial hardware suppliers, and specialized interface companies. Companies are investing in advanced materials research, precision manufacturing technologies, ergonomic design development, and comprehensive quality assurance programs to deliver reliable, durable, and user-friendly control interface solutions. Strategic partnerships, market expansion, and customer-focused innovation are central to strengthening market positions and building long-term customer relationships across diverse industrial sectors.

Vishay, internationally based, leads the market through comprehensive component portfolios, engineering expertise, and global distribution networks that serve diverse industrial applications. The company provides specialized control knobs, technical consultation services, and quality assurance programs that address complex application requirements. ELESA + GANTER and SIKO Global offer focused product lines with emphasis on ergonomic design and precision manufacturing that provide competitive advantages in demanding industrial applications.

TE Connectivity, Boteco, and Davies Molding provide established product lines with proven performance records and strong customer relationships built through consistent quality and reliable service delivery. These companies focus on core market segments while developing specialized solutions for demanding applications that require superior performance characteristics. ELEN, Selco Product, and COMITRONIC-BTI serve regional markets through localized expertise, responsive customer service, and competitive pricing strategies that appeal to cost-conscious customers seeking reliable performance.

Tecnodin, Pizzato Elettrica, Hander Well Enterprise, and United Automation offer specialized capabilities including custom manufacturing, application-specific designs, and project-specific solutions that address unique industrial requirements. These companies contribute market diversity through alternative approaches to product development and customer service that serve previously underaddressed market segments and specialized application requirements.

The control knobs for panel potentiometer market represents a critical interface component in industrial automation, medical devices, and precision instrumentation where tactile feedback and operational reliability are paramount. With the market growing from $448 million to a projected $716 million at 5% CAGR, this mature yet evolving sector requires coordinated efforts across standards bodies, materials suppliers, precision manufacturers, system integrators, and specialized financiers to address increasing demands for miniaturization, enhanced durability, and integration with digital control systems.

How Governments Could Support Industrial Component Resilience?

Supply Chain Security Programs: Implement domestic sourcing incentives for critical control components used in defense, healthcare, and infrastructure applications. Establish strategic reserves of specialty materials like conductive plastics and precision-molded aluminum alloys used in high-reliability knobs.

Materials Research Funding: Support development of advanced polymers and metal alloys that offer superior chemical resistance, temperature stability, and electromagnetic compatibility for harsh industrial environments. Fund research into sustainable alternatives to traditional ABS and aluminum materials.

Precision Manufacturing Support: Provide tax incentives for companies investing in ultra-precision molding equipment, automated quality control systems, and cleanroom facilities necessary for medical-grade and aerospace-qualified control knobs.

Standards Harmonization: Work with international bodies to align safety certifications, EMC compliance, and material specifications across regions to reduce certification costs and enable global supply chains for specialized control components.

Export Control Balance: Maintain appropriate controls on dual-use precision manufacturing technologies while enabling legitimate commercial trade in standard industrial control components to support domestic manufacturers' global competitiveness.

How Industry Bodies Could Enhance Market Standardization?

Tactile Performance Standards: Develop standardized testing protocols for knob torque, detent feel, grip ergonomics, and wear resistance that enable engineers to specify components with confidence across different supplier options.

Material Compatibility Guidelines: Create comprehensive compatibility matrices for knob materials with different potentiometer shafts, panel substrates, and environmental conditions including chemical exposure, temperature cycling, and UV degradation.

Dimensional Standardization: Establish common shaft diameters, mounting patterns, and grip geometries that allow interchangeability between suppliers while enabling product differentiation through surface treatments and ergonomic refinements.

Quality Certification Programs: Develop tiered certification schemes for different application classes - standard industrial, medical device, aerospace, and harsh environment - with corresponding testing requirements and supplier qualification processes.

End-User Education: Provide technical guides helping design engineers select appropriate knob specifications for specific applications, considering factors like operator safety, precision requirements, and maintenance accessibility.

How OEMs and Precision Manufacturers Could Strengthen Technical Capabilities?

Advanced Materials Integration: Develop proprietary material formulations combining aluminum cores with specialized polymer overmolds that provide optimal grip, chemical resistance, and electrical properties for specific industrial applications.

Micro-Precision Manufacturing: Invest in advanced injection molding, CNC machining, and surface treatment technologies that achieve tight tolerances necessary for smooth operation and long-term reliability in critical control applications.

Customization Capabilities: Build flexible manufacturing systems that can efficiently produce small-batch custom knobs with specific colors, textures, markings, and dimensional requirements for OEM panel manufacturers.

Smart Integration Features: Develop knobs with integrated LED illumination, capacitive touch sensing, or RFID identification that enable enhanced functionality in modern digital control systems while maintaining traditional tactile operation.

Environmental Qualification: Establish comprehensive testing capabilities for extreme temperature, chemical exposure, vibration, and sterilization requirements that validate knob performance in demanding applications like medical devices and process control.

How System Integrators and Panel Manufacturers Could Navigate Component Evolution?

Integrated Design Solutions: Offer complete control panel solutions that optimize knob selection, potentiometer matching, and panel ergonomics to improve operator efficiency and reduce assembly complexity for end customers.

Inventory Optimization: Develop forecasting systems that anticipate demand for different knob variants based on end-market trends, seasonal patterns, and customer project timelines to minimize stockouts and excess inventory.

Technical Support Services: Provide application engineering support helping customers select optimal knob specifications, troubleshoot compatibility issues, and adapt to new materials or designs as product lines evolve.

Quality Assurance Programs: Implement incoming inspection protocols and supplier qualification processes that ensure consistent knob performance across different batches and suppliers while maintaining cost competitiveness.

Lifecycle Management: Establish long-term availability commitments and obsolescence management programs that provide security for customers designing products with 10-20 year operational lives in industrial and medical applications.

How Investors and Specialized Financiers Could Enable Market Development?

Precision Equipment Financing: Provide equipment financing for advanced molding machines, automated assembly systems, and precision measurement equipment required to compete in high-tolerance control component markets.

Materials Innovation Investment: Back companies developing next-generation materials and manufacturing processes that offer improved performance, reduced environmental impact, or cost advantages in specialized control component applications.

Market Consolidation Capital: Support strategic acquisitions that combine complementary capabilities in materials, manufacturing, and distribution to create more comprehensive suppliers capable of serving global OEM customers.

Working Capital Solutions: Provide inventory financing and supply chain financing programs that help manufacturers maintain adequate stock levels of diverse knob variants while managing cash flow through long customer payment cycles.

Technology Licensing Funds: Finance licensing agreements for proprietary materials, manufacturing processes, or design technologies that enable smaller manufacturers to compete with larger suppliers in specialized market segments.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 448 million |

| Material Type | Aluminum, ABS, Others |

| End-Use | Industrial Control Panels, Medical Devices, Others |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, India, Brazil, Australia and 40+ countries |

| Key Companies Profiled | Vishay, ELESA + GANTER, SIKO Global, TE Connectivity, Boteco, Davies Molding, ELEN, Selco Product, COMITRONIC-BTI, Tecnodin, Pizzato Elettrica, Hander Well Enterprise, United Automation |

| Additional Attributes | Dollar sales by material type and end-use application, regional demand trends across North America, Europe, and Asia-Pacific, competitive landscape with established component manufacturers and specialized suppliers, buyer preferences for machined versus molded components, integration with industrial automation and control systems, innovations in ergonomic design and advanced materials, and adoption of smart connectivity features with enhanced durability and precision characteristics for demanding industrial applications |

The global control knobs for panel potentiometer market is estimated to be valued at USD 447.9 million in 2025.

The market size for the control knobs for panel potentiometer market is projected to reach USD 715.9 million by 2035.

The control knobs for panel potentiometer market is expected to grow at a 4.8% CAGR between 2025 and 2035.

The key product types in control knobs for panel potentiometer market are material: aluminum, material: abs and others.

In terms of application, industrial control panels segment to command 62.7% share in the control knobs for panel potentiometer market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Control Network Modules Market Size and Share Forecast Outlook 2025 to 2035

Control Room Solution Market Size and Share Forecast Outlook 2025 to 2035

Controlled-Release Drug Delivery Technology Market Size and Share Forecast Outlook 2025 to 2035

Controlled Environment Agriculture (CEA) Market Size and Share Forecast Outlook 2025 to 2035

Control Cable Market Size and Share Forecast Outlook 2025 to 2035

Control Towers Market Size and Share Forecast Outlook 2025 to 2035

Controlled & Slow Release Fertilizers Market 2025-2035

Controlled Intelligent Packaging Market

Controllable Shunt Reactor for UHV Market Size and Share Forecast Outlook 2025 to 2035

Biocontrol Solutions Market Size and Share Forecast Outlook 2025 to 2035

Biocontrol Agents Market Size and Share Forecast Outlook 2025 to 2035

Oil Control Shampoo Market Size and Share Forecast Outlook 2025 to 2035

LED Control Unit Market Size and Share Forecast Outlook 2025 to 2035

Sun Control Films Market Size and Share Forecast Outlook 2025 to 2035

CNC Controller Market Size and Share Forecast Outlook 2025 to 2035

PID Controller Market Size and Share Forecast Outlook 2025 to 2035

Market Share Breakdown of Sun Control Films Manufacturers

PLC Controlled Packing Machine Market Trends – Forecast 2024-2034

Seat Control Module (SCM) Market Forecast and Outlook 2025 to 2035

HVAC Control System Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA