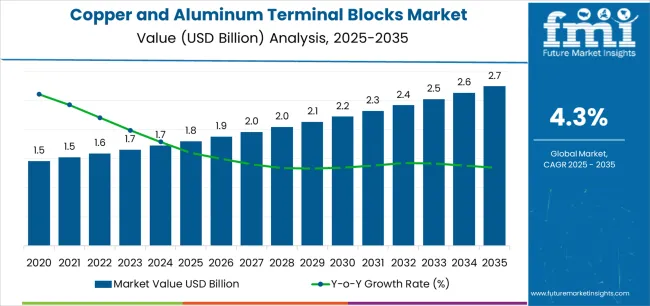

The global copper and aluminum terminal blocks market is valued at USD 1.8 billion in 2025 and is slated to reach USD 2.7 billion by 2035, recording an absolute increase of USD 931.2 million over the forecast period. This translates into a total growth of 52.4%, with the market forecast to expand at a compound annual growth rate (CAGR) of 4.3% between 2025 and 2035. The overall market size is expected to grow by approximately 1.52X during the same period, supported by increasing demand for electrical infrastructure development, growing adoption of automation technologies across global industrial sectors, and rising preference for reliable connection systems across power distribution and manufacturing applications.

The copper and aluminum terminal blocks market represents a specialized segment of the global electrical components industry, characterized by technological advancement and robust demand across electrical power distribution and industrial automation channels. Market dynamics are influenced by changing infrastructure requirements toward reliable electrical connections, growing interest in modular wiring technologies, and expanding partnerships between terminal block manufacturers and electrical system integrators in developed and emerging economies. Traditional wiring connection systems continue to evolve as electrical engineers seek proven terminal solutions that offer enhanced conductivity and reliable connections.

Consumer behavior in the copper and aluminum terminal blocks market reflects broader electrical trends toward high-performance, corrosion-resistant systems that provide both connectivity reliability benefits and extended operational life improvements. The market benefits from the growing popularity of standardized screw eye aperture applications, which are recognized for their advanced connection integration and user-friendly approach to electrical system management. Additionally, the versatility of copper and aluminum terminal blocks as both standalone connection components and integrated electrical system elements supports sustained demand across multiple industrial applications and voltage segments.

Regional adoption patterns vary significantly, with Asian markets showing a strong preference for compact screw eye aperture implementations. In contrast, European markets demonstrate increasing adoption of industrial-grade solutions alongside conventional power distribution systems. The electrical landscape continues to evolve with sophisticated and feature-rich terminal products gaining traction in mainstream electrical installations, reflecting manufacturers' willingness to invest in proven connection technology improvements and engineer-oriented features.

The competitive environment features established electrical component companies alongside specialized terminal block providers that focus on unique material combinations and advanced connection methods. Manufacturing efficiency and product development optimization remain critical factors for market participants, particularly as raw material costs and regulatory compliance continue to fluctuate. Distribution strategies increasingly emphasize multi-channel approaches that combine traditional electrical supply chains with direct manufacturer partnerships through technology licensing agreements and system integration contracts.

Market consolidation trends indicate that larger electrical manufacturers are acquiring specialty terminal companies to diversify their product portfolios and access specialized connection technology segments. Original equipment integration has gained momentum as industrial equipment companies seek to differentiate their offerings while maintaining competitive cost structures. The emergence of specialized aperture variants, including compact and industrial-grade options, reflects changing electrical priorities and creates new market opportunities for innovative connection system developers. Manufacturing automation and quality control improvements enable consistent product scaling while maintaining traditional electrical characteristics that electrical contractors expect from established connection materials.

Between 2025 and 2030, the copper and aluminum terminal blocks market is projected to expand from USD 1.8 billion to USD 2.2 billion, representing a 23% increase. This increase represents 44.7% of the total forecasted growth for the decade. This phase of development will be driven by the growing adoption of compact aperture systems, rising demand for industrial electrical solutions, and a heightened focus on connection reliability and improved conductivity. Electrical manufacturers are enhancing production capabilities to meet the demand for specialized terminal blocks, advanced connection options, and application-specific solutions across various industrial segments.

| Metric | Value |

|---|---|

| Estimated Value (2025E) | USD 1.8 billion. |

| Forecast Value (2035F) | USD 2.7 billion |

| Forecast CAGR (2025-2035) | 4.30% |

From 2030 to 2035, the market is forecast to grow from USD 2.2 billion to USD 2.7 billion, adding USD 514.5 million, which accounts for 55.3% of the overall ten-year expansion. This period will be marked by the growth of industrial electrical systems, the integration of innovative connection solutions, and the development of specialized terminal blocks with enhanced conductivity and extended performance capabilities. The increasing use of advanced materials will drive demand for copper and aluminum terminal blocks with superior corrosion resistance and compatibility with modern electrical technologies in power distribution operations.

Between 2020 and 2025, the copper and aluminum terminal blocks market experienced steady growth, driven by increasing demand for standardized screw eye aperture systems and growing recognition of terminal blocks as essential components for modern electrical connection programs across power distribution and industrial automation applications. The market developed as electrical manufacturers recognized the potential for terminal solutions to provide both connectivity benefits and operational advantages while enabling streamlined installation protocols. Technological advancement in materials engineering and application-based development began emphasizing the critical importance of maintaining connection performance and system reliability in diverse electrical environments.

Market expansion is being supported by the increasing global demand for advanced electrical connection systems and the corresponding need for terminal block technologies that can provide superior conductivity resistance benefits and connection reliability advantages while enabling enhanced system performance and extended compatibility across various power distribution and industrial automation applications. Modern electrical engineers and electrical industry specialists are increasingly focused on implementing proven connection technologies that can deliver effective current control, minimize traditional connection dependency, and provide consistent performance throughout complex electrical configurations and diverse operational conditions. Copper and aluminum terminal blocks proven ability to deliver exceptional conductivity efficacy against traditional alternatives, enable advanced electrical integration, and support modern connection protocols makes them an essential component for contemporary electrical and system distribution operations.

The growing emphasis on system reliability and electrical efficiency optimization is driving demand for copper and aluminum terminal blocks that can support large-scale installation requirements, improve connection outcomes, and enable advanced electrical systems. Engineer preference for products that combine effective corrosion resistance with proven electrical conductivity and connection benefits is creating opportunities for innovative terminal implementations. The rising influence of industrial automation trends and electrical performance awareness is also contributing to increased demand for copper and aluminum terminal blocks that can provide advanced features, seamless system integration, and reliable performance across extended operational periods.

The copper and aluminum terminal blocks market is poised for steady growth and technological advancement. As electrical manufacturers across North America, Europe, Asia-Pacific, and emerging markets seek systems that deliver exceptional connection quality, advanced conductivity capabilities, and reliable performance options, copper and aluminum terminal block solutions are gaining prominence not just as electrical components but as strategic enablers of system technologies and advanced connection functionality.

Rising compact aperture adoption in Asia-Pacific and expanding industrial automation initiatives globally amplify demand, while manufacturers are leveraging innovations in materials engineering, advanced connection integration, and conductivity management technologies.

Pathways like industrial automation implementations, power distribution platforms, and specialized metallurgical solutions promise strong margin uplift, especially in premium electrical segments. Geographic expansion and product diversification will capture volume, particularly where local electrical preferences and advanced technology adoption are critical. Regulatory support around electrical connection standards, conductivity efficacy protocols, and industrial safety requirements give structural support.

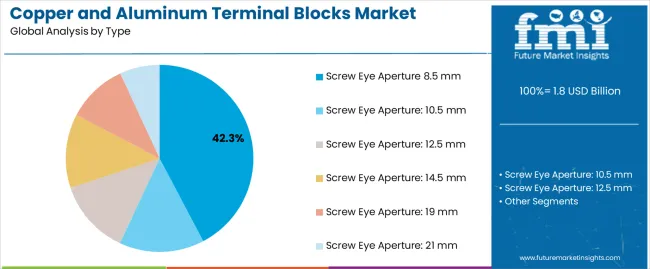

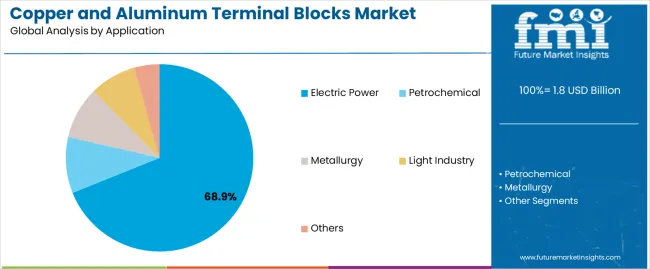

The market is segmented by type, application, end user, current rating, material composition, installation method, distribution channel, price range, and region. By type, the market is divided into screw eye aperture 8.5 mm, screw eye aperture 10.5 mm, screw eye aperture 12.5 mm, screw eye aperture 14.5 mm, screw eye aperture 19 mm, and screw eye aperture 21 mm categories. By application, it covers electric power, petrochemical, metallurgy, light industry, and others segments. By end user, it encompasses power utilities, industrial manufacturers, construction companies, and electrical contractors.

By current rating, the market includes 0-10A, 11-25A, 26-50A, and above 50A. By material composition, the market is categorized into pure copper, aluminum alloy, and copper-aluminum hybrid categories. By installation method, the market is divided into DIN rail mount, panel mount, and PCB mount. By distribution channel, the market includes direct sales, distributors, and online channels. By price range, the market covers premium, mid-range, and economy. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and the Middle East & Africa.

The screw eye aperture 8.5 mm segment is projected to account for 42.3% of the copper and aluminum terminal blocks market in 2025, reaffirming its position as the leading type category. Electrical manufacturers and system integrators increasingly utilize 8.5 mm aperture implementations for their superior connection protection when operating across diverse electrical platforms, excellent installation properties, and widespread acceptance in applications ranging from basic power distribution to premium industrial operations. Screw eye aperture 8.5 mm technology's established installation methods and proven conductivity capabilities directly address the engineer requirements for dependable connection solutions in complex electrical environments.

This type segment forms the foundation of modern electrical adoption patterns, as it represents the implementation with the greatest market penetration and established contractor acceptance across multiple application categories and voltage segments. Manufacturer investments in aperture standardization and system consistency continue to strengthen adoption among electrical producers and installation companies. With engineers prioritizing conductivity and connection reliability, 8.5 mm aperture implementations align with both functionality preferences and cost expectations, making them the central component of comprehensive electrical connection strategies.

Electric power applications are projected to represent 68.9% of copper and aluminum terminal block demand in 2025, underscoring their critical role as the primary application channel for electrical connectivity across power distribution, utility operations, and electrical infrastructure applications. Power utilities prefer copper and aluminum terminal blocks for electric power use for their exceptional conductivity characteristics, scalable installation options, and ability to enhance system reliability while ensuring consistent electrical quality throughout diverse power platforms and distribution operations. Positioned as essential connection components for modern power generation, copper and aluminum terminal block solutions offer both technological advantages and installation efficiency benefits.

The segment is supported by continuous innovation in power distribution technologies and the growing availability of specialized implementations that enable diverse electrical requirements with enhanced conductivity uniformity and extended operational capabilities. Power utilities are investing in advanced technologies to support large-scale system integration and infrastructure development. As electrical reliability trends become more prevalent and connection performance awareness increases, electric power applications will continue to represent a major implementation market while supporting advanced power utilization and technology integration strategies.

The copper and aluminum terminal blocks market is advancing steadily due to increasing demand for advanced electrical connection systems and growing adoption of terminal block technologies that provide superior conductivity resistance characteristics and connection reliability benefits while enabling enhanced system performance across diverse power distribution and industrial automation applications. The market faces challenges, including complex materials formulation requirements, evolving electrical regulations, and the need for specialized installation expertise and performance programs. Innovation in materials chemistry and advanced connection systems continues to influence product development and market expansion patterns.

The growing adoption of advanced electrical connectivity, sophisticated conductivity management capabilities, and system connection awareness is enabling system developers to produce advanced copper and aluminum terminal block solutions with superior electrical positioning, enhanced conductivity profiles, and seamless integration functionalities. Advanced electrical connection systems provide improved performance outcomes while allowing more efficient installation workflows and reliable performance across various electrical applications and environmental conditions. Developers are increasingly recognizing the competitive advantages of system integration capabilities for market differentiation and conductivity positioning.

Modern copper and aluminum terminal block providers are incorporating advanced materials technology, conductivity protocol integration, and sophisticated connection solutions to enhance system appeal, enable intelligent electrical features, and deliver value-added solutions to electrical customers. These technologies improve terminal performance while enabling new market opportunities, including multi-layer systems, optimized surface treatments, and enhanced corrosion resistance characteristics. Advanced conductivity integration also allows developers to support comprehensive electrical terminal technologies and market expansion beyond traditional connection approaches.

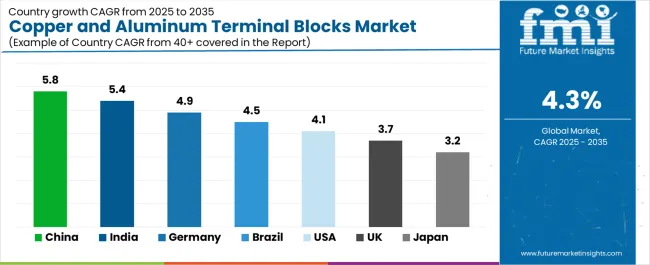

| Country | CAGR (2025-2035) |

|---|---|

| China | 5.8% |

| India | 5.4% |

| Germany | 4.9% |

| Brazil | 4.5% |

| USA | 4.1% |

| UK | 3.7% |

| Japan | 3.2% |

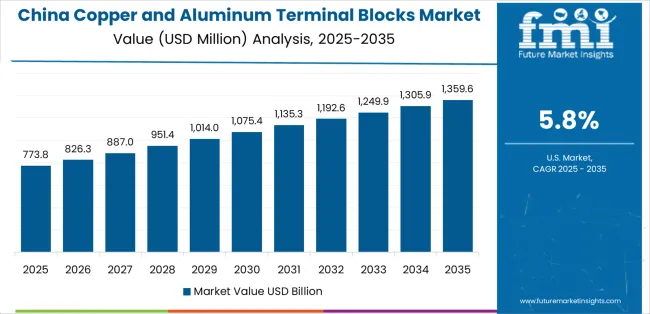

The copper and aluminum terminal blocks market is experiencing steady growth globally, with China leading at a 5.8% CAGR through 2035, driven by expanding electrical infrastructure capacity, growing power distribution modernization programs, and significant investment in electrical component development. India follows at 5.4%, supported by increasing industrial automation production expansion, growing electrical technology integration patterns, and expanding power infrastructure development.

Germany shows growth at 4.9%, emphasizing electrical technology leadership and connection development. Brazil records 4.5%, focusing on expanding industrial capabilities and electrical technology modernization. The USA exhibits 4.1% growth, emphasizing electrical innovation excellence and premium component development. The UK demonstrates 3.7% growth, prioritizing advanced electrical technology development and connection reliability trends. Japan shows 3.2% growth, supported by electrical technology initiatives and quality-focused production patterns.

The report covers an in-depth analysis of 40+ countries, with top-performing countries highlighted below.

Revenue from copper and aluminum terminal blocks in China is projected to exhibit robust growth with a CAGR of 5.8% through 2035, driven by expanding electrical infrastructure capacity and rapidly growing power distribution integration supported by government initiatives promoting electrical technology development. The country's strong position in industrial production and increasing investment in electrical infrastructure are creating substantial demand for advanced terminal implementations. Major electrical manufacturers and technology companies are establishing comprehensive integration capabilities to serve both domestic electrical demand and expanding export markets.

Demand for copper and aluminum terminal blocks in India is expanding at a CAGR of 5.4%, supported by the country's growing industrial sector, expanding electrical technology capacity, and increasing adoption of electrical connection technologies. The country's initiatives promoting industrial modernization and growing power development awareness are driving requirements for technology-integrated electrical systems. International electrical providers and domestic industrial companies are establishing extensive manufacturing and integration capabilities to address the growing demand for advanced connection solutions.

Revenue from copper and aluminum terminal blocks in Germany is projected to grow at a CAGR of 4.9%, supported by the country's electrical technology heritage, strong emphasis on connection technology, and robust demand for advanced terminal systems in industrial and power applications. The nation's mature electrical sector and technology-focused operations are driving sophisticated terminal implementations throughout the industrial sector. Leading manufacturers and electrical specialists are investing extensively in connection development and advanced integration technologies to serve both domestic and international markets.

Demand for copper and aluminum terminal blocks in Brazil is anticipated to expand at a CAGR of 4.5%, driven by the country's expanding industrial sector, growing power infrastructure programs, and increasing investment in electrical technology development. Brazil's large industrial market and commitment to electrical advancement are supporting demand for diverse terminal solutions across multiple application segments. Manufacturers are establishing comprehensive integration capabilities to serve the growing domestic market and expanding industrial opportunities.

Revenue from copper and aluminum terminal blocks in the USA is expanding at a CAGR of 4.1%, supported by the country's advanced electrical technology sector, strategic focus on connection solutions, and established industrial capabilities. The USA's electrical innovation leadership and technology integration are driving demand for specialized terminal implementations in premium products, industrial applications, and advanced electrical systems. Manufacturers are investing in comprehensive technology development to serve both domestic specialty markets and international quality applications.

Demand for copper and aluminum terminal blocks in the UK is growing at a CAGR of 3.7%, driven by the country's focus on electrical technology advancement, emphasis on premium product innovation, and strong position in connection development. The UK's established electrical innovation capabilities and commitment to technology diversification are supporting investment in specialized terminal technologies throughout major industrial regions. Industry leaders are establishing comprehensive technology integration systems to serve domestic premium product production and electrical applications.

Revenue from copper and aluminum terminal blocks in Japan is expanding at a CAGR of 3.2%, supported by the country's electrical excellence initiatives, growing quality technology sector, and strategic emphasis on advanced product development. Japan's advanced quality control capabilities and integrated electrical systems are driving demand for high-quality terminal platforms in premium products, electrical technology, and advanced connection applications. Leading manufacturers are investing in specialized capabilities to serve the stringent requirements of technology-focused electrical and premium product industries.

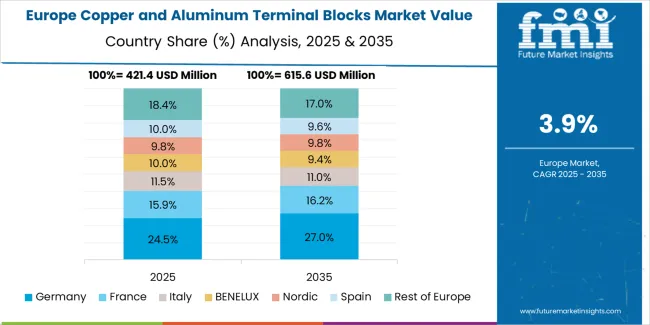

The copper and aluminum terminal blocks market in Europe is projected to grow from USD 428.7 million in 2025 to USD 654.3 million by 2035, registering a CAGR of 4.3% over the forecast period. Germany is expected to maintain its leadership position with a 39.2% market share in 2025, growing to 40.1% by 2035, supported by its strong electrical engineering culture, sophisticated industrial capabilities, and comprehensive electrical industry serving diverse copper and aluminum terminal block applications across Europe.

France follows with a 21.4% share in 2025, projected to reach 21.8% by 2035, driven by robust demand for electrical connection technologies in industrial applications, advanced power distribution programs, and electrical infrastructure markets, combined with established industrial infrastructure and technology integration expertise. The United Kingdom holds a 16.3% share in 2025, expected to reach 15.9% by 2035, supported by strong electrical technology sector and growing premium product activities.

Italy commands a 12.7% share in 2025, projected to reach 12.4% by 2035, while Netherlands accounts for 6.2% in 2025, expected to reach 6.3% by 2035. Spain maintains a 3.1% share in 2025, growing to 3.4% by 2035. The Rest of Europe region, including Nordic countries, Eastern Europe, Belgium, Poland, and other nations, is anticipated to maintain momentum, with its collective share moving from 1.1% to 0.1% by 2035, attributed to increasing electrical modernization in Eastern Europe and growing technology penetration in Nordic countries implementing advanced electrical connection programs.

The copper and aluminum terminal blocks market is characterized by competition among established electrical component companies, specialized terminal technology developers, and integrated electrical solution providers. Companies are investing in materials research, connection optimization, advanced terminal system development, and comprehensive electrical portfolios to deliver consistent, high-quality, and application-specific copper and aluminum terminal block solutions. Innovation in advanced conductivity integration, connection enhancement, and electrical compatibility improvement is central to strengthening market position and competitive advantage.

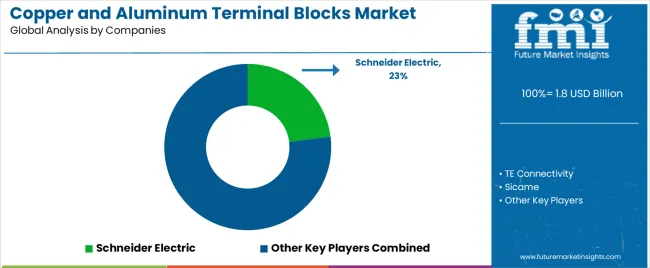

Schneider Electric leads the market with a 23% market share, offering comprehensive electrical technology solutions including quality terminal platforms and advanced integration systems with a focus on premium and industrial applications. TE Connectivity provides specialized connection capabilities with an emphasis on advanced terminal implementations and innovative electrical solutions. Sicame delivers comprehensive electrical services with a focus on integrated platforms and large-scale industrial applications. Klauke specializes in advanced connection technologies and specialized terminal implementations for premium applications. Morek focuses on consumer-oriented electrical integration and innovative technology solutions.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.8 billion |

| Type | Screw Eye Aperture: 8.5 mm; Screw Eye Aperture: 10.5 mm; Screw Eye Aperture: 12.5 mm; Screw Eye Aperture: 14.5 mm; Screw Eye Aperture: 19 mm; Screw Eye Aperture: 21 mm |

| Application | Electric Power; Petrochemical; Metallurgy; Light Industry; Others |

| End User | Power Utilities; Industrial Manufacturers; Construction Companies; Electrical Contractors |

| Current Rating | 0-10A; 11-25A; 26-50A; Above 50A |

| Material Composition | Pure Copper; Aluminum Alloy; Copper-Aluminum Hybrid |

| Installation Method | DIN Rail Mount; Panel Mount; PCB Mount |

| Distribution Channel | Direct Sales; Distributors; Online Channels |

| Price Segment | Premium; Mid-range; Economy |

| Regions Covered | North America; Europe; East Asia; South Asia & Pacific; Latin America; Middle East & Africa |

| Countries Covered | China; India; Germany; Brazil; United States; United Kingdom; Japan; France; and 40+ additional countries |

| Key Companies Profiled | Schneider Electric; TE Connectivity; Sicame; Klauke; Morek; Weidmueller |

| Additional Attributes | Dollar sales by type and application category; regional demand trends; competitive landscape; technological advancements in materials engineering; advanced connection development; conductivity innovation; electrical integration protocols |

The global copper and aluminum terminal blocks market is estimated to be valued at USD 1.8 billion in 2025.

The market size for the copper and aluminum terminal blocks market is projected to reach USD 2.7 billion by 2035.

The copper and aluminum terminal blocks market is expected to grow at a 4.3% CAGR between 2025 and 2035.

The key product types in copper and aluminum terminal blocks market are screw eye aperture 8.5 mm , screw eye aperture: 10.5 mm, screw eye aperture: 12.5 mm, screw eye aperture: 14.5 mm, screw eye aperture: 19 mm and screw eye aperture: 21 mm.

In terms of application, electric power segment to command 68.9% share in the copper and aluminum terminal blocks market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Copper Coated Film Market Size and Share Forecast Outlook 2025 to 2035

Copper Foil Rolling Mill Market Forecast and Outlook 2025 to 2035

Copper Chromite Black Pigment Market Size and Share Forecast Outlook 2025 to 2035

Copper Cabling Systems Market Size and Share Forecast Outlook 2025 to 2035

Copper Bismuth Catalyst Market Size and Share Forecast Outlook 2025 to 2035

Copper Oxychloride Market Size and Share Forecast Outlook 2025 to 2035

Copper Fungicides Market Size and Share Forecast Outlook 2025 to 2035

Copper Tube Market Size and Share Forecast Outlook 2025 to 2035

Copper Foil Market Growth - Trends & Forecast 2025 to 2035

Copper Azoles Market

Copper and Brass Flat Products Market Size and Share Forecast Outlook 2025 to 2035

Copper and Copper Alloy Scrap and Recycling Market Size and Share Forecast Outlook 2025 to 2035

Copper and Aluminum Welding Bar Market Size and Share Forecast Outlook 2025 to 2035

Copper Pipes and Tubes Market Size and Share Forecast Outlook 2025 to 2035

Beryllium Copper Billet Market Size and Share Forecast Outlook 2025 to 2035

Structural Copper Wire Market Size and Share Forecast Outlook 2025 to 2035

Oxygen-free Copper Market Size and Share Forecast Outlook 2025 to 2035

USA and Canada Copper Market Insights - Demand, Size & Industry Trends 2025 to 2035

Rare-earth Barium Copper Oxide (REBCO) Wire Market Size and Share Forecast Outlook 2025 to 2035

Chromium Zirconium Copper Rod Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA