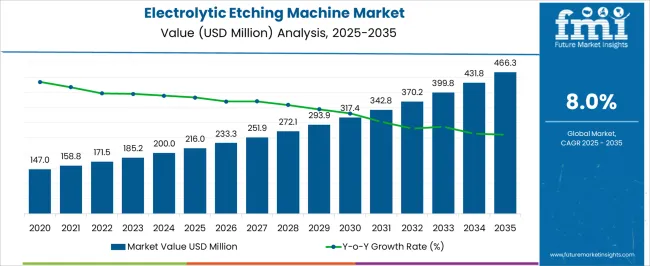

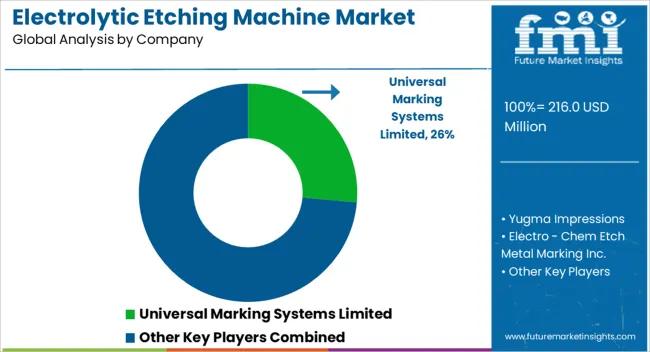

The Electrolytic Etching Machine Market is estimated to be valued at USD 216.0 million in 2025 and is projected to reach USD 466.3 million by 2035, registering a compound annual growth rate (CAGR) of 8.0% over the forecast period.

| Metric | Value |

|---|---|

| Electrolytic Etching Machine Market Estimated Value in (2025 E) | USD 216.0 million |

| Electrolytic Etching Machine Market Forecast Value in (2035 F) | USD 466.3 million |

| Forecast CAGR (2025 to 2035) | 8.0% |

The Electrolytic Etching Machine market is experiencing steady growth due to the rising demand for precise and automated surface treatment solutions across multiple industrial sectors. The market is being shaped by the need for higher accuracy, reduced production time, and improved quality control in metal finishing and component marking processes. Technological advancements in automation and process optimization have enabled manufacturers to enhance productivity while reducing operational costs.

Growing adoption in industries such as automotive, aerospace, electronics, and stainless steel fabrication is driving the demand for efficient etching solutions. In addition, the increasing emphasis on quality compliance and traceability in industrial manufacturing has further reinforced the adoption of electrolytic etching machines.

Future growth opportunities are expected in developing regions where industrial modernization and automation investments are increasing The market is also being influenced by the shift toward environmentally friendly processes that minimize chemical usage and energy consumption, positioning automated electrolytic etching systems as a preferred solution for modern manufacturing environments.

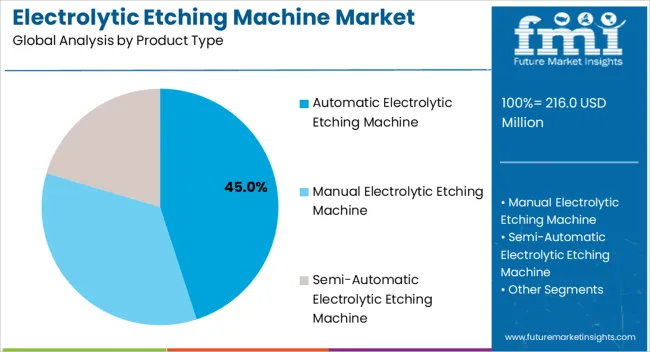

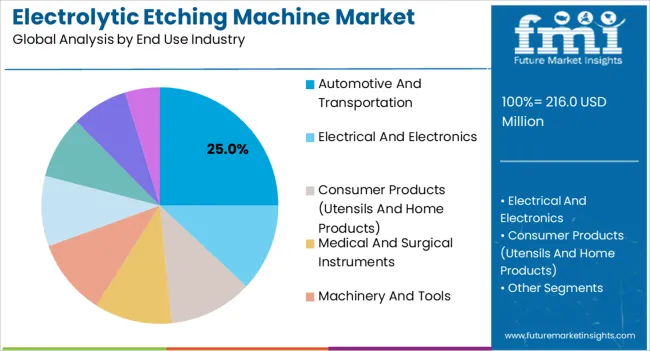

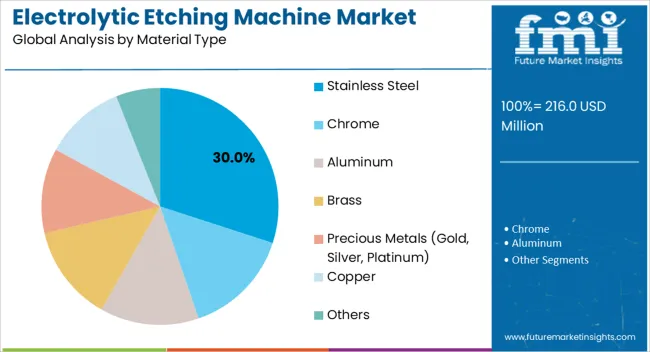

The electrolytic etching machine market is segmented by product type, end use industry, material type, and geographic regions. By product type, electrolytic etching machine market is divided into Automatic Electrolytic Etching Machine, Manual Electrolytic Etching Machine, and Semi-Automatic Electrolytic Etching Machine. In terms of end use industry, electrolytic etching machine market is classified into Automotive And Transportation, Electrical And Electronics, Consumer Products (Utensils And Home Products), Medical And Surgical Instruments, Machinery And Tools, Construction, Defense, Oil And Gas, and Others. Based on material type, electrolytic etching machine market is segmented into Stainless Steel, Chrome, Aluminum, Brass, Precious Metals (Gold, Silver, Platinum), Copper, and Others. Regionally, the electrolytic etching machine industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Automatic Electrolytic Etching Machine segment is projected to hold 45.00% of the Electrolytic Etching Machine market revenue in 2025, making it the leading product type. This dominance is being driven by the superior precision, speed, and repeatability offered by automatic systems compared to manual counterparts.

Adoption has been accelerated in sectors where high-volume production and consistent surface quality are critical, as automatic machines reduce human error and improve process efficiency. The flexibility to integrate with production lines and compatibility with advanced control software has reinforced growth in this segment.

Additionally, reduced labor requirements and the ability to maintain uniform etching across complex geometries have made automatic machines highly attractive for industrial applications Future demand is expected to remain strong as industries continue to prioritize automation, higher throughput, and operational efficiency, solidifying the automatic machine as the preferred choice for modern etching processes.

The Automotive and Transportation end-use industry is expected to account for 25.00% of the Electrolytic Etching Machine market revenue in 2025, emerging as the leading end-use sector. Growth in this segment is being driven by the increasing complexity and precision requirements of automotive components, which necessitate reliable surface marking and finishing.

The adoption of electrolytic etching machines is being reinforced by the need for traceability, quality control, and regulatory compliance in component manufacturing. Manufacturers are increasingly implementing these machines to achieve uniform markings on stainless steel, aluminum, and other metals used in vehicles, enhancing both safety and performance standards.

Additionally, the integration of automated etching systems into high-volume production lines has improved efficiency and reduced production costs The demand is expected to continue rising as the automotive industry evolves toward higher automation, electric vehicle production, and enhanced quality standards, ensuring sustained adoption of electrolytic etching technology in this sector.

The Stainless Steel material type segment is projected to hold 30.00% of the Electrolytic Etching Machine market revenue in 2025, making it the leading material application. This growth is being driven by the increasing use of stainless steel across industries requiring corrosion-resistant, durable, and aesthetically finished components.

The adoption of electrolytic etching machines for stainless steel is being reinforced by their ability to deliver precise, uniform, and high-quality surface markings without compromising material integrity. Industries such as automotive, aerospace, and industrial machinery are favoring this approach to ensure traceability, branding, and compliance with stringent manufacturing standards.

The versatility of stainless steel in combination with advanced etching technologies has accelerated the replacement of traditional mechanical engraving methods, offering enhanced productivity and reduced maintenance Future growth is expected to be supported by rising demand for stainless steel components globally and the need for scalable, automated etching solutions that deliver consistent performance and quality.

Electrolytic Etching Machine works by the use of electric current instead of chemicals or acids. Electrolytic etching machine can be used for marking a wide variety of ferrous and non-ferrous based materials. Major application includes marking of graphics/logos, serial numbers, time and dates, trademarks amongst others.

A number of products such as cutlery, bath ware, sanitary ware, gears, and automotive components, and bearings, surgical and other medical instruments are marked using electrolytic etching machine. The electrolytic machine used in the current scenario is integrated with data matrix, algorithms and software and it doesn’t deform or damage the component to be marked.

Therefore electrolytic etching machine is being used for marking small pipes, shims and feeler gauges. The major advantage of electrolytic etching machine is that is it doesn’t produce any toxic fumes (fumes generated are oxygen and hydrogen) as produced when the marking is done through chemical means.

The electrolyte used is environmentally safe and the solution is reusable. A wide variety of materials including copper, silver, brass, and steel, gold can be etched efficiently using electrolytic etching machine.

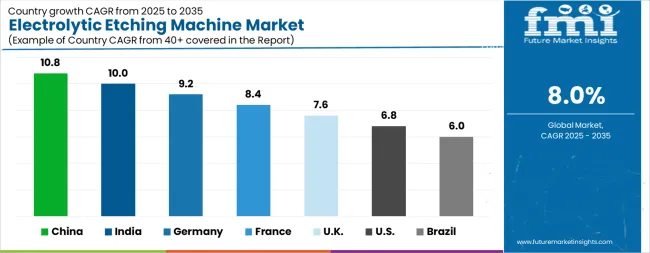

| Country | CAGR |

|---|---|

| China | 10.8% |

| India | 10.0% |

| Germany | 9.2% |

| France | 8.4% |

| U.K. | 7.6% |

| U.S. | 6.8% |

| Brazil | 6.0% |

The Electrolytic Etching Machine Market is expected to register a CAGR of 8.0% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 10.8%, followed by India at 10.0%. Developed markets such as Germany, France, and the U.K. continue to expand steadily, while the U.S. is likely to grow at consistent rates. Brazil posts the lowest CAGR at 6.0%, yet still underscores a broadly positive trajectory for the global Electrolytic Etching Machine Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 9.2%. The U.S. Electrolytic Etching Machine Market is estimated to be valued at USD 81.6 million in 2025 and is anticipated to reach a valuation of USD 157.5 million by 2035. Sales are projected to rise at a CAGR of 6.8% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 11.6 million and USD 6.7 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 216.0 Million |

| Product Type | Automatic Electrolytic Etching Machine, Manual Electrolytic Etching Machine, and Semi-Automatic Electrolytic Etching Machine |

| End Use Industry | Automotive And Transportation, Electrical And Electronics, Consumer Products (Utensils And Home Products), Medical And Surgical Instruments, Machinery And Tools, Construction, Defense, Oil And Gas, and Others |

| Material Type | Stainless Steel, Chrome, Aluminum, Brass, Precious Metals (Gold, Silver, Platinum), Copper, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Universal Marking Systems Limited, Yugma Impressions, Electro - Chem Etch Metal Marking Inc., Automator International srl, Bose Signature, EtchON Marks Control, Cougartron Inc, Monode Marking Products Inc, Ostling Etchmark, Millennium Signatures Marking Systems, and Wuxi Kuntai Automation Co.Ltd. |

The global electrolytic etching machine market is estimated to be valued at USD 216.0 million in 2025.

The market size for the electrolytic etching machine market is projected to reach USD 466.3 million by 2035.

The electrolytic etching machine market is expected to grow at a 8.0% CAGR between 2025 and 2035.

The key product types in electrolytic etching machine market are automatic electrolytic etching machine, manual electrolytic etching machine and semi-automatic electrolytic etching machine.

In terms of end use industry, automotive and transportation segment to command 25.0% share in the electrolytic etching machine market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Electrolytic Capacitor Market Size and Share Forecast Outlook 2025 to 2035

Plug-In Aluminum Electrolytic Capacitor Market Size and Share Forecast Outlook 2025 to 2035

Dental Etching Liquid Market Size and Share Forecast Outlook 2025 to 2035

Tape Stretching Line Market Analysis – Growth & Trends 2025 to 2035

Raffia Tape Stretching Line Market

Machine Glazed Paper Market Size and Share Forecast Outlook 2025 to 2035

Machine Vision Camera Market Size and Share Forecast Outlook 2025 to 2035

Machine Tool Oils Market Size and Share Forecast Outlook 2025 to 2035

Machine Vision System And Services Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Western Europe Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Korea Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Japan Size and Share Forecast Outlook 2025 to 2035

Machine Tool Cooling System Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Machine Tool Touch Probe Market Analysis - Size, Growth, and Forecast 2025 to 2035

Machine Mount Market Analysis - Size & Industry Trends 2025 to 2035

Machine Control System Market Growth – Trends & Forecast 2025 to 2035

Machine Automation Controller Market Growth – Trends & Forecast 2025 to 2035

Machine-to-Machine (M2M) Connections Market – IoT & Smart Devices 2025 to 2035

Machine Safety Market Analysis by Component, Industry, and Region Through 2035

Key Players & Market Share in Machine Glazed Paper Industry

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA