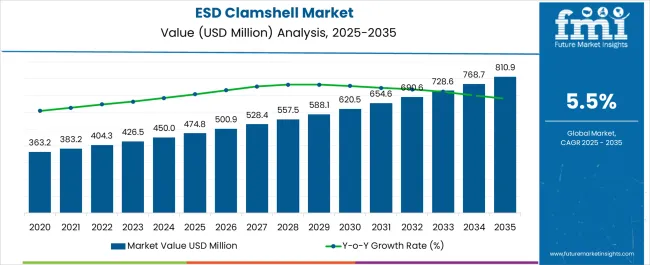

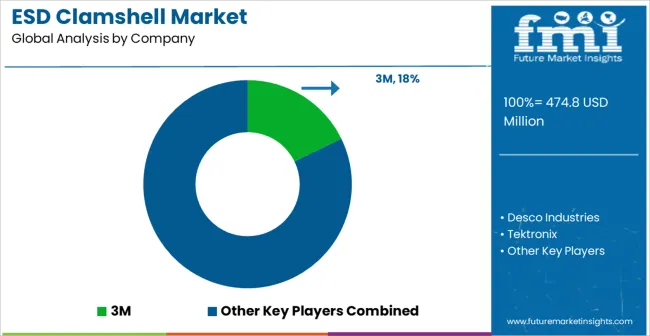

The ESD Clamshell Market is estimated to be valued at USD 474.8 million in 2025 and is projected to reach USD 810.9 million by 2035, registering a compound annual growth rate (CAGR) of 5.5% over the forecast period.

| Metric | Value |

|---|---|

| ESD Clamshell Market Estimated Value in (2025 E) | USD 474.8 million |

| ESD Clamshell Market Forecast Value in (2035 F) | USD 810.9 million |

| Forecast CAGR (2025 to 2035) | 5.5% |

The ESD Clamshell market is witnessing significant growth, driven by increasing demand for electrostatic discharge protection in the manufacturing, transportation, and storage of sensitive electronic components. Rising adoption of advanced electronics across industries such as consumer electronics, automotive, and industrial automation is creating strong demand for protective packaging solutions. Enhanced awareness regarding product safety, quality assurance, and regulatory compliance is further supporting market expansion.

Materials with inherent electrostatic dissipative properties and precision molding techniques are being leveraged to improve the performance of ESD clamshells, ensuring effective protection against static electricity and mechanical damage. The integration of sustainability considerations, such as recyclable materials and environmentally friendly additives, is gaining prominence.

Manufacturers are focusing on scalable and customizable designs to accommodate diverse electronic components, while supply chain optimization and logistics efficiency remain key priorities As global electronics production continues to rise and the need for reliable packaging solutions intensifies, the ESD clamshell market is positioned for sustained growth, driven by innovation in materials, design, and application capabilities.

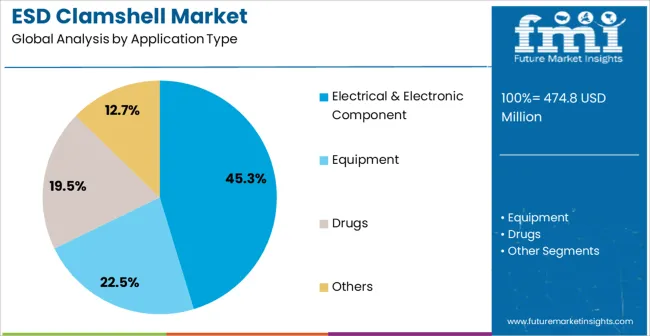

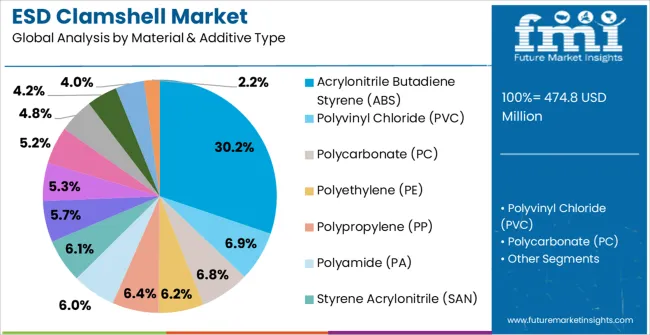

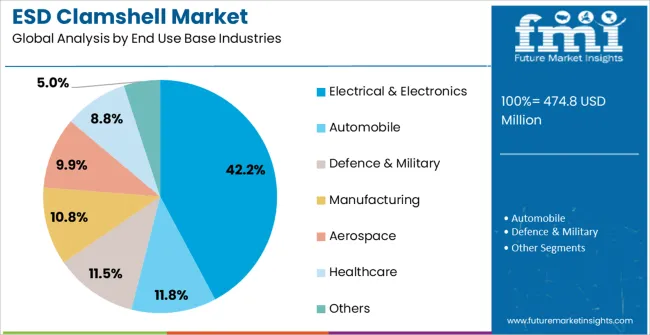

The esd clamshell market is segmented by application type, material & additive type, end use base industries, and geographic regions. By application type, esd clamshell market is divided into Electrical & Electronic Component, Equipment, Drugs, and Others. In terms of material & additive type, esd clamshell market is classified into Acrylonitrile Butadiene Styrene (ABS), Polyvinyl Chloride (PVC), Polycarbonate (PC), Polyethylene (PE), Polypropylene (PP), Polyamide (PA), Styrene Acrylonitrile (SAN), Others, Aluminium, Steel, Tin, Copper, Electrical & Electronic Additive, Automobile Additive, Defence & Military Additive, Manufacturing Additive, Aerospace Additive, and Healthcare Additive. Based on end use base industries, esd clamshell market is segmented into Electrical & Electronics, Automobile, Defence & Military, Manufacturing, Aerospace, Healthcare, and Others. Regionally, the esd clamshell industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The electrical and electronic component segment is projected to hold 45.3% of the market revenue in 2025, establishing it as the leading application type. Its growth is driven by the increasing production of sensitive electronic devices that require protection against electrostatic discharge during handling, transportation, and storage. ESD clamshells provide reliable containment while reducing the risk of functional damage, failure, and associated costs.

Manufacturers are adopting clamshell designs that offer customizable dimensions, enhanced durability, and anti-static properties tailored to different electronic components. The rising emphasis on compliance with industry standards for quality and safety further reinforces the adoption of ESD protective packaging.

Integration with automated assembly and packaging lines is facilitating efficient operations, enabling high-volume production while maintaining component safety As electronics manufacturing continues to expand globally, the electrical and electronic component application segment is expected to maintain its leading position, supported by growing technological requirements and operational reliability.

The Acrylonitrile Butadiene Styrene (ABS) segment is anticipated to account for 30.2% of the market revenue in 2025, making it the leading material and additive type. Growth is being driven by ABS’s inherent mechanical strength, impact resistance, and ease of processing, which are critical for producing durable ESD clamshells. Its capacity to incorporate anti-static additives during manufacturing enhances protection for sensitive electronic components, reducing damage during handling and transportation.

The material’s lightweight nature, cost-effectiveness, and compatibility with various molding techniques further support widespread adoption. ABS clamshells are being increasingly utilized in industries requiring high precision and consistent performance, while offering opportunities for design customization to accommodate diverse component sizes.

Ongoing advancements in polymer processing and additive technologies are enhancing the reliability, efficiency, and environmental profile of ABS-based ESD clamshells As demand for protective packaging continues to rise across electronics manufacturing and distribution, the ABS material segment is expected to maintain its market leadership.

The electrical and electronics end-use industry segment is projected to hold 42.2% of the market revenue in 2025, establishing it as the leading sector. Growth in this segment is being driven by the rapid expansion of consumer electronics, automotive electronics, industrial automation systems, and telecommunications equipment, all of which rely on ESD-sensitive components.

Protective clamshell packaging is critical for maintaining product integrity, minimizing failure rates, and ensuring compliance with safety and quality standards. Adoption is further reinforced by integration with supply chains, automated assembly processes, and storage systems, enabling efficient handling of large volumes of electronic components.

Manufacturers are increasingly prioritizing scalable and customizable solutions that can meet the evolving requirements of high-tech industries while protecting against electrostatic discharge and mechanical damage With ongoing growth in electronics production and heightened attention to operational reliability, the electrical and electronics end-use industry segment is expected to remain the primary driver of ESD clamshell market expansion.

As the world moves towards modernization, the development of the packaging industry is highly important owing to the wide range of applications in the logistics industry. Manufacturers producing ESD clamshell are progressively focusing on investing in packaging machinery and equipment which has enabled increasing output ESD clamshell production.

Future Market Insights recent study suggests that high adoption of technology in automobiles and development of IoT and smart cities actively drives market growth. In addition to this, the FMI report further indicates immense growth owing to a range of distinctive features for the protection of electronic items particularly static items by making sure the integrity of the products enclosed within the pack.

Manufacturers are increasingly becoming interested in investing in good ESD Clamshells owing to the increased need for convenience of transport, enhancing product demand over the past few years. Research shows great potential of ESD Clamshell that provide all the features such as-

To reach potential outcomes, organizations are investing in intelligent and innovative ESD Clamshells. Moreover, companies in the market are adopting new technology and launching new products. The market is increasingly witnessing the development of high-end machinery and equipment for industrial applications.

For instance, in July 2025, CASE Construction Equipment introduced a whole new industry-first equipment category during a special edition of CASE LIVE on Tuesday. The first-of-its-kind machine introduction will transform jobsites and deliver extreme versatility to businesses of all sizes, from site development and landscaping to residential construction and rental.

CASE Construction Equipment is a global full-line manufacturer of construction equipment that combines generations of manufacturing expertise with practical innovation. CASE is dedicated to improving productivity, simplifying operation and maintenance while achieving lower total cost of ownership for fleets around the world.

The global market for electronic devices such as Printed Circuit Board PCB’s and Semi-Conductor accounts to nearly US$ 3.1 trillion with about nearly six percent of the products gets damaged from the static flow of electricity. Improper packaging of ESD sensitive component, assemblies, and equipment result in soft damages which cost manufacturers and users millions of dollar.

To tackle this challenge, packaging manufacturers opt for ESD protective packaging, one such form of ESD protective packaging product which is highly demanded across the electronic industry is ESD clamshell.

Every time an assembly and component is placed in or removed from a package, it can transfer electrical charge. To prevent devices from any static discharge ESD clamshell is used which resist the static flow of electricity in small electronic devices and component.

ESD clamshell is totally enclosed container in a plastic container which is clear antistatic plastic that is usually thermoformed and is optical and resistive. Also, as the market value of electrical components across the globe is expected to witness a CAGR of approximately nine percent.

This factor is fuelling the demand for ESD clamshell which is expected to create an immense growth during the forecast period. Moreover, ESD clamshell manufacturers are engaged in the continuous material and technological development which has rather reduced the overall production cost of ESD clamshell.

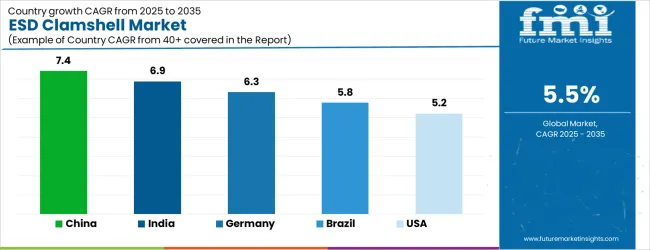

| Country | CAGR |

|---|---|

| China | 7.4% |

| India | 6.9% |

| Germany | 6.3% |

| Brazil | 5.8% |

| USA | 5.2% |

| UK | 4.7% |

| Japan | 4.1% |

The ESD Clamshell Market is expected to register a CAGR of 5.5% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 7.4%, followed by India at 6.9%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 4.1%, yet still underscores a broadly positive trajectory for the global ESD Clamshell Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 6.3%. The USA ESD Clamshell Market is estimated to be valued at USD 175.4 million in 2025 and is anticipated to reach a valuation of USD 175.4 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 22.8 million and USD 14.1 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 474.8 Million |

| Application Type | Electrical & Electronic Component, Equipment, Drugs, and Others |

| Material & Additive Type | Acrylonitrile Butadiene Styrene (ABS), Polyvinyl Chloride (PVC), Polycarbonate (PC), Polyethylene (PE), Polypropylene (PP), Polyamide (PA), Styrene Acrylonitrile (SAN), Others, Aluminium, Steel, Tin, Copper, Electrical & Electronic Additive, Automobile Additive, Defence & Military Additive, Manufacturing Additive, Aerospace Additive, and Healthcare Additive |

| End Use Base Industries | Electrical & Electronics, Automobile, Defence & Military, Manufacturing, Aerospace, Healthcare, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | 3M, Desco Industries, Tektronix, Static Control Components, Conductive Containers Inc., Elcom (UK) Ltd., Protektive Pak, Tandem Equipment Sales Inc., ESD Systems, and SCS |

The global ESD clamshell market is estimated to be valued at USD 474.8 million in 2025.

The market size for the ESD clamshell market is projected to reach USD 810.9 million by 2035.

The ESD clamshell market is expected to grow at a 5.5% CAGR between 2025 and 2035.

The key product types in ESD clamshell market are electrical & electronic component, equipment, drugs and others.

In terms of material & additive type, acrylonitrile butadiene styrene (abs) segment to command 30.2% share in the ESD clamshell market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

ESD Divider Market Size and Share Forecast Outlook 2025 to 2035

Clamshell Packaging Market Size and Share Forecast Outlook 2025 to 2035

ESD Valve Market Forecast and Outlook 2025 to 2035

ESD Safe Matting Market Size and Share Forecast Outlook 2025 to 2035

ESD Trays Market Size and Share Forecast Outlook 2025 to 2035

ESD Protective Signage Labels Market Size and Share Forecast Outlook 2025 to 2035

ESD Totes Market Size and Share Forecast Outlook 2025 to 2035

ESD Foldable Container Market Size and Share Forecast Outlook 2025 to 2035

Clamshell Sealer Market Analysis Size and Share Forecast Outlook 2025 to 2035

Market Share Insights of Clamshell Packaging Providers

ESD Tapes and Labels Market from 2025 to 2035

Clamshell Labelling Machines Market Growth - Trends & Forecast 2022 to 2032

ESD Stackable Box Market Trends & Industry Analysis 2024-2034

ESD Protection Devices Market Insights – Trends & Demand 2023-2033

ESD workstations Market

ESD Suppressors Market

PET Clamshell Market

Food Clamshells Market Trends – Demand, Growth & Future Outlook 2025 to 2035

Stock Clamshell Packaging Market

Paperboard Clamshell Boxes Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA