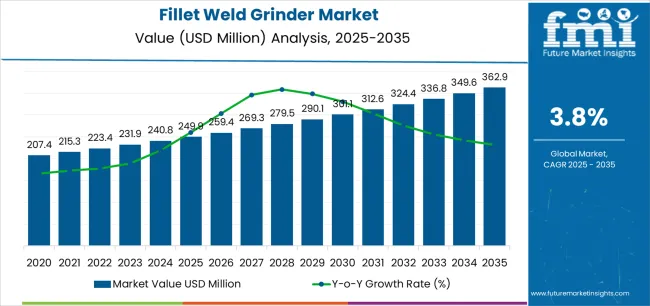

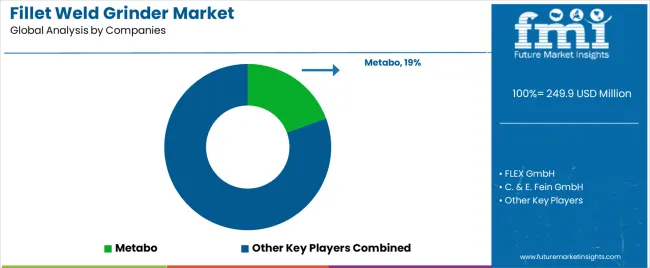

The global fillet weld grinder market is valued at USD 249.9 million in 2025 and is set to reach USD 362.9 million by 2035, recording an absolute increase of USD 113.0 million over the forecast period. This translates into a total growth of 45.2%, with the fillet weld grinder market forecast to expand at a CAGR of 3.8% between 2025 and 2035. The overall market size is expected to grow by approximately 1.5 times during the same period, supported by increasing industrial automation adoption, growing demand for precision welding applications, and rising requirements for efficient metal fabrication processes across construction, automotive, and heavy machinery manufacturing sectors.

The global market represents a specialized segment within the metalworking and fabrication equipment industry, driven by the critical need for precise weld finishing and joint preparation capabilities in demanding manufacturing environments. These specialized grinding tools operate through advanced abrasive systems and ergonomic designs, providing controlled material removal and consistent surface preparation for various welding applications including structural steelwork, pipeline construction, and heavy machinery fabrication. The grinding mechanism enables precise angle control and consistent pressure application, making these devices particularly suitable for high-quality welding applications and systems requiring exact joint geometry specifications.

The fillet weld grinder market encompasses various power configurations, abrasive systems, and specialized designs tailored for specific welding preparation requirements. Modern fillet weld grinders incorporate advanced motor technology, integrated dust collection systems, and enhanced ergonomic features that can operate efficiently across variable workpiece conditions while maintaining consistent performance over extended operational periods. The integration of variable speed controls, specialized grinding wheels, and enhanced safety features has further enhanced the value proposition of these grinding systems among welding professionals seeking operational precision and productivity enhancement.

Market dynamics are significantly influenced by stringent welding quality standards, particularly in structural fabrication applications, pipeline construction projects, and aerospace manufacturing where joint integrity and surface preparation are paramount. The construction sector's increasing focus on structural steel applications, advanced welding methodologies, and quality assurance protocols has created substantial demand for high-performance weld grinding solutions in fabrication shops, construction sites, and specialized manufacturing facilities. The growing trend toward automated welding processes and precision manufacturing has amplified the need for consistent grinding systems capable of integration with modern fabrication workflows and quality control networks.

Consumer purchasing patterns show a marked preference for portable grinding systems that combine powerful motor capabilities with ergonomic design features, multiple speed configurations, and comprehensive dust management systems for diverse fabrication applications. The fillet weld grinder market has witnessed significant technological advancement in motor efficiency design, abrasive wheel development, and dust collection systems, making these devices more suitable for demanding operational environments, extended duty cycles, and precision-critical applications.

Between 2025 and 2030, the fillet weld grinder market is projected to expand from USD 249.9 million to USD 290.2 million, resulting in a value increase of USD 40.3 million, which represents 35.7% of the total forecast growth for the decade. This phase of development will be shaped by increasing precision manufacturing adoption, rising demand for automated fabrication solutions, and growing availability of advanced grinding technologies across industrial facilities and construction applications.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 249.9 million |

| Forecast Value in (2035F) | USD 362.9 million |

| Forecast CAGR (2025 to 2035) | 3.8% |

From 2030 to 2035, the fillet weld grinder market is forecast to grow from USD 290.2 million to USD 362.9 million, adding another USD 72.7 million, which constitutes 64.3% of the overall ten-year expansion. This period is expected to be characterized by the advancement of artificial intelligence integration in grinding control systems, the integration of predictive analytics for optimal performance management, and the development of specialized grinding configurations for high-precision manufacturing applications. The growing focus on process optimization and equipment reliability will drive demand for premium varieties with enhanced grinding performance capabilities, improved connectivity options, and superior automated control characteristics.

Between 2020 and 2024, the fillet weld grinder market experienced robust growth, driven by increasing awareness of welding quality requirements and growing recognition of specialized grinding systems' effectiveness in supporting efficient fabrication operations across industrial facilities and construction applications. The fillet weld grinder market developed as users recognized the potential for fillet weld grinders to deliver operational advantages while meeting modern requirements for precise joint preparation and reliable quality performance. Technological advancement in grinding optimization and abrasive component development began emphasizing the critical importance of maintaining precision control while extending operational life and improving user satisfaction across diverse welding applications.

Market expansion is being supported by the increasing global focus on welding quality standards and the corresponding shift toward high-performance grinding systems that can provide superior precision control characteristics while meeting user requirements for consistent weld preparation and cost-effective manufacturing solutions. Modern fabrication professionals are increasingly focused on incorporating grinding systems that can enhance operational reliability while satisfying demands for consistent, precisely controlled joint preparation and optimized productivity practices. Fillet weld grinders' proven ability to deliver precision grinding excellence, quality assurance benefits, and diverse application possibilities makes them essential components for quality-focused fabrication facilities and precision manufacturing professionals.

The growing focus on structural integrity standards and manufacturing quality optimization is driving demand for high-performance grinding systems that can support distinctive operational outcomes and comprehensive quality management across welding applications, construction projects, and premium manufacturing systems. User preference for grinding solutions that combine functional excellence with productivity enhancement is creating opportunities for innovative implementations in both traditional and emerging fabrication applications. The rising influence of automated manufacturing technologies and advanced quality systems is also contributing to increased adoption of precision grinding solutions that can provide authentic operational benefits and reliable quality monitoring characteristics.

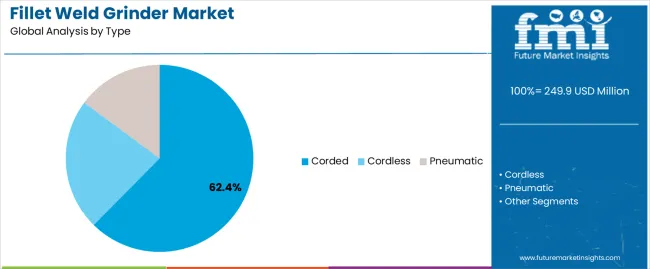

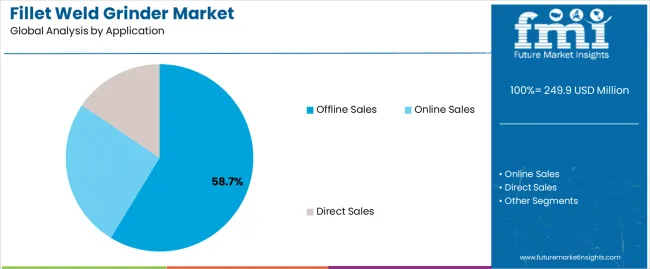

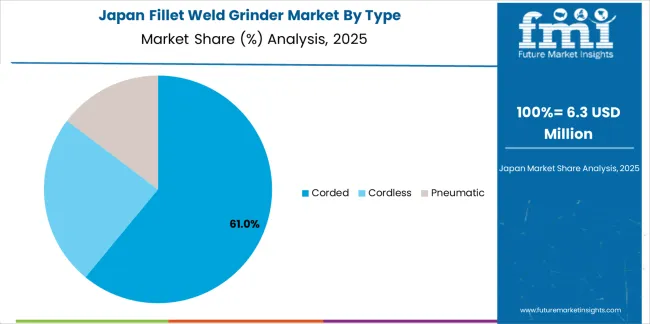

The fillet weld grinder market is segmented by type, application, end use, power rating, and region. By type, the fillet weld grinder market is divided into corded, cordless, and pneumatic configurations. Based on application, the fillet weld grinder market is categorized into online sales, offline sales, and direct sales channels. By end use, the fillet weld grinder market includes construction, automotive, shipbuilding, and general manufacturing categories. By power rating, the fillet weld grinder market encompasses low power, medium power, and high power configurations. Regionally, the fillet weld grinder market is divided into North America, Europe, Asia Pacific, Latin America, the Middle East & Africa, and other regions.

The corded segment is projected to account for 62.4% of the fillet weld grinder market in 2025, reaffirming its position as the leading type category. Fabrication operators and welding professionals increasingly utilize corded systems for their superior power delivery characteristics, established reliability standards, and essential functionality in diverse high-demand grinding applications across multiple manufacturing sectors. Corded grinders' proven performance characteristics and established cost-effectiveness directly address user requirements for reliable grinding control and optimal operational precision in industrial and construction applications.

This type segment forms the foundation of modern precision grinding performance patterns, as it represents the configuration with the greatest power capability and established compatibility across multiple fabrication systems. Manufacturing investments in advanced grinding technology and productivity optimization continue to strengthen adoption among efficiency-focused users. With fabrication managers prioritizing performance consistency and operational reliability, corded systems align with both productivity objectives and quality requirements, making them the central component of comprehensive grinding strategies.

Offline sales are projected to represent 58.7% of the fillet weld grinder market in 2025, underscoring its critical role as the primary distribution channel for quality-focused users seeking superior product evaluation benefits and enhanced technical support credentials. Industrial users and procurement professionals prefer offline channels for their established service requirements, proven technical expertise, and ability to maintain exceptional product assessment while supporting comprehensive equipment evaluation during diverse purchasing activities. Positioned as essential channels for quality-focused manufacturing professionals, offline offerings provide both product excellence and technical consultation advantages.

The segment is supported by continuous improvement in distribution technology and the widespread availability of established technical support standards that enable performance assurance and premium positioning at the facility level. Industrial users are optimizing purchasing strategies to support equipment-specific applications and comprehensive technical consultation strategies. As manufacturing technology continues to advance and facilities seek reliable procurement methods, offline channels will continue to drive market growth while supporting operational efficiency and technical optimization strategies.

The fillet weld grinder market is advancing rapidly due to increasing precision manufacturing adoption and the growing need for specialized grinding solutions that emphasize superior performance characteristics across industrial segments and fabrication applications. The fillet weld grinder market faces challenges, including competition from general-purpose grinding technologies, skilled operator requirements, and initial investment cost factors affecting adoption rates. Innovation in grinding efficiency enhancement and advanced control systems continues to influence market development and expansion patterns.

The growing adoption of fillet weld grinders with manufacturing automation connectivity and smart facility integration is enabling users to develop grinding strategies that provide distinctive monitoring benefits while commanding automated operation and enhanced real-time performance analysis characteristics. Automated manufacturing applications provide superior operational consistency while allowing more sophisticated productivity optimization features across various industrial categories. Users are increasingly recognizing the operational advantages of intelligent grinding positioning for comprehensive manufacturing control outcomes and technology-integrated facility management.

Modern fillet weld grinder manufacturers are incorporating advanced quality sensors, real-time performance monitoring capabilities, and grinding analytics systems to enhance operational precision, improve equipment efficiency effectiveness, and meet manufacturing demands for intelligent grinding solutions. These systems improve operational effectiveness while enabling new applications, including continuous quality monitoring programs and automated optimization protocols. Advanced analytics integration also allows users to support proactive quality positioning and performance assurance beyond traditional grinding operation requirements.

| Country | CAGR (2025-2035) |

|---|---|

| China | 5.1% |

| India | 4.8% |

| Germany | 4.4% |

| Brazil | 4.0% |

| USA | 3.6% |

| UK | 3.2% |

| Japan | 2.9% |

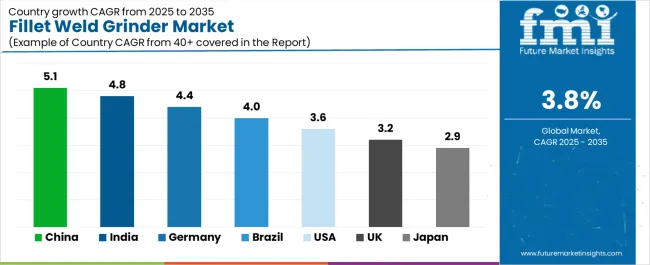

The fillet weld grinder market is experiencing robust growth globally, with China leading at a 5.1% CAGR through 2035, driven by the expanding manufacturing sector, growing industrial automation requirements, and increasing adoption of advanced fabrication technologies. India follows at 4.8%, supported by rising industrialization, expanding construction development industry, and growing acceptance of precision manufacturing technologies. Germany shows growth at 4.4%, emphasizing established engineering standards and comprehensive manufacturing development. Brazil records 4.0%, focusing on industrial modernization and manufacturing efficiency growth. The USA demonstrates 3.6% growth, prioritizing advanced manufacturing technologies and precision optimization.

The report covers an in-depth analysis of 40+ countries, top-performing countries are highlighted below.

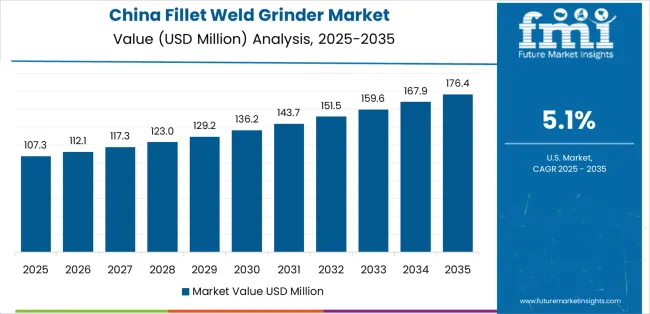

China is projected to exhibit exceptional growth with a CAGR of 5.1% through 2035, driven by the country's rapidly expanding manufacturing sector, favorable government policies toward industrial modernization, and initiatives promoting advanced fabrication technologies across major industrial regions. China's position as a global manufacturing hub and increasing focus on precision manufacturing systems are creating substantial demand for high-quality fillet weld grinders in both domestic and export markets. Major manufacturing equipment companies and industrial distributors are establishing comprehensive grinding capabilities to serve growing demand and emerging automation opportunities.

India is expanding at a CAGR of 4.8%, supported by rising industrialization investment, growing manufacturing consciousness, and expanding equipment distributor capabilities. The country's developing industrial infrastructure and increasing investment in manufacturing technologies are driving demand for grinding equipment across both traditional and modern fabrication applications. International manufacturing equipment companies and domestic distributors are establishing comprehensive operational networks to address growing market demand for precision grinding devices and efficient manufacturing solutions.

Germany is projected to grow at a CAGR of 4.4% through 2035, supported by the country's mature engineering standards, established manufacturing regulations, and leadership in precision manufacturing technology. Germany's sophisticated quality standards and strong support for advanced manufacturing systems are creating steady demand for both traditional and innovative grinding varieties. Leading manufacturing equipment manufacturers and specialty distributors are establishing comprehensive operational strategies to serve both domestic markets and growing export opportunities.

Brazil is projected to grow at a CAGR of 4.0% through 2035, driven by the country's focus on industrial development, manufacturing modernization growth, and growing equipment distributor capabilities. Brazilian industrial users and manufacturing facilities consistently seek efficiency-focused equipment that enhances operational performance and supports modernization excellence for both traditional and modern manufacturing applications. The country's position as a Latin American industrial leader continues to drive innovation in specialized grinding applications and manufacturing standards.

The USA is projected to grow at a CAGR of 3.6% through 2035, supported by the country's focus on manufacturing technology advancement, operational efficiency optimization, and advanced automation integration requiring efficient grinding solutions. American manufacturing users and precision-focused facilities prioritize performance reliability and quality precision, making specialized fillet weld grinders essential components for both traditional and modern manufacturing applications. The country's comprehensive manufacturing technology leadership and advancing precision patterns support continued market expansion.

The UK is projected to grow at a CAGR of 3.2% through 2035, supported by established manufacturing standards, mature industrial markets, and focus on operational efficiency across construction and manufacturing sectors. British manufacturing users and industrial professionals prioritize quality performance and operational consistency, creating steady demand for premium grinding solutions. The country's comprehensive market maturity and established manufacturing practices support continued development in specialized applications.

Japan is projected to grow at a CAGR of 2.9% through 2035, supported by the country's focus on precision engineering, operational excellence, and advanced technology integration requiring efficient grinding solutions. Japanese manufacturing users and precision-focused facilities prioritize technical performance and engineering precision, making specialized fillet weld grinders essential components for both traditional and modern manufacturing applications. The country's comprehensive engineering leadership and advancing precision patterns support continued market expansion.

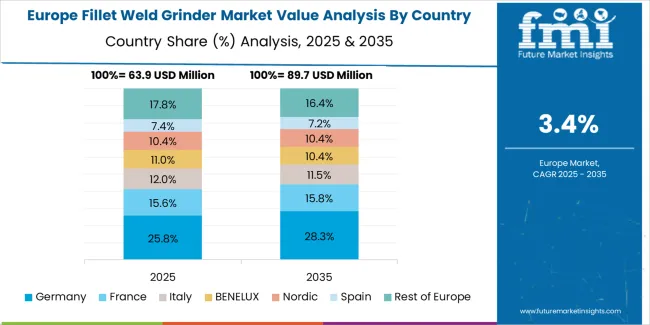

The Europe fillet weld grinder market is projected to grow from USD 72.8 million in 2025 to USD 105.6 million by 2035, recording a CAGR of 3.7% over the forecast period. Germany leads the region with a 43.2% share in 2025, moderating slightly to 42.8% by 2035, supported by its strong engineering traditions and demand for premium, precision-manufactured grinding solutions. The United Kingdom follows with 21.7% in 2025, easing to 21.3% by 2035, driven by a mature manufacturing market and focus on operational efficiency and quality performance. France accounts for 14.8% in 2025, rising to 15.2% by 2035, reflecting steady adoption of manufacturing technologies and precision optimization. Italy holds 9.3% in 2025, expanding to 9.8% by 2035 as industrial modernization and specialty manufacturing applications grow. Spain contributes 5.4% in 2025, growing to 5.7% by 2035, supported by expanding manufacturing development and industrial awareness modernization. The Nordic countries rise from 3.1% in 2025 to 3.3% by 2035 on the back of strong precision consciousness and advanced manufacturing methodologies. BENELUX remains at 2.5% share across both 2025 and 2035, reflecting mature, efficiency-focused manufacturing markets.

The fillet weld grinder market is characterized by competition among established power tool manufacturers, specialized grinding equipment companies, and integrated metalworking providers. Companies are investing in advanced motor technologies, specialized abrasive systems, product innovation capabilities, and comprehensive distribution networks to deliver consistent, high-quality, and reliable grinding systems. Innovation in motor efficiency optimization, grinding technology advancement, and precision-focused product development is central to strengthening market position and customer satisfaction.

Metabo leads the fillet weld grinder market with a 19.4% share, with a strong focus on grinding technology innovation and comprehensive metalworking solutions, offering industrial and construction systems with a focus on performance excellence and engineering heritage. FLEX GmbH provides integrated manufacturing automation with a focus on industrial market applications and precision control networks. C. & E. Fein GmbH delivers comprehensive grinding technology solutions with a focus on professional positioning and operational efficiency. Aerotech Abrasives specializes in comprehensive grinding systems with a focus on industrial applications. Suhner focuses on comprehensive manufacturing equipment with advanced design and premium positioning capabilities.

The success of fillet weld grinders in meeting manufacturing demands, precision requirements, and operational integration will not only enhance manufacturing performance outcomes but also strengthen global metalworking manufacturing capabilities. It will consolidate emerging regions' positions as hubs for efficient grinding equipment production and align advanced economies with comprehensive manufacturing systems. This calls for a concerted effort by all stakeholders -- governments, industry bodies, manufacturers, distributors, and investors. Each can be a crucial enabler in preparing the fillet weld grinder market for its next phase of growth.

How Governments Could Spur Local Production and Adoption?

How Industry Bodies Could Support Market Development?

How Distributors and Manufacturing Equipment Players Could Strengthen the Ecosystem?

How Manufacturers Could Navigate the Shift?

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 249.9 million |

| Type | Corded, Cordless, Pneumatic |

| Application | Online Sales, Offline Sales, Direct Sales |

| End Use | Construction, Automotive, Shipbuilding, General Manufacturing |

| Power Rating | Low Power, Medium Power, High Power |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, Middle East & Africa, Other Regions |

| Countries Covered | China, India, Germany, Brazil, United States, United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | Metabo, FLEX GmbH, C. & E. Fein GmbH, Aerotech Abrasives, Suhner, and other leading fillet weld grinder companies |

| Additional Attributes | Dollar sales by type, application, end use, power rating, and region; regional demand trends, competitive landscape, technological advancements in grinding engineering, motor optimization initiatives, precision enhancement programs, and premium product development strategies |

The global fillet weld grinder market is estimated to be valued at USD 249.9 million in 2025.

The market size for the fillet weld grinder market is projected to reach USD 362.9 million by 2035.

The fillet weld grinder market is expected to grow at a 3.8% CAGR between 2025 and 2035.

The key product types in fillet weld grinder market are corded, cordless and pneumatic.

In terms of application, offline sales segment to command 58.7% share in the fillet weld grinder market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Fish Filleting Machine Market Size and Share Forecast Outlook 2025 to 2035

Fishless Fillet Market Insights - Demand & Future Trends 2025 to 2035

Welding Electrodes and Rods Market Size and Share Forecast Outlook 2025 to 2035

Welding Filler Metal Market Size and Share Forecast Outlook 2025 to 2035

Welding Fume Extraction Equipment Market Size and Share Forecast Outlook 2025 to 2035

Welded Blisters Market Size and Share Forecast Outlook 2025 to 2035

Welding Equipment And Consumables Market Size and Share Forecast Outlook 2025 to 2035

Welding Material Market Analysis by Type, Technology, End User, and Region 2025 to 2035

Welding Guns Market Growth - Trends & Forecast 2025 to 2035

Welding Consumables Market Growth - Trends & Forecast 2025 to 2035

Welding Torch and Tip Changing Robotic Station Market Growth – Trends & Forecast 2024-2034

Welding Helmets Market

Stud Welding Equipment Market Size and Share Forecast Outlook 2025 to 2035

Seam Welding Machine Market Size and Share Forecast Outlook 2025 to 2035

Side Weld Bags Market

Laser Welding Equipment Market Forecast and Outlook 2025 to 2035

Laser Welding Market Size and Share Forecast Outlook 2025 to 2035

Smart Welding Monitoring Solution Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Laser Welding Machine Market Size and Share Forecast Outlook 2025 to 2035

Robotics Welding Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA