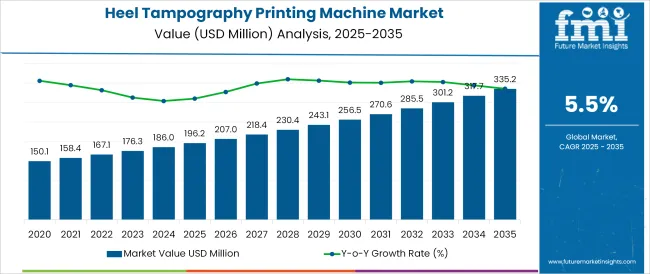

The Heel Tampography Printing Machine Market is estimated to be valued at USD 196.2 million in 2025 and is projected to reach USD 335.2 million by 2035, registering a compound annual growth rate (CAGR) of 5.5% over the forecast period.

The heel tampography printing machine market is progressing steadily, driven by increasing customization demands in the footwear industry and advancements in precision printing technology. Industry publications and manufacturing updates have highlighted the growing application of tampography in delivering detailed logos, patterns, and design elements on complex shoe surfaces.

Footwear brands have expanded their product personalization options, incorporating tampography printing to meet evolving consumer preferences for unique and aesthetically appealing products. Additionally, machinery manufacturers have focused on developing automated and multi-color printing systems that enhance production efficiency and print quality.

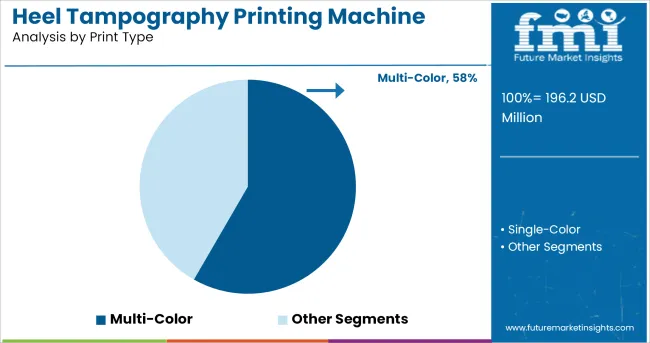

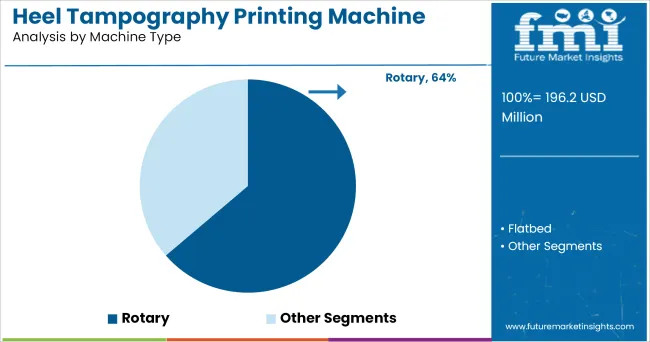

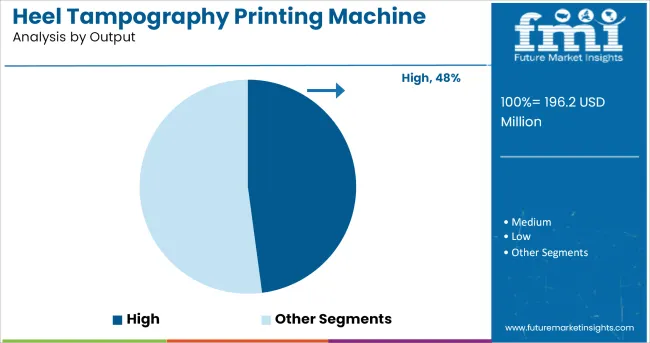

Rising global demand for athletic, casual, and lifestyle footwear has further stimulated machine adoption across both large-scale manufacturing units and mid-sized production facilities. As the market moves forward, innovations in machine automation, energy efficiency, and eco-friendly inks are expected to drive future growth. Segmental demand is being led by Multi-Color print types, Rotary machine types, and High output capabilities, reflecting industry focus on versatile, scalable, and efficient printing operations.

The market is segmented by Print Type, Machine Type, and Output and region. By Print Type, the market is divided into Multi-Color and Single-Color. In terms of Machine Type, the market is classified into Rotary and Flatbed. Based on Output, the market is segmented into High, Medium, and Low. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Multi-Color segment is projected to contribute 58.3% of the heel tampography printing machine market revenue in 2025, establishing itself as the leading print type. Growth in this segment has been supported by footwear manufacturers' demand for vibrant, multi-tone designs that enhance product visual appeal and brand differentiation.

Multi-color printing capabilities have enabled the application of intricate logos, patterns, and promotional graphics, meeting brand marketing objectives and customer customization trends. Equipment manufacturers have enhanced multi-color tampography systems with advanced ink management and rapid color change mechanisms, reducing downtime and improving production flexibility.

The segment's growth has also been fueled by increasing demand for limited-edition and custom-designed footwear lines, where aesthetic precision plays a critical role. As the footwear industry continues to embrace mass customization and fashion-driven product lines, the Multi-Color segment is expected to maintain its dominance in heel printing applications.

The Rotary segment is projected to hold 63.7% of the heel tampography printing machine market revenue in 2025, securing its position as the dominant machine type. Growth of this segment has been driven by its operational efficiency in handling continuous, high-speed production cycles.

Rotary machines have been favored for their ability to print on curved and irregular heel surfaces with consistent pressure and alignment, ensuring high print accuracy. Manufacturers have prioritized rotary systems for their compact design and automation-ready configurations, enabling seamless integration into footwear production lines.

Furthermore, rotary tampography machines have minimized setup times and optimized ink transfer, supporting lean manufacturing practices in the footwear industry. As demand for high-volume, customized heel printing increases, the Rotary segment is expected to remain the preferred machine type due to its reliability, precision, and adaptability in varied production environments.

The High output segment is projected to account for 47.9% of the heel tampography printing machine market revenue in 2025, reflecting its critical role in meeting large-scale production demands. Growth in this segment has been driven by footwear manufacturers' focus on optimizing production throughput without compromising print quality.

High output machines have been engineered with faster cycle times, automated printhead adjustments, and multi station operations, allowing for efficient production of complex designs at scale. Footwear brands targeting mass market releases and seasonal launches have prioritized high-capacity printing solutions to meet market timelines and volume targets.

Additionally, advancements in machine durability and maintenance efficiency have supported continuous operation, reducing downtime and maximizing plant productivity. As the global footwear market expands and consumer demand for personalized products increases, the High output segment is expected to sustain its growth, supporting manufacturers' need for scalable and cost-efficient printing solutions.

The tampography printing process is an indirect process for photogravure printing where the image from a 2D format is transferred to a 3D object. In the tampography printing process depression of desired design are made on a flat plate and ink is filled into these depressions.

Then the silicone pads which act as transfer medium are dipped in the depressions and then pressed onto the desired object. The machine offers high flexibility and freedom for the users to print on a large variety of objects.

The tampography printing machines are widely used in the consumer goods, automotive, medical devices, pharmaceutical, electronics, and apparel and footwear industry for printing on various substrates.

The growing demand for efficient printing solutions for objects with varied shapes from several end-use industries is projected to drive the market growth of heel tampography printing machines.

The growing popularity of printing multicolor designs and prints on various consumer items is one of the trends positively influencing the market for heel tampography printing machines.

As in the case of the tampography printing process, only the required amount of paint is picked by the silicone pad and just a thin layer is applied onto the object the drying time is significantly reduced.

The reduced drying time makes multicolor printing through this method very efficient as another set of prints with different colors can be applied to the object without wasting much time. The multicolor prints are highly desirable in the fashion industry which is raising the demand for heel tampography printing machines in the market.

The rising per capita income levels of consumers across the globe is fuelling the growth of the fashion industry. Further, the growing e-commerce sector is another factor that is bolstering the demand for several products in the fashion industry.

The heel tampography printing machines are convenient and cost-effective tools widely used in the fashion industry for printing on heels and soles of footwear products. The consistent growth of the fashion industry is anticipated to boost the market demand for heel tampography printing machines in the market.

The heel tampography printing machines are highly vulnerable when compared to other alternatives in terms of the environmental conditions surrounding the printing area. The change in humidity, temperature and pressure conditions that includes increase or decrease can negatively impact the print quality.

However, there are other alternative printing techniques like transfer printing or laser printing that do not have these restraints. The heel tampography printing machine market growth might be restrained as a result of the wide availability of alternatives and high vulnerability towards external environmental conditions.

Key global players such as

In the Asian region, players like

Key players in the heel tampography printing machine market are adopting a combination of strategies to increase their market share. The key players in the market are making strategic partnerships with regional manufacturers across the globe in an attempt to enhance their geographical footprint. Focusing on research and development of the product is another strategy adopted by manufacturers.

The heel tampography printing process involves two important aspects that influence the quality of the print, the printing ink and silicone pad specifications. In the current market scenario, there are not many options available in terms of customizations of these products.

As a result, innovation for customization of these products can prove to be a game-changing opportunity for manufacturers that will provide them with an edge over competitors in the heel tampography printing machine market and help to capture maximum market share.

The machinery industry of China is anticipated to expand consistently due to its favorable manufacturing industry infrastructure. The country offers ease in the procurement of raw materials, availability of cheaper labor and favorable national government policies for manufacturing processes.

Furthermore, the fashion industry in China is well established as a result of the presence of many regional as well as global manufacturers of footwear and apparel. All these factors are anticipated to augment the demand for tampography printing machine market in the country.

The global heel tampography printing machine market is estimated to be valued at USD 196.2 million in 2025.

The market size for the heel tampography printing machine market is projected to reach USD 335.2 million by 2035.

The heel tampography printing machine market is expected to grow at a 5.5% CAGR between 2025 and 2035.

The key product types in heel tampography printing machine market are multi-color and single-color.

In terms of machine type, rotary segment to command 63.7% share in the heel tampography printing machine market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

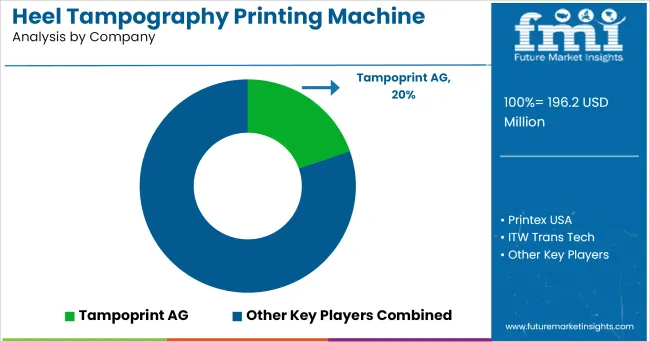

Examining Market Share Trends in the Heel Tampography Printing Machine Industry

Heel And Elbow Suspension Market Size and Share Forecast Outlook 2025 to 2035

Wheeled Bins Market Size and Share Forecast Outlook 2025 to 2035

Wheel Loader Scales Market Size and Share Forecast Outlook 2025 to 2035

Wheel Excavator Market Size and Share Forecast Outlook 2025 to 2035

Wheel Loader Market Size and Share Forecast Outlook 2025 to 2035

Wheel Balancing Market Size and Share Forecast Outlook 2025 to 2035

Wheel Aligner Equipment Market Size and Share Forecast Outlook 2025 to 2035

Wheel Tractor Scrapers Market Size and Share Forecast Outlook 2025 to 2035

Wheeled Insulated Cooler Market Trends - Growth & Demand Forecast 2025 to 2035

Competitive Breakdown of Wheeled Bin Providers

Germany Wheeled Bin Industry Analysis – Growth & Outlook 2024-2034

Wheelchair Market Analysis – Size, Share & Forecast 2024-2034

Wheel studs Market

3-Wheel Sit-Down Counterbalance Forklift Market Size and Share Forecast Outlook 2025 to 2035

4-Wheel Sit-Down Counterbalance Forklift Market Size and Share Forecast Outlook 2025 to 2035

4-Wheel Mobility Scooters Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Competitive Overview of 4-Wheeled Container Companies

4-Wheeled Container Market Trends – Size, Demand & Forecast 2024-2034

Flywheel Energy Storage Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA