The industrial safety gloves market is gaining steady momentum, driven by rising workplace safety standards, stricter regulatory oversight, and growing awareness of occupational hazards across industries. Safety compliance guidelines issued by organizations such as OSHA and ILO have encouraged widespread adoption of protective handwear in high-risk work environments.

Public and private sector investments in industrial safety infrastructure have also supported demand, particularly in heavy manufacturing, chemical processing, and logistics. Advances in glove material science have enabled the production of gloves with enhanced chemical resistance, thermal insulation, and tactile sensitivity, increasing their applicability across specialized tasks.

Additionally, the rise of disposable gloves in industries that prioritize hygiene and contamination control has accelerated market growth. Press releases and industry reports have indicated a growing shift toward sustainable, biodegradable glove options to address environmental concerns. Looking ahead, the market is expected to be shaped by innovations in cut-resistant and smart sensor-integrated gloves, with further expansion driven by growth in emerging industrial economies and compliance-driven procurement practices.

| Metric | Value |

|---|---|

| Industrial Safety Gloves Market Estimated Value in (2025 E) | USD 9.1 billion |

| Industrial Safety Gloves Market Forecast Value in (2035 F) | USD 14.1 billion |

| Forecast CAGR (2025 to 2035) | 4.5% |

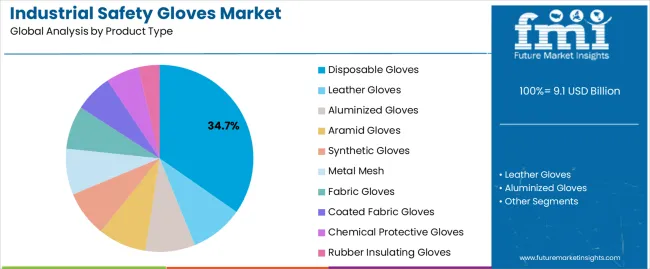

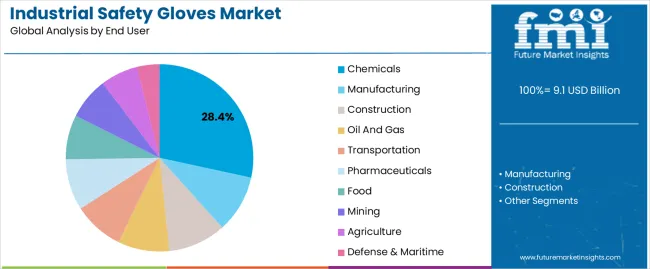

The market is segmented by Product Type and End User and region. By Product Type, the market is divided into Disposable Gloves, Leather Gloves, Aluminized Gloves, Aramid Gloves, Synthetic Gloves, Metal Mesh, Fabric Gloves, Coated Fabric Gloves, Chemical Protective Gloves, and Rubber Insulating Gloves. In terms of End User, the market is classified into Chemicals, Manufacturing, Construction, Oil And Gas, Transportation, Pharmaceuticals, Food, Mining, Agriculture, and Defense & Maritime. Regionally, the market is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The Disposable Gloves segment is projected to account for 34.7% of the industrial safety gloves market revenue in 2025, maintaining a strong position in the overall product landscape. Growth in this segment has been propelled by the increasing demand for single-use hand protection in industries that require stringent hygiene, contamination control, or chemical exposure management.

Disposable gloves have been widely adopted in food processing, pharmaceuticals, and laboratories, but their presence in industrial manufacturing and chemical handling has also expanded due to convenience and compliance benefits. Their ability to provide barrier protection without the need for repeated sanitization has supported usage in fast-paced environments.

Manufacturers have responded by developing powder-free, puncture-resistant, and latex-free options to address occupational allergies and enhance usability. Regulatory frameworks mandating worker safety and PPE accessibility have further reinforced demand for disposable gloves. With industries placing greater emphasis on infection prevention, cost-efficiency, and sustainability, the Disposable Gloves segment is expected to maintain a robust growth trajectory.

The Chemicals segment is expected to contribute 28.4% of the industrial safety gloves market revenue in 2025, establishing itself as the leading end-user category. The segment’s growth has been driven by the hazardous nature of chemical manufacturing processes, where hand protection is essential against exposure to corrosive, toxic, and reactive substances.

Industry protocols and safety audits have increasingly mandated the use of chemically resistant gloves made from nitrile, neoprene, or butyl rubber to ensure worker safety and minimize workplace accidents. Chemical plants and laboratories have prioritized durable gloves that offer protection without sacrificing dexterity, enabling safe handling of complex instruments and materials.

Additionally, regulatory bodies have tightened enforcement of occupational health standards, requiring consistent PPE usage in chemical environments. The rise of specialty chemical manufacturing and increased investments in industrial safety training have further strengthened this segment’s growth. As the chemical sector continues to innovate and expand globally, the Chemicals end-user segment is anticipated to remain a primary contributor to industrial safety glove demand.

Consumer Trends towards Multi-functional and Specialized Industrial Safety Gloves

Consumer trends towards multi-functional and specialized safety gloves reflect the increasing demand for versatile and customized protective solutions across various industries. Rising popularity of multi-functional gloves can be attributed to the ability to protect against multiple hazards and efficiency in addressing numerous workplace safety challenges.

The gloves are becoming appealing to manufacturers due to cost-efficiency and convenience as these consolidate several protective features into a single product. This helps manufacturers streamline inventory management and reduce procurement costs for the business.

Specialized industrial safety gloves catering to particular applications or sectors are witnessing increased adoption as organizations prioritize employee safety and productivity. Industries with specific safety requirements necessitate gloves with specialized features such as anti-static properties, enhanced grip, or oil and water resistance.

By offering tailored coverage and performance enhancements, specialized gloves also contribute to amplifying operational efficiency and product quality, along with improved employee safety, in demanding work environments.

Market Penetration of Disposable Industrial Safety Gloves in Healthcare and Laboratories

The healthcare sector and laboratories are prominent consumers of disposal industrial safety gloves owing to strict hygiene standards and the necessity to prevent cross-contamination. New adoption trends, therefore, significantly impact the market dynamics and product innovation in the overall industrial safety gloves sector.

The industry is witnessing a significant shift in product preferences as these sectors are increasingly preferring disposable gloves over reusable ones. Manufacturers catering to these sectors are experiencing a surge in demand for disposable gloves amid increasing emphasis on infection control measures. They are hence focusing on developing disposable gloves with additional features such as tactile sensitivity, enhanced barrier protection, and comfort.

The prospective market for glove makers expands as disposable industrial safety gloves become prevalent in labs and healthcare settings. This gives key players an opportunity to diversify the scope of product offerings and focus on untapped consumer markets, which propels expansion and revenue growth.

Analysis of Ergonomic Designs in Industrial Safety Gloves for Improved Comfort

The analysis of ergonomic designs in the industrial safety gloves sector reveals a pivotal focus within the sector to optimize wearer satisfaction, productivity, and safety compliance.

Ergonomic considerations incorporate several design elements that are intended to improve hand fatigue, and dexterity, and ensure optimal fit to minimize the risk of injuries to muscles and joints and enhance user experience. These designs prioritize the use of lightweight and flexible materials that provide superior comfort without compromising on protection.

The designs further facilitate precise tool handling, thereby promoting efficiency and productivity. Proper fit is paramount for comfort and functionality in safety gloves.

Customizable fit options minimize bulkiness and prevent slippage, thereby increasing wearer comfort and reducing the risk of hand injuries. Adequate ventilation is essential to prevent heat buildup and moisture accumulation inside gloves that can lead to discomfort and skin irritation.

Ergonomic designs incorporate all these crucial points to provide improved comfort, efficiency, and productivity, thereby becoming a critical aspect in the production of industrial safety gloves.

The market size of industrial safety gloves was USD 7.3 billion in 2020. The sector grew at a CAGR of 1.9% from 2020 to 2025. It registered a value of USD 9.1 billion in 2025.

This growth was attributed to increasing awareness regarding workplace safety regulations, technological developments in gloves, and rapidly increasing industrialization across various regions. The COVID-19 pandemic underscored the importance of personal protective equipment (PPE) to prevent the spread of infectious diseases.

Manufacturers were focused on product innovation, expanding distribution networks, and catering to numerous end-user industries to capitalize on emerging opportunities. Industrial safety gloves market sales analysis exhibits a surge in demand for these gloves during and after the pandemic. The growing requirement for disposable PPE gear owing to hygiene concerns during the pandemic played a crucial role in increasing sales in the sector.

Industrial safety gloves market forecast suggests the sector to reach a value of USD 9.1 billion in 2025. The global industrial safety gloves market analysis anticipates robust growth by 2035.

Increasing adoption of automation across several industries is set to be a key driver during the forecast period. Demand for specialized gloves encompassing enhanced protective features is driven by increased awareness of health risks owing to chemical exposure, infectious diseases, and puncture injuries.

The industry is expected to undergo a shift toward multi-functional and specialized gloves amid rising demand for customized gloves tailored to specific industry requirements.

Manufacturers are progressively investing in research and development, sustainability initiatives, and modern technology to drive product differentiation and competitiveness. Expansion of manufacturing sectors in Asia and Europe is likely to increase the demand for industrial safety gloves.

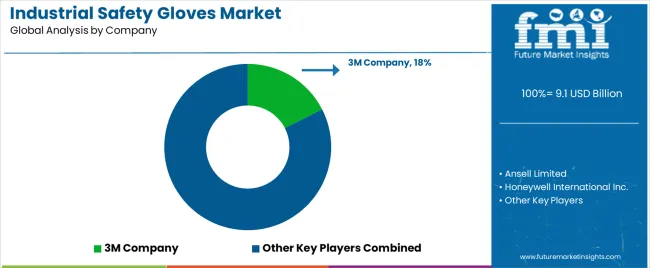

Tier 1 organizations are best recognized by stability and brand recognition. These players hold a dominant share in the sector and employ advanced technologies to streamline manufacturing processes. These companies have massive manufacturing facilities across several regions and an extensive product portfolio. Companies in Tier 1 include Honeywell International Inc., 3M Company, Ansell Limited, Top Glove Corporation, and MCR Safety.

Tier 2 encompasses organizations that operate in specific regions and have a significant impact on the local economy. These are renowned in foreign industries and possess massive experience in the industry. Prominent companies in Tier 2 include Superior Glove Works Ltd., Lakeland Industries, Inc., Showa Group, Cintas Corporation, and Radians Inc.

A great portion of Tier 3 consists of medium to small-sized enterprises that operate locally. These companies cater to specific industries and have a limited geographic scope. This translates to less competition. Organizations in Tier 3 are less formalized and structured compared to companies in Tier 1 and 2. Key companies in Tier 3 are DIPPED PRODUCTS PLC, Southern Glove, Inc., Towa Corporation, PIP Global, and Globus Group.

The section below provides an analysis of how different countries are playing a key role in shaping the global industrial safety gloves sector. It explores the latest trends, drivers, and threats to the industry and determines the market size of industrial safety gloves in leading countries. Businesses can obtain a significant understanding of the evolving dynamics of the industry by examining the country-wise influence of the sector.

India is estimated to emerge as a dominating country from 2025 to 2035, with a projected CAGR of 6.7%. China, Spain, and France are expected to follow closely with projected CAGRs of 5%, 3.4%, and 3.2%, respectively. A deep understanding of country-wise statistics would enable businesses to tailor new strategies and product offerings to fit the preferences of local consumers.

| Countries | CAGR 2025 to 2035 |

|---|---|

| India | 6.7% |

| China | 5% |

| Spain | 3.4% |

| France | 3.2% |

| Italy | 2.9% |

India is undergoing a rapid expansion, resulting in a spike in demand for industrial safety gear, including gloves. This makes the country a considerable and readily available domestic sector for glove manufacturers.

The country offers companies a competitive edge in terms of production costs compared to established players in Europe and North America. This enables India-based manufacturers to potentially reduce prices, making new gloves more cost-competitive across the globe.

Authorities and governments are emphasizing worker safety and hence implementing stringent regulations that mandate the use of PPE, translating to a guaranteed demand for safety gloves in the country. India’s large pool of skilled labor can easily support the growing glove manufacturing industry. They can further contribute to the efficient production of industrial safety gloves and potentially lower costs.

China’s massive manufacturing sector consumes a significant portion of industrial safety gloves. This domestic demand pushes production capacity, positioning the country as one of the leading consumers across the globe. The pandemic has spurred the production capacity of nitrile gloves in the country, allowing China to maintain a competitive edge and potentially capture a significant share of the sector.

China, like India, offers impressive cost advantages in the production sector compared to other developed nations. This allows manufacturers to offer competitive prices in the global market, making the gloves appealing to price-sensitive consumers.

Like several European countries, Spain is experiencing a growing emphasis on worker safety. This results in the implementation of stringent regulations and increased enforcement, mandating the use of PPE, including gloves.

The country’s well-developed industries like chemicals, automotive, and food processing heavily rely on safety gear, thereby driving the domestic demand for various glove types. Consumers in Europe prioritize quality and technical features over price, creating a golden opportunity for businesses in Spain to cater to this segment of consumers by offering innovative and high-performance gloves.

The following section provides businesses with valuable information and analysis of two leading categories in of the target sector. This segmentation of leading categories would help investors understand the dynamics and invest in the most beneficial zone.

By evaluating the opportunities, trends, and challenges in the sector, enterprises can gain an in-depth understanding of the industry. Businesses can make wise decisions with the help of insightful data to navigate the business environment.

Disposable gloves are dominating in terms of product type with a value share of 32.1% in 2025. Construction has emerged as the leading end-user with a value share of 22.8% in 2025.

| Segment | Disposable Gloves (Product Type) |

|---|---|

| Value Share (2025) | 32.1% |

Disposable gloves offer an effective and convenient solution to prevent cross-contamination and reduce the transmission of diseases, chemicals, and other contaminants in sensitive environments. These eliminate the requirement of cleaning or sanitization, thereby saving time and labor costs associated with reusable gloves. These are also a cost-effective option for organizations that require frequent glove changes.

Certain glove materials may cause allergies or sensitivities to some workers. Disposable gloves are made from alternative materials such as vinyl or nitrile, thereby reducing the risk of adverse reactions and accommodating a broad range of users.

Disposable gloves are further available in a wide variety of materials, sizes, and thicknesses, making these suitable for diverse applications across industries. These have a streamlined dispensing process that enhances efficiency and helps businesses effectively manage their glove inventory. Advanced manufacturing techniques and material innovations have resulted in the development of gloves that have improved barrier properties and durability, ensuring optimal protection for users.

| Segment | Construction (End-user) |

|---|---|

| Value Share (2025) | 22.8% |

Construction sites have several safety hazards. Industrial safety gloves provide vital protection against these dangers by lowering the risk of injuries and chemical burns. Construction companies are subject to strict occupational health and safety laws that are aimed at ensuring worker protection. Compliance with these regulations necessitates the use of appropriate PPE to navigate workplace hazards and minimize the risk of accidents.

Construction activities demand versatile glove designs that can withstand several types of chemical, thermal, and mechanical hazards. The sector employs a huge workforce across the globe. This significant size translates to a substantial demand for industrial safety gloves to protect workers across diverse construction activities.

Safety gloves play a vital role in the implementation of risk management strategies. Manufacturers are consistently innovating these gloves to meet the evolving requirements of the construction industry.

Key players in the industry, including 3M Company, Ansell Limited, Honeywell International Inc., Top Glove Corporation Bhd, and Radians are in a battle for innovation. Providing specialized gloves for specific industries is a prominent strategy companies are utilizing.

Technologies providing improved dexterity and moisture management are gaining traction. There is an increasing focus on using advanced materials and designs to create ergonomic gloves that reduce hand fatigue and improve work compliance.

Emerging economies are experiencing industrial growth, creating a surge in demand for safety gloves. Companies catering to these sectors with cost-effective yet high-quality products will be well-positioned. Integration of smart technologies, advancements in ergonomic designs, and enhanced glove performance, comfort, and user experience are crucial to stay competitive.

Reaching a wide audience will be important in such a competitive industry. Organizations can leverage social media and e-commerce platforms to showcase new products and target small businesses or individual buyers.

Industry Updates

Based on product type, the sector is divided into leather, aluminized, aramid, disposable, synthetic, metal mash, fabric, coated fabric, chemical protective, and rubber-insulating gloves.

By end-user, the sector is segmented into manufacturing, construction, oil and gas, transportation, pharmaceuticals, chemicals, food, mining, agriculture, and defense and maritime.

The industrial safety gloves industry is spread across North America, Latin America, Western Europe, South Asia, East Asia, Eastern Europe, and the Middle East and Africa.

The global industrial safety gloves market is estimated to be valued at USD 9.1 billion in 2025.

The market size for the industrial safety gloves market is projected to reach USD 14.1 billion by 2035.

The industrial safety gloves market is expected to grow at a 4.5% CAGR between 2025 and 2035.

The key product types in industrial safety gloves market are disposable gloves, leather gloves, aluminized gloves, aramid gloves, synthetic gloves, metal mesh, fabric gloves, coated fabric gloves, chemical protective gloves and rubber insulating gloves.

In terms of end user, chemicals segment to command 28.4% share in the industrial safety gloves market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Industrial Precision Oven Market Size and Share Forecast Outlook 2025 to 2035

Industrial Water Chiller for PCB Market Size and Share Forecast Outlook 2025 to 2035

Industrial & Commercial HVLS Fans Market Size and Share Forecast Outlook 2025 to 2035

Industrial Robot Controller Market Size and Share Forecast Outlook 2025 to 2035

Industrial Wired Routers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Evaporative Condensers Market Size and Share Forecast Outlook 2025 to 2035

Industrial Energy Management System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Insulation Market Size and Share Forecast Outlook 2025 to 2035

Industrial Cleaner Market Size and Share Forecast Outlook 2025 to 2035

Industrial Dust Treatment System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Vertical Washing Tower Market Size and Share Forecast Outlook 2025 to 2035

Industrial Pepper Market Size and Share Forecast Outlook 2025 to 2035

Industrial Electronics Packaging Market Forecast and Outlook 2025 to 2035

Industrial Absorbent Market Forecast and Outlook 2025 to 2035

Industrial Furnace Industry Analysis in Europe Forecast and Outlook 2025 to 2035

Industrial Denox System Market Size and Share Forecast Outlook 2025 to 2035

Industrial Electronic Pressure Switch Market Size and Share Forecast Outlook 2025 to 2035

Industrial WiFi Module Market Size and Share Forecast Outlook 2025 to 2035

Industrial Security System Market Forecast Outlook 2025 to 2035

Industrial Film Market Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA