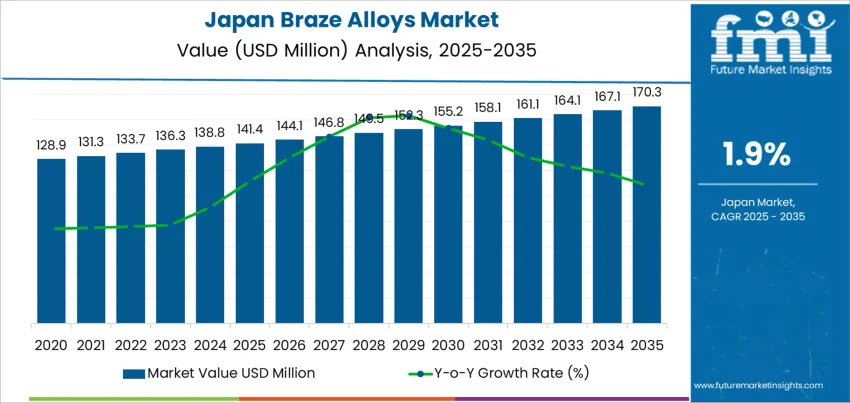

The demand for braze alloys in Japan is expected to grow from USD 141.4 million in 2025 to USD 170.3 million by 2035, reflecting a compound annual growth rate (CAGR) of 1.9%. Braze alloys, used to join different metals via high-temperature brazing, play a crucial role in several industries, including automotive, aerospace, electronics, and HVAC. These alloys are essential for creating strong, durable, and efficient bonds between materials that are difficult to weld. As the demand for high-performance and precise materials continues to rise, particularly in industries with stringent requirements for durability and efficiency, the demand for braze alloys is expected to see consistent growth.

The automotive industry, which relies heavily on brazing to assemble components such as heat exchangers and engine parts, is a significant driver of demand for braze alloys. The rising demand for electric vehicles (EVs), coupled with increasing requirements for lightweight materials and fuel efficiency, will continue to promote the use of braze alloys. Aerospace and electronics industries, which require advanced materials for components such as turbines, batteries, and semiconductors, are also expected to drive growth in demand for braze alloys, as they are critical to improving the performance and longevity of these devices.

Between 2025 and 2030, the demand for braze alloys in Japan is expected to grow from USD 141.4 million to USD 144.1 million. This phase will experience gradual growth as the automotive and aerospace industries maintain steady demand for brazing solutions. The incremental growth during this period will be supported by continued investments in lightweight materials and energy-efficient technologies in key sectors like automotive and HVAC. The increased focus on improving fuel efficiency and component durability in electric vehicles and other high-performance systems will drive a steady demand for braze alloys.

From 2030 to 2035, the demand for braze alloys is projected to accelerate, growing from USD 144.1 million to USD 170.3 million. This period will witness faster growth as industries adopt more sophisticated materials for advanced manufacturing processes. The expansion of the aerospace sector, driven by growing air travel demand and technological advancements in aircraft systems, will significantly boost the use of braze alloys. Furthermore, innovations in semiconductor manufacturing and electronics packaging will increase the need for braze alloys, which are used to form strong bonds in the production of delicate components such as batteries and microchips.

| Metric | Value |

|---|---|

| Demand for Braze Alloys in Japan Value (2025) | USD 141.4 million |

| Demand for Braze Alloys in Japan Forecast Value (2035) | USD 170.3 million |

| Demand for Braze Alloys in Japan Forecast CAGR (2025-2035) | 1.9% |

The demand for braze alloys in Japan is growing due to their essential role in a variety of industries, particularly in manufacturing, electronics, automotive, and aerospace sectors. Braze alloys are used in the joining of metals, offering superior strength and durability in high-performance applications where welding and soldering may not be effective. As Japan continues to advance in industrial technology and precision manufacturing, the demand for braze alloys is increasing, particularly for applications that require high-quality, reliable, and durable metal bonding solutions.

A major driver of this growth is the increasing demand for high-performance materials in sectors like automotive and electronics. Braze alloys are critical in automotive engine and transmission components, as well as in electronic devices that require heat management and durability. With the continuous innovation in the automotive and electronics industries, including the development of electric vehicles (EVs) and consumer electronics, the need for advanced joining techniques such as brazing is expected to rise. Braze alloys provide the necessary strength and heat resistance for these applications, which is driving their growing use.

Japan’s strong emphasis on industrial automation and the ongoing demand for high-precision manufacturing in industries like aerospace is also contributing to the rise in braze alloy demand. The versatility of braze alloys in creating strong bonds between dissimilar materials and in environments with high thermal or mechanical stresses makes them an essential component in many manufacturing processes. As Japan continues to push for innovation and excellence in precision engineering, the demand for braze alloys is expected to grow steadily through 2035.

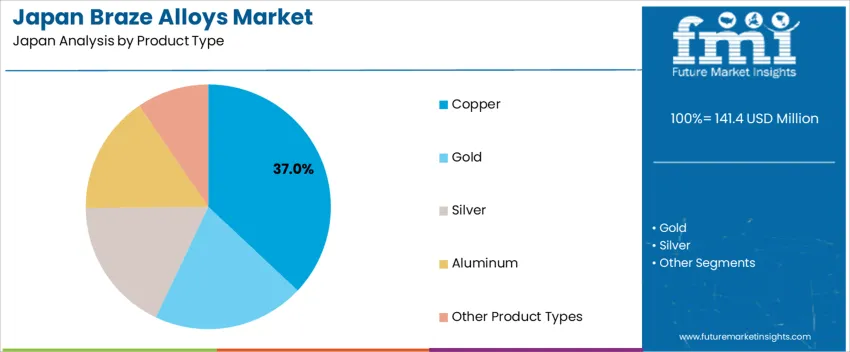

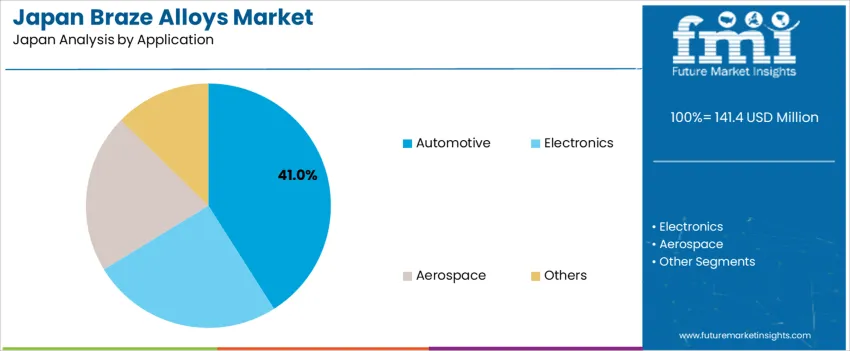

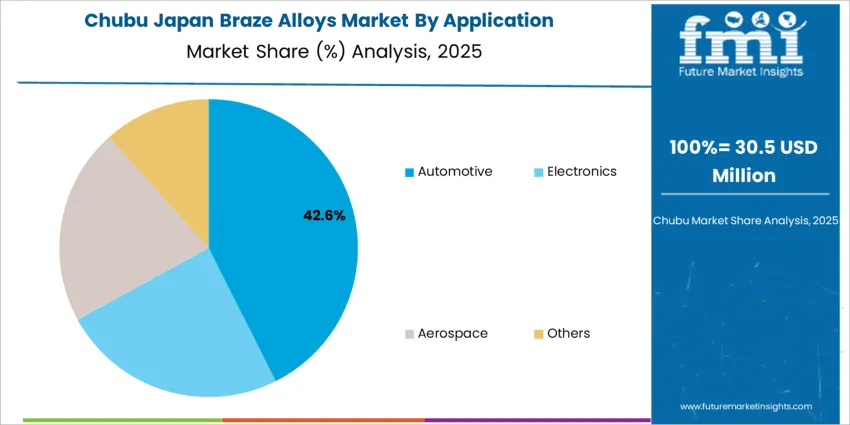

Demand for braze alloys in Japan is segmented by product type and application. By product type, demand is divided into copper, gold, silver, aluminum, and other product types, with copper leading the demand at 37%. The demand is also segmented by application, including automotive, electronics, aerospace, and others, with the automotive industry holding the largest share at 41%. Braze alloys are used extensively for joining metal parts and ensuring strong, durable bonds in various industries. Regionally, demand is divided into Kanto, Kinki, Chubu, Kyushu & Okinawa, Tohoku, and the Rest of Japan.

Copper accounts for 37% of the demand for braze alloys in Japan. Copper braze alloys are highly valued for their excellent thermal and electrical conductivity, making them essential for applications in industries like automotive, electronics, and manufacturing. Copper’s ability to form strong, durable joints without compromising the material properties of the parts being joined is a key factor in its dominance. The relatively low melting point of copper alloys also facilitates faster, more efficient bonding processes. These properties make copper braze alloys the preferred choice for industries requiring high-performance and cost-effective joining solutions, especially in sectors like electronics and automotive where precision and reliability are paramount. As Japan’s manufacturing industries continue to prioritize energy-efficient and high-performance materials, copper braze alloys will remain a vital component in the production of advanced and durable products.

The automotive industry accounts for 41% of the demand for braze alloys in Japan. Braze alloys are essential in the manufacturing of automotive components, particularly in engines, exhaust systems, and parts that require high strength and resistance to extreme temperatures. These alloys ensure durable, safe, and efficient bonding of parts, allowing the automotive industry to produce reliable, high-performance vehicles. As automotive manufacturers focus on reducing weight and improving fuel efficiency, braze alloys are used to join dissimilar materials, such as metals and composites, which is crucial for the production of advanced vehicle components. The growing demand for fuel-efficient, high-performance vehicles continues to drive the automotive sector’s use of braze alloys. As the automotive industry continues to innovate, the demand for braze alloys, especially in critical applications requiring heat resistance and structural integrity, will remain strong in Japan.

The demand for braze alloys in Japan is driven by their application across multiple industries, including automotive, electronics, HVAC, aerospace, and industrial manufacturing. As industries move toward lightweight, energy-efficient solutions, the need for brazing increases, particularly in the automotive sector with electric vehicles, and in electronics where precise, high-performance joining is required. The rising need for efficient heat exchangers and the transition to more thermally resilient systems also boosts the demand for braze alloys.

What Are the Key Trends Driving Demand for Braze Alloys in Japan?

The demand for braze alloys in Japan is being driven by several key trends. The growing shift toward electric vehicles (EVs) is particularly notable, as EV battery systems and power modules require specialized brazing solutions to ensure durability and performance. Japan’s expanding electronics manufacturing sector, especially in power modules, LEDs, and heat exchangers, continues to increase the need for brazing. The demand for more efficient, environmentally friendly materials also plays a significant role, with stricter regulations encouraging the use of lead-free and cadmium-free brazing alloys. These trends reflect a broader industry focus on sustainability, cost-effectiveness, and high-performance materials, which collectively boost the demand for braze alloys across diverse applications.

What Are the Key Restraints in the Demand for Braze Alloys in Japan?

Key restraints in the demand for braze alloys in Japan include high material costs, particularly for silver-based alloys, which may not be suitable for cost-sensitive applications. The brazing process itself is more complex compared to simpler joining techniques like soldering, requiring high precision and significant resources, which can increase production costs. The volatility of raw material prices, especially precious metals used in brazing, can create financial instability and impact profitability. The shift toward lead-free and cadmium-free alloys, while necessary for regulatory compliance, increases production costs and reduces the availability of certain alloys. These restraints can limit the adoption of braze alloys, especially in industries with tighter cost constraints.

What Challenges Limit Wider Adoption of Braze Alloys in Japan?

Wider adoption of braze alloys in Japan faces several challenges. High production costs, especially for silver-based and specialty alloys, remain a significant barrier, particularly in cost-sensitive sectors. The complexity of the brazing process, which requires precision and specialized equipment, can deter smaller manufacturers or applications with low volumes. Regulatory challenges are also prominent, as the push for safer, environmentally friendly materials like lead-free alloys raises production costs and limits the availability of certain brazing materials. Furthermore, the need for high-quality control standards and the intricate process of brazing compared to simpler methods like soldering adds to the difficulty, limiting adoption in some industries.

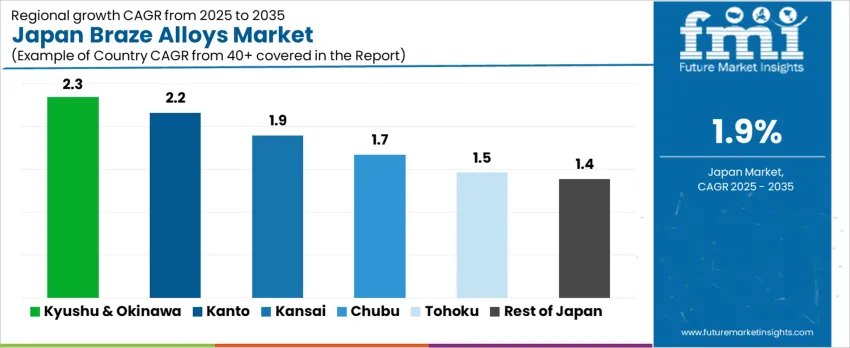

| Region | CAGR (%) |

|---|---|

| Kyushu & Okinawa | 2.3% |

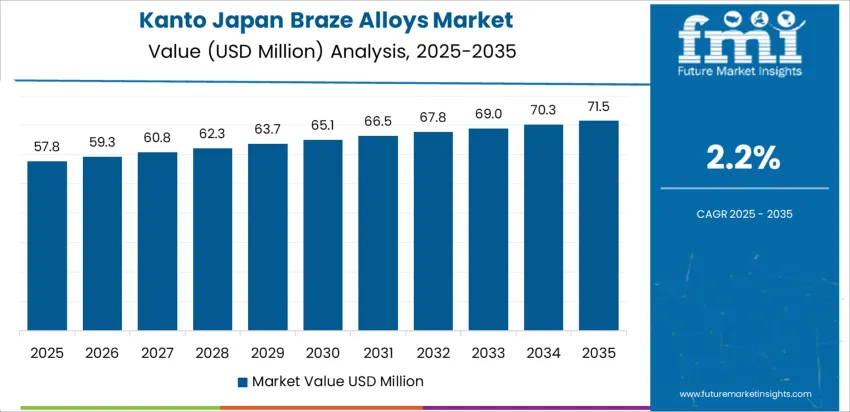

| Kanto | 2.2% |

| Kinki | 1.9% |

| Chubu | 1.7% |

| Tohoku | 1.5% |

| Rest of Japan | 1.4% |

Demand for braze alloys in Japan is growing steadily, with Kyushu & Okinawa leading at a 2.3% CAGR, driven by strong industrial activities and an emphasis on advanced manufacturing technologies. The Kanto region follows closely with a 2.2% CAGR, supported by its large electronics, automotive, and manufacturing sectors. Kinki shows a 1.9% CAGR, fueled by its diverse industrial base, including automotive and electronics, where brazing is critical for high-precision applications. Chubu experiences a 1.7% CAGR, with demand driven by the automotive industry, particularly in high-performance vehicle components. Tohoku and the Rest of Japan see slower growth at 1.5% and 1.4%, respectively, as regional industries gradually modernize and adopt advanced brazing solutions.

Kyushu & Okinawa is experiencing moderate demand for braze alloys, growing at a 2.3% CAGR. The demand in this region is driven by its growing manufacturing and industrial sectors, where braze alloys are used for joining metal parts in electronics, automotive, and machinery. Kyushu, known for its strong industrial base, is investing in advanced manufacturing processes, leading to an increased need for brazing materials. Okinawa’s focus on expanding its manufacturing capabilities, particularly in high-tech and renewable energy sectors, is also contributing to the rising demand for braze alloys. The increasing adoption of advanced technologies, including 5G, is pushing for more precision in metal joining processes, making braze alloys essential. As these industries continue to grow and evolve, Kyushu & Okinawa are expected to see sustained demand for braze alloys.

Kanto, particularly Tokyo, is seeing steady demand for braze alloys, growing at a 2.2% CAGR. The region’s demand is driven by its well-established electronics, automotive, and manufacturing industries, where brazing plays a crucial role in metal joining and assembly. The growth in Kanto’s high-tech manufacturing sector, including the production of semiconductors and telecommunications equipment, is a major contributor to this demand. With the continuous expansion of the automotive and consumer electronics industries, Kanto is experiencing a rise in the need for advanced joining materials like braze alloys, which are essential for components requiring high precision and reliability. Kanto’s emphasis on innovation and technology development in electronics and renewable energy is further driving the demand for brazing solutions. As these sectors expand, Kanto’s need for braze alloys will continue to rise.

In Kinki, demand for braze alloys is growing at a 1.9% CAGR. The region’s manufacturing industry, especially in automotive and electronics, is the main driver of this demand. Kinki, home to major industrial hubs like Osaka and Kobe, has a well-established base in precision manufacturing, where braze alloys are essential for joining metal parts in high-performance applications. As Japan's automotive and electronics sectors continue to innovate, there is a rising need for brazing materials that offer strong and durable joins, especially in advanced electronic devices and vehicle components. Kinki’s focus on green technologies and energy-efficient manufacturing processes is also contributing to the need for braze alloys in these sectors. While the growth in Kinki is moderate compared to other regions, its manufacturing-driven economy ensures steady demand for brazing solutions in various industries.

Chubu is seeing a modest demand for braze alloys, with a 1.7% CAGR. The region's industrial activities, particularly in automotive manufacturing and electronics, drive the demand for brazing materials. Chubu, home to major automotive companies like Toyota, relies on brazing to join parts for vehicles, particularly in high-precision applications like engine components. As the region focuses on enhancing its manufacturing capabilities and adopting advanced production technologies, the need for braze alloys continues to grow, especially in applications requiring strong bonds in demanding environments. The growth rate in Chubu is moderate, as the region's industries move toward more automated and precise manufacturing processes, reducing reliance on traditional brazing methods in some sectors. However, the continued development of automotive and electronics sectors ensures that Chubu will maintain steady demand for braze alloys.

Tohoku is experiencing steady demand for braze alloys, growing at a 1.5% CAGR. The region’s manufacturing and industrial sectors, particularly in machinery and electronics, are driving this growth. While Tohoku is traditionally not as industrialized as some other regions, there is an increasing trend toward automation and high-precision manufacturing, particularly in small to medium-sized enterprises. As Tohoku focuses on improving its industrial infrastructure and adopting advanced technologies, the demand for brazing solutions in the production of machinery, electronics, and automotive parts is rising. The region’s emphasis on renewable energy projects and energy-efficient manufacturing is also contributing to the need for brazing materials. Although the growth rate is lower compared to other regions, Tohoku’s steady push for modernization ensures that the demand for braze alloys will continue to increase gradually.

The Rest of Japan is seeing modest demand for braze alloys, with a 1.4% CAGR. The demand in these regions is largely driven by the growth in small to medium-sized manufacturing sectors, particularly in machinery, electronics, and automotive components. As industries across the country continue to adopt more advanced production technologies, the need for brazing solutions in high-precision applications grows. While the growth rate in the Rest of Japan is slower compared to larger industrial hubs, these regions are still benefiting from increased demand for braze alloys in smaller manufacturing plants and local production. The rise of energy-efficient technologies, particularly in regional manufacturing, is also contributing to the demand for brazing materials. As these areas modernize their industrial operations, the demand for braze alloys is expected to continue increasing at a steady pace.

The demand for braze alloys in Japan is increasing as they are essential in joining metal parts across various industries such as automotive, aerospace, electronics, and refrigeration. Braze alloys are used for their ability to create strong, durable bonds between metals, even at high temperatures, making them crucial for applications requiring high-performance materials. With Japan’s strong industrial and technological sectors, including its focus on precision manufacturing and advanced machinery, the demand for high-quality braze alloys is expected to continue growing.

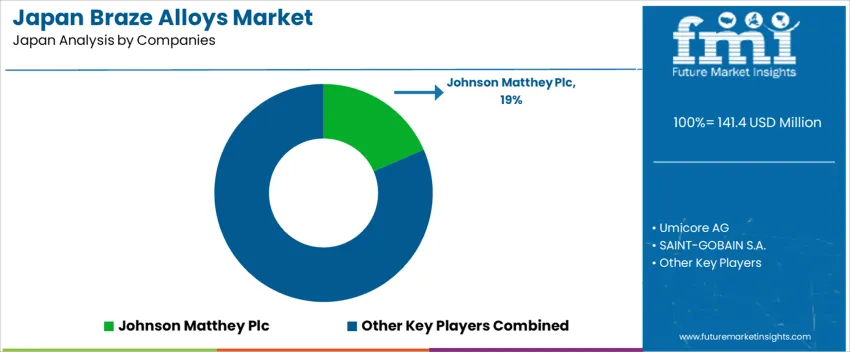

Key players in the braze alloys industry in Japan include Johnson Matthey Plc, Umicore AG, SAINT-GOBAIN S.A., Fusion, Inc., and Materion Corporation. Johnson Matthey Plc leads with a significant industry share of 18.5%, offering a wide range of braze alloys for different industrial applications, with a focus on innovation and quality. Umicore AG is a key player, providing high-performance brazing materials for automotive and electronics industries. SAINT-GOBAIN S.A. produces brazing solutions for industrial and electronics applications, while Fusion, Inc. specializes in manufacturing braze alloys used in heat exchangers and other high-temperature environments. Materion Corporation is also a prominent supplier, offering precision brazing alloys used in electronics, aerospace, and other specialized sectors.

Competition in the braze alloys industry in Japan is driven by the increasing demand for advanced, high-performance brazing materials across diverse applications. As industries such as automotive, electronics, and aerospace continue to evolve, the need for stronger, more durable bonding materials increases. Companies compete by offering innovative, high-quality products that meet the specific requirements of modern manufacturing processes, including higher temperatures and more demanding mechanical properties.

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD million |

| Product Type | Copper, Gold, Silver, Aluminum, Other Product Types |

| Application | Automotive, Electronics, Aerospace, Others |

| Region | Kyushu & Okinawa, Kanto, Kinki, Chubu, Tohoku, Rest of Japan |

| Countries Covered | Japan |

| Key Companies Profiled | Johnson Matthey Plc, Umicore AG, SAINT-GOBAIN S.A., Fusion, Inc., Materion Corporation |

| Additional Attributes | Dollar sales by product type and application; regional CAGR and adoption trends; demand trends in braze alloys; growth in automotive, electronics, and aerospace sectors; technology adoption for brazing solutions; vendor offerings including alloys, formulations, and services; regulatory influences and industry standards |

The demand for braze alloys in Japan is estimated to be valued at USD 141.4 million in 2025.

The market size for the braze alloys in Japan is projected to reach USD 170.3 million by 2035.

The demand for braze alloys in Japan is expected to grow at a 1.9% CAGR between 2025 and 2035.

The key product types in braze alloys in Japan are copper, gold, silver, aluminum and other product types.

In terms of application, automotive segment is expected to command 41.0% share in the braze alloys in Japan in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Braze Alloys Market Growth - Trends & Forecast 2025 to 2035

Demand for Braze Alloys in USA Size and Share Forecast Outlook 2025 to 2035

Brazed Fixtures Market Size and Share Forecast Outlook 2025 to 2035

Japan Faith-based Tourism Market Size and Share Forecast Outlook 2025 to 2035

Japan Sports Tourism Market Size and Share Forecast Outlook 2025 to 2035

Japan Respiratory Inhaler Devices Market Size and Share Forecast Outlook 2025 to 2035

Japan Halal Tourism Market Size and Share Forecast Outlook 2025 to 2035

Brazed Plate Heat Exchangers Market Size and Share Forecast Outlook 2025 to 2035

Japan Automated People Mover Industry Size and Share Forecast Outlook 2025 to 2035

Japan Automotive Load Floor Industry Analysis Size and Share Forecast Outlook 2025 to 2035

Japan Food Cling Film Market Size and Share Forecast Outlook 2025 to 2035

Japan Polypropylene Packaging Films Market Size and Share Forecast Outlook 2025 to 2035

Japan Probiotic Yogurt Market is segmented by product type, source type, nature type, flavor type, fat content, sales channel and key city/province through 2025 to 2035.

japan Tortilla Market - Growth, Trends and Forecast from 2025 to 2035

Japan Cosmetics ODM Market Analysis - Size, Share & Trends 2025 to 2035

Japan Automotive Turbocharger Market Insights – Demand, Size & Industry Trends 2025–2035

Japan Yeast Market Insights – Demand, Size & Industry Trends 2025–2035

Japan Green and Bio-based Polyol Market Insights – Demand, Size & Industry Trends 2025–2035

Japan Natural Food Color Market Trends – Growth, Demand & Forecast 2025–2035

Japan Coated Fabrics Market Growth – Trends, Demand & Innovations 2025–2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA