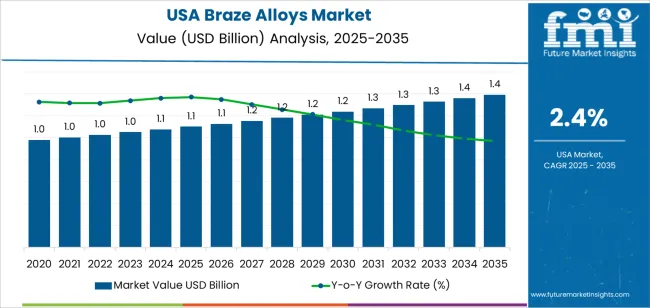

The demand for braze alloys in the USA is projected to increase from USD 1.1 billion in 2025 to USD 1.4 billion by 2035, reflecting a compound annual growth rate (CAGR) of 2.4%. This growth is driven by the use of braze alloys in a range of industries, including automotive, aerospace, electronics, and manufacturing. Braze alloys are essential for joining different metal components and are especially valued for their ability to withstand high-temperature environments. These alloys are used in critical applications such as heat exchangers, automotive components, and turbine engines, contributing to the steady demand across various sectors.

Year-over-year (Y-o-Y) growth for braze alloys shows a consistent, gradual increase in demand. Starting at USD 1.1 billion in 2025, the market remains stable at USD 1.1 billion for the next few years, reflecting steady adoption. By 2029, demand is expected to rise slightly to USD 1.2 billion, with continued stability in demand through 2031. From 2032 to 2035, the market is forecasted to show slight growth, reaching USD 1.4 billion by 2035. This consistent yet modest increase indicates that the braze alloys market will continue to grow steadily, driven by demand from industries requiring high-performance joining solutions.

The braze alloys market in the USA is forecasted to grow at a modest pace through 2035. From a value of USD 1.1 billion in 2025, the market is expected to gradually increase to USD 1.4 billion by 2035. The compound annual growth rate (CAGR) for this period is estimated at 2.4%, indicating steady, if unspectacular, growth. This consistent rise reflects the ongoing demand for braze alloys in various industries such as aerospace, automotive, and electronics, where the material is essential for joining metal parts in high-performance applications.

Over the years, the demand for braze alloys will remain relatively stable, with incremental increases expected year after year. The market will experience gradual growth, with key sectors relying on these materials for producing durable and heat-resistant components. By 2029, the market is forecasted to reach USD 1.2 billion, and the increase will continue, albeit at a slower pace. The continued demand for high-quality joining materials across diverse industries will sustain the market, culminating in the expected USD 1.4 billion valuation by 2035. This steady growth underscores the importance of braze alloys in manufacturing high-performance products.

| Metric | Value |

|---|---|

| Industry Sales Value (2025) | USD 1.1 billion |

| Industry Forecast Value (2035) | USD 1.4 billion |

| Industry Forecast CAGR (2025-2035) | 2.4% |

The demand for braze alloys in the USA is expanding as multiple industries shift toward brazing instead of traditional welding or soldering methods. The USA market is experiencing growth driven by the automotive, aerospace, electronics, HVAC, and industrial sectors. Automotive applications, such as heat exchangers, radiators, exhaust systems, and components in electric vehicle (EV) thermal management systems, account for a significant share of braze alloy consumption. The increasing focus on lightweight, efficient thermal systems in the automotive sector is further propelling the demand for high-performance braze alloys. In aerospace, braze alloys are critical for the manufacturing of turbine engines, jet engine components, and other high-heat, high-stress parts. Additionally, the electronics and electrical industries use brazing in circuit boards, connectors, and power modules to ensure strong, reliable joints and excellent thermal conductivity. Furthermore, HVAC and energy industries increasingly adopt brazing techniques to meet the need for durable, heat-resistant materials in equipment and renewable energy systems.

As demand grows, trends in the USA show a shift toward specialized, higher-performance braze alloys. Silver-based alloys continue to dominate in aerospace and defense applications, valued for their high strength, corrosion resistance, and excellent wettability. Meanwhile, copper-based and aluminum-based alloys are preferred for their cost-effectiveness, high conductivity, and compatibility with lighter automotive and electronics materials. Pressure from environmental regulations has also led to increased demand for lead-free and eco-friendly brazing solutions. Technological advancements, such as automation and additive manufacturing, are driving further adoption of brazing in high-precision applications that require strong, consistent joints across dissimilar metals. As industries continue to embrace lightweight, sustainable, and efficient manufacturing practices, the demand for braze alloys in the USA is expected to grow steadily through the next decade.

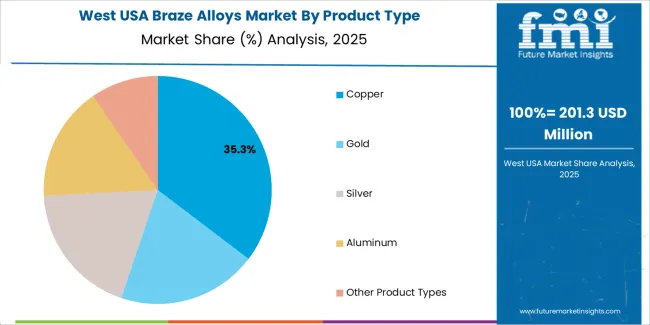

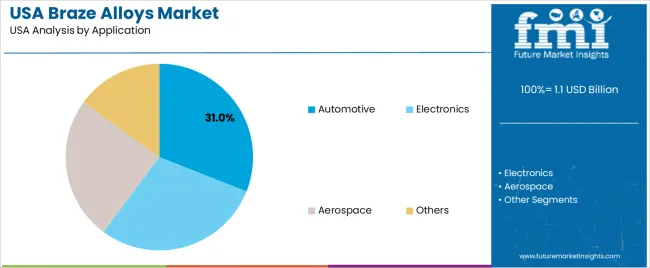

The demand for braze alloys in the USA is driven by product type and application. The leading product type is copper, capturing 36% of the market share, while automotive is the dominant application, accounting for 31% of the demand. Braze alloys are essential in joining metals with high precision and strength, and their applications span various industries, including automotive, electronics, and aerospace. The demand continues to grow as industries seek materials that offer durability, high thermal resistance, and corrosion resistance.

Copper is the leading product type for braze alloys in the USA, holding 36% of the market share. Copper-based braze alloys are widely used in a range of applications due to their excellent thermal and electrical conductivity, as well as their ability to form strong, reliable bonds between different metals. These alloys are particularly valuable in industries where heat dissipation is crucial, such as in heat exchangers, refrigeration systems, and automotive components.

The demand for copper braze alloys is driven by their versatility and effectiveness in high-temperature applications. Copper alloys offer good fluidity during the brazing process, ensuring strong and clean joints. As the automotive and electronics industries continue to prioritize efficiency, heat management, and component durability, copper-based braze alloys remain a key solution in these sectors. Their use in manufacturing complex components that require high precision, such as in the production of car radiators and air conditioning systems, ensures continued demand for copper braze alloys in the USA.

Automotive is the largest application segment for braze alloys in the USA, accounting for 31% of the demand. In the automotive industry, braze alloys are crucial for joining metal components in applications like heat exchangers, radiators, and transmission systems. These alloys are particularly valued for their ability to form strong, durable joints in parts that experience high thermal and mechanical stress, such as engine components and exhaust systems.

The demand for braze alloys in automotive applications is driven by the industry's focus on improving performance, energy efficiency, and durability. As vehicles become more complex and manufacturers seek to reduce weight while enhancing fuel efficiency, braze alloys are increasingly used to create lightweight, high-strength joints in critical components. With the growing emphasis on electric vehicles (EVs) and the need for efficient battery management systems, the demand for braze alloys in the automotive sector is expected to continue to rise, ensuring their continued prominence in the market.

Demand for braze alloys in the United States reflects the ongoing need for reliable metal joining solutions across automotive, electronics, aerospace, HVAC and industrial applications. As manufacturers pursue lighter, more efficient and thermally stable components, brazing replaces or complements welding and soldering in many contexts. Growth in sectors such as electric vehicles, renewable energy, and high performance electronics further amplifies demand for alloys that offer strong mechanical joints, corrosion resistance and thermal stability. At the same time, volatility in raw material prices, supply chain pressures and competition from alternative joining or adhesive technologies moderate growth. These competing forces shape the current demand environment for braze alloys in the USA.

What Are the Primary Growth Drivers for Braze Alloy Demand in the USA? Several factors support growth in the USA braze alloys market. First, expansion of the automotive sector including internal combustion and electric vehicles drives demand for brazed components such as heat exchangers, radiators, HVAC modules and battery system thermal management. Second, growth in electronics and electrical equipment (heat sinks, power modules, connectors) requires precision joining and thermal conductive properties offered by braze alloys. Third, increasing use in HVAC, refrigeration, and building system fabrication leverages brazing for leak tight, durable joints in coils, piping, and heat exchangers. Fourth, demand from aerospace and industrial manufacturing for high temperature, high stress resistant joints sustains alloy use where welding or mechanical joining may fail.

What Are the Key Restraints Affecting Braze Alloy Demand in the USA? Several constraints limit broader adoption. First, price volatility and rising cost of base metals (silver, copper, nickel etc.) increase alloy costs, which may deter cost sensitive buyers or price competitive applications. Second, supply chain disruptions and shortages for specialty fillers or flux materials can delay production or raise lead times. Third, alternative joining techniques such as laser welding, adhesive bonding, friction stir welding, or advanced soldering may compete with brazing where thermal or joint strength trade offs are acceptable. Fourth, environmental and regulatory pressures may restrict use of certain alloying elements, requiring reformulation or substitution that can slow adoption or increase costs.

What Are the Key Trends Shaping Braze Alloy Demand in the USA? Important trends include increasing demand for lead free and environmentally compliant brazing alloys as industry moves toward greener manufacturing. There is growing adoption of brazing in electric vehicle and battery system manufacturing, where thermal management and corrosion resistance are critical. Expansion of automation and induction or furnace based brazing technologies supports higher throughput and consistent quality, favouring alloy USAge. Additionally, miniaturization in electronics and heat sensitive applications is raising demand for alloys with lower melting points and better thermal conductivity. Finally, diversification of alloy types (copper , nickel , aluminum and silver based) tailored to specific end use requirements is broadening the application base of brazing materials.

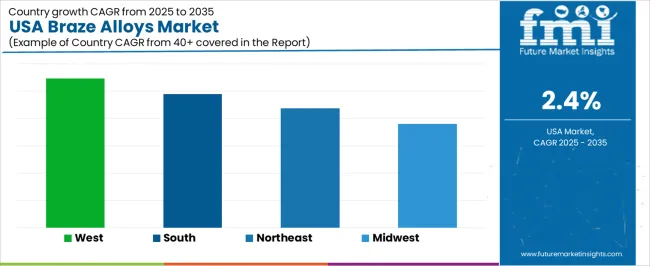

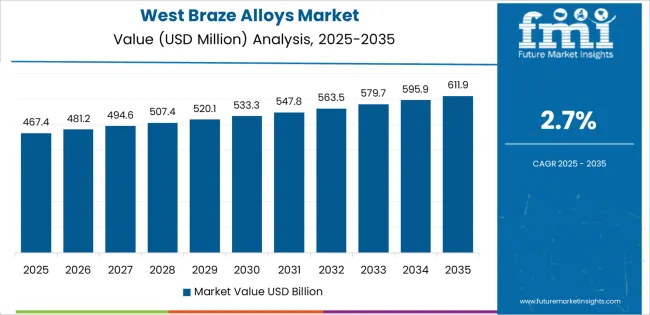

The demand for braze alloys in the USA shows modest growth across different regions, with the West leading at a CAGR of 2.7%. The South follows with a CAGR of 2.4%, driven by growing industrial applications in sectors like automotive and aerospace. The Northeast shows steady growth at 2.2%, supported by its established manufacturing base and high-tech industries. The Midwest has the lowest growth rate at 1.9%, reflecting a more traditional industrial landscape. These regional differences are influenced by factors such as industrial activity, technological advancements, and sector-specific demands for braze alloys.

| Region | CAGR (%) |

|---|---|

| West | 2.7 |

| South | 2.4 |

| Northeast | 2.2 |

| Midwest | 1.9 |

The demand for braze alloys in the West is projected to grow at a CAGR of 2.7%, driven by the region’s strong presence in high-tech industries, including aerospace, electronics, and renewable energy. The West, particularly states like California, is home to many leading manufacturers of advanced technologies, where braze alloys are crucial in the joining of components in electronic devices, power systems, and high-performance machinery. The region’s focus on innovation and technology, coupled with the growing demand for lightweight, durable, and heat-resistant materials, is fueling the adoption of braze alloys. Additionally, the expanding aerospace sector, where braze alloys are used for their ability to withstand extreme temperatures and pressures, is a key driver of demand in the West. As the demand for high-tech applications increases, the need for efficient and precise brazing techniques will continue to grow, supporting the region’s strong demand for braze alloys.

In the South, the demand for braze alloys is expected to grow at a CAGR of 2.4%, driven by the region’s expanding industrial and manufacturing sectors. The South is a major hub for industries such as automotive, aerospace, and energy, all of which require brazing technologies to join metal components in high-stress environments. The increasing demand for electric vehicles (EVs) and their advanced manufacturing processes is also contributing to the rise in braze alloy USAge, as these vehicles require specialized brazing for components like batteries, heat exchangers, and powertrains. The South’s growing focus on industrial innovation and the development of new materials is pushing the demand for braze alloys used in advanced manufacturing processes. The region’s strong infrastructure and continued investments in manufacturing technologies ensure that the demand for braze alloys will continue to rise steadily.

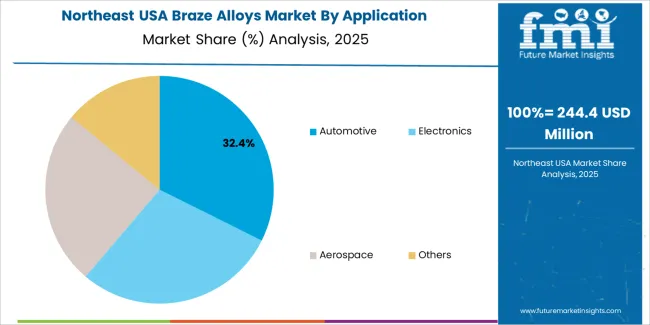

In the Northeast, the demand for braze alloys is projected to grow at a CAGR of 2.2%, supported by the region’s well-established industrial base, particularly in high-tech and precision manufacturing sectors. The Northeast is home to many advanced manufacturing facilities that produce high-performance components used in industries such as aerospace, electronics, and medical devices, where braze alloys are essential for joining delicate and heat-resistant materials. Additionally, the region’s focus on innovation in fields like semiconductors and clean energy is driving the demand for specialized brazing techniques. While growth is steady, the Northeast’s more mature manufacturing landscape means that the adoption of braze alloys tends to be slower compared to more rapidly developing regions. Nevertheless, as demand for precision and high-quality production continues, the use of braze alloys is expected to remain strong in the Northeast.

The demand for braze alloys in the Midwest is expected to grow at a CAGR of 1.9%, reflecting slower growth compared to other regions. The Midwest is traditionally a manufacturing hub, with a strong presence in automotive and heavy industrial sectors. However, the region’s slower pace of adoption of new technologies and more conservative approach to manufacturing advancements may limit the growth of braze alloys compared to the West and South. While braze alloys are still in demand for automotive and industrial applications, the Midwest’s manufacturing base tends to rely on more conventional methods, leading to more gradual increases in brazing material adoption. Despite this, the Midwest’s significant industrial infrastructure and the continued need for durable, high-performance components will support the steady, if slower, demand for braze alloys in the coming years.

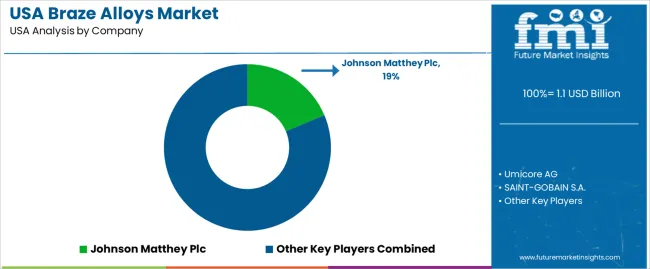

Demand for braze alloys in the United States remains strong because of ongoing demand in sectors such as aerospace, automotive, energy, and industrial manufacturing. Suppliers such as Johnson Matthey Plc (holding around 18.7% market share), Umicore AG, SAINT-GOBAIN S.A., and Fusion, Inc. play leading roles. These firms provide brazing filler metals and alloy materials used for joining components subjected to high stress, high temperature, or corrosive conditions.

Competition in this industry centers on alloy composition, quality control, and supply reliability. Suppliers focus on developing braze alloys that offer high strength, corrosion resistance, and stable performance under thermal cycles, to meet demanding specifications in industrial, automotive, and energy applications. Another competitive aspect involves compliance with industry standards and certifications required by end use sectors, especially aerospace and power generation, which demand traceability and material validation. Manufacturing consistency and supply chain resilience matter as well, since projects often depend on large, timely deliveries of brazing material. Product documentation typically highlights alloy grade, melting range, joint strength, compatibility with base metals, and compliance with relevant standards. By ensuring technical performance and reliable supply, these companies aim to maintain and grow their presence in the USA braze alloys industry.

| Items | Details |

|---|---|

| Quantitative Units | USD Billion |

| Regions Covered | USA |

| Product Type | Copper, Gold, Silver, Aluminum, Other Product Types |

| Application | Automotive, Electronics, Aerospace, Others |

| Key Companies Profiled | Johnson Matthey Plc, Umicore AG, SAINT-GOBAIN S.A., Fusion, Inc. |

| Additional Attributes | The market analysis includes dollar sales by product type, application, and company categories. It also covers regional demand trends in the USA, driven by the increasing use of braze alloys in automotive, electronics, and aerospace applications. The competitive landscape highlights key manufacturers focusing on innovations in braze alloys, including copper, gold, silver, and aluminum-based solutions. Trends in the growing demand for high-performance and eco-friendly brazing materials for precision industries, such as electronics and aerospace, are explored, along with advancements in alloy composition and brazing techniques. |

The demand for braze alloys in USA is estimated to be valued at USD 1.1 billion in 2025.

The market size for the braze alloys in USA is projected to reach USD 1.4 billion by 2035.

The demand for braze alloys in USA is expected to grow at a 2.4% CAGR between 2025 and 2035.

The key product types in braze alloys in USA are copper, gold, silver, aluminum and other product types.

In terms of application, automotive segment is expected to command 31.0% share in the braze alloys in USA in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Braze Alloys Market Growth - Trends & Forecast 2025 to 2035

Brazed Fixtures Market Size and Share Forecast Outlook 2025 to 2035

Brazed Plate Heat Exchangers Market Size and Share Forecast Outlook 2025 to 2035

USA Medical Coding Market Size and Share Forecast Outlook 2025 to 2035

USA Labels Market Size and Share Forecast Outlook 2025 to 2035

USA Plant-based Creamers Market Size and Share Forecast Outlook 2025 to 2035

USA Barrier Coated Paper Market Size and Share Forecast Outlook 2025 to 2035

USA Electronic Health Records (EHR) Market Size and Share Forecast Outlook 2025 to 2035

USA Animal Model Market Size and Share Forecast Outlook 2025 to 2035

USA and Canada Packer Bottle Market Size and Share Forecast Outlook 2025 to 2035

USA Stretch Hood Films Market Size and Share Forecast Outlook 2025 to 2035

USA and Canada Fence Screen Market Size and Share Forecast Outlook 2025 to 2035

USA Lubricant Contaminated HDPE Container Waste Market Size and Share Forecast Outlook 2025 to 2035

USA Commercial Walk-In Refrigeration Market Size and Share Forecast Outlook 2025 to 2035

USA & Canada Pre-painted Steel Roofing and Cladding Market Size and Share Forecast Outlook 2025 to 2035

USA Residential Cotton Candy Maker Market Size and Share Forecast Outlook 2025 to 2035

USA Faith Based Tourism Market Size and Share Forecast Outlook 2025 to 2035

United States NFC Lemon Juice Market Analysis - Size, Growth and Forecast 2025 to 2035

USA and Canada Copper Market Insights - Demand, Size & Industry Trends 2025 to 2035

USA Ground and Precipitated Calcium Carbonate Market Growth by Product Type, Application, End-Use, and Region in 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA