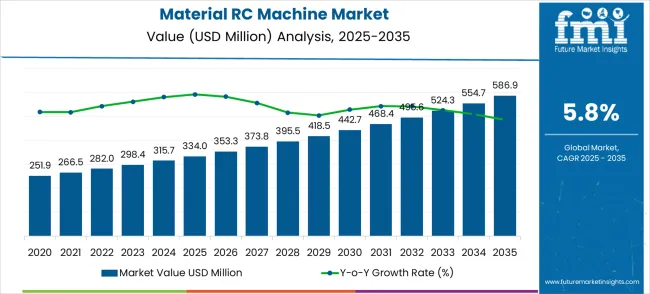

The material rack correction machine market is valued at USD 334.0 million in 2025 and is expected to expand to USD 586.9 million by 2035, reflecting a CAGR of 5.8%. From 2021 to 2025, the market shows consistent growth, progressing from USD 266.5 million to USD 334.0 million. During this period, the market sees steady increments through USD 282.0 million, 298.4 million, and 315.7 million. This phase indicates moderate growth, driven by rising demand from industries like manufacturing, warehousing, and logistics, where accurate material handling and correction systems are critical for operational efficiency.

Between 2026 and 2030, the market continues to grow, reaching USD 442.7 million by 2030. The intermediate years see incremental increases through USD 353.3 million, 373.8 million, 395.5 million, and 418.5 million, driven by advancements in automation and a focus on improving warehouse operations. From 2031 to 2035, the market reaches USD 586.9 million, passing through intermediate values of USD 468.4 million, 495.6 million, 524.3 million, and 554.7 million. The overall peak-to-trough analysis highlights steady growth, with no significant downturns, driven by continuous technological improvements and an ongoing shift toward more efficient and automated material handling solutions across various industries.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 334.0 million |

| Forecast Value in (2035F) | USD 586.9 million |

| Forecast CAGR (2025 to 2035) | 5.8% |

The manufacturing industry leads the market, accounting for 40-45%, as material rack correction machines are essential for ensuring the accurate alignment, positioning, and storage of materials on racks, optimizing space and workflow efficiency in production lines. The logistics and warehousing sector follows closely with 25-30%, driven by the growing demand for automated systems in distribution centers and warehouses to handle large volumes of goods and reduce inefficiencies. The automotive industry contributes 15-18%, where material rack correction machines are used to organize parts and components, ensuring smooth production lines and minimizing downtime. The retail and e-commerce industries add 10-12%, with warehouses adopting these machines to manage inventory more effectively, ensuring that products are stored correctly for easier retrieval and faster order fulfillment. Other industries, including food and beverage, pharmaceuticals, and consumer electronics, contribute 5-8%, using material rack correction machines to ensure proper storage and handling, improving operational efficiency and inventory management.

Market expansion is being supported by the increasing global focus on manufacturing efficiency and the corresponding need for precision material handling equipment that can ensure proper material alignment, reduce waste, and maintain consistent production quality across various metal processing and manufacturing applications. Modern manufacturing facilities and production managers are increasingly focused on implementing automation solutions that can eliminate material misalignment, improve production throughput, and provide consistent quality control in demanding manufacturing environments. Material rack correction machines' proven ability to deliver precise material positioning, reduce production waste, and enhance manufacturing efficiency makes them essential equipment for contemporary production operations and quality management.

The growing focus on automated manufacturing and production optimization is driving demand for material rack correction machines that can support continuous production, ensure material quality, and enable comprehensive process control. Manufacturing operators' preference for equipment that combines automation with precision control and maintenance efficiency is creating opportunities for innovative material rack correction machine implementations. The rising influence of Industry 4.0 and smart manufacturing is also contributing to increased adoption of material rack correction machines that can provide intelligent correction capabilities without compromising production speed or operational efficiency.

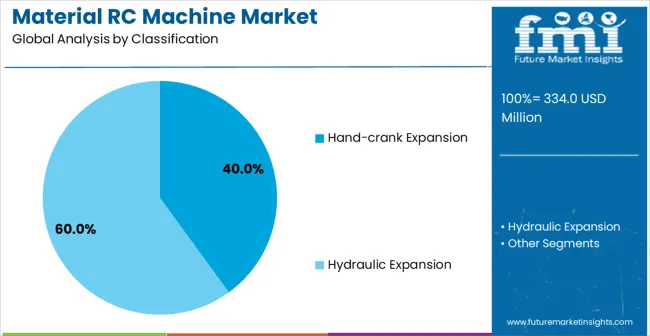

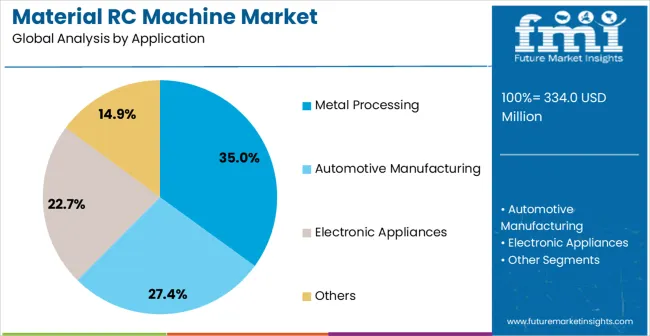

The market is segmented by expansion mechanism, application, and region. By expansion mechanism, the market is divided into hand-crank expansion, hydraulic expansion, and others. Based on application, the market is categorized into metal processing, automotive manufacturing, electronic appliances, and others. Regionally, the market is divided into Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa.

The hand-crank expansion segment is projected to maintain its leading position in the material rack correction machine market in 2025, capturing 40% of the market share. Manufacturing operators and equipment technicians increasingly prefer hand-crank expansion systems for their precise control capabilities, reliable operation, and versatility across various material correction requirements. Hand-crank technology’s proven reliability and ability to provide manual control directly address the manufacturing need for accurate material positioning and adjustment in diverse production environments. This actuation system forms the foundation of modern material correction operations, offering the highest control precision across multiple manufacturing processes and material handling applications. With material correction requiring precise control and operator intervention, hand-crank expansion systems remain central to comprehensive material handling strategies.

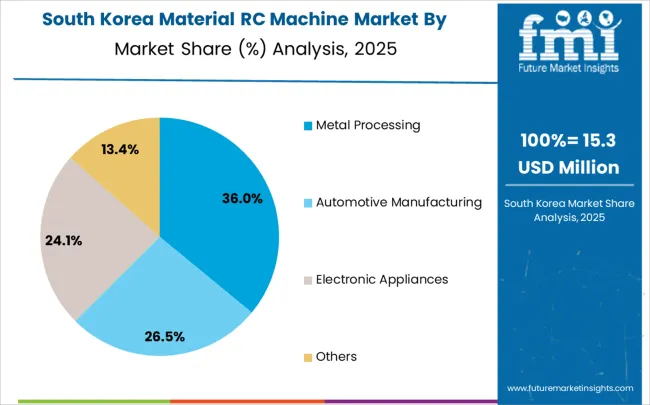

The metal processing application segment is projected to represent the largest share of material rack correction machine demand in 2025, accounting for 35% of the market. Metal processing facilities prefer material rack correction machines for their ability to meet the high precision material handling requirements, quality control needs, and consistent material alignment during production. These machines play a critical role in steel processing, sheet metal fabrication, and metal forming operations. They help ensure continuous production, reduce waste, and support operational efficiency. As metal processing technologies evolve, the need for specialized correction systems with enhanced automation and quality control grows. Investments in comprehensive material handling programs further drive demand for these systems, making the metal processing segment a dominant force in the market as the industry continues to push for higher precision and production optimization.

The material rack correction machine market is advancing steadily due to increasing demand for manufacturing automation and growing adoption of precision material handling technologies that provide enhanced production efficiency and quality control across diverse manufacturing applications. The market faces challenges, including high equipment costs and installation complexity, technical requirements for system integration and operator training, and competition from alternative material handling solutions. Innovation in intelligent automation and IoT connectivity continues to influence product development and market expansion patterns.

The growing adoption of intelligent automation systems and IoT connectivity is enabling manufacturers to achieve superior material handling precision, enhanced production monitoring, and comprehensive data collection for improved manufacturing processes. Intelligent automation systems provide improved operational efficiency while allowing more predictable material correction and consistent quality control across various production applications and manufacturing environments. Manufacturers are increasingly recognizing the competitive advantages of intelligent automation capabilities for operational differentiation and production optimization.

Modern material rack correction machine manufacturers are incorporating advanced servo control technologies and precision positioning systems to enhance correction accuracy, enable automated adjustment protocols, and provide superior material handling through real-time feedback and control optimization. These technologies improve operational precision while enabling new applications, including adaptive correction and predictive material handling. Advanced control integration also allows manufacturers to support comprehensive production automation and quality optimization beyond traditional manual correction approaches.

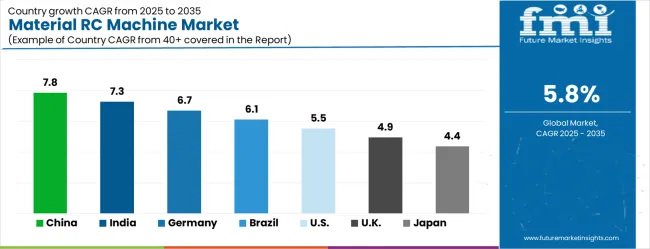

| Country | CAGR (2025-2035) |

|---|---|

| China | 7.8% |

| India | 7.3% |

| Germany | 6.7% |

| Brazil | 6.1% |

| USA | 5.5% |

| UK | 4.9% |

| Japan | 4.4% |

The material rack correction machine market is experiencing solid growth globally, with China leading at a 7.8% CAGR through 2035, driven by the expanding manufacturing sector, growing industrial automation adoption, and significant investment in production equipment modernization and material handling technology advancement. India follows at 7.3%, supported by rapid industrial development, increasing manufacturing capabilities, and growing adoption of automated material handling equipment in manufacturing facilities. Germany shows growth at 6.7%, emphasizing precision engineering and advanced manufacturing automation technologies. Brazil records 6.1%, focusing on industrial modernization and manufacturing equipment upgrade initiatives. The USA demonstrates 5.5% growth, supported by an established manufacturing infrastructure and a focus on production automation. The UK exhibits 4.9% growth, emphasizing manufacturing excellence and automation technology advancement. Japan shows 4.4% growth, supported by advanced manufacturing technologies and precision equipment development.

The report covers an in-depth analysis of 40+ countries; seven top-performing countries are highlighted below.

The material rack correction machine market in China is projected to grow at a CAGR of 7.8% from 2025 to 2035. As the country continues to expand its manufacturing and industrial sectors, the demand for machinery that can ensure precise correction and alignment of material racks is increasing. The growth in the automotive, construction, and logistics industries is expected to drive this demand. China’s large-scale production facilities and continued investment in automation are key factors supporting the growth of this market. The country is also embracing new technologies, which further contribute to improved efficiency and accuracy in material handling. With the increasing focus on supply chain optimization and efficient warehouse management, material rack correction machines are poised to become indispensable in industrial operations across China.

Demand for material rack correction machine in India is anticipated to grow at a CAGR of 7.3% from 2025 to 2035. As India's industrial base continues to expand, particularly in sectors like automotive, manufacturing, and logistics, the need for advanced material handling equipment is increasing. Material rack correction machines play a critical role in ensuring the correct alignment of materials, preventing damage during handling and storage. India’s growing infrastructure development and logistics networks also contribute to this rise. The demand for such machinery is further fueled by the country’s rapid adoption of automation in warehouses and factories. The ongoing shift towards modern industrial processes is expected to drive significant growth in this market.

The material rack correction machine market in Germany is set to grow at a CAGR of 6.7% from 2025 to 2035. As one of the leading manufacturing hubs in Europe, Germany continues to invest in state-of-the-art technology and industrial equipment to maintain its competitive edge. The demand for material rack correction machines is driven by the need for high precision and efficiency in the automotive, manufacturing, and logistics sectors. With stringent regulations and a growing focus on operational efficiency, German industries are increasingly adopting advanced solutions to ensure better handling of materials in production and distribution processes. Germany’s focus on Industry 4.0 and smart manufacturing technologies will further propel the demand for automated and high-precision machinery in the market.

Demand for material rack correction machine market is growing at a CAGR of 6.1% from 2025 to 2035. Brazil’s growing industrial activities, particularly in automotive and manufacturing, are contributing to the increasing demand for advanced material handling solutions. The expansion of infrastructure, including logistics and distribution networks, also creates opportunities for correction machinery that ensures precise alignment of material racks in large-scale operations. As Brazilian industries focus on enhancing productivity and reducing operational downtime, the market for efficient and automated material handling equipment is expected to witness steady growth. With increased foreign investments and the modernization of Brazil's industrial base, the market for material rack correction machines will continue to thrive.

The material rack correction machine market in the USA is projected to grow at a CAGR of 5.5% from 2025 to 2035. The United States continues to lead in industrial innovation, with significant growth in sectors like automotive, aerospace, and logistics. As American industries focus on improving productivity and efficiency, material rack correction machines have become essential in ensuring smooth material handling and precise alignment in production processes. The rise of e-commerce and growing demand for warehousing solutions will also drive the demand for such machinery. The USA's investment in automation and robotics, particularly in distribution centers, will further support market growth.

The material rack correction machine market in the UK is forecast to grow at a CAGR of 4.9% from 2025 to 2035. As the UK continues to modernize its manufacturing and industrial sectors, there is a growing need for advanced material handling and correction equipment. The demand for material rack correction machines is expected to rise with increased focus on production efficiency and automation. The UK's strong automotive, aerospace, and manufacturing industries will be key contributors to this growth. The focus on energy-efficient solutions in UK industries will further drive the adoption of these advanced machines, ensuring accurate and smooth material handling in warehouses and factories.

Sales of material rack correction machine in Japan is expected to grow at a CAGR of 4.4% from 2025 to 2035. With its well-established manufacturing sector, Japan is one of the key players in the global market for material handling solutions. The country’s focus on automation and robotics in manufacturing has led to an increased demand for precision machinery such as material rack correction machines. The automotive and electronics industries, in particular, are contributing significantly to this demand, as they require accurate and reliable systems for handling materials in production facilities. Japan’s continued investment in high-tech solutions for industrial applications will further support market growth.

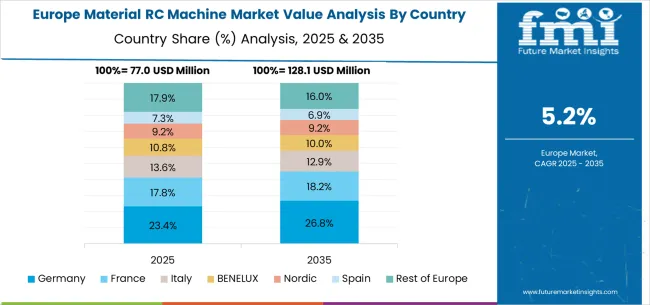

The material rack correction machine market in Europe is projected to grow from USD 123.2 million in 2025 to USD 205.8 million by 2035, registering a CAGR of 5.3% over the forecast period. Germany is expected to maintain its leadership position with a 27.0% market share in 2025, moderating slightly to 26.8% by 2035, supported by its strong automotive sector, advanced manufacturing technologies, and comprehensive material handling infrastructure serving major European markets.

The United Kingdom follows with 20.0% in 2025, projected to reach 19.8% by 2035, driven by established manufacturing excellence, a comprehensive automation framework, and advanced production technology programs. France holds 18.5% in 2025, rising to 18.7% by 2035, supported by automotive manufacturing leadership and growing adoption of advanced material handling technologies. Italy commands 14.0% in 2025, projected to reach 14.1% by 2035, while Spain accounts for 9.0% in 2025, expected to reach 9.1% by 2035. The Netherlands maintains a 4.0% share in 2025, growing to 4.1% by 2035. The Rest of Europe region, including Nordic countries, Eastern Europe, and other markets, is anticipated to maintain its position, holding its collective share at 7.5% by 2035, attributed to increasing manufacturing modernization and growing automation technology adoption across emerging industrial markets implementing advanced material handling standards.

The material rack correction machine market is characterized by competition among established industrial equipment manufacturers, specialized material handling companies, and integrated automation solution providers. Companies are investing in advanced automation technology research, precision engineering, quality assurance, and comprehensive product portfolios to deliver reliable, precise, and efficient material rack correction machine solutions. Innovation in intelligent control systems, IoT integration, and automated positioning technologies is central to strengthening market position and competitive advantage.

Mahlo GmbH + Co. KG leads the market with comprehensive textile and material handling solutions, offering advanced material rack correction machines with a focus on precision control and automation excellence in industrial applications. Ideal Machine provides specialized manufacturing equipment with an focus on material processing and production optimization. GESCO-Group delivers integrated industrial solutions with a focus on material handling and manufacturing automation. Shung Dar specializes in machinery manufacturing with focus on precision equipment and industrial applications. Shanghai Wansheng Machinery Automation focuses on industrial automation and material handling systems. Lihao Machine offers comprehensive manufacturing equipment with a focus on precision and reliability.

Material rack correction machines represent a specialized automation segment within precision manufacturing and material handling, projected to grow from USD 334.0 million in 2025 to USD 586.9 million by 2035 at a 5.8% CAGR. These precision equipment systems-primarily hand-crank expansion mechanisms for operator control-ensure proper material alignment and correction during metal processing, automotive manufacturing, and electronics production. Market expansion is driven by increasing manufacturing automation demands, growing focus on production quality control, Industry 4.0 integration requirements, and the rising need for waste reduction through precise material positioning across diverse industrial processing applications.

How Manufacturing Industry Associations Could Advance Automation Standards and Best Practices?

How Equipment Manufacturers Could Drive Innovation and Market Expansion?

How Manufacturing Facilities Could Optimize Production Efficiency and Quality Control?

How Technology Integration Partners Could Enable Smart Manufacturing?

How End-User Industries Could Drive Demand and Innovation?

How Investors and Financial Enablers Could Support Market Development?

| Items | Values |

|---|---|

| Quantitative Units (2025) | USD 334.0 Million |

| Expansion Mechanism | Hand-crank Expansion, Hydraulic Expansion, Others |

| Application | Metal Processing, Automotive Manufacturing, Electronic Appliances, Others |

| Regions Covered | Asia Pacific, North America, Europe, Latin America, Middle East & Africa |

| Countries Covered | China, India, Germany, Brazil, the United States, the United Kingdom, Japan, and 40+ countries |

| Key Companies Profiled | Mahlo GmbH + Co. KG, Ideal Machine, GESCO-Group, Shung Dar, Shanghai Wansheng Machinery Automation, and Lihao Machine |

| Additional Attributes | Dollar sales by expansion mechanism and application category, regional demand trends, competitive landscape, technological advancements in automation systems, precision control development, IoT integration innovation, and manufacturing optimization |

Asia Pacific

North America

Europe

Latin America

Middle East & Africa

The global material rack correction machine market is estimated to be valued at USD 334.0 million in 2025.

The market size for the material rack correction machine market is projected to reach USD 586.9 million by 2035.

The material rack correction machine market is expected to grow at a 5.8% CAGR between 2025 and 2035.

The key product types in material rack correction machine market are hand-crank expansion and hydraulic expansion.

In terms of application, metal processing segment to command 35.0% share in the material rack correction machine market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

2-in-1 Material Rack Correction Machine Market Size and Share Forecast Outlook 2025 to 2035

Material Shrinkage-reducing Agents Market Size and Share Forecast Outlook 2025 to 2035

Material Handling Integration Market Size and Share Forecast Outlook 2025 to 2035

Material-Based Hydrogen Energy Storage Market Size and Share Forecast Outlook 2025 to 2035

Material Tester Market Growth – Trends & Forecast 2025 to 2035

Material Handling Equipment Market Growth - Trends & Forecast 2025 to 2035

Material Handling Monorails Market

Biomaterial Tester Market Size and Share Forecast Outlook 2025 to 2035

Biomaterial In Surgical Mesh Market Size and Share Forecast Outlook 2025 to 2035

Biomaterial Market Analysis – Size, Share & Forecast 2025 to 2035

Metamaterial Market Size and Share Forecast Outlook 2025 to 2035

PET Material Packaging Market Size and Share Forecast Outlook 2025 to 2035

Metamaterial Absorbers Materials Market Size and Share Forecast Outlook 2025 to 2035

Nanomaterial Supercapacitors Market Size and Share Forecast Outlook 2025 to 2035

Nanomaterials Market Insights - Size, Share & Industry Growth 2025 to 2035

Competitive Overview of PET Material Packaging Market Share

Tire Materials Market Insights – Size, Trends & Forecast 2025–2035

Mono-material Packaging Market Analysis: Size, Share, and Forecast 2025 to 2035

Case Material Market Size and Share Forecast Outlook 2025 to 2035

Mono Material Pump Market Analysis - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA