The nano composite zirconia market is estimated to be valued at USD 16.2 billion in 2025 and is projected to reach USD 46.1 billion by 2035, registering a compound annual growth rate (CAGR) of 11.0% over the forecast period.

The 5-year growth block analysis of the nano composite zirconia market reveals a steady upward trend from USD 16.2 billion in 2025 to USD 27.3 billion by 2030, with a compound annual growth rate (CAGR) of 11%. This growth block represents the first phase of the market’s expected long-term expansion, with values increasing year on year, from USD 16.2 billion in 2025 to USD 18 billion in 2026, USD 20 billion in 2027, and continuing to grow progressively through 2029.

The continuous rise in demand for nano composite zirconia, especially in the fields of dental materials, ceramics, and advanced coatings, plays a key role in this robust growth. Industries are increasingly adopting these materials for their enhanced strength, durability, and biocompatibility, thus driving significant growth over the next five years. As the market moves toward 2030, further advancements and applications are expected, positioning nano composite zirconia as a dominant material in its sector. By the end of the 5-year period, the market is projected to approach USD 27.3 billion, setting the stage for the second phase of growth toward 2035.

The market faces intricate manufacturing complexities that create persistent operational tensions between precision requirements and production scalability demands. Companies confront substantial challenges with particle size control where achieving consistent sub-10nm uniformity requires sophisticated equipment and advanced characterization techniques that significantly increase production costs. The synthesis of high-quality nano composite zirconia involves precise control over particle size, morphology, and composition to achieve desired material properties, necessitating stringent quality control measures that lead to increased production costs and operational complexities.

Manufacturing facilities struggle with the complex interplay between temperature control, precursor concentration, and reaction conditions where small variations can dramatically affect final product characteristics. The scalability of production processes remains technically constrained by resource availability and the difficulty of transitioning from laboratory-scale synthesis to commercial-scale manufacturing.

Raw material constraints create supply chain vulnerabilities where zirconium availability remains limited compared to other metals, leading to price fluctuations that affect overall product accessibility and market pricing strategies. Processing challenges require specialized fabrication equipment that adds operational complexity and capital investment requirements, creating barriers for small and medium-sized enterprises seeking market entry.

The scarcity and high cost of fluorinated precursors and stabilizing agents contribute to elevated production costs that impact competitiveness against alternative materials. Companies must navigate volatile raw material pricing structures that affect long-term planning and customer relationships, particularly in cost-sensitive applications where price premiums cannot be easily justified.

| Metric | Value |

|---|---|

| Nano Composite Zirconia Market Estimated Value in (2025 E) | USD 16.2 billion |

| Nano Composite Zirconia Market Forecast Value in (2035 F) | USD 46.1 billion |

| Forecast CAGR (2025 to 2035) | 11.0% |

The nano composite zirconia market is experiencing steady expansion, supported by its exceptional mechanical strength, wear resistance, and biocompatibility, which are driving adoption across multiple industries. Advances in nanotechnology and precision manufacturing have significantly improved the material’s structural properties, enabling its use in high-performance applications where durability and reliability are critical.

Rising demand from the healthcare sector for dental implants, prosthetics, and surgical tools is contributing to sustained growth, while increasing utilization in electronics, energy, and industrial ceramics is expanding the addressable market. The ability of nano composite zirconia to maintain stability under extreme temperatures and resist corrosion is enhancing its appeal in specialized engineering and manufacturing processes.

Research efforts focusing on cost-effective synthesis methods and improved dispersion techniques are supporting commercial scalability As global manufacturing standards shift toward materials that offer both functional performance and sustainability benefits, nano composite zirconia is expected to remain a preferred choice in advanced applications, paving the way for long-term market growth.

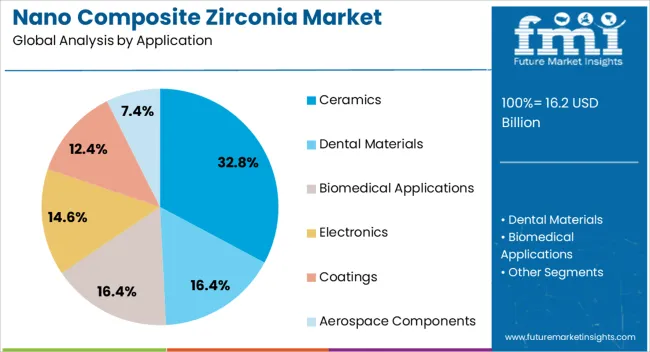

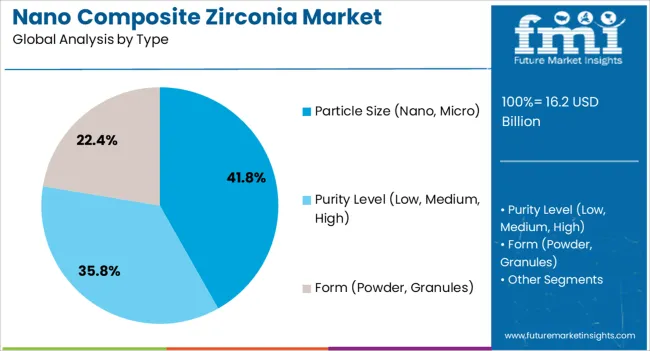

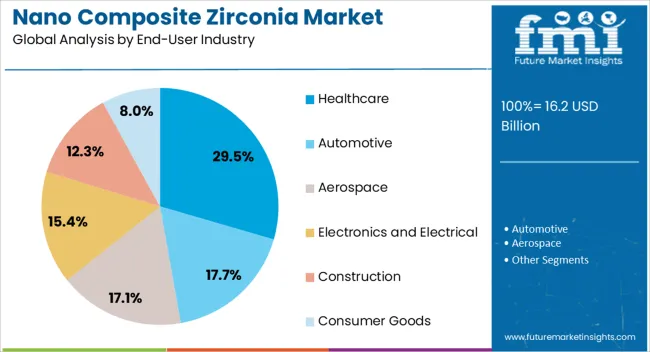

The nano composite zirconia market is segmented by application, type, end-user industry, distribution channel, formulation, and geographic regions. By application, nano composite zirconia market is divided into Ceramics, Dental Materials, Biomedical Applications, Electronics, Coatings, and Aerospace Components. In terms of type, nano composite zirconia market is classified into Particle Size (Nano, Micro), Purity Level (Low, Medium, High), and Form (Powder, Granules). Based on end-user industry, nano composite zirconia market is segmented into Healthcare, Automotive, Aerospace, Electronics and Electrical, Construction, and Consumer Goods. By distribution channel, nano composite zirconia market is segmented into Direct Sales, Distributors, and Online Platforms. By formulation, nano composite zirconia market is segmented into Solid State, Suspension-Based, and Composite Forms. Regionally, the nano composite zirconia industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The ceramics application segment is projected to hold 32.8% of the nano composite zirconia market revenue share in 2025, establishing itself as the leading application category. This dominance is being supported by the material’s ability to deliver exceptional hardness, thermal stability, and fracture toughness, making it highly suitable for advanced ceramic products.

Nano composite zirconia enhances wear resistance and extends the service life of ceramic components used in demanding environments such as industrial machinery, consumer electronics, and thermal insulation systems. The segment’s growth is also linked to the rising demand for high-precision, aesthetically appealing ceramics in dental and decorative applications, where both functionality and visual quality are critical.

Continuous improvements in powder processing, particle dispersion, and sintering technologies are enabling manufacturers to achieve superior microstructural uniformity, further improving mechanical performance The versatility of nano composite zirconia in meeting application-specific requirements, coupled with its compatibility with advanced manufacturing methods, is ensuring its continued preference within the global ceramics industry.

The particle size category covering nano and micro variants is expected to account for 41.8% of the nano composite zirconia market revenue share in 2025, positioning it as the leading type segment. This leadership is attributed to the superior material properties that can be tailored through precise control of particle size distribution. Nano-sized zirconia particles offer enhanced surface area, improved mechanical strength, and higher reactivity, making them ideal for advanced structural and functional applications.

Micro-sized particles, while less reactive, provide cost-effective solutions for applications that prioritize bulk material performance over nanoscale properties. The ability to combine nano and micro particles in composite formulations enables manufacturers to optimize performance characteristics for specific end-use requirements.

Ongoing advancements in nanomilling, surface modification, and dispersion technologies are enhancing product consistency and scalability As industries demand materials that balance performance, durability, and cost efficiency, the controlled particle size category is expected to maintain its leading position in the global market.

The healthcare end-user industry segment is anticipated to represent 29.5% of the nano composite zirconia market revenue share in 2025, making it the dominant end-use category. This leadership is driven by the material’s outstanding biocompatibility, strength, and resistance to wear, which are essential for medical applications such as dental implants, crowns, orthopedic components, and surgical instruments. Nano composite zirconia’s ability to mimic the appearance of natural teeth while delivering superior mechanical performance has made it a preferred choice in restorative dentistry.

In orthopedic applications, its high fracture resistance and stability under physiological conditions enhance implant longevity and patient safety. Continuous innovation in medical-grade zirconia processing is improving precision, customization, and performance consistency, aligning with the growing trend toward patient-specific solutions.

Stringent regulatory standards in healthcare are also encouraging the use of advanced materials with proven safety and durability profiles As global healthcare infrastructure expands and demand for high-quality medical devices rises, the segment’s market share is expected to remain strong in the years ahead.

The nano composite zirconia market is experiencing strong growth, particularly driven by the dental and medical industries, as well as aerospace and automotive applications. Technological advancements in synthesis methods are making the material more accessible, although challenges related to high production costs remain. As innovations in manufacturing continue to reduce costs, the material is likely to see broader adoption, offering opportunities across multiple sectors. The outlook for the market remains positive, with ongoing advancements fueling demand across industries.

Nano composite zirconia is increasingly being adopted in dental and medical fields due to its superior mechanical properties, high wear resistance, and biocompatibility. In dental applications, it is used for crowns, bridges, and implants, offering better strength and aesthetics compared to traditional materials. The growing demand for dental treatments and implants, along with the preference for durable materials in medical devices, is driving the market. As the healthcare sector grows, particularly in emerging markets, the demand for nano composite zirconia is expected to continue its upward trajectory.

The aerospace and automotive industries present lucrative opportunities for the nano composite zirconia market. Its high-temperature stability and durability make it ideal for use in components exposed to extreme conditions, such as turbine blades, heat shields, and engine parts. As manufacturers strive for lightweight, high-strength materials to improve fuel efficiency and performance, nano composite zirconia is becoming a material of choice. The adoption of these composites in these sectors is likely to rise, boosting market growth in the coming years.

Advances in the synthesis and fabrication of nano composite zirconia are enabling the production of more cost-effective and higher-quality materials. Techniques like sol-gel and hydrothermal processes are being refined to enhance the material's performance while reducing production costs. These innovations are making nano composite zirconia more accessible to various industries, including those in medical, automotive, and electronics sectors. Such technological trends are expected to increase the market penetration of nano zirconia composites and drive growth, particularly as more efficient and sustainable production methods are introduced.

The primary challenge in the nano composite zirconia market lies in the high production costs and complex synthesis processes. Manufacturing nano composite zirconia requires advanced equipment and specialized knowledge, which increases the overall cost compared to traditional materials. Additionally, scaling up production while maintaining material quality remains a significant hurdle for manufacturers. These factors can limit the widespread adoption of nano zirconia in price-sensitive industries and regions. Overcoming these production challenges through process optimization and cost-efficient techniques will be crucial for the market's expansion.

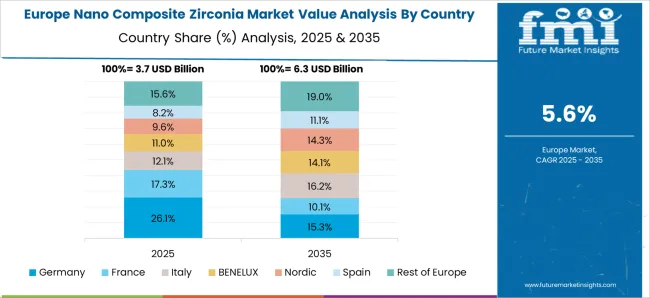

The global nano composite zirconia market is projected to grow at an 11% CAGR from 2025 to 2035. China leads with a growth rate of 14.9%, followed by India at 13.8%, and Germany at 12.7%. The United Kingdom records a growth rate of 10.5%, while the United States shows the slowest growth at 9.4%. These varying growth rates are driven by the increasing demand for nano composite zirconia in dental, automotive, aerospace, and electronics applications, where its strength, wear resistance, and thermal stability are highly valued. Emerging markets like China and India are experiencing higher growth due to rapid industrialization, increased healthcare demand, and expanding automotive sectors. More mature markets like the USA and the UK see steady growth, driven by advancements in technology and the continued need for high-performance materials. This report includes insights on 40+ countries; the top markets are shown here for reference.

The nano composite zirconia market in China is projected to grow at a robust CAGR of 14.9%. China’s expanding healthcare and dental sectors are major drivers for the adoption of nano composite zirconia, particularly in dental applications. Furthermore, the country's growing automotive and electronics industries are increasingly incorporating high-performance materials like nano composite zirconia for its durability, wear resistance, and thermal stability. China’s ongoing industrial advancements are expected to continue driving demand for this material, making it one of the fastest-growing markets globally.

The nano composite zirconia market in India is projected to grow at a CAGR of 13.8%. India’s rising demand for high-quality dental materials is driving the market, with more consumers opting for durable and aesthetically pleasing dental restorations. The automotive and electronics industries in India are also adopting nano composite zirconia for its excellent wear resistance and high thermal stability. With increasing investments in manufacturing and technological advancements, India is expected to continue seeing strong growth in nano composite zirconia consumption.

The nano composite zirconia market in Germany is projected to grow at a CAGR of 12.7%. Germany’s strong industrial sectors, especially automotive and aerospace, are significant consumers of nano composite zirconia due to its high strength, durability, and resistance to wear. The growing adoption of high-performance dental materials is also contributing to the market expansion. As Germany continues to prioritize innovation and advanced material technologies, nano composite zirconia is expected to see sustained demand across multiple sectors.

The nano composite zirconia market in the United Kingdom is projected to grow at a CAGR of 10.5%. The UK is experiencing strong demand for nano composite zirconia in dental applications, where it is used for creating durable and aesthetically pleasing dental restorations. Additionally, sectors like aerospace and automotive are increasingly adopting nano composite zirconia for its wear resistance and thermal stability. The growing trend toward advanced, high-performance materials in manufacturing is expected to contribute to the continued growth of the market.

The nano composite zirconia market in the United States is projected to grow at a CAGR of 9.4%. The USA is experiencing steady demand for nano composite zirconia, primarily driven by the growing dental industry, where the material is used for its superior strength and aesthetic properties. Additionally, industries like aerospace and electronics are incorporating nano composite zirconia for its wear resistance and high thermal stability. The steady pace of technological advancements and innovations in material science is expected to keep the USA market growing at a consistent rate.

| Item | Value |

|---|---|

| Quantitative Units | USD 16.2 Billion |

| Application | Ceramics, Dental Materials, Biomedical Applications, Electronics, Coatings, and Aerospace Components |

| Type | Particle Size (Nano, Micro), Purity Level (Low, Medium, High), and Form (Powder, Granules) |

| End-User Industry | Healthcare, Automotive, Aerospace, Electronics and Electrical, Construction, and Consumer Goods |

| Distribution Channel | Direct Sales, Distributors, and Online Platforms |

| Formulation | Solid State, Suspension-Based, and Composite Forms |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Saint-Gobain, Showa Denko K.K., Solvay S.A., Tosoh Corporation, Kyocera Corporation, Daiichi Kigenso Kagaku Kogyo Co. Ltd., CeramTec GmbH, H.C. Starck GmbH, VITA Zahnfabrik, Shandong Sinocera, Guangdong Orient, Emperor Nano Material, Wan Jing New Material, Jiangsu Lida Gaoke, Huawang, and Rauschert GmbH. |

| Additional Attributes | Dollar sales by composition (zirconia content, additives) and form (powder, pellets, coatings) are critical metrics. Trends include rising demand in dental, medical, and electronics applications, along with innovations in mechanical properties and biocompatibility. Regional variations, technological advancements, and the shift towards sustainable manufacturing practices are influencing market growth. |

The global nano composite zirconia market is estimated to be valued at USD 16.2 billion in 2025.

The market size for the nano composite zirconia market is projected to reach USD 46.1 billion by 2035.

The nano composite zirconia market is expected to grow at a 11.0% CAGR between 2025 and 2035.

The key product types in nano composite zirconia market are ceramics, dental materials, biomedical applications, electronics, coatings and aerospace components.

In terms of type, particle size (nano, micro) segment to command 41.8% share in the nano composite zirconia market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Graphene Nanocomposites Market 2025 to 2035

Self Sensing Nanocomposites Market Size and Share Forecast Outlook 2025 to 2035

Nanoscale Zero-Valent Iron Market Size and Share Forecast Outlook 2025 to 2035

Nanoscale Sand Mill Market Size and Share Forecast Outlook 2025 to 2035

Zirconia Based Dental Ceramics Market Size and Share Forecast Outlook 2025 to 2035

Composite Resin Market Size and Share Forecast Outlook 2025 to 2035

Composite Pin Insulator Market Size and Share Forecast Outlook 2025 to 2035

Composite Roller Market Size and Share Forecast Outlook 2025 to 2035

Composite Insulator Market Size and Share Forecast Outlook 2025 to 2035

Composite Paper Cans Market Size and Share Forecast Outlook 2025 to 2035

Nano Coating Market Size and Share Forecast Outlook 2025 to 2035

Composite Drums Market Size and Share Forecast Outlook 2025 to 2035

Nano Fibers Market Size and Share Forecast Outlook 2025 to 2035

Nanotechnology Photocatalysis Surface Coating Industry Analysis in AMEA Size and Share Forecast Outlook 2025 to 2035

Nanosensors Market Size and Share Forecast Outlook 2025 to 2035

Composite Textile Production Equipment Market Size and Share Forecast Outlook 2025 to 2035

Nano Precipitated Calcium Carbonate Market Size and Share Forecast Outlook 2025 to 2035

Nanocatalysts Market Size and Share Forecast Outlook 2025 to 2035

Nano Suspension Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Nanotechnology Packaging Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA