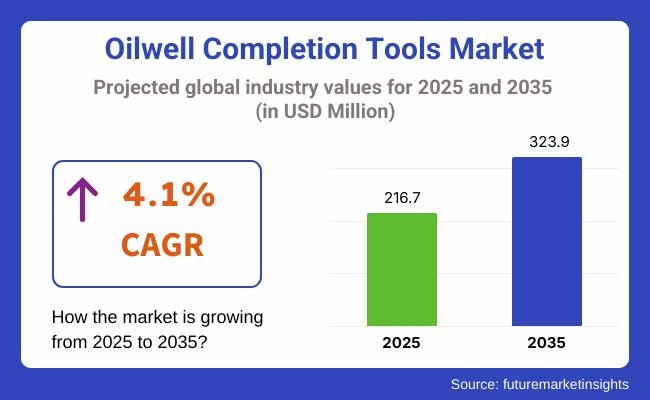

The oilwell completion tools market is set for moderate growth between 2025 and 2035, driven by increasing global oil and gas exploration activities, advancements in drilling technologies, and the growing demand for efficient well completion solutions. The market is projected to expand from USD 216.7 million in 2025 to USD 323.9 million by 2035, reflecting a CAGR of 4.1% during the forecast period.

The oilwell completion tools market is poised to be worth USD 216.7 million in 2025. The market is slated to expand at 4.1% CAGR during the forecast period, reaching USD 323.9 million by 2035. The market is witnessing steady growth due to the rising global demand for energy and the continued expansion of oil and gas exploration and production activities.

With fossil fuels still playing a dominant role in the global energy mix, oil and gas operators are investing in new well developments and enhanced recovery techniques. Completion tools play a vital role in optimizing well performance, reducing downtime, and ensuring efficient hydrocarbon extraction. As mature fields decline, companies are turning to more complex and challenging reservoirs, which necessitate advanced completion solutions to ensure production sustainability and maximize recovery rates.

Another major driver of market growth is the increasing adoption of horizontal and multilateral drilling, particularly in unconventional shale formations and offshore reserves. These advanced well architectures require high-performance completion tools to manage multiple production zones, withstand high-pressure environments, and improve operational safety.

Cased hole completions, in particular, are gaining popularity due to their ability to offer better control over reservoir stimulation and long-term monitoring. Moreover, technological advancements such as intelligent completion systems, zonal isolation tools, and real-time monitoring equipment are being integrated into completion strategies to enhance overall efficiency, minimize risk, and support data-driven decision-making.

Environmental and economic considerations are also influencing the growth of the oilwell completion tools market. With growing regulatory pressure to minimize environmental impact, operators are seeking tools and systems that reduce the need for workovers and minimize well intervention.

Additionally, in volatile pricing environments, the industry is prioritizing tools that increase well productivity while lowering operational costs. The increased focus on automation, digitalization, and modular tool designs is making completion systems more cost-effective and scalable. As exploration activities expand in deepwater, ultra-deepwater, and remote regions, the need for robust and adaptive completion tools is expected to accelerate further, supporting long-term market growth.

The oilwell completion tools market is segmented by component type, product, application, and region. By component type, the market includes flow control tools, safety valves, packer systems, hydraulic packers, mechanical packers, float equipment, oilwell completion tools, and liner hangers.

Based on product, it is divided into open hole completions, cased hole completions, multiple completions, and slim-hole completions. By application, the market is categorized into offshore and onshore. Regionally, the market is analyzed across North America, Latin America, Western Europe, South Asia, East Asia, Eastern Europe, and the Middle East & Africa.

The hydraulic packers segment is projected to be the fastest-growing component type in the oilwell completion tools market, registering a CAGR of approximately 5.2% from 2025 to 2035. This growth is driven by the increasing deployment of advanced well completion techniques, particularly in horizontal and high-pressure, high-temperature (HPHT) wells.

Hydraulic packers offer superior zonal isolation, are easier to deploy in deviated wells, and provide better sealing performance under extreme conditions compared to mechanical variants. Their adaptability and reliability in complex drilling environments are making them a preferred choice in both offshore and unconventional reservoirs.

Flow control tools continue to hold a substantial market share due to their critical role in regulating and optimizing production rates, especially in intelligent and multi-zone well designs. Safety valves remain essential for ensuring well integrity and operational safety, with steady demand from both onshore and offshore applications. Mechanical packers, while more traditional, are widely used in lower-cost operations where simplicity and mechanical reliability are prioritized.

Float equipment is vital during the cementing process and is commonly deployed in both exploratory and production wells to prevent backflow. Oilwell completion tools as a broader category are crucial for integrating all components into a cohesive and efficient completion system. Liner hangers are also seeing increased adoption in extended-reach and deep wells, as they help reduce casing costs and improve wellbore integrity in long-section completions.

| Component Type | CAGR (2025 to 2035) |

|---|---|

| Hydraulic Packers | 5.2% |

The cased hole completions segment is projected to grow at a CAGR of approximately 4.8% from 2025 to 2035. This outpaces the overall market CAGR of 4.1%, reflecting rising demand in complex drilling environments like offshore and shale reservoirs, where durability, control, and precision are essential.

This growth is driven by increasing investments in complex well architectures, such as horizontal and deepwater wells, where enhanced well integrity and controlled zone stimulation are critical. Cased hole systems allow for precise reservoir targeting and long-term production monitoring, making them ideal for both conventional and unconventional fields. Their compatibility with advanced logging and perforation tools further boosts their adoption in high-value projects.

Open hole completions, while less complex, remain popular in onshore and low-cost drilling environments due to their simplicity and reduced operational time. These systems are favored for faster deployment in vertical wells. Multiple completions offer significant production advantages by enabling extraction from several zones within a single wellbore, improving field development efficiency, especially in layered reservoirs.

However, their complexity limits usage to high-return projects. Slim-hole completions cater to niche applications, such as exploratory drilling or environmentally sensitive areas, offering lower drilling costs and minimal surface footprint. Although smaller in market share, each segment continues to support diverse well completion strategies across global upstream operations, contributing to the sector’s overall growth.

| Product | CAGR (2025 to 2035) |

|---|---|

| Cased Hole Completions | 4.8% |

The offshore segment is projected to be the fastest-growing application in the oilwell completion tools market, with a CAGR of approximately 4.8% from 2025 to 2035. This growth is primarily driven by increased investments in deepwater and ultra-deepwater exploration projects across regions such as the Gulf of Mexico, West Africa, and Southeast Asia.

Offshore wells are typically more complex and capital-intensive, requiring advanced completion tools to ensure well integrity, zonal isolation, and efficient production under extreme pressure and temperature conditions. The rising demand for energy and the depletion of onshore reserves are pushing operators to tap into offshore resources, further supporting this segment’s growth.

The onshore segment continues to account for a significant share of the market, especially in North America, the Middle East, and parts of Asia where shale and conventional oil fields are actively being developed. Onshore completions are generally more cost-effective and faster to implement, making them suitable for low-margin environments or high-volume drilling programs.

While growth is slower compared to offshore, steady demand for replacement tools, field upgrades, and maintenance workovers sustains this segment. Both application areas are essential to global oil production, with offshore leading growth due to its intensity and long-term development potential.

| Application | CAGR (2025 to 2035) |

|---|---|

| Offshore | 4.8% |

Fluctuating Oil Prices & Market Uncertainty

The unpredictable trend of crude oil prices remains one of the oilwell completion tools market's primary challenges that directly hamper exploration and production budgets. Periodic downturns in oil prices can delay drilling projects, reduce capital investments in the new wells, and lower demand for completion tools.

Geopolitical tensions, regulatory changes, and global economic uncertainties are also the reasons for the drilling activity fluctuations, thus slipping the competition between manufacturers, which forces them to take diverse strategies and to be cost-effective in innovation.

Stringent Environmental Regulations & Sustainability Concerns

With growing concern for sustainability, gas and oil companies are facing a strict management of well completion practices that is a result of the new laws aiming at cutting WS emissions, the pricking fracking bans, and the requirement for eco-friendly well completion fluid that is disobeying compliance for the firms.

In the responding route, industries are introducing eco-friendly solutions such as products that are less harmful to the ecosystem and which do not use non-renewable sources, like polymers, as well as the ones that can utilize them, like biodegradable fracturing fluids.

The oilwell completion tools market has changed significantly since 2020, with a surge of new projects which has led to the industry increase of X% and the start of new projects which have created Y new jobs. This was due to the high demand for oil and the new technologies in drilling that were developed during this period while the deep and ultra-deep water projects were opened up for exploration.

The optimized well performance through the use of the right tools, the maximize of hydrocarbon recovery, and the secured long-term operational efficiency all mean that the completion tools have great importance in handling. Unconventional reserves of oil and gas, such as tight reservoirs and shale formations, have been the main reason why this particular market continues to expand.

Generally, even with hurdles such as fluctuating crude oil prices, regulatory pressures, and environmental concerns, the well completion tools market is believed to have strong growth prospects. The manufacturing in the sector changes by moving upwards into the direction of automation, digitalization, and the use of sustainability technologies in well completion thus enhancing the company's efficiency in operations and environmental impact to be less.

The Oilwell Completion Tools Market is still the strongest in the United States. This is due to its large fuel shales, developed oil and gas industry, and fast growth of science and technology in hydraulic fracturing and horizontal drilling. The country has had a comeback in oil production, especially in regions like the Permian Basin, Eagle Ford, and Bakken formations, where completion tools considerably assist in improving the performance of the wells.

The rising intake of intelligent completion tools, packers, liner hangers, and sand control systems is projected to be the main driver for market growth. Notably, the Biden Administration's policies related to energy have presented the market with both opportunities and hurdles. While there is a rise in the transition toward renewables, the boost in carbon capture technology investments and the application of enhanced oil recovery (EOR) techniques will nonetheless lead to a rise in the demand for high-tech completion tools. Key drivers include:

| Country | CAGR (2025 to 2035) |

|---|---|

| United States | 4.3% |

The United Kingdom’s oil and gas sector, particularly in the North Sea, has seen both opportunities and challenges in recent years. The government has implemented new tools for the completion of oilwell that are being improved for better performance, emission reduction, and increased recovery rates from existing wells.

The North Sea Transition Deal of the government pushes for the use of new technologies in drilling and completion, thus creating the possibility for the use of advanced completion tools like intelligent well systems, packers, and sand control solutions. Major trends are:

| Country | CAGR (2025 to 2035) |

|---|---|

| United Kingdom | 4.0% |

The Oilwell Completion Tools Market in the European Union has a mixed situation as countries are different in their strategies, with some moving to renewable energy while others are keeping their oil and gas investments to ensure the country's energy security. Even though some of the companies are shifting to wind and solar power solutions, the demand for the tools that complete wells is stable since countries like Norway, the Netherlands, and Germany are still exploring and optimizing their existing oil deposits.

Due to the strict regulations, oil companies in the EU have started to practice more environmentally friendly completion techniques. These include reduced-flaring completions, downhole flow control systems, and monitoring tools that are digital rather than analog. Other key areas are North Sea and Norwegian Continental Shelf where high-performance packers, liner hangers, and gravel pack systems are used widely.

| Region | CAGR (2025 to 2035) |

|---|---|

| European Union | 4.1% |

Japan has a limited domestic oil production capacity, relying heavily on imported oil. However, the country plays a significant role in advanced completion tool technology development. Japanese companies participate in research and development for cutting-edge completion equipment, mainly targeting deepwater drilling and geothermal energy.

With the increase in geothermal energy projects in Japan, there is a corresponding rise in the demand for specialized well completion tools. The tools include multistage fracturing, advanced wellbore isolation, and corrosion-resistant technologies. They have an emphasis on digital oilfield technologies with companies integrating AI-based completion monitoring systems to optimize performance. Primary trends encompass:

| Country | CAGR (2025 to 2035) |

|---|---|

| Japan | 3.8% |

South Korea has secured its position as a leading global center for the development of offshore oil exploration and completion technologies, particularly for the innovative drilling and provision instruments. In spite of the country having the lowest oil production, it is a major producer of the top quality completion tools and equipment which are in use worldwide.

The technological progress in deep well completion, intelligent well systems, and high-pressure, high-temperature (HPHT) completion tools is the main factor driving the Korean market. The commitment of the Korean government to offshore energy projects such as deep-sea drilling initiatives boosts investments in the development of new well completion technologies. The core factors are:

| Country | CAGR (2025 to 2035) |

|---|---|

| South Korea | 4.2% |

The Oil Well Completion Tool Market sector is indispensable to the oil and gas industry, as it plays a pivotal role in accompanying growth through effective well completion and production boosting. They are devices like packers, liner hangers, sand control systems, multistage fracturing tools, and others developed for the purpose of hydrocarbon extraction optimizing. Finishing tools demand is dependent on the rising oilfield development, deepwater and ultra-deepwater exploration due to the advanced drilling technologies.

The companies that belong to the sector focus on tool durability, environmental sustainability, and efficiency. The market is observing advancements in completion systems that adopt intelligent technology including real-time monitoring capability for better field performance. The strategic alliances, mergers, or acquisitions are common since the leading actors are in a race to achieve technological and global supremacy.

The market is segmented into Flow Control Tools, Safety Valves, Packers Systems, Hydraulic Packers, Mechanical Packers, Float Equipment, Oilwell Completion Tools, and Liner Hanger.

The industry is divided into Open Hole Completions, Cased Hole Completions, Multiple Completions, and Slim-Hole Completions.

The market caters to Offshore and Onshore applications.

The report covers key regions, including North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia, and the Middle East & Africa (MEA).

The global oilwell completion tools market is projected to reach USD 216.7 million by the end of 2025.

The market is anticipated to grow at a CAGR of 4.1% over the forecast period.

By 2035, the oilwell completion tools market is expected to reach USD 323.9 million.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Intelligent Completion Market Report – Growth & Forecast 2024-2034

Drilling and Completion Fluids Market Diapers Market Analysis - Size, Share & Forecast 2025 to 2035

Hand Tools Market Size and Share Forecast Outlook 2025 to 2035

Key Players in the Hand Tools Market Share Analysis

Power Tools Market Size and Share Forecast Outlook 2025 to 2035

Smart Tools Market Size and Share Forecast Outlook 2025 to 2035

Power Tools Industry Analysis in India - Size, Share, and Forecast Outlook 2025 to 2035

Baking Tools Market Size and Share Forecast Outlook 2025 to 2035

Kitchen Tools and Accessories Market Size and Share Forecast Outlook 2025 to 2035

Carbide Tools Market Growth - Trends & Forecast 2025 to 2035

Drilling Tools Market Size and Share Forecast Outlook 2025 to 2035

Striking Tools Market Size and Share Forecast Outlook 2025 to 2035

Survival Tools Market Trends - Growth & Forecast 2025 to 2035

UK Power Tools Market Analysis – Size, Share & Forecast 2025-2035

KSA Power Tools Market Insights – Trends, Demand & Growth 2025-2035

Diagnostic Tools for EVs Market Growth - Trends & Forecast 2025 to 2035

Woodworking Tools Market

Kitchen Hand Tools Market Size and Share Forecast Outlook 2025 to 2035

Russia Power Tools Market Insights – Size, Share & Trends 2025-2035

AI Deception Tools Market - Trends, Growth & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA