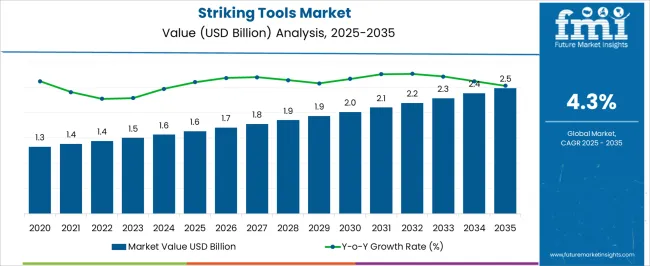

The Striking Tools Market is estimated to be valued at USD 1.6 billion in 2025 and is projected to reach USD 2.5 billion by 2035, registering a compound annual growth rate (CAGR) of 4.3% over the forecast period. Between 2025 and 2030, the market grows from USD 1.6 billion to USD 1.9 billion, contributing an incremental USD 0.3 billion in growth, representing a CAGR of 3.8%. This period of steady growth is driven by rising demand in construction, automotive, and industrial sectors, where striking tools such as hammers, mallets, and chisels are integral to manufacturing and assembly processes. From 2030 to 2035, the market expands at a slightly higher rate, increasing from USD 1.9 billion to USD 2.5 billion, contributing USD 0.6 billion in growth.

The CAGR of 5.0% during this period is indicative of rising adoption of more specialized, high-performance tools driven by industry advancements and increasing investment in automation and precision tools. This period also reflects the continued growth in demand for tools used in maintenance and repair across various industries. The overall CAGR of 4.3% signifies consistent growth in the market, driven by ongoing demand in both established and emerging industrial sectors.

| Metric | Value |

|---|---|

| Striking Tools Market Estimated Value in (2025 E) | USD 1.6 billion |

| Striking Tools Market Forecast Value in (2035 F) | USD 2.5 billion |

| Forecast CAGR (2025 to 2035) | 4.3% |

Demand is being supported by both professional-grade and DIY applications across construction, automotive, manufacturing, and maintenance sectors. Manufacturers are investing in improved shock absorption, material quality, and handle designs to enhance productivity and safety during high-impact tasks.

Moreover, integration of advanced heat treatment processes and automation in tool forging is improving consistency and fatigue resistance. Distribution networks are expanding through online platforms and retail partnerships, increasing product accessibility.

As urbanization accelerates and repair-and-rebuild activities rise globally, the market is expected to remain strong. Environmental and sustainability considerations are also shaping procurement decisions, with recycled metal and reduced packaging gaining traction in developed markets.

The striking tools market is segmented by product type, material, price, end use, distribution channel, and geographic regions. By product type, the striking tools market is divided into Hammers, Picks and axes, Mallets, Chisels and punches, Diggers, and Others (tampers, etc.). In terms of material, the striking tools market is classified into Steel, Wood, Fiberglass, Plastic, Aluminum, and Others (composite materials, etc.). Based on the price of the striking tools, the market is segmented into Medium, Low, and High. By end use, the striking tools market is segmented into Industrial, DIY and homeowners, and Professionals. The distribution channel of the striking tools market is segmented into Offline and Online. Regionally, the striking tools industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

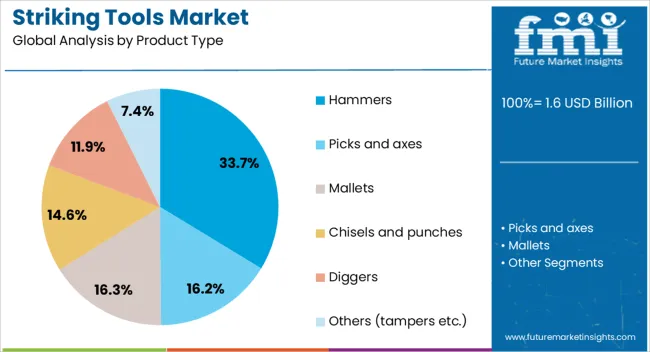

Hammers are projected to account for 33.70% of the overall market revenue in 2025, positioning them as the leading product type in the striking tools market. Their dominance is being attributed to wide-ranging applicability in carpentry, masonry, metalwork, and general-purpose repair across residential, commercial, and industrial sectors.

Ergonomic advancements, such as vibration-dampening grips and balanced head-to-handle weight ratios, have enhanced user comfort and tool precision. Manufacturers are also optimizing hammer designs for specific trades, supporting both general use and specialized applications.

The ability to manufacture hammers at scale while maintaining cost efficiency and tool longevity has further supported their widespread adoption, particularly among tradespeople and contractor segments.

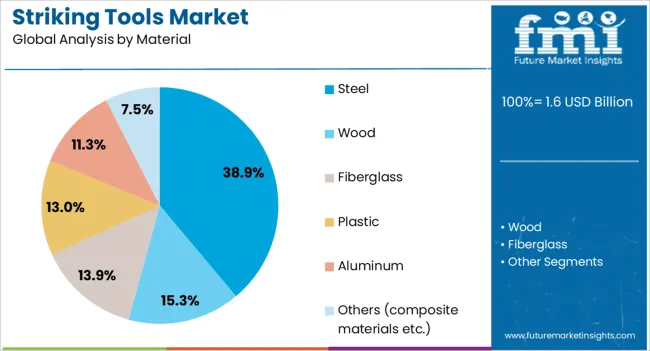

Steel is expected to represent 38.90% of the material-based market share in 2025, making it the most preferred material in striking tools. This preference is being driven by steel’s high tensile strength, durability, and adaptability to diverse forging techniques.

Steel-based striking tools offer consistent performance under impact stress, making them reliable for heavy-duty and repetitive-use environments. Heat treatment and alloying technologies have improved tool hardness and wear resistance without compromising ductility.

Additionally, steel is widely recyclable, which supports sustainability targets among environmentally conscious manufacturers and buyers. The material’s long service life and compatibility with molded grips and protective coatings have helped retain its leadership across segments.

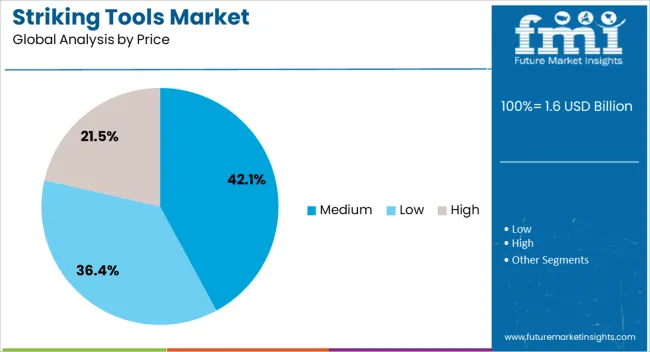

The medium price range is anticipated to hold a 42.10% share of the market by 2025, emerging as the leading price tier in the striking tools market. This segment's popularity is being influenced by the balance it offers between cost and performance, making it accessible for both skilled professionals and prosumer buyers.

Medium-priced tools are increasingly featuring premium ergonomic designs, improved grip materials, and higher-grade finishes, offering enhanced durability at a competitive cost. Retailers and brands are targeting this segment with bundled offerings, loyalty programs, and digital sales campaigns to reach a wider customer base.

As demand shifts toward tools that combine affordability with long-term usability, the medium price segment continues to capture preference in both developed and emerging economies.

The striking tools market encompasses a wide range of tools designed to deliver force to a workpiece. Common tools include hammers, mallets, chisels, and screwdrivers, which are utilized across construction, automotive, manufacturing, and DIY sectors. These tools play a crucial role in a variety of applications, from heavy-duty industrial tasks to everyday home projects. The market is being driven by growing demand in industries like construction, automotive repair, and manufacturing, where precision and durability are critical. Manufacturers are increasingly focusing on improving the ergonomics, material strength, and versatility of striking tools to cater to diverse end-user needs.

The striking tools market is a crucial component of multiple industries, including construction, automotive, manufacturing, and DIY sectors. These tools, such as hammers, chisels, mallets, and screwdrivers, are essential for various tasks, ranging from heavy-duty industrial activities to routine home repairs. The market is driven by the rising demand for reliable and durable tools used for precise and efficient work. As industries like construction and automotive continue to grow globally, the need for high-performance striking tools becomes more prominent. Manufacturers are focusing on enhancing the quality, ergonomic design, and material strength of these tools to cater to the diverse needs of professionals and DIY enthusiasts.

Technological advancements and innovations in materials are significantly influencing the striking tools market. Manufacturers are increasingly incorporating advanced materials such as high-carbon steel, fiberglass, and composite materials into their tool designs. These materials offer superior durability, enhanced strength, and lighter weight, which provide users with longer-lasting and more reliable tools. In addition to material innovations, the ergonomic design of striking tools has seen significant improvement, reducing user fatigue and enhancing comfort during prolonged use. The adoption of composite and lightweight materials has made it easier for manufacturers to create tools that are not only more durable but also more practical for professional and DIY use. These advancements allow for greater precision, safety, and comfort, which are crucial factors for both professionals in industrial environments and casual users performing home repairs.

Despite the growing demand for striking tools, the market faces several challenges, including issues related to product standardization and safety concerns. The lack of consistent quality standards across regions and industries can result in variations in product performance, leading to unreliable tools. Manufacturers must adhere to strict safety regulations to ensure their tools are safe to use under heavy conditions. Tools that do not meet these standards can cause accidents, especially if they break or malfunction during use. Poorly designed tools with inadequate grips or weak construction can lead to injuries, particularly among inexperienced users. As safety remains a priority for both consumers and manufacturers, there is a continuous effort to improve tool durability, handle design, and materials. Addressing these challenges ensures better trust in the market and enhances product safety for various users.

The growing trend of DIY (do-it-yourself) projects and home improvement is offering significant opportunities for the striking tools market. As more consumers engage in home renovations, repairs, and other DIY activities, there is an increasing demand for reliable and affordable tools. DIY enthusiasts are seeking tools that offer ease of use, durability, and versatility, with products catering specifically to home projects. Manufacturers are capitalizing on this demand by developing compact, user-friendly striking tools designed for non-professional users. The expansion of e-commerce platforms has also contributed to this trend, making it easier for consumers to access a variety of striking tools for their personal projects. As more individuals pursue home improvement activities, the demand for striking tools continues to rise, providing manufacturers with ample opportunities to meet the needs of this growing market segment and expand their customer base.

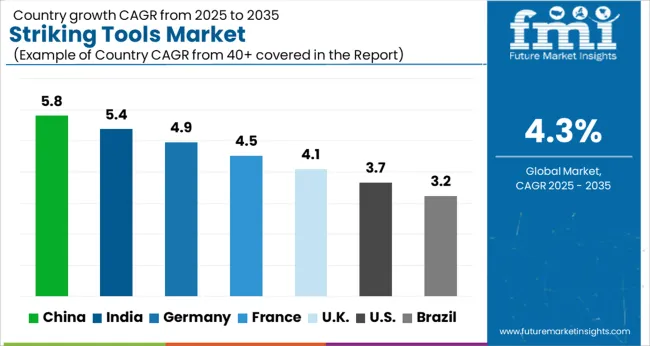

The striking tools market is projected to grow at a CAGR of 4.3% from 2025 to 2035. China leads at 5.8%, followed by India at 5.4%, and France at 4.5%. The United Kingdom records 4.1%, while the United States stands at 3.7%. Growth in BRICS nations like China and India is driven by rapid industrialization, increased infrastructure development, and rising demand for tools in construction and manufacturing sectors. Meanwhile, OECD countries like France, the UK, and the USA show steady growth, supported by the need for high-quality, durable tools in both industrial applications and consumer markets. The analysis spans over 40+ countries, with the top countries shown below.

China is projected to grow at a CAGR of 5.8% through 2035, driven by its booming manufacturing sector and increasing demand for tools in construction, automotive, and industrial applications. As China is the largest manufacturing hub in the world, the demand for striking tools, such as hammers, mallets, and chisels, is expected to rise significantly. The adoption of advanced tools for precision and durability in sectors like metalworking and woodworking contributes to market growth. With the increasing urbanization and infrastructure development in China, the demand for robust construction and manufacturing tools is on the rise.

India is expected to grow at a CAGR of 5.4% through 2035, driven by expanding infrastructure projects, manufacturing, and construction industries. The increasing demand for high-quality, durable tools in sectors such as construction, automotive, and metalworking is accelerating the adoption of striking tools. India’s industrialization and urbanization are key drivers for the market, alongside government investments in infrastructure development. The rising middle class and demand for consumer goods further support the growth of the tools market. The government's push for "Make in India" and increased manufacturing output also adds to the market’s positive outlook.

France is expected to grow at a CAGR of 4.5% through 2035, with demand driven by sectors such as construction, automotive, and aerospace. The growing need for high-performance, reliable tools in industrial and consumer applications is boosting the market. France's industrial growth and demand for quality materials in construction and manufacturing are significant drivers of the tools market. France’s focus on developing smart and ergonomic tools to enhance efficiency and reduce worker fatigue supports market expansion. The increasing adoption of advanced technologies in production further stimulates demand for precision-engineered striking tools.

The United Kingdom is projected to grow at a CAGR of 4.1% through 2035, with demand for striking tools driven by the construction and manufacturing sectors. The UK is focused on infrastructure development, which fuels the need for advanced and reliable tools. The automotive sector, as well as other industrial segments, relies heavily on durable striking tools for various applications. The trend toward high-quality, precision tools for both professional and consumer use continues to rise. With an increasing emphasis on high standards of safety and performance, demand for striking tools is expected to see steady growth in the UK

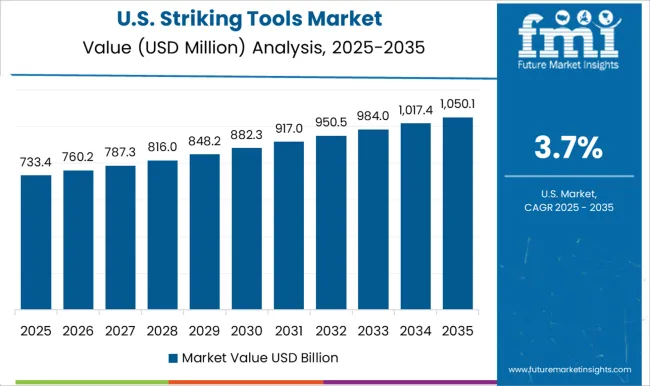

The United States is projected to grow at a CAGR of 3.7% through 2035, supported by strong demand for striking tools across the construction, automotive, and consumer sectors. With a high level of infrastructure development and manufacturing activities, the USA continues to invest in durable and high-quality tools. The growth in DIY (do-it-yourself) culture, home improvement, and repair sectors also contributes to the rising demand for striking tools. The focus on safety standards, tool efficiency, and technological advancements in manufacturing continues to push the adoption of innovative and high-performance tools in the USA

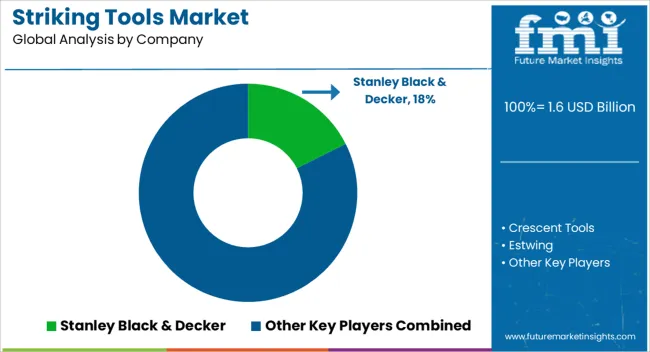

The striking tools market is driven by leading manufacturers offering high-quality, durable hand tools for a wide range of applications, including construction, automotive, industrial, and home improvement sectors. Stanley Black & Decker is a dominant player in the market, providing a wide variety of striking tools such as hammers, mallets, and pry bars under well-known brands like Stanley and DeWalt, catering to both professionals and DIY consumers. Crescent Tools and Estwing are also key players, specializing in hand tools known for their strength, precision, and ergonomic design, particularly in the hammer and wrench segments. Fiskars stands out for its focus on high-performance hand tools designed for gardening and home improvement, with an emphasis on comfort and ease of use.

Gedore, Husky Tools, and Kendo Tools offer a wide range of striking tools with a focus on durability and reliability, serving the industrial and automotive sectors with heavy-duty tools. Klein Tools is well-known for producing striking tools used in electrical and construction work, offering products that combine functionality with safety features. Milwaukee Tool and Proto provide high-performance striking tools with innovative features aimed at improving user efficiency and comfort in heavy-duty industrial applications.

Peddinghaus, Roughneck Tools, and Snap-on Tools cater to niche segments such as professional tradesmen and mechanics, offering specialized striking tools with enhanced performance and durability. Tajima Tools and Vaughan focus on high-quality, precision-crafted tools for both industrial and DIY applications, offering a wide selection of hammers, chisels, and prying tools. Competitive differentiation is driven by product durability, ergonomics, material quality, and innovation in design. Barriers to entry include the need for strong brand reputation, manufacturing expertise, and relationships with distributors. Strategic priorities include developing ergonomic, user-friendly designs, expanding product portfolios to serve a wide range of industries, and focusing on sustainability in production processes.

Manufacturers are increasingly focused on using high-durability materials for striking tools. Forged steel, carbon steel, and alloyed metals are being used to enhance the durability and lifespan of tools like hammers, mallets, and sledgehammers. Additionally, the introduction of composite handles made from fiberglass or rubber is gaining traction due to their ability to reduce vibration, increase comfort, and prevent breakage.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.6 Billion |

| Product Type | Hammers, Picks and axes, Mallets, Chisels and punches, Diggers, and Others (tampers etc.) |

| Material | Steel, Wood, Fiberglass, Plastic, Aluminum, and Others (composite materials etc.) |

| Price | Medium, Low, and High |

| End Use | Industrial, DIY and homeowners, and Professionals |

| Distribution Channel | Offline and Online |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Stanley Black & Decker, Crescent Tools, Estwing, Fiskars, Gedore, Husky Tools, Kendo Tools, Klein Tools, Milwaukee Tool, Peddinghaus, Proto, Roughneck Tools, Snap-on Tools, Tajima Tools, and Vaughan |

| Additional Attributes | Dollar sales by tool type (hammers, mallets, pry bars, chisels, and specialty striking tools) and end-use segments (construction, automotive, industrial, DIY). Demand dynamics are driven by the growing construction and home improvement sectors, as well as the rise in industrial applications requiring heavy-duty hand tools. Regional trends show North America and Europe as dominant markets for professional-grade striking tools, while Asia-Pacific is experiencing growth due to increasing industrialization and construction activities. I |

The global striking tools market is estimated to be valued at USD 1.6 billion in 2025.

The market size for the striking tools market is projected to reach USD 2.5 billion by 2035.

The striking tools market is expected to grow at a 4.3% CAGR between 2025 and 2035.

The key product types in striking tools market are hammers, picks and axes, mallets, chisels and punches, diggers and others (tampers etc.).

In terms of material, steel segment to command 38.9% share in the striking tools market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Brow Tools Market Size and Share Forecast Outlook 2025 to 2035

Hand Tools Market Size and Share Forecast Outlook 2025 to 2035

Key Players in the Hand Tools Market Share Analysis

Power Tools Market Size and Share Forecast Outlook 2025 to 2035

Smart Tools Market Size and Share Forecast Outlook 2025 to 2035

Power Tools Industry Analysis in India - Size, Share, and Forecast Outlook 2025 to 2035

Baking Tools Market Size and Share Forecast Outlook 2025 to 2035

Kitchen Tools and Accessories Market Size and Share Forecast Outlook 2025 to 2035

Carbide Tools Market Growth - Trends & Forecast 2025 to 2035

Drilling Tools Market Size and Share Forecast Outlook 2025 to 2035

Survival Tools Market Trends - Growth & Forecast 2025 to 2035

UK Power Tools Market Analysis – Size, Share & Forecast 2025-2035

KSA Power Tools Market Insights – Trends, Demand & Growth 2025-2035

Diagnostic Tools for EVs Market Growth - Trends & Forecast 2025 to 2035

Woodworking Tools Market

Kitchen Hand Tools Market Size and Share Forecast Outlook 2025 to 2035

Russia Power Tools Market Insights – Size, Share & Trends 2025-2035

AI Deception Tools Market - Trends, Growth & Forecast 2025 to 2035

AR Metrology Tools Market Trends – Growth & Forecast through 2034

Sand Control Tools Market

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA