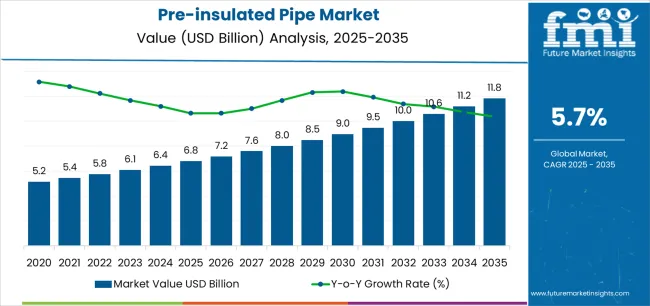

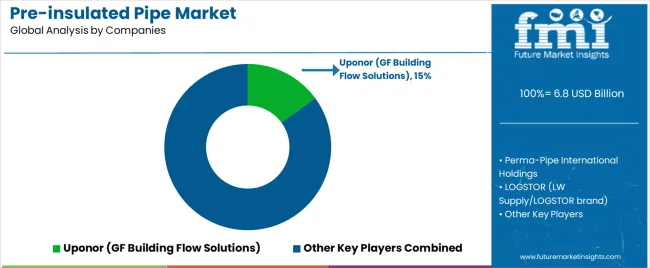

The global pre-insulated pipe market is valued at USD 6.8 billion in 2025 and is expected to reach USD 11.8 billion by 2035, advancing at a CAGR of 5.4%. Sales of pre-insulated pipes are gaining momentum as cities, utilities, and industrial facilities prioritize thermal efficiency, long-term cost savings, and compliance with tightening energy standards. Demand for pre-insulated pipe systems is closely tied to the modernization of district heating networks, which are being upgraded to handle growing urban populations and stricter decarbonization mandates. Adoption of advanced insulation technologies ensures reliable heat distribution, minimal energy loss, and reduced operational costs, making pre-insulated pipe systems central to future energy infrastructure planning.

The expansion of the market is not confined to Europe, where district heating is well established. Middle Eastern projects are beginning to adopt high-efficiency pipe systems for cooling and heating applications, while North American municipalities are accelerating investments in sustainable utility infrastructure. Industrial users, ranging from petrochemicals to food processing, are also turning to pre-insulated pipes for maintaining temperature integrity across long distances. These shifts indicate that sales of pre-insulated pipe systems are no longer tied to niche applications but are becoming integral to energy transition strategies worldwide.

In the earlier years of the forecast period, up to 2030, adoption of metal and alloy-based pipe systems will dominate. These materials are preferred for their durability, mechanical strength, and ability to withstand extreme operating conditions. Market participants are expected to benefit from rising demand for advanced insulation layers, combined with automated monitoring technologies that allow real-time detection of leaks or heat losses. Utilities and contractors are embracing digital solutions, pairing pipe infrastructure with smart control platforms that enhance reliability and extend asset lifecycles. This shift indicates that energy efficiency is not simply a regulatory obligation but an operational necessity.

Between 2030 and 2035, sales of pre-insulated pipe solutions will accelerate further, supported by the widespread adoption of below-ground installation systems and seamless integration with energy management platforms. Growth during this phase will also reflect strong interest in hybrid insulation materials, where polymers and composites offer new levels of flexibility and thermal resistance. The trajectory points toward mass adoption, with demand no longer concentrated in a handful of advanced markets but spread across developing economies investing in resilient heating and cooling infrastructure. Governments are backing such transitions with subsidies, carbon reduction frameworks, and stricter building codes, ensuring that adoption of pre-insulated pipe technology is sustained over the long term.

As per Future Market Insights, validated for research in industrial sensors, robotics, and connected systems, by 2035, demand for pre-insulated pipes will be firmly embedded in both developed and emerging markets.

Where revenue comes from -- now vs next (industry-level view)

| Period | Primary Revenue Buckets | Share | Notes |

|---|---|---|---|

| Today | New pipe system sales (metal, polymer) | 48% | Capex-led, infrastructure-driven purchases |

| Installation & commissioning services | 22% | Trenching, welding, testing for networks | |

| Maintenance & repair contracts | 18% | Leak detection, insulation replacement | |

| Retrofit & upgrades | 12% | Legacy system enhancement, efficiency improvement | |

| Future (3-5 yrs) | Advanced metal & alloy systems | 42-46% | High-efficiency insulation, smart monitoring |

| Digital monitoring & analytics | 16-20% | Real-time thermal tracking, predictive maintenance | |

| Service-as-a-subscription | 14-18% | Performance guarantees, energy savings contracts | |

| Installation & integration | 12-16% | Below-ground expertise, specialized welding | |

| Retrofit & modernization | 8-12% | Network upgrades, efficiency enhancement | |

| Data services (efficiency metrics, heat loss monitoring) | 4-7% | Benchmarking for district heating operators |

| Metric | Value |

|---|---|

| Market Value (2025) | USD 6.8 billion |

| Market Forecast (2035) | USD 11.8 billion |

| Growth Rate | 5.7% CAGR |

| Leading Material | Metal & Alloys |

| Primary Application | District Heating & Cooling Segment |

The market demonstrates strong fundamentals with metal and alloy-based pre-insulated systems capturing a dominant share through advanced thermal efficiency capabilities and district heating network optimization. District heating and cooling applications drive primary demand, supported by increasing energy efficiency requirements and infrastructure modernization. Geographic expansion remains concentrated in developed markets with established district heating infrastructure, while emerging economies show accelerating adoption rates driven by smart city initiatives and rising energy efficiency standards.

Design for efficiency, not just installation speed

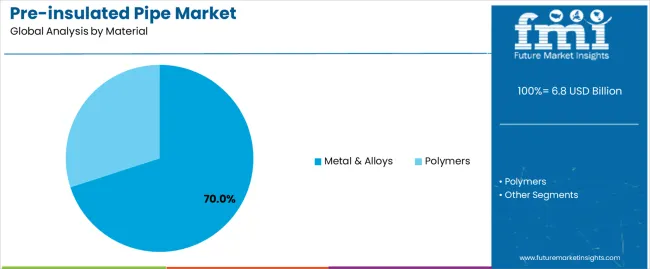

Primary Classification: The market segments by material into metal & alloys and polymers, representing the evolution from traditional thermal distribution systems to advanced insulation solutions for comprehensive district heating optimization.

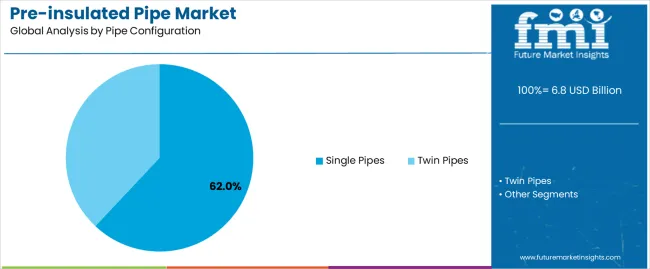

Secondary Classification: Pipe configuration segmentation divides the market into single pipes and twin pipes sectors, reflecting distinct requirements for network design, operational efficiency, and thermal distribution standards.

Tertiary Classification: Installation segmentation covers below ground and above ground sectors, while end-use applications span district heating & cooling, oil & gas, chemical, pharmaceutical, and others.

Regional Classification: Geographic distribution covers North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia Pacific, and Middle East & Africa, with developed markets leading adoption while emerging economies show accelerating growth patterns driven by district heating network expansion programs.

The segmentation structure reveals technology progression from conventional pipe systems toward sophisticated thermal distribution solutions with enhanced insulation and monitoring capabilities, while application diversity spans from district heating facilities to industrial process operations requiring precise thermal control solutions.

Market Position: Metal & Alloys pre-insulated systems command the leading position in the pre-insulated pipe market with 70.0% market share through advanced thermal features, including superior insulation performance, operational durability, and district heating network optimization that enable infrastructure operators to achieve optimal thermal efficiency across diverse heating and industrial environments.

Value Drivers: The segment benefits from district heating facility preference for reliable pipe systems that provide consistent thermal performance, extended service life, and operational efficiency optimization without requiring significant infrastructure modifications. Advanced design features enable automated monitoring systems, thermal consistency, and integration with existing heating equipment, where operational performance and energy efficiency represent critical facility requirements.

Competitive Advantages: Metal & Alloys pre-insulated systems differentiate through proven operational reliability, consistent thermal characteristics, and integration with automated district heating systems that enhance facility effectiveness while maintaining optimal energy standards suitable for diverse heating and industrial applications.

Key market characteristics:

Polymer-based pre-insulated systems maintain a 30.0% market position in the pre-insulated pipe market due to their flexibility properties and installation advantages. These systems appeal to facilities requiring moderate thermal capacity with competitive pricing for specialized heating applications. Market growth is driven by district heating expansion, emphasizing lightweight installation solutions and operational efficiency through optimized system designs.

Market Context: Single Pipes demonstrate strong market dominance in the pre-insulated pipe market with 62.0% market share due to widespread adoption of versatile distribution systems and increasing focus on district heating network optimization, installation cost efficiency, and thermal distribution applications that maximize energy output while maintaining efficiency standards.

Appeal Factors: Single Pipe system operators prioritize installation versatility, thermal balance, and integration with existing district heating infrastructure that enables coordinated distribution operations across multiple network sections. The segment benefits from substantial district heating investment and modernization programs that emphasize the acquisition of single pipe systems for network optimization and thermal efficiency applications.

Growth Drivers: District heating expansion programs incorporate single pipe systems as standard equipment for thermal operations, while smart city development increases demand for flexible configuration capabilities that comply with energy standards and minimize installation complexity.

Market Challenges: Varying thermal requirements and network complexity may limit system standardization across different facilities or distribution scenarios.

Application dynamics include:

Twin Pipes applications capture 38.0% market share through specialized thermal requirements in high-capacity heating networks, industrial facilities, and large-scale applications. These installations demand efficient distribution systems capable of operating with simultaneous supply and return flows while providing effective thermal management and operational reliability capabilities.

Market Position: Below Ground installations command significant market position with 78.0% market share through optimal thermal protection that meets efficiency and durability requirements for diverse district heating applications.

Value Drivers: This installation method provides the ideal combination of thermal retention and infrastructure protection, meeting requirements for long-term operations, urban applications, and heating network installations without excessive maintenance or exposure risks.

Growth Characteristics: The segment benefits from broad applicability across district heating sectors, established installation specifications, and comprehensive infrastructure programs that support widespread adoption and operational efficiency.

Above Ground applications account for 22.0% market share, including industrial facilities, exposed installations, and temporary heating operations requiring visible access capabilities for maintenance and operational monitoring.

Market Context: District Heating & Cooling dominates the market with 34.0% market share, reflecting the primary demand source for pre-insulated pipe technology in thermal energy distribution and urban heating operations.

Business Model Advantages: District heating networks provide direct market demand for advanced pipe systems, driving technology innovation and infrastructure expansion while maintaining thermal efficiency and energy conservation requirements.

Operational Benefits: District heating applications include urban energy distribution, municipal heating networks, and thermal management that drive consistent demand for pipe systems while providing access to latest thermal technologies.

Oil & Gas applications capture 28.0% market share through thermal process requirements in refineries, pipeline operations, and industrial facilities requiring high-temperature thermal management and operational reliability.

Chemical applications account for 14.0% market share, including process heating, chemical manufacturing, and industrial operations requiring precise thermal control and specialized insulation capabilities.

Pharmaceutical applications capture 6.0% market share through controlled thermal requirements in manufacturing facilities, research operations, and cleanroom applications demanding strict temperature control and validated thermal systems.

Others applications account for 18.0% market share, encompassing food processing, residential developments, campus heating, and specialized thermal applications requiring customized pre-insulated pipe solutions.

| Category | Factor | Impact | Why It Matters |

|---|---|---|---|

| Driver | District heating network expansion & urban infrastructure modernization | ★★★★★ | Growing energy efficiency mandates require advanced thermal distribution systems with minimal heat loss and long-term reliability across heating networks. |

| Driver | Energy efficiency regulations & carbon reduction targets (EU directives, national standards) | ★★★★★ | Transforms advanced insulation systems from "optional" to "mandatory"; vendors that provide thermal performance certification and efficiency documentation gain competitive advantage. |

| Driver | Smart city development & renewable energy integration | ★★★★☆ | Smart infrastructure needs integrated, monitored pipe systems; demand for digital connectivity and thermal tracking expanding addressable market. |

| Restraint | High installation investment & project complexity (especially for below-ground systems) | ★★★★☆ | Small heating operators defer installations; increases price sensitivity and slows advanced system adoption in emerging markets. |

| Restraint | Complex welding requirements & specialized installation procedures | ★★★☆☆ | District heating projects face lengthy commissioning procedures and quality validation requirements, limiting installation flexibility and increasing project complexity. |

| Trend | Digital monitoring integration & smart thermal management | ★★★★★ | Real-time heat loss tracking, predictive maintenance, and thermal analytics transform operations; IoT connectivity and data integration become core value propositions. |

| Trend | Decentralized heating networks & micro-district systems | ★★★★☆ | Flexible pipe systems for localized heating solutions; modular designs and quick installation capabilities drive competition toward customization solutions. |

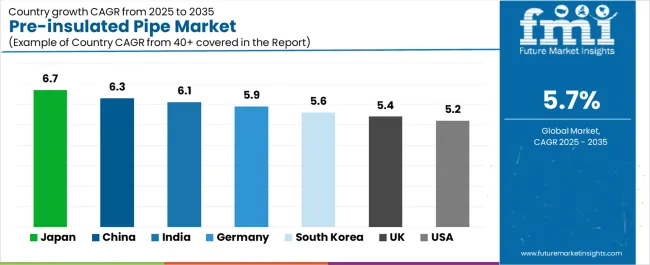

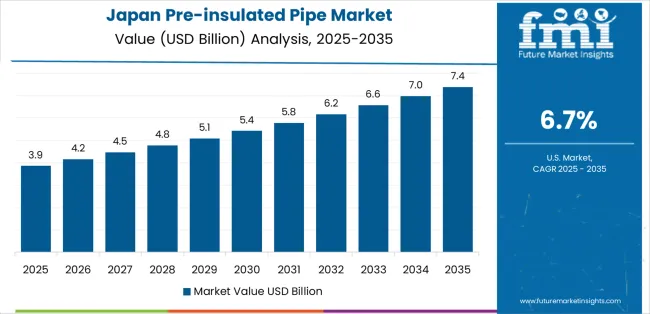

The pre-insulated pipe market demonstrates varied regional dynamics with Growth Leaders including Japan (6.7% growth rate) and China (6.3% growth rate) driving expansion through district energy retrofit initiatives and urban heat network development. Steady Performers encompass Germany (5.9% growth rate), United States (5.2% growth rate), and developed regions, benefiting from established district heating infrastructure and heat transition programs. Emerging Markets feature India (6.1% growth rate) and South Korea (5.6% growth rate), where smart city initiatives and industrial development support consistent growth patterns.

Regional synthesis reveals East Asian markets leading adoption through district heating expansion and infrastructure modernization, while North American countries maintain steady expansion supported by campus heating technology advancement and efficiency program requirements. European markets show moderate growth driven by heat transition applications and decarbonization integration trends.

| Region/Country | 2025-2035 Growth | How to win | What to watch out |

|---|---|---|---|

| Japan | 6.7% | Focus on retrofit solutions | Aging infrastructure challenges; regulatory complexity |

| China | 6.3% | Lead with urban heat networks | Localization requirements; price competition |

| India | 6.1% | Provide smart city solutions | Installation expertise gaps; payment cycles |

| Germany | 5.9% | Offer premium efficiency systems | Over-specification; lengthy approval cycles |

| South Korea | 5.6% | Target industrial clusters | Technology transfer requirements; quality standards |

| UK | 5.4% | Push decarbonization programs | Policy uncertainty; skilled labor shortage |

| USA | 5.2% | Campus & military modernization | Budget constraints; regional variation |

Japan establishes fastest market growth through aggressive district energy retrofit programs and comprehensive infrastructure modernization development, integrating advanced pre-insulated pipes as standard components in heating network upgrades and efficiency enhancement installations. The country's 6.7% growth rate reflects government initiatives promoting thermal efficiency and infrastructure renewal that mandate the use of advanced pipe systems in district heating and industrial facilities. Growth concentrates in major urban centers, including Tokyo, Osaka, and Nagoya, where district energy technology showcases integrated pipe systems that appeal to heating operators seeking advanced thermal optimization capabilities and efficiency management applications.

Japanese manufacturers are developing high-efficiency pipe solutions that combine domestic engineering excellence with advanced insulation features, including automated monitoring systems and enhanced thermal retention capabilities. Distribution channels through energy infrastructure suppliers and district heating service providers expand market access, while government support for energy efficiency supports adoption across diverse heating and industrial segments.

Strategic Market Indicators:

In Beijing, Shanghai, and Guangzhou, district heating networks and industrial facilities are implementing advanced pre-insulated pipes as standard equipment for thermal optimization and efficiency compliance applications, driven by increasing government energy investment and infrastructure modernization programs that emphasize the importance of thermal efficiency capabilities. The market holds a 6.3% growth rate, supported by government clean energy initiatives and urban development programs that promote advanced pipe systems for district heating and industrial facilities. Chinese operators are adopting pipe systems that provide consistent thermal performance and energy efficiency features, particularly appealing in urban regions where heat network efficiency and environmental standards represent critical operational requirements.

Market expansion benefits from growing urban heat network capabilities and domestic manufacturing development that enables local production of advanced pipe systems for heating and industrial applications. Technology adoption follows patterns established in energy infrastructure, where reliability and thermal performance drive procurement decisions and operational deployment.

Market Intelligence Brief:

India demonstrates strong market growth through data center cooling initiatives and smart city development programs, integrating pre-insulated pipes across industrial and commercial applications. The country's 6.1% growth rate reflects government infrastructure investment and industrial expansion that supports adoption of thermal management systems in manufacturing and facility operations. Growth concentrates in major industrial hubs, including Mumbai, Delhi, and Bangalore, where smart city projects showcase pipe installations that appeal to facility operators seeking efficient thermal distribution capabilities.

Indian operators are adopting cost-effective pipe solutions that balance thermal performance with competitive pricing, particularly important in data center cooling and hospital applications. The market benefits from growing industrial infrastructure and increasing recognition of energy efficiency benefits in commercial and institutional facilities.

Market Intelligence Brief:

Germany's advanced district heating technology market demonstrates sophisticated pre-insulated pipe deployment with documented thermal effectiveness in municipal heating applications and network modernization through integration with existing district heating systems and energy infrastructure. The country leverages engineering expertise in thermal technology and energy efficiency integration to maintain a 5.9% growth rate. Industrial centers, including Baden-Württemberg, Bavaria, and North Rhine-Westphalia, showcase premium installations where pipe systems integrate with comprehensive heat planning platforms and municipal energy systems to optimize thermal operations and efficiency effectiveness.

German manufacturers prioritize system precision and EU compliance in pipe development, creating demand for premium systems with advanced features, including network monitoring integration and automated heat loss detection. The market benefits from established heat transition infrastructure and willingness to invest in advanced thermal technologies that provide long-term operational benefits and compliance with European energy standards.

Market Intelligence Brief:

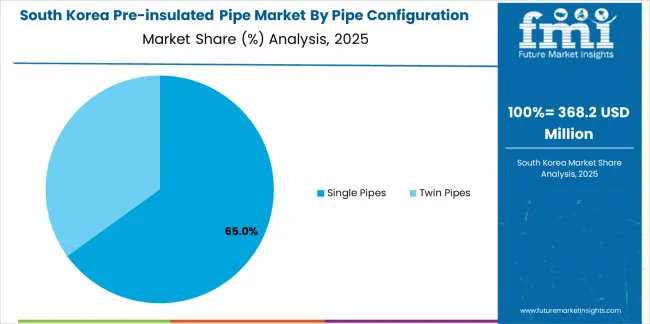

South Korea's market expansion benefits from new-town district cooling developments and semiconductor facility utilities, including industrial campus heating in Seoul and Busan, manufacturing facility upgrades, and technology park infrastructure that increasingly incorporate pre-insulated solutions for thermal management applications. The country maintains a 5.6% growth rate, driven by industrial development activity and increasing recognition of thermal efficiency benefits, including precise temperature control and enhanced energy performance.

Market dynamics focus on high-performance pipe solutions that balance advanced thermal characteristics with reliability considerations important to Korean industrial operators. Growing manufacturing industrialization creates continued demand for modern pipe systems in new facility infrastructure and industrial modernization projects.

Strategic Market Considerations:

United Kingdom establishes steady market growth through low-carbon heat zoning programs and public estate decarbonization initiatives, integrating pre-insulated pipes across district heating and institutional applications. The country's 5.4% growth rate reflects government heat strategy implementation and infrastructure modernization that supports adoption of thermal distribution systems in municipal and commercial facilities. Growth concentrates in major cities, including London, Manchester, and Birmingham, where heat network development showcases pipe installations that appeal to operators seeking decarbonization capabilities.

British infrastructure providers leverage established district heating networks and comprehensive planning frameworks, including zone mapping and feasibility studies that create project pipelines and operational opportunities. The market benefits from heat network regulations and government funding programs that mandate efficiency improvements while supporting technology advancement.

Market Intelligence Brief:

United States demonstrates market leadership through campus district heating modernization and military base infrastructure upgrades, integrating pre-insulated pipes across institutional and government applications. The country's 5.2% growth rate reflects established campus heating relationships and IRA-linked efficiency spending that supports use of thermal distribution systems in university and defense facilities. Growth concentrates in northern regions and established campus environments, including university districts and military installations, where heating infrastructure showcases mature pipe deployment.

American infrastructure providers leverage established facility management networks and comprehensive service capabilities, including engineering support and maintenance programs that create customer relationships and operational advantages. The market benefits from facility efficiency standards and government investment programs that support pipe system adoption while enabling technology advancement.

Market Intelligence Brief:

Brazil's market development benefits from limited district heating infrastructure but growing industrial thermal applications and data center cooling requirements in São Paulo and Rio de Janeiro. The market demonstrates emerging potential driven by industrial facility development and increasing energy efficiency awareness in commercial and manufacturing sectors.

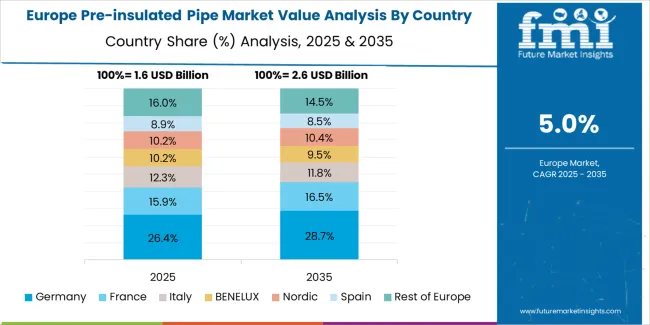

The pre-insulated pipe market in Europe is projected to grow from USD 2.7 billion in 2025 to USD 4.5 billion by 2035, registering a CAGR of 5.4% over the forecast period. Germany is expected to maintain leadership with a 23.0% market share in 2025, easing to 22.7% by 2035, supported by sustained district heating refurbishment programs and municipal heat planning initiatives in major heating networks.

United Kingdom follows with a 15.8% share in 2025, projected to reach 15.9% by 2035, driven by low-carbon heat zones and public estate decarbonization programs across urban heating networks. France holds a 15.2% share in 2025, rising to 15.4% by 2035 through network extensions tied to building renovation law and thermal efficiency mandates. Italy commands a 12.1% share in both 2025 and 2035, anchored by hospital campus networks and industrial utility applications. Spain accounts for 8.2% in 2025, moving to 8.4% by 2035 through tourism-region cooling networks and data center cluster development. Netherlands remains at 5.0% in 2025, reaching 5.1% by 2035, supported by dense urban heat grids and geothermal integration projects. The Rest of Europe region constitutes 20.7% in 2025, declining slightly to 20.6% by 2035, driven by Nordic district heating programs, Central and Eastern European infrastructure development, and Baltic states accelerating clean-heat infrastructure investments.

| Stakeholder | What they actually control | Typical strengths | Typical blind spots |

|---|---|---|---|

| Global platforms | Distribution reach, comprehensive product catalogs, installation networks | Broad availability, proven thermal performance, multi-region support | Technology refresh cycles; customer lock-in dependency |

| Technology innovators | R&D capabilities; high-efficiency insulation systems; digital monitoring interfaces | Latest thermal features first; attractive efficiency gains on district heating projects | Service density outside core regions; installation complexity |

| Regional specialists | Local compliance, fast delivery, nearby installation teams | "Close to site" support; pragmatic pricing; local heat network regulations | Technology gaps; talent retention in installation services |

| Service-focused ecosystems | Installation support, maintenance SLAs, commissioning capabilities | Lowest real downtime; comprehensive project support | Service costs if overpromised; technology obsolescence |

| Niche specialists | Specialized applications, custom configurations, industrial solutions | Win process heating applications; flexible specifications | Scalability limitations; narrow market focus |

| Item | Value |

|---|---|

| Quantitative Units | USD 6.8 billion |

| Material | Metal & Alloys, Polymers |

| Pipe Configuration | Single Pipes, Twin Pipes |

| Installation | Below Ground, Above Ground |

| End Use | District Heating & Cooling, Oil & Gas, Chemical, Pharmaceutical, Others |

| Regions Covered | North America, Latin America, Western Europe, Eastern Europe, East Asia, South Asia Pacific, Middle East & Africa |

| Countries Covered | United States, China, Germany, India, United Kingdom, Japan, Canada, Brazil, France, South Korea, Australia, and 25+ additional countries |

| Key Companies Profiled | Uponor (GF Building Flow Solutions), Perma-Pipe International Holdings, LOGSTOR, BRUGG Pipes, GF Piping Systems, Thermaflex, KE KELIT, Watts Water Technologies, Aquatherm GmbH, Polypipe/Genuit |

| Additional Attributes | Dollar sales by material and configuration categories, regional adoption trends across East Asia, Western Europe, and North America, competitive landscape with thermal equipment manufacturers and district heating infrastructure suppliers, heating network operator preferences for thermal efficiency control and system reliability, integration with energy management platforms and monitoring systems, innovations in insulation technology and thermal enhancement, and development of automated pipe solutions with enhanced performance and energy optimization capabilities. |

The global pre-insulated pipe market is estimated to be valued at USD 6.8 billion in 2025.

The market size for the pre-insulated pipe market is projected to reach USD 11.8 billion by 2035.

The pre-insulated pipe market is expected to grow at a 5.7% CAGR between 2025 and 2035.

The key product types in pre-insulated pipe market are metal & alloys and polymers.

In terms of pipe configuration, single pipes segment to command 62.0% share in the pre-insulated pipe market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Pipeline Integrity Market Size and Share Forecast Outlook 2025 to 2035

Pipe Market Size and Share Forecast Outlook 2025 to 2035

Pipe Insulation Films Market Size and Share Forecast Outlook 2025 to 2035

Pipetting Robots Market Size and Share Forecast Outlook 2025 to 2035

Pipeline Monitoring System Market Size and Share Forecast Outlook 2025 to 2035

Pipeline Safety Market Size and Share Forecast Outlook 2025 to 2035

Pipe Insulation Market Size and Share Forecast Outlook 2025 to 2035

Pipe Wrenches Market Size and Share Forecast Outlook 2025 to 2035

Pipe Insulation Products Market Size and Share Forecast Outlook 2025 to 2035

Pipe Coatings Market Size and Share Forecast Outlook 2025 to 2035

Pipette Tips Market Size and Share Forecast Outlook 2025 to 2035

Pipe Screw Extruder Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Pipette Controller Market – Trends & Forecast 2025 to 2035

Pipe Inspection Robot Market Growth – Trends & Forecast 2025 to 2035

Pipe Flange Market Analysis by Material Type, Facing, End-Use Industry, and Region through 2035

Market Leaders & Share in the Pipe Insulation Products Industry

Pipe Marking Tapes Market Growth - Demand, Trends & Forecast 2024 to 2034

Pipe Wrapping Machines Market

Piperylene Market

Oil Pipeline Infrastructure Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA