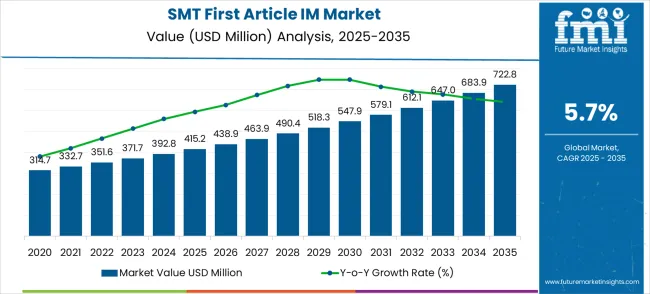

The SMT first article inspection machine market is expected to grow steadily, moving from USD 415.2 million in 2025 to USD 723 million by 2035, representing a compound annual growth rate (CAGR) of 5.7%. This growth is largely driven by the increasing demand for precision and quality control across the electronics manufacturing industry. As electronic components become more complex, the need for high-accuracy inspection equipment has become essential. These machines are critical in ensuring that the first articles of production meet strict standards for functionality, dimensions, and quality before mass production begins.

Industries involved in surface-mount technology (SMT) are increasingly relying on these machines to mitigate risks associated with faulty components, thereby reducing waste and ensuring product quality. The increasing focus on operational efficiency and product consistency is expected to drive further growth in this market.

The demand for SMT first article inspection machines is anticipated to rise due to the growing complexity of electronic products, which require more robust quality control systems. As manufacturers face increasing pressure to meet stringent quality standards, first article inspection machines offer an efficient solution to verify specifications early in the production process, thereby reducing costly errors during later stages.

Additionally, with the increasing use of automation in manufacturing processes, the adoption of advanced inspection machines is expected to accelerate. This market is expected to expand as industries move towards more automated, high-speed, and high-precision production lines. As manufacturers seek to reduce costs and enhance quality control, the demand for SMT first article inspection machines is projected to increase steadily in the coming decade.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 415.2 million |

| Forecast Value in (2035F) | USD 723 million |

| Forecast CAGR (2025 to 2035) | 5.7 % |

The SMT first article inspection machine market holds a significant share within the surface mount technology (SMT) equipment market, capturing approximately 12% due to its crucial role in quality control during assembly processes. In the industrial automation market, it contributes around 8%, driven by its integration into automated production lines. Within the electronic manufacturing services (EMS) market, the share is around 6%, reflecting its importance in ensuring the accuracy of electronic product manufacturing.

The semiconductor manufacturing market sees a smaller share of approximately 5%, where precision inspection is key. In the automated inspection systems market, the SMT first article inspection machine market accounts for roughly 9%, highlighting its significant contribution to the overall inspection process in production lines. These combined contributions emphasize its integral position in ensuring high-quality manufacturing across multiple sectors.

The SMT First Article Inspection Machine Market is poised for steady growth, projected to increase from USD 415.2 million in 2025 to USD 722.8 million by 2035 at a CAGR of 5.7%, driven by rising automation in electronics manufacturing, stringent quality control requirements, and the adoption of advanced inspection technologies. By 2035, these pathways collectively represent USD 200–250 million in incremental revenue opportunities.

Pathway A – Electronics & Semiconductor Automation. Fully automatic inspection machines are increasingly deployed in high-volume electronics and semiconductor production lines to ensure defect-free components and compliance with IPC standards, unlocking USD 60–80 million in near-term revenue.

Pathway B – Aerospace Industry Compliance. Semi-automatic inspection systems are used in aerospace manufacturing to meet rigorous safety and reliability requirements, representing a potential USD 40–60 million opportunity.

Pathway C – Automotive Quality Assurance. First article inspection machines are critical for validating PCB and electronic module designs in automotive applications, creating a revenue pool of USD 30–50 million.

Pathway D – Emerging Market Adoption. Rapid industrialization and electronics manufacturing growth in Asia, Latin America, and Eastern Europe drive demand for reliable inspection solutions, contributing USD 25–40 million.

Pathway E – Custom & High-Precision Solutions. Specialized inspection machines for complex PCB assemblies, high-density modules, and multi-layer boards provide niche opportunities, expected to add USD 20–30 million.

Pathway F – Technology Upgrades & Integration. Smart inspection systems with AI-enabled defect detection, automated reporting, and integration with production lines enhance efficiency and reduce downtime, offering USD 10–20 million in incremental revenue.

Pathway G – OEM & Turnkey Solutions. Providing customized inspection solutions for contract manufacturers and electronics OEMs adds USD 5–10 million in growth potential.

Pathway H – Software & Analytics Enhancements. Advanced analytics, traceability software, and predictive maintenance features embedded in inspection systems represent a smaller but emerging pool of USD 5–10 million.

Why is the SMT First Article Inspection Machine Market Growing?

Market expansion is being supported by the rapid increase in electronics production complexity worldwide and the corresponding need for specialized inspection machines that ensure manufacturing quality and prevent defective product shipments. Modern electronics manufacturing operations rely on precise first article inspection and automated quality verification to ensure proper assembly of sophisticated printed circuit boards including multi-layer designs, fine-pitch components, and high-density interconnects. Even minor assembly defects can cause significant quality issues and require comprehensive inspection validation to maintain optimal production quality and customer satisfaction.

The growing complexity of electronic assemblies and increasing regulatory requirements are driving demand for professional inspection equipment from established manufacturers with appropriate certifications and quality validation capabilities. Electronics manufacturers and contract assembly providers are increasingly requiring comprehensive first article documentation following production setup activities to maintain quality certifications and customer approval requirements. Quality standards and industry specifications are establishing mandatory inspection procedures that require specialized equipment and trained quality control personnel.

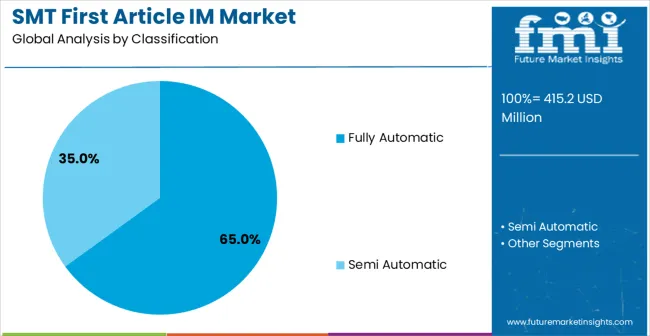

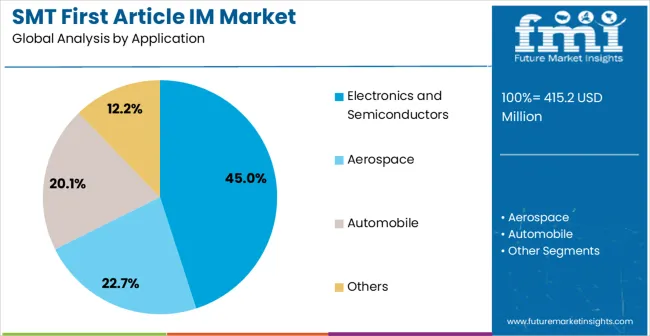

The market is segmented by machine type, end-use application, and region. By machine type, the market is divided into fully automatic inspection systems and semi-automatic machines. By end-use application, the market is categorized into electronics and semiconductors manufacturing, aerospace assembly, automobile electronics, and others. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

Fully automatic SMT first article inspection machines are expected to capture 65% of the market in 2025, driven by their adoption in high-volume electronics manufacturing. These systems offer advanced imaging and automated decision-making, making them ideal for modern assembly lines and contract manufacturing facilities. Fully automatic systems provide comprehensive inspection capabilities while minimizing human error and cycle times. They excel at handling complex printed circuit board assemblies with various components and dense placements, tasks that are challenging for manual or semi-automatic systems. Additionally, their ability to integrate with manufacturing execution systems enhances quality data collection and traceability, further cementing their role in consistent quality validation across production environments. The segment benefits from established automation technologies and wide equipment availability from specialized manufacturers.

The electronics and semiconductors segment is projected to account for 45% of the SMT first article inspection machine market in 2025, securing its dominant position. This significant market share is driven by the increasing complexity of electronics manufacturing, where precision and quality control are critical. SMT first article inspection machines play a crucial role in ensuring that the initial production samples meet the required specifications before full-scale manufacturing begins. As consumer demand for high-quality, reliable electronic devices continues to grow, and with advancements in semiconductor manufacturing, this segment is expected to maintain its leadership. The adoption of automated inspection systems is particularly strong in the electronics and semiconductor industries, where the need for zero-defect products is paramount.

The SMT first article inspection machine market is experiencing growth, driven by the increasing demand for precision in surface-mount technology (SMT) manufacturing. These machines are vital in ensuring the quality and accuracy of the first article in production runs, reducing defects, and improving efficiency. Opportunities are expanding due to the growth of electronics manufacturing and rising quality standards. However, challenges such as high investment costs, integration complexities, and the need for skilled operators may limit their adoption in certain regions and sectors.

A notable trend in the SMT first article inspection machine market is the growing integration of automation and AI-driven technologies in inspection systems. In opinion, manufacturers are increasingly adopting automated inspection solutions that use AI algorithms and machine learning to improve defect detection and quality assurance processes. These systems can identify issues with greater accuracy and at faster speeds than manual inspection methods. The adoption of automation is reducing the need for human intervention, lowering error rates, and accelerating production cycles, making it an essential development in high-volume electronics manufacturing environments.

The SMT first article inspection machine market faces challenges related to high costs and complex integration requirements. In opinion, the advanced technology required for these inspection machines often comes with a significant price tag, which may be prohibitive for smaller manufacturers or those operating with limited budgets. Additionally, the integration of these machines into existing production lines can be complex and time-consuming, requiring specialized knowledge and adjustments to the assembly process. Manufacturers must find ways to address these challenges by offering more affordable, user-friendly solutions that can be seamlessly integrated into various production environments.

| Country | CAGR (2025-2035) |

|---|---|

| China | 7.7% |

| India | 7.1% |

| Germany | 6.6% |

| Brazil | 6.0% |

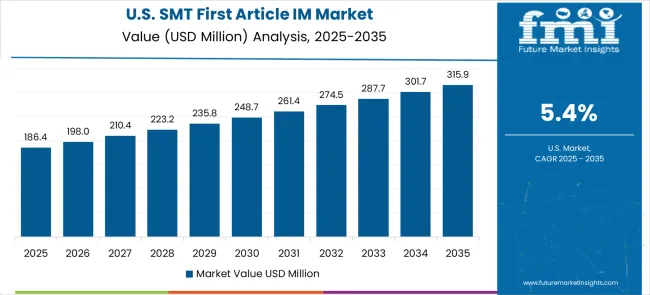

| United States | 5.4% |

| United Kingdom | 4.8% |

| Japan | 4.3% |

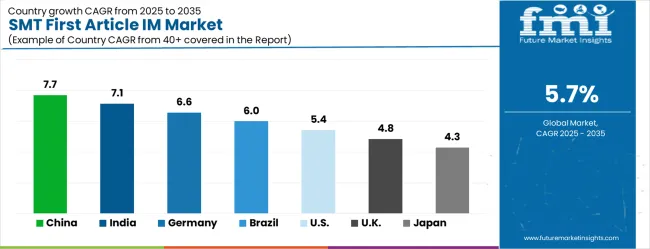

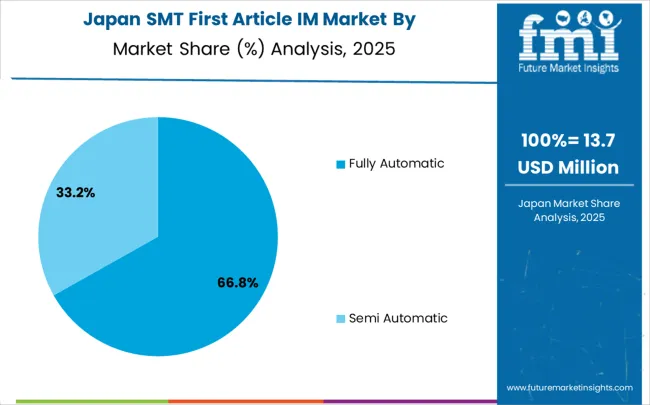

The SMT first article inspection machine market is growing robustly, with China leading at a 7.7% CAGR through 2035, driven by massive electronics manufacturing expansion, Industry 4.0 adoption, and increasing quality control automation. India follows at 7.1%, supported by growing electronics manufacturing capabilities and increasing contract manufacturing investments. Germany grows steadily at 6.6%, emphasizing precision engineering, quality excellence, and advanced manufacturing automation expertise. Brazil records 6.0%, integrating inspection technology into its expanding electronics manufacturing sector. The United States shows growth at 5.4%, focusing on advanced manufacturing technologies and quality control innovation. The United Kingdom demonstrates growth at 4.8%, supported by aerospace and automotive electronics manufacturing. Japan maintains expansion at 4.3%, driven by precision manufacturing requirements and quality control leadership. Overall, China and India emerge as the leading drivers of global SMT First Article Inspection Machine market expansion.

The report covers an in-depth analysis of 40+ countries, the top-performing countries are highlighted below.

The SMT first article inspection machine market in China is projected to grow at a CAGR of 7.7%, driven by the country’s rapidly expanding electronics manufacturing sector. With China being a global leader in electronics production, the demand for efficient and accurate inspection systems is increasing. The rise of advanced manufacturing processes, coupled with the emphasis on reducing production defects, boosts the need for first article inspection machines. China’s investment in automation and smart factory technologies further accelerates market growth, as manufacturers seek to enhance quality control and production efficiency.

The SMT first article inspection machine market in India is projected to grow at a CAGR of 7.1%, supported by the country’s growing electronics manufacturing industry and rising focus on quality control. As India becomes a key player in the global electronics supply chain, the demand for precise inspection systems is on the rise. The shift towards automation and Industry 4.0 practices, coupled with increasing quality standards in the electronics sector, accelerates the adoption of first article inspection machines. India's expanding manufacturing capabilities, especially in consumer electronics, further contributes to market growth.

The SMT first article inspection machine market in Germany is expected to grow at a CAGR of 6.6%, supported by the country’s robust electronics and automotive manufacturing sectors. Germany’s focus on precision engineering and high-quality manufacturing makes it an ideal market for SMT inspection systems. As German manufacturers seek to enhance product quality and reduce defects, the demand for advanced inspection solutions continues to rise. Furthermore, Germany’s emphasis on automation and digital transformation in manufacturing processes accelerates the adoption of first article inspection machines.

The SMT first article inspection machine market in Brazil is projected to grow at a CAGR of 6.0%, driven by the expansion of the electronics and automotive industries in the country. Brazil’s growing role in the global electronics supply chain has created a rising need for advanced quality control systems. The shift towards automation and the adoption of Industry 4.0 technologies in manufacturing processes further support the market’s growth. Additionally, Brazil’s focus on improving production efficiency and product reliability in sectors like consumer electronics and automotive drives the demand for SMT first article inspection machines.

The SMT first article inspection machine market in the United States is expected to grow at a CAGR of 5.4%, driven by the country’s large electronics manufacturing sector and the emphasis on quality control. As the USA continues to focus on advanced manufacturing practices and automation, the need for precise inspection systems increases. The demand for first article inspection machines is fueled by the rise of complex electronic devices and the increasing focus on minimizing defects and enhancing production efficiency. Government initiatives supporting manufacturing innovation also contribute to market growth.

The SMT first article inspection machine market in the United Kingdom is projected to grow at a CAGR of 4.8%, supported by the country’s strong electronics manufacturing base and its commitment to improving product quality. The rise of automation in production processes, along with increasing demand for high-precision inspection systems, contributes to the market’s growth. As manufacturers in the UK seek to meet stringent quality standards and improve efficiency, the demand for SMT first article inspection machines continues to rise, especially in consumer electronics and automotive sectors.

The SMT first article inspection machine market in Japan is expected to grow at a CAGR of 4.3%, driven by the country’s advanced electronics and automotive manufacturing industries. Japan’s strong emphasis on precision engineering and the continuous push for quality improvement in manufacturing processes supports the demand for inspection systems. The integration of automation and smart factory technologies in Japan's manufacturing sector further accelerates the adoption of SMT first article inspection machines, ensuring that production processes meet international quality standards and efficiency benchmarks.

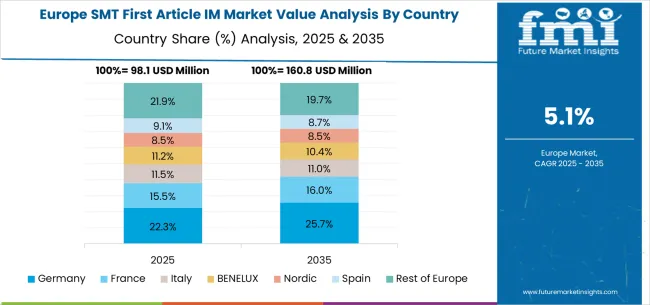

The SMT first article inspection machine market in Europe is projected to grow from USD 120.4 million in 2025 to USD 209.6 million by 2035, registering a CAGR of 6 % over the forecast period. Germany is expected to maintain its leadership with a 6.6% global market share in 2025, supported by its expansive electronics manufacturing ecosystem and advanced automation technology sector.

The United Kingdom region is projected to maintain steady growth, expanding its share with strong performance in aerospace electronics and automotive applications. France and Italy will also see consistent gains, while Nordic countries show strong potential, attributed to rising electronics manufacturing automation and stringent quality standards in precision assembly operations.

The SMT First Article Inspection Machine market is defined by competition among specialized inspection equipment manufacturers, automation technology providers, and electronics manufacturing solutions companies. Companies are investing in advanced imaging technologies, artificial intelligence integration, comprehensive software platforms, and global technical support services to deliver accurate, reliable, and cost-effective inspection solutions. Strategic partnerships, technological innovation, and regional market expansion are central to strengthening product portfolios and market presence.

Shenzhen Bluiris Technology offers comprehensive SMT inspection solutions with focus on automated quality control, advanced imaging capabilities, and technical expertise for electronics manufacturing applications. Dongguan ICT Technology provides specialized inspection equipment with emphasis on precision measurement and defect detection for high-volume production environments. Shenzhen PTI Technology Co., Ltd. delivers established inspection platforms with proven reliability and extensive industry experience across diverse electronics manufacturing sectors.

Shenzhen Jiedeng Intelligence specializes in intelligent inspection systems that integrate artificial intelligence and utilize adaptive algorithms for complex assembly configurations. Haichen SMT provides specialized inspection equipment with comprehensive technical support and application expertise for surface mount technology applications across regional and international markets.

| Item | Value |

|---|---|

| Quantitative Units (2025) | USD 415.2 million |

| Machine Type | Fully Automatic Inspection Systems, Semi-Automatic Machines, and Manual Inspection Equipment |

| End-Use Application | Electronics and Semiconductors Manufacturing, Aerospace Assembly, Automobile Electronics, and Other Industrial Applications |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, India, Brazil, Australia and 40+ countries |

| Key Companies Profiled | Shenzhen Bluiris Technology, Dongguan ICT Technology, Shenzhen PTI Technology Co., Ltd, Shenzhen Jiedeng Intelligence, Haichen SMT |

| Additional Attributes | Dollar sales by machine type, end-use application, and inspection technology, regional demand trends across North America, Europe, and Asia-Pacific, competitive landscape with established equipment manufacturers and emerging technology providers, buyer preferences for automated versus manual inspection approaches, integration with manufacturing execution systems and quality management platforms, innovations in artificial intelligence and machine learning for enhanced defect detection, and adoption of comprehensive inspection solutions |

The global SMT first article inspection machine market is estimated to be valued at USD 415.2 million in 2025.

The market size for the SMT first article inspection machine market is projected to reach USD 722.8 million by 2035.

The SMT first article inspection machine market is expected to grow at a 5.7% CAGR between 2025 and 2035.

The key product types in SMT first article inspection machine market are fully automatic and semi automatic.

In terms of application, electronics and semiconductors segment to command 45.0% share in the SMT first article inspection machine market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

First Mile Delivery Market Size and Share Forecast Outlook 2025 to 2035

First Generation Biofuel Market Size and Share Forecast Outlook 2025 to 2035

First Mile Logistics Delivery Software Market Size and Share Forecast Outlook 2025 to 2035

China First Aid Market Insights – Growth & Forecast 2022-2032

Machine Glazed Paper Market Size and Share Forecast Outlook 2025 to 2035

Machine Vision Camera Market Size and Share Forecast Outlook 2025 to 2035

Machine Tool Oils Market Size and Share Forecast Outlook 2025 to 2035

Machine Vision System And Services Market Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Western Europe Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Korea Size and Share Forecast Outlook 2025 to 2035

Machine Glazed Paper Industry Analysis in Japan Size and Share Forecast Outlook 2025 to 2035

Machine Tool Cooling System Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Machine Tool Touch Probe Market Analysis - Size, Growth, and Forecast 2025 to 2035

Machine Mount Market Analysis - Size & Industry Trends 2025 to 2035

Machine Control System Market Growth – Trends & Forecast 2025 to 2035

Machine Automation Controller Market Growth – Trends & Forecast 2025 to 2035

Machine-to-Machine (M2M) Connections Market – IoT & Smart Devices 2025 to 2035

Machine Safety Market Analysis by Component, Industry, and Region Through 2035

Key Players & Market Share in Machine Glazed Paper Industry

Machine Glazed Kraft Paper Market Growth - Demand & Forecast 2024 to 2034

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA