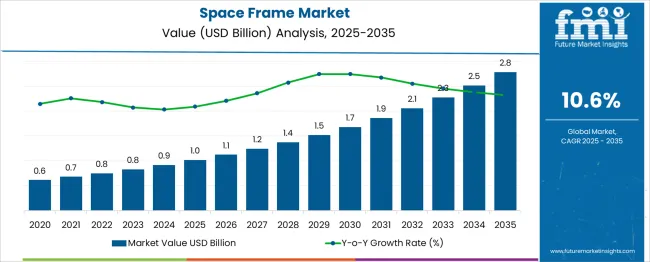

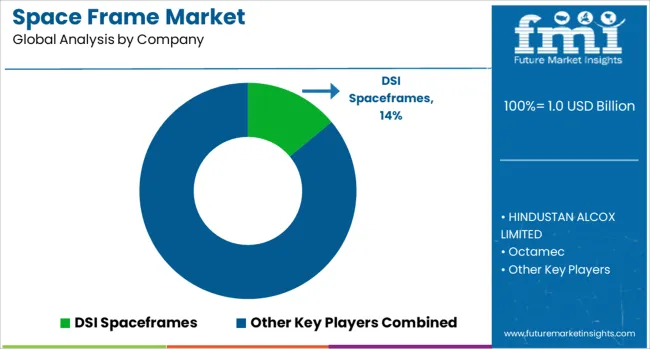

The Space Frame Market is estimated to be valued at USD 1.0 billion in 2025 and is projected to reach USD 2.8 billion by 2035, registering a compound annual growth rate (CAGR) of 10.6% over the forecast period. The market follows a typical technology adoption lifecycle, driven by demand in automotive, aerospace, construction, and industrial applications for lightweight, strong, and modular structural solutions.

From 2020 to 2024, the market is in the early adoption phase, expanding from USD 0.6-0.9 billion. During this phase, conventional steel and aluminum space frame structures dominate, analogous to “hydraulic” technologies well-established, cost-effective, and widely implemented in experimental and niche projects. Advanced modular frames using high-strength alloys or composites resemble “electric hydraulic” technologies and are in limited deployment, while fully integrated, automated space frame solutions with smart sensors and adaptive load distribution mirror EPS-like technologies, remaining at experimental stages.

From 2025 to 2030, the market enters the scaling phase, growing from USD 1.0-1.7 billion. Adoption accelerates across automotive and aerospace sectors as lightweight materials reduce energy consumption and improve performance. Advanced modular composite frames (electric hydraulic-like) gain wider adoption, while smart integrated systems (EPS-like) see selective implementation in premium and high-performance applications.

Between 2030 to 2035, the market transitions to consolidation, reaching USD 2.8 billion. Growth moderates as technology matures, standard designs dominate, and smart, sensor-enabled systems capture specialized, high-value segments. The overall maturity curve is sigmoid-shaped, reflecting early experimentation, rapid expansion, and eventual stabilization.

| Metric | Value |

|---|---|

| Space Frame Market Estimated Value in (2025 E) | USD 1.0 billion |

| Space Frame Market Forecast Value in (2035 F) | USD 2.8 billion |

| Forecast CAGR (2025 to 2035) | 10.6% |

The Space Frame market is experiencing consistent growth driven by increasing demand for lightweight, durable, and aesthetically versatile structural solutions. The current market landscape is characterized by widespread adoption across stadiums, airports, industrial buildings, and commercial complexes, as observed in construction industry journals, investor presentations, and architectural press releases. Rising investments in infrastructure development, urbanization, and the preference for modular construction techniques have significantly contributed to the market’s expansion.

Future growth opportunities are being supported by technological advancements in fabrication methods and the increasing use of sustainable and recyclable materials. Corporate announcements have highlighted the role of space frames in achieving cost-efficient large-span structures with minimal material usage, aligning with green building initiatives.

Moreover, improvements in design software and precision engineering have enhanced the appeal of space frames by ensuring superior load distribution and reduced construction timelines. These factors collectively are expected to sustain strong growth prospects in the global Space Frame market.

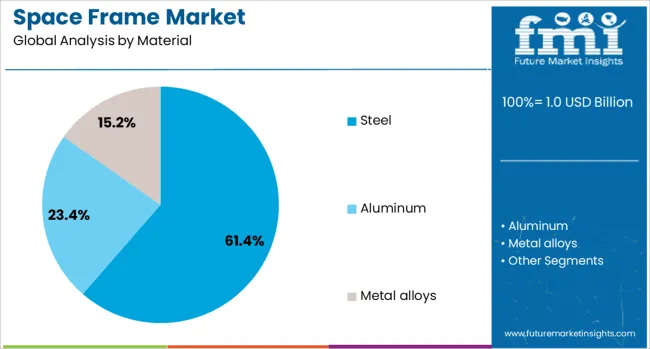

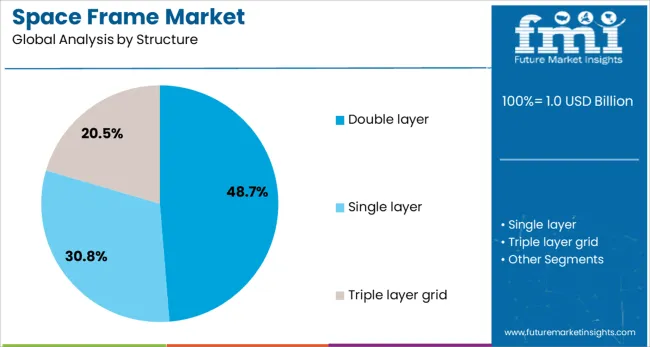

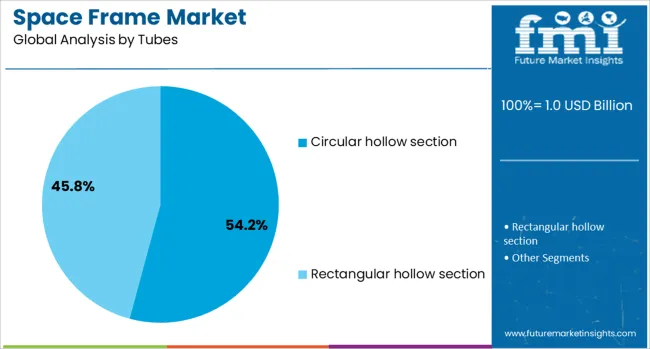

The space frame market is segmented by material, structure, tubes, application, and geographic regions. By material, the space frame market is divided into Steel, Aluminum, and Metal alloys. In terms of the structure of the space frame, the market is classified into double-layer, single-layer, and triple-layer grids. Based on tubes, the space frame market is segmented into Circular hollow section and Rectangular hollow section.

By application, the space frame market is segmented into Roof, Steel Dome roof, Skylight, Canopy & entry way, Atrium, Vertical glazed Others (Skywalks, side bridges, etc.). Regionally, the space frame industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The steel material segment is projected to hold 61.4% of the Space Frame market revenue share in 2025, making it the leading material choice. This dominance is being driven by steel’s exceptional strength-to-weight ratio, durability, and cost-effectiveness as noted in construction project specifications and manufacturer press statements. It has been observed that steel offers superior load-bearing capabilities while allowing for intricate design possibilities, which are highly valued in modern architectural applications.

The segment’s growth has also been reinforced by steel’s recyclability and compliance with sustainable construction standards. Technical publications have underscored its suitability for prefabrication and rapid on-site assembly, further reducing construction costs and timelines.

Additionally, steel’s proven performance in harsh environmental conditions and its ability to support large spans with minimal support structures have made it the preferred material for space frames. These factors have collectively maintained steel’s leadership position in the market.

The double-layer structure segment is expected to account for 48.7% of the Space Frame market revenue share in 2025, establishing it as the leading structural type. This prominence has been attributed to the structural efficiency and aesthetic appeal offered by double layer configurations, as reported in engineering journals and architectural design reviews. The segment has benefited from its ability to distribute loads evenly while maintaining rigidity and minimizing material usage.

Technical documentation has highlighted its suitability for medium to large-span structures, making it ideal for airports, exhibition halls, and sports facilities. Further, the segment’s dominance has been supported by ease of prefabrication and adaptability to various geometric shapes.

The enhanced stability and reduced deflection under load, as cited in engineering analyses, have contributed to its widespread adoption. These attributes have ensured the double layer structure’s continued preference in space frame applications.

The circular hollow section tubes segment is forecasted to hold 54.2% of the Space Frame market revenue share in 2025, maintaining its leadership among tube types. This growth has been driven by the superior torsional resistance, uniform strength distribution, and aesthetic appeal offered by circular hollow sections, as highlighted in manufacturer brochures and structural engineering studies.

It has been noted that these tubes facilitate efficient load transfer and ease of fabrication, contributing to reduced material waste and construction time. Industry publications have emphasized their suitability for creating smooth curves and visually appealing designs without compromising structural integrity.

The segment’s leadership has also been reinforced by its compatibility with advanced welding and jointing techniques, ensuring strong and durable connections. These qualities, combined with widespread availability and cost efficiency, have made circular hollow section tubes the preferred choice in space frame construction.

The space frame market is expanding as demand grows for lightweight, durable, and architecturally versatile structural systems. Widely used in stadiums, airports, commercial complexes, and industrial buildings, space frames allow large spans without internal supports, offering design flexibility. North America and Europe lead due to advanced construction projects, while Asia-Pacific shows growth from rapid urban infrastructure and commercial development. Advancements in steel, aluminum, and composite materials enhance strength-to-weight ratios. Rising interest in modern architecture and fast-track construction is driving consistent market expansion globally.

Space frames are preferred in buildings requiring large open spaces, such as airports, stadiums, and exhibition centers. Their modular design enables faster assembly and easier transportation, reducing construction timelines. Architects favor them for creating aesthetically unique structures without compromising load-bearing capabilities. Lightweight properties lower foundation requirements, resulting in cost savings. Industrial applications, including warehouses and manufacturing plants, benefit from reduced support columns and flexible layouts. Growing commercial and infrastructure investments in emerging economies further boost adoption, positioning space frames as an essential component in modern construction projects worldwide.

Use of high-strength steel, aluminum alloys, and composite materials improves durability and load-bearing capacity of space frames. Corrosion-resistant coatings and pre-fabricated modular components ensure long-term performance in diverse climates. Material improvements allow larger spans with minimal supports, reducing structural weight while maintaining safety standards. Enhanced fabrication techniques, including precision welding and CNC machining, improve assembly accuracy and reduce labor costs. Lightweight and modular properties make space frames suitable for retrofit and expansion projects. Advancements in materials increase reliability, enable design versatility, and support wider adoption in commercial, industrial, and public infrastructure projects.

Urban development and modern architecture trends drive demand for visually striking yet functional structures. Airports, shopping malls, and sports complexes increasingly adopt space frames for expansive, column-free spaces. Rapid urbanization in the Asia-Pacific, the Middle East, and Africa fuels large-scale infrastructure projects. Architects leverage space frames for sustainable and flexible designs, accommodating interior modifications with minimal disruption. Modular installation supports faster project completion and reduced labor requirements. As cities aim for iconic and efficient buildings, space frames are becoming integral to construction planning, enhancing adoption across public and private sector projects globally.

Manufacturers and construction firms form alliances to improve the design, fabrication, and installation of space frames. Collaborations with architectural firms enable customized and innovative structures. Partnerships with material suppliers ensure consistent quality and availability of steel, aluminum, and composite components. Joint ventures help companies expand into emerging markets, gain regulatory approvals, and provide turnkey solutions for large-scale projects. Strategic collaborations support knowledge sharing, reduce construction timelines, and improve cost efficiency. By leveraging partnerships, market players enhance global presence, strengthen competitive positioning, and meet growing demand for versatile and durable structural systems worldwide.

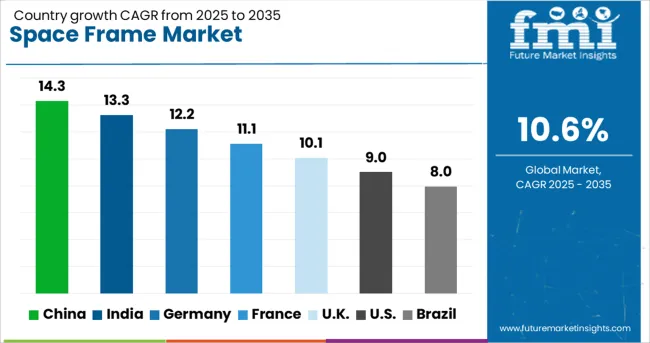

| Country | CAGR |

|---|---|

| China | 14.3% |

| India | 13.3% |

| Germany | 12.2% |

| France | 11.1% |

| UK | 10.1% |

| USA | 9.0% |

| Brazil | 8.0% |

The space frame market is projected to grow at a CAGR of 10.6%, reflecting increased adoption in construction, transportation, and large-scale infrastructure projects due to its strength, lightweight properties, and flexibility in design. China leads the market with a growth rate of 14.3%, driven by rapid urban development and large-scale architectural projects requiring durable and efficient structural systems. India follows at 13.3%, supported by rising industrial and commercial construction activities. Germany, growing at 12.2%, focuses on advanced engineering applications and precision-manufactured space frame components. The UK, at 10.1%, and the USA, at 9.0%, are leveraging space frames for stadiums, airports, and commercial complexes. This report includes insights on 40+ countries; the top countries are shown here for reference.

China leads the space frame market with a 14.3% growth rate, driven by rapid urbanization, large-scale infrastructure projects, and commercial construction demand. Compared to India, China benefits from extensive government investments in stadiums, airports, and industrial buildings where space frames offer lightweight yet strong structural solutions. Technological advancements in steel and aluminum alloys enhance design flexibility and structural efficiency. The construction of high-rise buildings and transportation hubs increases adoption. Domestic manufacturers focus on cost-effective, scalable solutions while maintaining quality standards. Export opportunities to Asia-Pacific regions also support market expansion. Sustainability and energy efficiency considerations drive preference for lightweight materials, reducing construction costs and environmental impact. Strategic partnerships with international design and engineering firms accelerate innovation in complex geometries. China's growing industrial and commercial infrastructure ensures robust demand and maintains its leading position in the global space frame market.

Space frame market in India grows at 13.3%, supported by rising commercial, industrial, and sports infrastructure projects. Compared to Germany, India focuses on cost-effective solutions for large-scale constructions such as airports, convention centers, and stadiums. Investments in steel and aluminum fabrication facilities increase production efficiency and structural reliability. The market benefits from urban expansion, smart city initiatives, and government-backed infrastructure programs. Architectural innovation and aesthetic design requirements also drive adoption. Domestic players are increasingly incorporating advanced welding and modular construction techniques. Export opportunities to neighboring countries contribute to revenue growth. Lightweight construction methods reduce material consumption, lower labor costs, and improve project timelines. Technological collaboration with international engineering firms enhances complex design capabilities. India's growing urban infrastructure and industrial development ensure steady adoption of space frames across commercial, transportation, and public utility projects.

Space frame market in Germany expands at 12.2%, driven by industrial, commercial, and architectural projects emphasizing structural efficiency and sustainability. Compared to the UK, Germany focuses on high-quality steel and aluminum alloys that meet strict engineering standards. Adoption in airports, exhibition centers, and industrial plants ensures steady demand. Emphasis on precision engineering, durability, and environmental compliance supports market growth. Technological innovations in modular and prefabricated construction enhance design complexity while reducing costs. The automotive and aerospace sectors also contribute to demand for lightweight structures. Export opportunities within the European Union and Middle East increase revenue potential. R&D investments focus on optimizing structural strength, corrosion resistance, and material efficiency. Germany’s expertise in engineering, quality compliance, and sustainable construction solutions sustains its competitive position in the global space frame market.

The UK market grows at 10.1%, driven by commercial and infrastructure developments requiring lightweight, high-strength structures. Compared to the US, the UK emphasizes sustainable construction, energy efficiency, and architectural aesthetics. Adoption is prominent in stadiums, airports, office buildings, and transportation hubs. Technological innovations in aluminum and steel fabrication allow intricate geometries and modular assembly. Urban redevelopment programs and public infrastructure investments create steady demand. Export potential exists for European and Middle Eastern projects. Lightweight structures reduce material costs, construction time, and environmental impact. Collaboration with international engineering and architectural firms accelerates design innovation. The UK’s focus on technological advancement, sustainability, and urban infrastructure projects supports continuous space frame market growth.

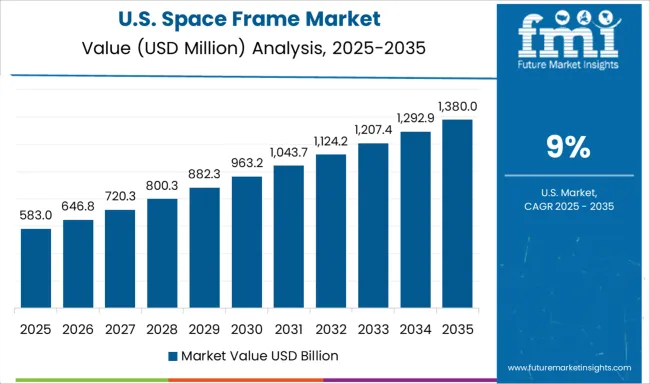

The US space frame market grows at 9.0%, supported by commercial, industrial, and sports infrastructure projects. Compared to China, the US emphasizes architectural design, structural performance, and compliance with rigorous building codes. Airports, stadiums, and high-rise office buildings increasingly adopt space frames for lightweight strength and flexibility. Technological innovations in steel and aluminum alloys enhance structural efficiency and durability. Modular construction methods reduce project timelines and costs. Export opportunities to North and South American regions contribute to revenue growth. Focus on sustainability and energy efficiency drives adoption of lightweight materials. Collaboration with international engineering firms and continuous R&D strengthens design capabilities. The US market benefits from industrial and commercial infrastructure development, technological innovation, and sustainable construction trends, ensuring steady space frame adoption.

The Space Frame market is expanding steadily, driven by the demand for lightweight, high-strength, and architecturally flexible structural systems in stadiums, airports, exhibition centers, and commercial buildings. Space frames are three-dimensional truss-like structures that efficiently distribute loads, allowing for large-span constructions with minimal material usage.

DSI Spaceframes is a leading provider of custom-engineered space frame solutions for commercial and industrial applications, emphasizing modularity and durability. Hindustan Alcox Limited and Octamec offer space frame systems focused on large-scale architectural projects, combining structural integrity with aesthetic design. CST Industries, Inc. and Delta Structures, Inc. specialize in innovative aluminum and steel space frames for both domestic and international markets.

Asian manufacturers such as Xuzhou LF Engineering & Construction Co., Zhejiang Southeast Space Frame Co., Ltd, and Jiangsu Andy Steel Structure Co., Ltd are increasingly competitive, providing cost-effective solutions for industrial and commercial buildings. Triocon Space Frame Technologies Pvt. Ltd and Pillow Space Frame Ltd focus on modular designs that simplify installation and reduce construction time.

Other notable players include Gossamer Space Frames, LLC, Lindner Group, HHSS GROUP, Core Metallic Ind. L.L.C, and MERO-TSK International GmbH & Co., KG, all of which offer specialized engineering services, advanced fabrication technologies, and custom-designed systems for complex architectural projects.

Market growth is driven by the increasing adoption of lightweight materials, demand for faster construction techniques, and the rising popularity of architecturally unique and sustainable structures. Innovations in modular design, high-strength alloys, and prefabricated components are further propelling the global space frame market.

Companies in the Space Frame Market focus on product innovation with lightweight, durable materials and modular designs, alongside strategic mergers, acquisitions, and partnerships to expand portfolios. They target high-growth regions, emphasize sustainability through eco-friendly materials, and offer end-to-end solutions, leveraging digital tools like BIM to enhance market penetration and customer engagement.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.0 Billion |

| Material | Steel, Aluminum, and Metal alloys |

| Structure | Double layer, Single layer, and Triple layer grid |

| Tubes | Circular hollow section and Rectangular hollow section |

| Application | Roof, Steel Dome roof, Skylight, Canopy & entry way, Atrium, Vertical glazed, and Others (Skywalks, side bridges etc.) |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | DSI Spaceframes, HINDUSTAN ALCOX LIMITED, Octamec, CST Industries, Inc, Xuzhou LF Engineering & Construction Co, Triocon Space Frame Technologies Pvt, Ltd, Delta Structures, Inc, USKON Space Frame System Construction Industry and Commerce Co. Inc, Pillow Space Frame Ltd, Gossamer Space Frames, LLC, Lindner Group, HHSS GROUP, Core Metallic Ind. L.L.C, Prisma Metal Industry L.L.C, MERO-TSK International GmbH & Co., KG, Zhejiang Southeast Space Frame Co., Ltd, and Jiangsu Andy Steel Structure Co., Ltd |

| Additional Attributes | Dollar sales in the Space Frame Market vary by type including tubular, modular, and integrated systems, application across commercial buildings, sports stadiums, and industrial structures, and region covering North America, Europe, and Asia-Pacific. Growth is driven by demand for lightweight, durable architectural solutions, modern construction designs, and large-span structural applications. |

The global space frame market is estimated to be valued at USD 1.0 billion in 2025.

The market size for the space frame market is projected to reach USD 2.8 billion by 2035.

The space frame market is expected to grow at a 10.6% CAGR between 2025 and 2035.

The key product types in space frame market are steel, aluminum and metal alloys.

In terms of structure, double layer segment to command 48.7% share in the space frame market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Frameless Structural Glass Balustrade Market Size and Share Forecast Outlook 2025 to 2035

Frame Cutting Jib Miner Market Size and Share Forecast Outlook 2025 to 2035

Space-based C4ISR Market Size and Share Forecast Outlook 2025 to 2035

Space Lander and Rover Market Size and Share Forecast Outlook 2025 to 2035

Space-Based Solar Power Market Size and Share Forecast Outlook 2025 to 2035

Space Situational Awareness Market Size and Share Forecast Outlook 2025 to 2035

Space Robotics Market Size and Share Forecast Outlook 2025 to 2035

Frame Alignment Systems Market Size and Share Forecast Outlook 2025 to 2035

Space On Board Computing Platform Market Size and Share Forecast Outlook 2025 to 2035

Space Militarization Market Size and Share Forecast Outlook 2025 to 2035

Space Economy Market Size and Share Forecast Outlook 2025 to 2035

Space Power Electronics Market Size and Share Forecast Outlook 2025 to 2035

Space Management Solutions Market Size and Share Forecast Outlook 2025 to 2035

Industry Share Analysis for Space Tourism Providers

Space Tourism Industry Analysis by Supplier, by Age Group, by Tourism Type, by Demographics, by Nationality, by Booking Channel, by Tour Type, and by Region - Forecast for 2025 to 2035

Spacer Tapes Market Insights & Growth Outlook through 2034

Space DC-DC Converter Market Insights – Growth & Forecast 2024-2034

In Space Manufacturing Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Fastener Manufacturing Solution Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Fluid Conveyance System Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA