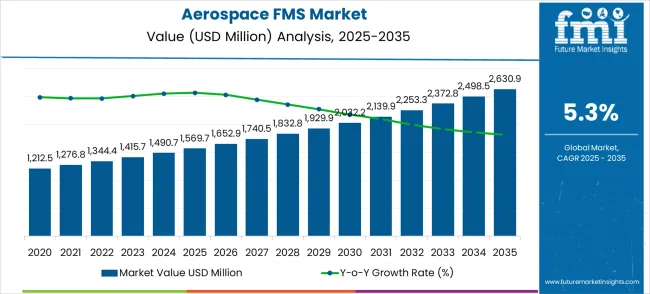

The aerospace fastener manufacturing solution market is expected to witness steady growth between 2025 and 2035, with a compound annual growth rate (CAGR) of 5.3%. This growth will see the market expand from USD 1,570 million in 2025 to USD 2,631 million by 2035. As the aerospace industry continues to evolve, the demand for high-performance fasteners, which are crucial for ensuring structural integrity and safety, is set to rise. Aerospace manufacturers are increasingly seeking fasteners that provide superior strength and reliability, driving the need for advanced manufacturing solutions. This market growth is expected to be particularly driven by the expansion of commercial aircraft fleets, military aviation, and space exploration initiatives, where stringent quality and performance standards are non-negotiable. The rising demand for lightweight materials and greater fuel efficiency will also fuel the market’s upward trajectory, as manufacturers look to reduce weight without compromising safety or performance.

The growth of the aerospace fastener manufacturing solution market is expected to be supported by the ongoing development of advanced materials and manufacturing techniques. Companies providing these solutions will be increasingly seen as key partners in the aerospace supply chain, as the need for precision-engineered components intensifies. The growing complexity of aerospace designs, with an increasing emphasis on hybrid and electric propulsion systems, will create a greater demand for customized fasteners. The demand for aerospace fastener manufacturing solutions is not only anticipated to increase within traditional aviation but also across the growing commercial space industry, where fasteners are essential for the durability of spacecraft and launch systems. As aerospace manufacturers continue to prioritize safety, weight reduction, and performance, the demand for advanced fasteners will remain robust, further driving growth in this vital market.

| Metric | Value |

|---|---|

| Estimated Value in (2025E) | USD 1,570 million |

| Forecast Value in (2035F) | USD 2,631 million |

| Forecast CAGR (2025 to 2035) | 5.3% |

The aerospace fastener manufacturing solution market plays a significant role in supporting the precision, reliability, and durability of aerospace products. Within the aerospace manufacturing market, this segment holds a share of about 8.2%, as fasteners are integral components of aircraft assembly. In the fastener manufacturing market, the contribution is stronger at 10.7%, driven by the specialized requirements of aerospace-grade fasteners. The industrial automation market records a 7.5% share, as automated systems are employed to enhance manufacturing efficiency and precision.

Within the aerospace parts and components market, the share stands at 9.3%, reflecting the importance of fasteners in various aerospace subassemblies. The metal fabrication market accounts for around 7.1%, as fasteners are produced through advanced metalworking processes. Collectively, these parent markets contribute to nearly 42.8%, indicating the pivotal role of aerospace fastener manufacturing solutions in the broader aerospace and manufacturing sectors. The market is essential in enabling high-performance materials and components, which are critical for the operational efficiency and safety standards required in the aerospace industry.

Market expansion is being supported by the rapid increase in global aircraft production worldwide and the corresponding need for high-quality fastening solutions to ensure structural integrity and operational safety. Modern aerospace manufacturing relies on precise fastener systems to join composite materials, titanium components, and aluminum structures while maintaining weight efficiency and meeting stringent safety requirements. Advanced fastener manufacturing solutions enable aerospace producers to achieve optimal assembly quality, reduce production time, and ensure compliance with international aviation safety standards.

The growing complexity of aerospace structures and increasing focus on weight reduction are driving demand for sophisticated fastener manufacturing solutions from certified suppliers with appropriate aerospace certifications and technical expertise. Aviation regulatory agencies are increasingly requiring comprehensive quality documentation for all aerospace fastening systems to ensure flight safety and structural reliability. Industry standards and aerospace specifications are establishing rigorous fastener requirements that require specialized manufacturing processes and extensive testing protocols for optimal performance validation.

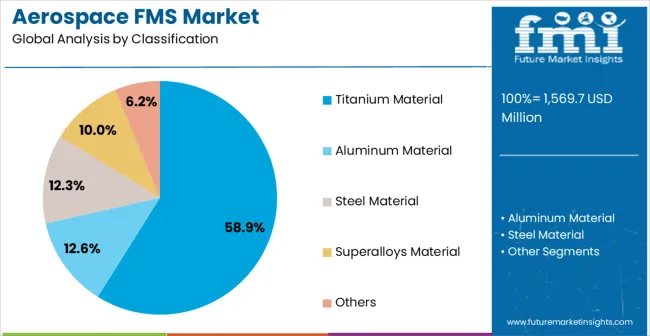

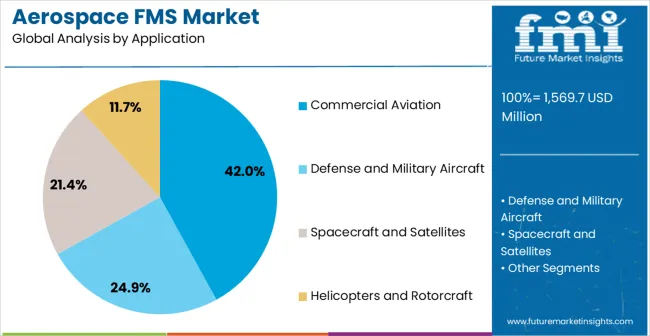

The market is segmented by material type, aerospace platform, and region. By material type, the market is divided into titanium material, aluminum material, steel material, superalloys material, and others. Based on aerospace platform, the market is categorized into commercial aviation, defense and military aircraft, spacecraft and satellites, helicopters and rotorcraft, and others. Regionally, the market is divided into North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa.

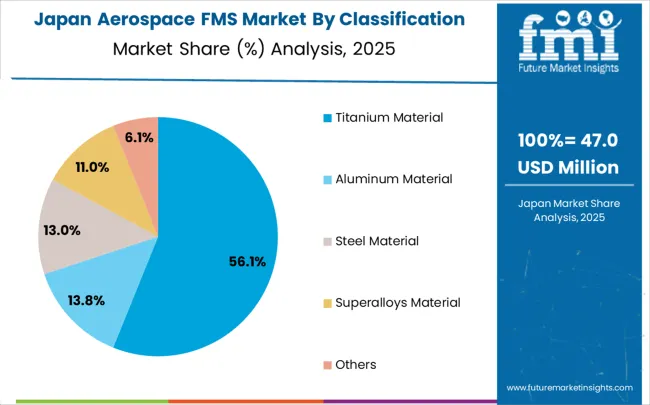

Titanium material fastening solutions are projected to account for 58.9% of the Aerospace Fastener Manufacturing Solution market in 2025. This leading share is supported by the widespread adoption of titanium alloys in modern aerospace applications, which represent the majority of current installations requiring high strength-to-weight ratios and exceptional corrosion resistance. Titanium fasteners provide optimal performance characteristics while maintaining lightweight properties for most aerospace applications including structural joints, engine components, and critical assembly connections. The segment benefits from established manufacturing procedures and comprehensive material certification from multiple aerospace-qualified suppliers. These materials offer superior mechanical properties for demanding aerospace environments while ensuring consistent performance standards across diverse aircraft platforms and maintaining competitive lifecycle costs for manufacturers requiring certified aerospace-grade fastening solutions.

Commercial aviation platform applications are expected to represent 42% of aerospace fastener manufacturing solution demand in 2025. This dominant share reflects the extensive use of advanced fastening systems in commercial aircraft production that requires high-volume manufacturing capabilities and stringent quality control for passenger safety compliance. Modern commercial aircraft increasingly feature complex composite structures that require specialized fastener installations for optimal structural integration and assembly efficiency across diverse aircraft configurations. The segment benefits from growing air travel demand and increasing emphasis on fuel efficiency optimization, supporting lightweight fastener technology adoption. Market expansion continues as aircraft manufacturers seek reliable fastening solutions for next-generation aircraft platforms and high-rate production applications requiring certified aerospace performance and enhanced manufacturing capabilities.

The aerospace fastener manufacturing solution market is advancing steadily due to increasing aircraft production rates and growing recognition of fastener quality importance for aerospace safety and operational performance. However, the market faces challenges including stringent certification requirements, need for specialized manufacturing equipment, and varying aerospace specifications across different aircraft platforms and regulatory jurisdictions. Technology standardization efforts and aerospace qualification programs continue to influence product development and manufacturing standards across the industry.

The growing deployment of 3D printing and additive manufacturing systems is enabling production of complex fastener geometries through layer-by-layer fabrication processes and customized design optimization for specific aerospace applications. Advanced manufacturing systems equipped with real-time quality monitoring provide optimal production control while reducing material waste for manufacturers while expanding design possibilities and operational efficiency. These technologies are particularly valuable for low-volume specialty fasteners and rapid prototyping applications that require quick turnaround without traditional tooling investments and enhanced design flexibility.

Modern aerospace fastener manufacturers are incorporating IoT sensors and predictive analytics that improve production quality and reduce manufacturing defects through real-time process monitoring and automated quality control systems. Integration of digital twin technology and machine learning algorithms enables more sophisticated production optimization and comprehensive quality assurance across complex manufacturing processes. Advanced digital platforms also support aerospace certification requirements while meeting growing demand for traceability and quality documentation in aerospace supply chain management.

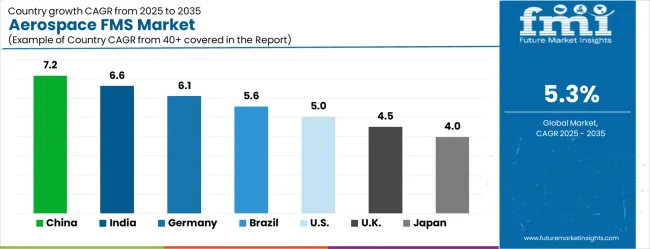

| Country | CAGR (2025-2035) |

|---|---|

| China | 7.2% |

| India | 6.6% |

| Germany | 6.1% |

| Brazil | 5.6% |

| United States | 5% |

| United Kingdom | 4.5% |

| Japan | 4% |

The aerospace fastener manufacturing solution market is growing steadily, with China leading at a 7.2% CAGR through 2035, driven by massive aerospace industry expansion, growing commercial aircraft production, and comprehensive manufacturing capability development supporting advanced fastener technology adoption. India follows at 6.6%, supported by expanding aerospace manufacturing sector and increasing government initiatives promoting domestic aircraft production and defense manufacturing capabilities. Germany records 6.1%, emphasizing precision aerospace engineering, advanced manufacturing technologies, and stringent quality certification standards. Brazil grows at 5.6%, integrating modern fastener manufacturing systems into established aerospace operations and expanding aircraft component production facilities. The United States shows 5% growth, focusing on next-generation aircraft programs and advanced manufacturing technology adoption. The United Kingdom and Japan demonstrate steady growth at 4.5% and 4% respectively, driven by aerospace innovation and high-precision manufacturing capabilities. The report covers an in-depth analysis of 40+ countries; the top-performing countries are highlighted below.

The aerospace fastener manufacturing solution market in China is growing at a CAGR of 7.2%, driven by the rapid expansion of the country’s aerospace industry and its increasing demand for high-performance fasteners. China’s commitment to advancing its aviation sector, including the development of commercial aircraft and military jets, is significantly boosting the market. Additionally, government support for technological advancements and infrastructure development further contributes to the market’s growth. As the Chinese aerospace industry continues to modernize and expand its capabilities, the demand for advanced, lightweight, and durable fastener solutions rises, providing opportunities for manufacturers.

The aerospace fastener manufacturing solution market in India is projected to grow at a CAGR of 6.6%, driven by the country’s increasing focus on expanding its aerospace industry and the rising production of both commercial and military aircraft. India’s growing investment in its defense and aviation sectors is fueling the demand for high-quality fasteners. The country’s increasing participation in international aerospace projects, along with its focus on building a competitive manufacturing ecosystem, is further boosting demand for aerospace fastener solutions. Additionally, India’s push for industrial modernization and smart manufacturing further accelerates the adoption of advanced fastener technologies.

The aerospace fastener manufacturing solution market in Germany is growing at a CAGR of 6.1%, supported by the country’s well-established aerospace industry and its emphasis on precision manufacturing. Germany’s aerospace sector, particularly in the production of commercial aircraft and military aviation, is driving the demand for high-quality, durable, and lightweight fasteners. The country’s commitment to innovation in aviation technology, along with its focus on sustainable and energy-efficient production methods, further supports market growth. Germany’s strong industrial base and highly skilled workforce continue to contribute to the growing demand for advanced aerospace fastener manufacturing solutions.

The aerospace fastener manufacturing solution market in Brazil is projected to grow at a CAGR of 5.6%, driven by the country’s growing aerospace industry and the increasing production of commercial and defense aircraft. Brazil’s aerospace market is becoming more competitive, with local manufacturers investing in advanced technologies to meet international standards. The government’s efforts to strengthen the domestic aerospace manufacturing ecosystem, along with the expansion of regional and global aerospace contracts, are driving demand for high-performance fasteners. As Brazil continues to expand its aerospace production capabilities, the market for fastener solutions is expected to grow steadily.

The aerospace fastener manufacturing solution market in the United States is expanding at a CAGR of 5%, driven by the country’s robust aerospace industry and its constant demand for high-quality, durable fasteners. The USA aerospace sector, particularly in the production of both civilian and military aircraft, continues to drive the market for aerospace fasteners. Advances in manufacturing processes, including automation and precision engineering, are further enhancing the adoption of advanced fastener technologies. Additionally, USA government defense contracts and ongoing investments in aerospace infrastructure contribute to the growing demand for fastener solutions.

The aerospace fastener manufacturing solution market in the United Kingdom is growing at a CAGR of 4.5%, with strong demand for fasteners in commercial and military aviation. The UK aerospace industry, which focuses on precision engineering and advanced manufacturing, is a key driver of the market. The country’s increasing investments in aerospace research and development, along with its role in global aerospace projects, is helping fuel the demand for advanced aerospace fastener solutions. The UK’s emphasis on sustainable manufacturing and reducing the environmental impact of production is also contributing to the adoption of high-quality, energy-efficient fasteners.

The aerospace fastener manufacturing solution market in Japan is growing at a CAGR of 4%, supported by the country’s advanced aerospace sector and technological expertise in manufacturing. Japan’s aerospace industry is expanding, with a focus on producing advanced commercial aircraft and military jets, driving the demand for high-quality fasteners. The country’s commitment to innovation, research, and technological advancements in aerospace manufacturing further supports the adoption of precision fastener solutions. Japan’s growing focus on automation and the adoption of smart manufacturing technologies also plays a significant role in driving the demand for advanced aerospace fastener manufacturing solutions.

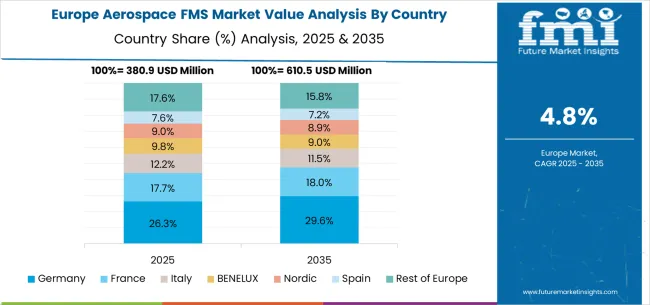

The aerospace fastener manufacturing solution market in Europe is projected to grow from USD 441.9 million in 2025 to USD 697.3 million by 2035, registering a CAGR of 4.7% over the forecast period. Germany is expected to maintain its leadership with a 28.7% share in 2025, supported by its extensive aerospace manufacturing infrastructure and advanced fastener technology capabilities.

The United Kingdom is projected to hold 22.3% market share, followed by France at 19.6%. Italy and Spain account for 13.8% and 10.4% respectively. The Rest of Europe region represents 5.2% of the market, attributed to growing aerospace investments in Eastern European countries and expanding aircraft component manufacturing capacity development across the region.

The aerospace fastener manufacturing solution market is defined by competition among specialized aerospace manufacturing equipment suppliers, fastener technology companies, and precision manufacturing solution providers. Companies are investing in advanced manufacturing technologies, aerospace certification capabilities, quality assurance systems, and technical support services to deliver reliable, efficient, and compliant fastener manufacturing solutions. Strategic partnerships, technological innovation, and geographic expansion are central to strengthening product portfolios and market presence.

Precision Castparts Corp, USA-based, offers comprehensive aerospace fastener manufacturing systems with focus on precision casting technology, advanced quality control, and technical expertise for critical aerospace applications. Howmet Aerospace, operating globally, provides specialized fastener manufacturing solutions integrated with aerospace material capabilities for diverse aircraft platform requirements. LISI Aerospace delivers technologically advanced fastener production systems with standardized aerospace procedures and certification integration. VIBA BV emphasizes custom fastener manufacturing designs and comprehensive coverage for European aerospace applications.

TriMas Corporation, providing North American solutions, offers aerospace fastener manufacturing integrated with comprehensive supply chain services. Paolo Astori, MS Aerospace, and NAFCO deliver specialized fastener manufacturing expertise with advanced technical capabilities and aerospace validation support. Stanley Black & Decker, Bollhoff, Poggipolini, and Gillis Aerospace offer specialized aerospace fastener manufacturing expertise, standardized aerospace certification procedures, and technical reliability across regional and international aerospace supply networks.

Aerospace fastener manufacturing solutions encompass specialized equipment, tooling, and processes required to produce high-performance fasteners that meet stringent aviation safety, weight reduction, and reliability requirements. With the market valued at USD 1,569.7 million in 2025 and projected to reach USD 2,630.9 million by 2035 at a 5.3% CAGR, this sector is driven by commercial aviation growth, defense modernization programs, and the emerging space economy. Success requires coordination between materials suppliers, precision manufacturers, certification bodies, and aerospace OEMs to deliver manufacturing solutions capable of producing fasteners that withstand extreme operating conditions while meeting zero-defect quality standards.

How Governments Could Strengthen Aerospace Manufacturing Capabilities?

How Industry Organizations Could Enhance Manufacturing Standards?

How Equipment Manufacturers Could Advance Manufacturing Technologies?

How Aerospace OEMs Could Optimize Fastener Integration?

How Material Suppliers Could Enable Advanced Manufacturing?

How Financial Partners Could Support Industry Growth?

| Item | Value |

|---|---|

| Quantitative Units (2025) | USD 1,570 million |

| Material Type | Titanium Material, Aluminum Material, Steel Material, Superalloys Material, Others |

| Aerospace Platform | Commercial Aviation, Defense and Military Aircraft, Spacecraft and Satellites, Helicopters and Rotorcraft, Others |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Countries Covered | United States, Canada, United Kingdom, Germany, France, China, Japan, South Korea, India, Brazil, Australia and 40+ countries |

| Key Companies Profiled | Precision Castparts Corp, Howmet Aerospace, LISI Aerospace, VIBA BV, TriMas Corporation, Paolo Astori, MS Aerospace, NAFCO, Stanley Black & Decker, Bollhoff, Poggipolini, Gillis Aerospace |

| Additional Attributes | Dollar sales by material type and aerospace platform segments, regional demand trends across Asia-Pacific, North America, and Europe, competitive landscape with established aerospace suppliers and emerging manufacturing technology providers, customer preferences for titanium versus alternative material fastening systems, integration with advanced manufacturing platforms and digital production systems |

The global aerospace fastener manufacturing solution market is estimated to be valued at USD 1,569.7 million in 2025.

The market size for the aerospace fastener manufacturing solution market is projected to reach USD 2,630.9 million by 2035.

The aerospace fastener manufacturing solution market is expected to grow at a 5.3% CAGR between 2025 and 2035.

The key product types in aerospace fastener manufacturing solution market are titanium material, aluminum material, steel material, superalloys material and others.

In terms of application, commercial aviation segment to command 42.0% share in the aerospace fastener manufacturing solution market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Aerospace Fluid Conveyance System Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Adhesives and Sealants Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Forging Materials Market Size and Share Forecast Outlook 2025 to 2035

Aerospace and Defense Cyber Security Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Cold Forgings Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Defense Ducting Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Defense C Class Parts Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Electrical Inserts Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Foams Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Robotics Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Engineering Services Outsourcing (ESO) Market Analysis - Size, Share, and Forecast Outlook (025 to 2035

Aerospace DC-DC Converter Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Aerospace 3D Printing Materials Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Radome Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Interior Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Floor Panels Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Tester Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Landing Gear Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Avionics Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Lightning Strike Protection Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA