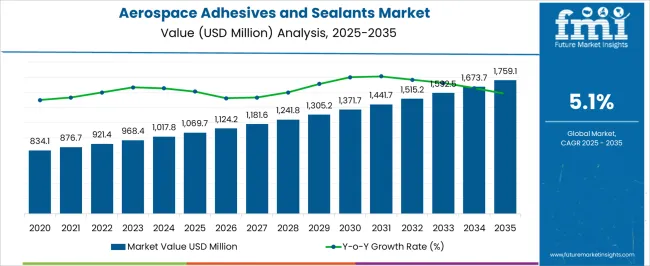

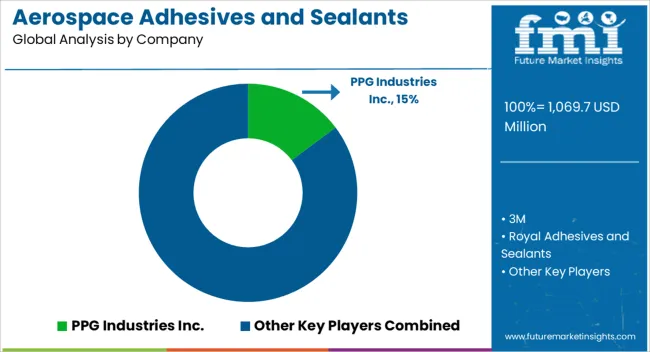

The Aerospace Adhesives and Sealants Market is estimated to be valued at USD 1069.7 million in 2025 and is projected to reach USD 1759.1 million by 2035, registering a compound annual growth rate (CAGR) of 5.1% over the forecast period.

| Metric | Value |

|---|---|

| Aerospace Adhesives and Sealants Market Estimated Value in (2025 E) | USD 1069.7 million |

| Aerospace Adhesives and Sealants Market Forecast Value in (2035 F) | USD 1759.1 million |

| Forecast CAGR (2025 to 2035) | 5.1% |

The aerospace adhesives and sealants market is experiencing significant growth driven by increasing demand for lightweight, fuel-efficient aircraft and high-performance aerospace components. The shift toward composite materials in aircraft structures has accelerated the adoption of advanced adhesives and sealants that provide superior bonding, corrosion resistance, and structural integrity.

Rising investments in commercial, military, and space aerospace sectors are further boosting market demand, as manufacturers seek materials that reduce assembly time and improve operational reliability. Technological advancements in adhesive chemistry and sealant formulations, including high-temperature tolerance and enhanced environmental durability, are enabling broader application across fuselage, wings, engines, and interior components.

Regulatory requirements emphasizing safety, environmental compliance, and performance standards are influencing material selection, encouraging the use of advanced resin-based solutions As aerospace manufacturers prioritize long-term cost savings, durability, and operational efficiency, the market for high-performance adhesives and sealants is expected to expand steadily, with increasing adoption across commercial, defense, and space aerospace platforms globally.

The aerospace adhesives and sealants market is segmented by type, resin type, technology, end-use, and geographic regions. By type, aerospace adhesives and sealants market is divided into Adhesives and Sealants. In terms of resin type, aerospace adhesives and sealants market is classified into Epoxy, Polyurethane, Polyimide, and Others. Based on technology, aerospace adhesives and sealants market is segmented into Solvent-Based, Water-Based, Powder Coating, and Others. By end-use, aerospace adhesives and sealants market is segmented into Commercial, Military, and General Aviation. Regionally, the aerospace adhesives and sealants industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

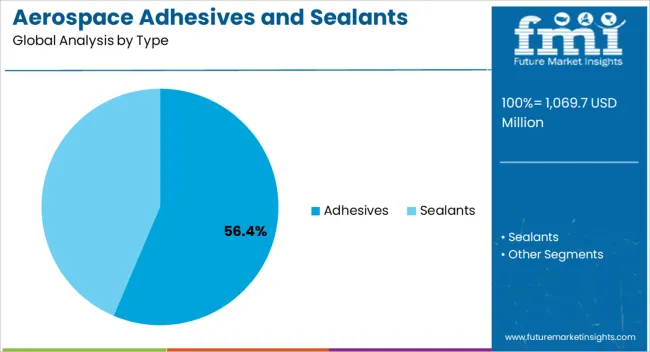

The adhesives segment is projected to hold 56.4% of the aerospace adhesives and sealants market revenue share in 2025, making it the leading type category. This dominance is being supported by the increasing need for high-strength bonding solutions in aircraft structures, where adhesives provide superior load distribution and enhanced fatigue resistance compared to traditional mechanical fasteners.

The segment benefits from its ability to bond diverse materials, including metals, composites, and polymers, enabling lightweight and structurally optimized assemblies. Continuous innovation in resin formulations and curing technologies allows adhesives to withstand extreme temperature fluctuations, vibration, and chemical exposure common in aerospace environments.

Additionally, the adhesives segment is being reinforced by growing adoption in both assembly and repair applications, driven by manufacturers’ goals to improve production efficiency, reduce assembly weight, and extend component life As aerospace programs expand globally, the preference for adhesives as a versatile and reliable bonding solution is expected to continue, solidifying its leadership position in the market.

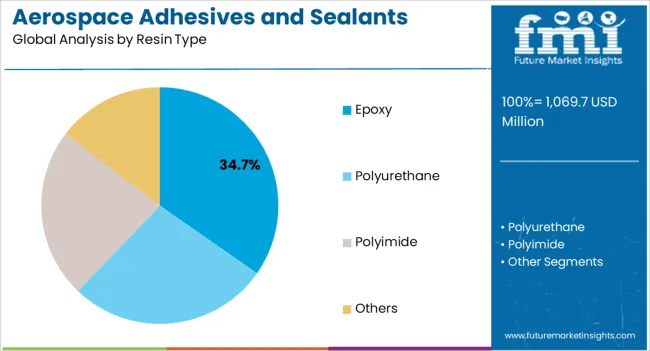

The epoxy resin type segment is anticipated to account for 34.7% of the aerospace adhesives and sealants market revenue share in 2025, positioning it as the leading resin category. This leadership is being driven by epoxy’s excellent mechanical strength, thermal stability, and chemical resistance, which make it highly suitable for critical structural applications in aircraft and spacecraft.

The material’s inherent adhesion properties and versatility allow bonding across a wide range of substrates, including metals, composites, and high-performance polymers. Continuous improvements in epoxy formulations, including low-viscosity and fast-curing variants, have enabled more efficient assembly processes and better adaptability to automated manufacturing systems.

Adoption is further reinforced by the aerospace industry’s need for materials that meet stringent safety, durability, and certification standards The combination of performance reliability, regulatory compliance, and long-term durability positions epoxy as the preferred resin type in aerospace bonding and structural applications, ensuring its continued dominance in the market.

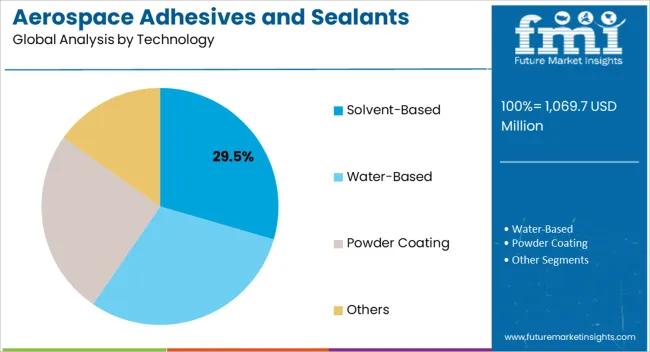

The solvent-based technology segment is expected to hold 29.5% of the aerospace adhesives and sealants market revenue share in 2025, establishing it as the leading technology category. This preference is being driven by the material’s ability to provide uniform coating, strong adhesion, and excellent gap-filling performance for complex aerospace components. Solvent-based systems allow precise control over viscosity, application, and curing times, which enhances process efficiency and reliability in both assembly and maintenance operations.

The segment benefits from widespread adoption in bonding, sealing, and protective coatings across aircraft interiors, exteriors, and engine components. Stringent performance requirements, including resistance to temperature extremes, vibration, and chemical exposure, are being met effectively by solvent-based formulations, supporting their continued use.

Additionally, regulatory compliance with environmental and safety standards has led manufacturers to optimize formulations for reduced emissions while maintaining high-performance characteristics As the aerospace industry continues to focus on operational efficiency, durability, and reliability, the solvent-based technology segment is positioned to retain its leadership within the adhesives and sealants market.

The rise of the global demand for aircraft adhesives and sealants is projected to be aided by the development of low-cost carriers around the world and rising local passenger traffic in many emerging economies. Another interesting area for market sellers is an investment in new space initiatives that is booming in recent years out of competition among a few space exploration-capable countries.

As per the aerospace adhesives and sealants market survey report, epoxy retained the largest share of its global market, accounting for more than 45% of the total sales. Large wingskins, composite ribs, sandwich panels, and other carbon composite substrates all require epoxy-based components. It also has a low elongation to fracture, a high coefficient of thermal expansion, and a high compressive strength. Oppositely, Polyurethane is expected to register a higher CAGR of 5.8% in the adhesive market during the upcoming forecast years.

Higher investments and improvement of manufacturing facilities as well as new product innovation are anticipated to remain major growth strategies for contemporary aerospace adhesives and sealants market key players. For example, in February 2025, Henkel Company of the US declared the establishment of a specialist factory for modern aerospace applications in Montornès, Spain. Such endeavors are also expected to boost market rivalry and motivate other countries to establish a competitive aerospace adhesive and sealants industry soon

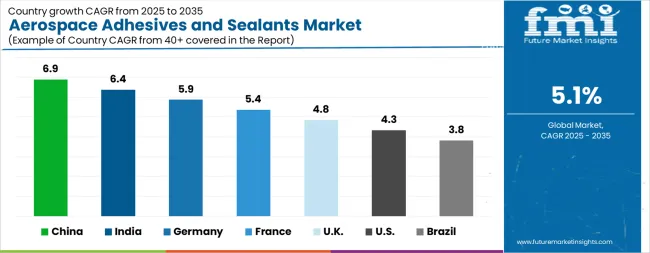

| Country | CAGR |

|---|---|

| China | 6.9% |

| India | 6.4% |

| Germany | 5.9% |

| France | 5.4% |

| UK | 4.8% |

| USA | 4.3% |

| Brazil | 3.8% |

The Aerospace Adhesives and Sealants Market is expected to register a CAGR of 5.1% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 6.9%, followed by India at 6.4%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Brazil posts the lowest CAGR at 3.8%, yet still underscores a broadly positive trajectory for the global Aerospace Adhesives and Sealants Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 5.9%. The USA Aerospace Adhesives and Sealants Market is estimated to be valued at USD 368.1 million in 2025 and is anticipated to reach a valuation of USD 562.7 million by 2035. Sales are projected to rise at a CAGR of 4.3% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 58.8 million and USD 37.2 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 1069.7 Million |

| Type | Adhesives and Sealants |

| Resin Type | Epoxy, Polyurethane, Polyimide, and Others |

| Technology | Solvent-Based, Water-Based, Powder Coating, and Others |

| End-Use | Commercial, Military, and General Aviation |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | PPG Industries Inc., 3M, Royal Adhesives and Sealants, Cytec Industries Inc., Huntsman Corporation, United Resin Corporation, Hexcel Corporation, Beacon Adhesives Inc., Henkel AG and Company, Solvay Group, Bostik, Permabond, Lord Corporation, and B. Fuller |

The global aerospace adhesives and sealants market is estimated to be valued at USD 1,069.7 million in 2025.

The market size for the aerospace adhesives and sealants market is projected to reach USD 1,759.1 million by 2035.

The aerospace adhesives and sealants market is expected to grow at a 5.1% CAGR between 2025 and 2035.

The key product types in aerospace adhesives and sealants market are adhesives and sealants.

In terms of resin type, epoxy segment to command 34.7% share in the aerospace adhesives and sealants market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Evaluating Aerospace Sealants Market Share & Provider Insights

Adhesives And Sealants Market Size and Share Forecast Outlook 2025 to 2035

Silicone Adhesives And Sealants Market Size and Share Forecast Outlook 2025 to 2035

Automotive Adhesives & Sealants Market Size and Share Forecast Outlook 2025 to 2035

Adhesives for Electric Vehicle Power Batteries Market Forecast and Outlook 2025 to 2035

Aerospace Fastener Manufacturing Solution Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Fluid Conveyance System Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Forging Materials Market Size and Share Forecast Outlook 2025 to 2035

Aerospace and Defense Cyber Security Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Cold Forgings Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Defense Ducting Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Defense C Class Parts Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Electrical Inserts Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Foams Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Robotics Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Engineering Services Outsourcing (ESO) Market Analysis - Size, Share, and Forecast Outlook (025 to 2035

Aerospace DC-DC Converter Market Analysis - Size, Share, and Forecast Outlook 2025 to 2035

Aerospace Fastener Market Analysis Size Share and Forecast Outlook 2025 to 2035

Aerospace 3D Printing Materials Market Size and Share Forecast Outlook 2025 to 2035

Aerospace Radome Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA