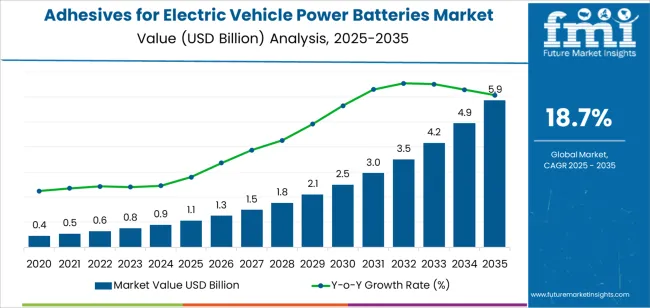

The global Adhesives for Electric Vehicle Power Batteries market is projected to grow from USD 1.1 billion in 2025 to approximately USD 5.9 billion by 2035, recording an absolute increase of USD 4812.49 million over the forecast period. This translates into a total growth of 455.4%, with the market forecast to expand at a CAGR of 18.7% between 2025 and 2035.

The overall market size is expected to grow by nearly 5.6X during the same period, supported by accelerating electric vehicle adoption, expanding battery manufacturing capacity worldwide, and increasing demand for high-performance thermal management and structural bonding solutions across various EV battery assembly applications.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 1.1 billion |

| Market Forecast Value (2035) | USD 5.9 billion |

| Forecast CAGR (2025 to 2035) | 18.7% |

| MANUFACTURING TRENDS | TECHNOLOGY ADVANCEMENT | QUALITY & PERFORMANCE |

|---|---|---|

| Electric Vehicle Production Expansion - Rapid scaling of EV manufacturing across automotive industry driving unprecedented demand for specialized battery assembly adhesives with thermal management capabilities. | Advanced Thermal Interface Materials - Development of high-performance thermal conductivity adhesives enabling efficient heat dissipation and battery management system optimization. | Safety Standards Enhancement - Stringent automotive safety requirements establishing performance benchmarks for fire resistance, thermal stability, and structural integrity in battery applications. |

| Battery Manufacturing Automation - Growing adoption of automated battery pack assembly processes requiring precise adhesive dispensing systems and consistent bonding performance for high-volume production. | Chemical Resistance Innovation - Enhanced formulations providing superior resistance to electrolyte exposure, temperature cycling, and mechanical stress while maintaining adhesion strength. | Reliability Testing Standards - Industry requirements for extensive accelerated aging, vibration testing, and thermal cycling validation ensuring long-term performance in automotive applications. |

| Gigafactory Construction - Massive battery manufacturing facilities worldwide creating demand for industrial-scale adhesive supply chains and specialized application equipment for high-throughput operations. | Dispensing Technology Integration - Advanced robotic dispensing systems requiring adhesives with precise viscosity control, extended pot life, and rapid cure capabilities for manufacturing efficiency. | Quality Assurance Protocols - Automotive-grade quality standards requiring comprehensive testing, traceability, and statistical process control throughout adhesive manufacturing and application. |

| Category | Segments / Values |

|---|---|

| By Product Type | Polyurethane Adhesive; Epoxy Adhesive; Organic Silicone Adhesive; Acrylic Adhesive; Others |

| By Application | Passenger Car; Commercial Vehicle; Two-Wheeler; Others |

| By End-Use | Cell-to-Pack Assembly; Thermal Interface; Housing Assembly; Cable Management; Battery Module Bonding; Others |

| By Curing Method | Heat Cure; Room Temperature Cure; UV Cure; Moisture Cure |

| By Performance Property | Thermal Conductive; Electrically Insulating; Fire Retardant; Structural Bonding; Gap Filling |

| By Distribution Channel | Direct Manufacturer Sales; Specialized Chemical Distributors; Automotive Suppliers; Online Industrial Platforms |

| By Region | North America; Europe; Asia Pacific; Latin America; Middle East & Africa |

| Segment | 2025 to 2035 Outlook |

|---|---|

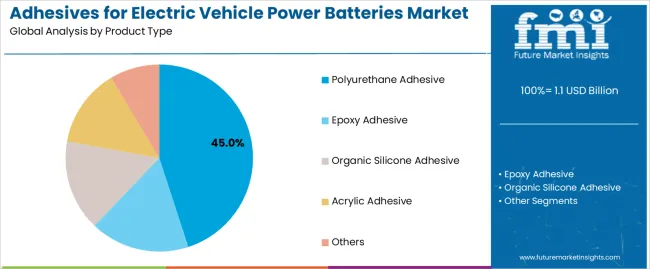

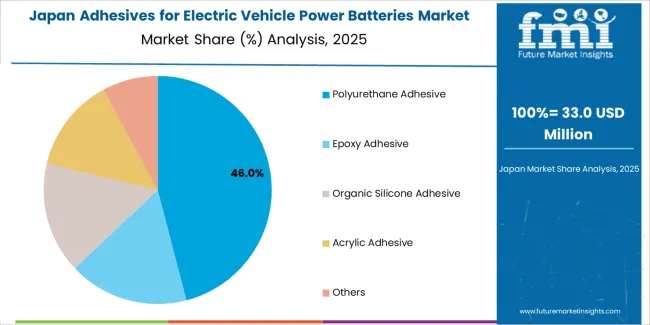

| Polyurethane Adhesive | Leader in 2025 with 45.0% market share; expected to maintain dominance through 2035. Superior flexibility, chemical resistance, and processing characteristics ideal for battery housing and structural applications. Momentum: strong growth from commercial vehicle and energy storage applications. Watchouts: competition from specialized silicone formulations and regulatory changes. |

| Epoxy Adhesive | Significant segment with 28.5% share, benefiting from excellent thermal conductivity and structural strength in cell-to-pack applications requiring high-performance bonding solutions. Momentum: rising demand in premium EV segments and thermal management applications. Watchouts: processing complexity and cure time limitations in high-volume manufacturing. |

| Organic Silicone Adhesive | Growing segment at 18.0% share, offering exceptional temperature resistance and flexibility for thermal interface applications and cable management systems. Momentum: increasing adoption in battery thermal management and high-temperature applications. Watchouts: higher cost compared to conventional adhesives and compatibility considerations. |

| Acrylic Adhesive | Emerging segment with specialized applications in component assembly and sealing applications requiring transparency and weather resistance. Momentum: moderate growth in specific battery component applications requiring optical clarity and UV resistance. |

| Others | Specialized formulations including anaerobic, cyanoacrylate, and hybrid adhesives for specific assembly requirements and niche applications requiring unique performance characteristics. |

| Segment | 2025 to 2035 Outlook |

|---|---|

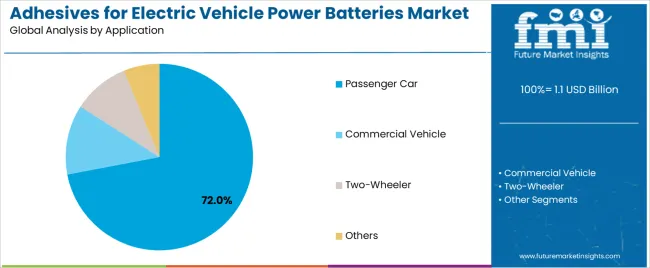

| Passenger Car | Dominant application segment in 2025 at 72.0% share, driven by rapid EV adoption worldwide and increasing battery pack complexity requiring advanced adhesive solutions. Supported by government incentives and consumer acceptance of electric mobility. Momentum: exceptional growth from luxury EV segments and mainstream market penetration. Watchouts: price competition and standardization pressures affecting premium adhesive demand. |

| Commercial Vehicle | Strategic segment at 20.0% share, encompassing electric buses, delivery trucks, and logistics vehicles requiring heavy-duty adhesive solutions for large battery systems and demanding operational conditions. Momentum: strong growth from urban electrification initiatives and commercial fleet conversion programs. Watchouts: longer replacement cycles and cost sensitivity in commercial applications. |

| Two-Wheeler | Emerging segment at 6.0% share, covering electric motorcycles and scooters with compact battery designs requiring specialized bonding solutions for space-constrained applications. Momentum: rapid growth in Asia Pacific markets and urban mobility solutions. Watchouts: price sensitivity and simplified assembly requirements limiting premium adhesive adoption. |

| Others | Specialized applications including marine vessels, aircraft ground support equipment, and industrial vehicles requiring specialized adhesive formulations for unique operational environments and performance requirements. |

| Distribution Channel | Status & Outlook (2025 to 2035) |

|---|---|

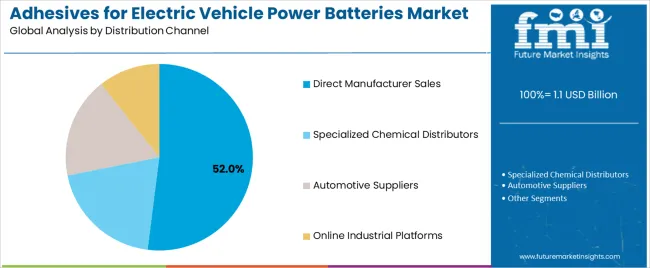

| Direct Manufacturer Sales | Dominant channel in 2025 with 52% share serving major automotive OEMs and battery manufacturers. Provides technical support, customized formulations, and supply chain integration. Momentum: strong growth driven by automotive industry consolidation and quality requirements. Watchouts: customer concentration risks and pricing pressures from large buyers. |

| Specialized Chemical Distributors | Important channel at 28% share serving tier-2 and tier-3 suppliers with inventory management and technical consultation services. Provides value through regional presence and application expertise. Momentum: moderate growth as manufacturers seek supply chain efficiency and technical support capabilities. |

| Automotive Suppliers | Strategic channel at 14% share for component manufacturers and assembly suppliers requiring integrated adhesive solutions with automotive supply chain compatibility and quality certifications. Momentum: steady growth through automotive supply chain expansion and vertical integration trends. |

| Online Industrial Platforms | Emerging channel at 6% share for smaller manufacturers and research institutions seeking competitive pricing and product information. Limited technical support but convenient ordering and documentation access. Momentum: rising growth as digital transformation accelerates B2B purchasing and smaller manufacturers seek cost-effective sourcing. |

| DRIVERS | RESTRAINTS | KEY TRENDS |

|---|---|---|

| Electric Vehicle Market Expansion across passenger cars, commercial vehicles, and two-wheelers driving unprecedented demand for battery assembly adhesives with advanced performance characteristics. | Raw material cost volatility and supply chain disruptions continue to impact manufacturing margins and availability of specialized chemical components. | Development of thermal interface materials with enhanced conductivity, improved processing characteristics, and superior long-term reliability enabling advanced battery thermal management. |

| Battery Technology Advancement - Increasing energy density, faster charging capabilities, and improved safety requirements creating demand for high-performance adhesives supporting next-generation battery designs. | Regulatory Compliance Complexity - Stringent automotive safety standards and environmental regulations requiring extensive testing and certification processes for new adhesive formulations. | Automation Integration - Advanced dispensing systems, precision application equipment, and quality monitoring technologies enabling high-volume manufacturing with consistent adhesive performance. |

| Gigafactory Manufacturing Scale - Massive battery production facilities requiring industrial-scale adhesive supply chains, automated application systems, and consistent quality protocols for high-throughput operations. | Technical Performance Requirements - Demanding specifications for thermal cycling, chemical resistance, and long-term durability requiring continuous R&D investment and validation testing. | Specialized Application Development - Emerging demand for adhesives tailored to solid-state batteries, structural battery packs, and integrated thermal management systems with unique performance requirements. |

| Thermal Management Innovation - Advanced battery cooling systems and thermal interface requirements driving demand for adhesives with superior heat transfer properties and temperature resistance capabilities. | Competition from Alternative Technologies - Development of mechanical fastening systems and welding technologies affecting traditional adhesive applications in specific assembly processes. | Ongoing R&D Focus - Continuous improvement in cure speed, processing temperature, chemical compatibility, and environmental resistance to meet evolving automotive industry standards. |

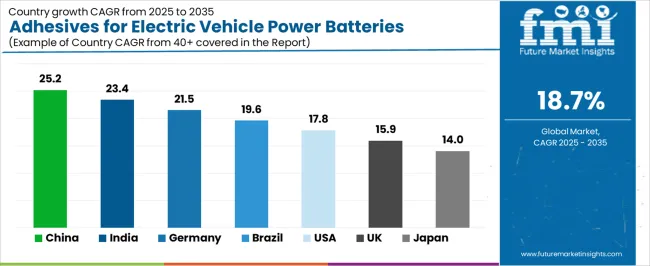

| Country | CAGR (2025 to 2035) |

|---|---|

| China | 25.2% |

| India | 23.4% |

| Germany | 21.5% |

| Brazil | 19.6% |

| United States | 17.8% |

| United Kingdom | 15.9% |

| Japan | 14.0% |

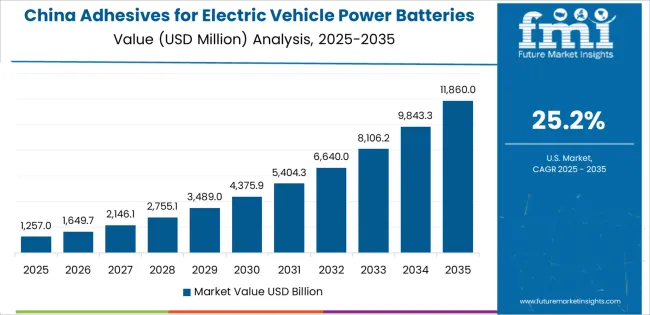

Revenue from adhesives for electric vehicle power batteries in China is projected to exhibit exceptional growth with a CAGR of 25.2% from 2025 to 2035, driven by the world's largest EV manufacturing base and comprehensive battery production ecosystem creating unprecedented opportunities for adhesive suppliers across passenger vehicle manufacturing, commercial vehicle electrification, and energy storage applications.

The country's established manufacturing tradition and rapidly expanding EV infrastructure are creating massive demand for both thermal conductive and structural bonding adhesive systems. Major automotive manufacturers and battery producers including BYD, CATL, and Tesla Gigafactory Shanghai are establishing comprehensive local adhesive supply facilities to support large-scale production operations and meet growing demand for high-performance bonding solutions.

Revenue from adhesives for electric vehicle power batteries in India is expanding to reach a CAGR of 23.4% from 2025 to 2035, supported by aggressive EV adoption policies and comprehensive automotive manufacturing development creating demand for reliable adhesive solutions across diverse vehicle categories and export-oriented production segments. The country's growing automotive sector and expanding EV infrastructure are driving demand for adhesive solutions that provide consistent manufacturing performance while supporting cost-effective production requirements. Component suppliers and manufacturing service providers are investing in local market development to support growing industrial operations and professional manufacturing demand.

Demand for adhesives for electric vehicle power batteries in Germany is projected to reach a CAGR of 21.5% from 2025 to 2035, supported by the country's leadership in automotive engineering and advanced adhesive technologies requiring sophisticated formulations for premium vehicle applications and industrial automation systems. German automotive manufacturers are implementing high-precision production systems that support advanced bonding capabilities, operational reliability, and comprehensive quality protocols. The market is characterized by focus on engineering excellence, component precision, and compliance with stringent environmental and performance standards.

Revenue from adhesives for electric vehicle power batteries in Brazil is growing to reach a CAGR of 19.6% from 2025 to 2035, driven by automotive electrification programs and increasing EV manufacturing creating opportunities for adhesive suppliers serving both domestic production operations and export-oriented manufacturing contractors. The country's expanding automotive base and growing electrification capabilities are creating demand for adhesive components that support diverse production requirements while maintaining performance standards. Manufacturing service providers and chemical supply companies are developing distribution strategies to support operational efficiency and customer satisfaction.

Demand for adhesives for electric vehicle power batteries in the United States is projected to reach a CAGR of 17.8% from 2025 to 2035, driven by advanced automotive manufacturing excellence and specialized EV capabilities supporting premium battery development and comprehensive high-performance applications. The country's established automotive tradition and mature EV market segments are creating demand for high-quality adhesive components that support operational performance and manufacturing standards. Component manufacturers and chemical suppliers are maintaining comprehensive development capabilities to support diverse manufacturing requirements.

Revenue from adhesives for electric vehicle power batteries in the United Kingdom is growing to reach a CAGR of 15.9% from 2025 to 2035, supported by automotive innovation and established manufacturing capabilities driving demand for premium adhesive solutions across traditional automotive systems and specialty EV applications. The country's automotive heritage and established industrial capabilities create demand for adhesive components that support both traditional production methods and modern high-efficiency battery assembly applications.

Demand for adhesives for electric vehicle power batteries in Japan is projected to reach a CAGR of 14.0% from 2025 to 2035, driven by precision manufacturing tradition and established chemical technology leadership supporting both domestic automotive markets and export-oriented component production. Japanese companies maintain sophisticated adhesive development capabilities, with established manufacturers continuing to lead in formulation technology and precision manufacturing standards.

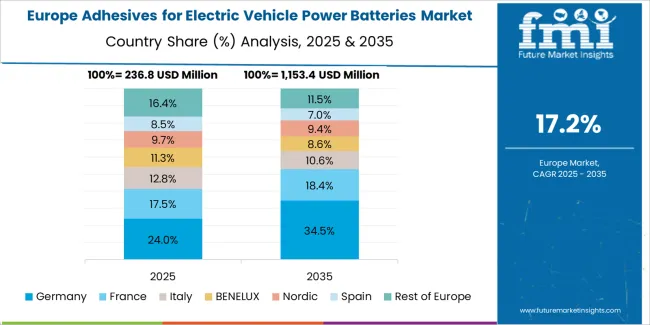

European Adhesives for Electric Vehicle Power Batteries operations are increasingly concentrated between German automotive engineering excellence and French chemical technology innovation. German facilities dominate thermal conductive adhesive production for premium automotive applications, leveraging advanced formulation technologies and strict quality protocols that command price premiums in global markets. French manufacturers maintain leadership in specialized polyurethane and silicone formulations, with companies like Arkema developing technical specifications that smaller suppliers must meet to access premium automotive manufacturing contracts.

Nordic operations in Sweden and Norway are capturing high-performance applications through advanced materials expertise and environmental compliance advantages, particularly in structural bonding adhesives for commercial vehicle and energy storage applications. These facilities increasingly serve as technology development centers for European automotive brands while developing their own specialized formulation expertise.

The regulatory environment presents both opportunities and constraints. REACH compliance requirements create quality standards that favor established European manufacturers over imports while ensuring consistent performance specifications. Brexit has created complexity for UK adhesive sourcing from EU suppliers, driving opportunities for direct relationships between manufacturers and international chemical distributors.

Supply chain consolidation accelerates as manufacturers seek economies of scale to absorb rising raw material costs and environmental compliance expenses. Vertical integration increases, with major automotive manufacturers acquiring specialized adhesive production facilities to secure component supplies and quality control. Smaller manufacturers face pressure to specialize in niche applications or risk displacement by larger, more efficient operations serving mainstream automotive manufacturing requirements.

South Korean Adhesives for Electric Vehicle Power Batteries operations reflect the country's advanced automotive sector and technology-oriented business model. Major electronics and automotive companies including Samsung SDI, LG Energy Solution, and Hyundai Motor Group drive component procurement strategies for their battery manufacturing operations, establishing direct relationships with specialized adhesive suppliers to secure consistent quality and pricing for their production processes targeting both domestic and international markets.

The Korean market demonstrates particular strength in integrating adhesive technologies into advanced battery management systems, with companies developing products that meet stringent quality standards for next-generation EV applications including solid-state batteries and high-energy density systems. This integration approach creates demand for specific performance specifications that differ from traditional applications, requiring suppliers to adapt formulations and curing characteristics for automated manufacturing processes.

Regulatory frameworks emphasize manufacturing safety and environmental protection, with Korean standards often exceeding international requirements for automotive applications. This creates barriers for smaller component suppliers but benefits established manufacturers who can demonstrate compliance capabilities. The regulatory environment particularly favors suppliers with KC certification and comprehensive automotive qualification systems.

Supply chain efficiency remains critical given Korea's technological advancement focus and competitive automotive manufacturing dynamics. Companies increasingly pursue development contracts with suppliers in Japan, Germany, and specialized chemical manufacturers to ensure access to advanced adhesive technologies while managing cost pressures. Investment in research and development supports quality advancement during extended automotive product development cycles.

Profit pools are consolidating upstream in specialized chemical formulation manufacturing and downstream in application-specific adhesive systems for automotive, battery thermal management, and high-performance assembly markets where certification, bonding performance, and thermal properties command premiums.

Value is migrating from basic adhesive production to specification-driven, automotive-qualified components where formulation expertise, thermal interface technology, and reliable manufacturing performance create competitive advantages. Several archetypes define market leadership: established chemical manufacturers defending share through R&D excellence and automotive relationships; specialty adhesive companies leveraging advanced formulation expertise and customer integration; integrated automotive suppliers with internal adhesive capabilities and market access; and emerging manufacturers pursuing cost-competitive production while developing automotive qualification capabilities.

Switching costs - automotive qualification, performance validation, production integration - provide stability for established suppliers, while technological advancement and performance requirements create opportunities for innovative manufacturers. Consolidation continues as companies seek formulation scale; direct sales channels grow for automotive OEM products while technical distribution remains relationship-driven.

Focus areas: secure automotive OEM and battery manufacturer positions with application-specific performance specifications and technical support; develop thermal management and structural bonding capabilities; explore specialized applications including solid-state batteries and advanced thermal interface materials.

| Stakeholder Type | Primary Advantage | Repeatable Plays |

|---|---|---|

| Established Chemical Manufacturers | R&D capabilities; automotive relationships; global production scale | Innovation leadership; technical service; automotive certification |

| Specialty Adhesive Companies | Advanced formulations; application expertise; customer integration | Customized solutions; performance optimization; niche market focus |

| Integrated Automotive Suppliers | Vertical integration; OEM access; supply chain control | Internal supply security; quality control; market responsiveness |

| Emerging Technology Manufacturers | Innovation focus; specialized applications; competitive positioning | Technology differentiation; targeted applications; partnership strategies |

| Technical Distributors | Market knowledge; customer relationships; technical support services | Application expertise; inventory management; customer education and training |

| Item | Value |

|---|---|

| Quantitative Units (2025) | USD 1.1 billion |

| Product Types | Polyurethane Adhesive; Epoxy Adhesive; Organic Silicone Adhesive; Acrylic Adhesive; Others |

| Applications | Passenger Car; Commercial Vehicle; Two-Wheeler; Others |

| End-Use | Cell-to-Pack Assembly; Thermal Interface; Housing Assembly; Cable Management; Battery Module Bonding; Others |

| Curing Methods | Heat Cure; Room Temperature Cure; UV Cure; Moisture Cure |

| Performance Properties | Thermal Conductive; Electrically Insulating; Fire Retardant; Structural Bonding; Gap Filling |

| Distribution Channels | Direct Manufacturer Sales; Specialized Chemical Distributors; Automotive Suppliers; Online Industrial Platforms |

| Regions Covered | North America; Latin America; Europe; Asia Pacific; Middle East & Africa |

| Key Countries | China; India; Germany; Brazil; United States; United Kingdom; Japan (+35 additional countries) |

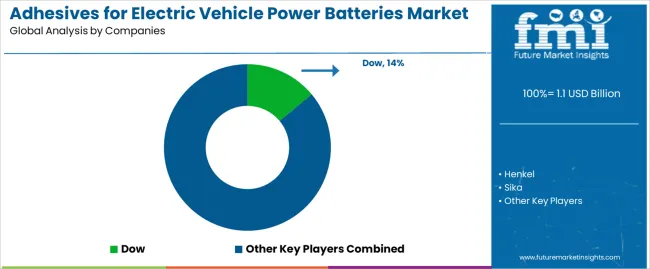

| Key Companies Profiled | Dow; Henkel; Sika; 3M; DuPont; Parker Hannifin; Huntsman; Darbond; Huitian New Material; H.B. Fuller; PPG; Arkema; Wacker Chemie; BASF; Lord Corporation; Momentive; Permabond; Master Bond; Dymax Corporation; Cyberbond |

| Additional Attributes | Dollar sales by product type and distribution channel; Regional demand trends (NA, EU, APAC); Competitive landscape; Direct vs. distributor adoption patterns; Automotive qualification and testing protocols; Advanced thermal interface innovations driving manufacturing enhancement, performance reliability, and technical excellence |

The global adhesives for electric vehicle power batteries market is estimated to be valued at USD 1.1 billion in 2025.

The market size for the adhesives for electric vehicle power batteries market is projected to reach USD 5.9 billion by 2035.

The adhesives for electric vehicle power batteries market is expected to grow at a 18.7% CAGR between 2025 and 2035.

The key product types in adhesives for electric vehicle power batteries market are polyurethane adhesive, epoxy adhesive, organic silicone adhesive, acrylic adhesive and others.

In terms of application, passenger car segment to command 72.0% share in the adhesives for electric vehicle power batteries market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Adhesives And Sealants Market Size and Share Forecast Outlook 2025 to 2035

UV Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Bioadhesives for Packaging Market

Wood Adhesives and Binders Market Size and Share Forecast Outlook 2025 to 2035

Wood Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Skin Adhesives Market

Spray Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Dental Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Medical Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Adhesives Market Growth - Trends & Forecast 2025 to 2035

2K Epoxy Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Silicone Adhesives And Sealants Market Size and Share Forecast Outlook 2025 to 2035

Hot Melt Adhesives Market Growth - Trends & Forecast 2025 to 2035

Footwear Adhesives Market

Aerospace Adhesives and Sealants Market Size and Share Forecast Outlook 2025 to 2035

Anaerobic Adhesives Market

Industrial Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Windscreen Adhesives Market Size and Share Forecast Outlook 2025 to 2035

Automotive Adhesives & Sealants Market Size and Share Forecast Outlook 2025 to 2035

Laminating Adhesives Market Growth - Trends & Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA