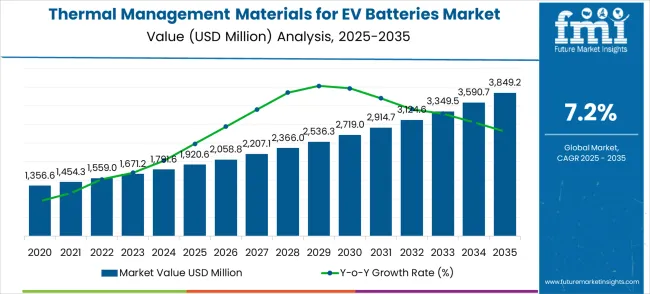

The thermal management materials for EV batteries market is valued at USD 1,920.6 million in 2025 and projected to reach USD 3,849.2 million by 2035, growing at a CAGR of 7.2%. A compound absolute growth analysis provides insights into the incremental revenue accumulated across each block of the forecast period, helping to visualize where the largest contributions occur. From 2020 to 2025, revenue expands from USD 1,356.6 million to USD 1,920.6 million, delivering an absolute gain of USD 564.0 million. This initial phase highlights growing demand for advanced thermal interface materials, phase change solutions, and liquid cooling aids, driven by rising EV adoption and the need to ensure battery safety and performance.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 1,920.6 million |

| Market Forecast Value (2035) | USD 3,849.2 million |

| Forecast CAGR (2025-2035) | 7.2% |

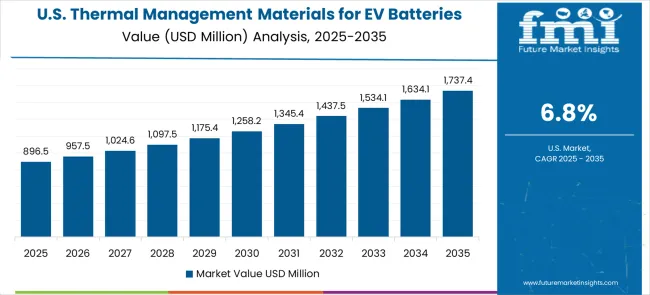

Between 2025 and 2030, revenue climbs from USD 1,920.6 million to USD 2,719.0 million, adding USD 798.4 million in absolute terms. Compound growth analysis shows that this phase contributes more significantly than the earlier block, as large-scale EV production and battery manufacturing investments accelerate. This stage is characterized by increased reliance on advanced composites, adhesives, and cooling gels designed for both performance and cost efficiency. The compounding effect of wider adoption across multiple EV segments including passenger cars, buses, and commercial vehicles further strengthens revenue contribution, making this period a central driver of cumulative value creation.

From 2030 to 2035, the market grows from USD 2,719 million to USD 3,849.2 million, producing an absolute gain of USD 1,130.2 million. This final stage marks the largest contribution, reflecting not only volume expansion but also higher material intensity per vehicle as battery capacities grow. Compound absolute growth analysis shows that later-stage contributions are more substantial, with nearly double the gains of the initial phase. This underlines the structural importance of thermal management in next-generation EV architectures. By 2035, cumulative growth demonstrates how compounding value accelerates, ensuring that the bulk of revenue gains are realized in the second half of the forecast horizon.

Market expansion is being supported by revolutionary advances in electric vehicle battery technology and thermal management solutions, creating unprecedented opportunities for battery safety optimization and performance enhancement. Modern electric vehicles increasingly demand sophisticated thermal management materials that ensure optimal battery operating temperatures, prevent thermal runaway, and provide reliable thermal protection during charging and discharging cycles. The integration of advanced thermal materials with high-performance battery systems enables previously impossible levels of thermal control precision and battery safety assurance.

The growing focus on electric vehicle adoption and battery safety optimization is driving massive demand for thermal management materials from leading automotive manufacturers with proven track records of innovation and battery safety expertise. Automotive companies are investing significantly in thermal management technologies that offer superior battery protection while providing enhanced performance and extended battery life through comprehensive thermal regulation. Battery safety standards are establishing performance benchmarks that favor advanced thermal materials with superior heat dissipation capabilities and enhanced thermal protection features.

The automotive industry's transformation toward electrification is creating substantial demand for intelligent thermal materials capable of delivering professional-grade battery thermal management and safety protection through advanced thermal regulation platforms. The battery technology sector continues to drive innovation in thermal safety applications while maintaining performance reliability and efficiency, leading to development of breakthrough thermal management materials with enhanced heat transfer properties and comprehensive battery protection capabilities.

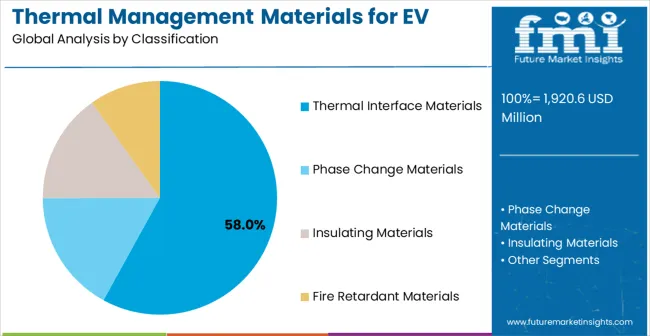

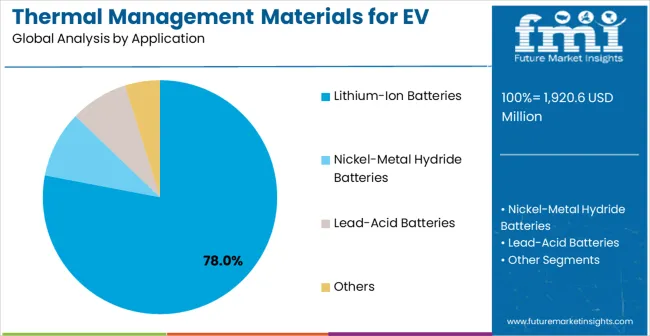

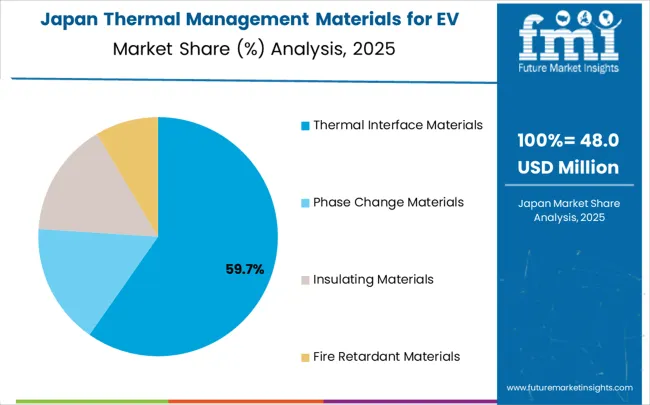

The market is segmented by material type, application, and region. By material type, the market is divided into thermal interface materials, phase change materials, insulating materials, fire retardant materials, and other configurations. Based on application, the market is categorized into lithium-ion batteries, nickel-metal hydride batteries, lead-acid batteries, and other applications. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

Thermal interface materials configurations are projected to account for 58% of the thermal management materials for EV batteries market in 2025. This leading share is supported by explosive adoption of high-performance thermal conductive materials and growing demand for efficient heat transfer solutions in advanced battery systems. Thermal interface materials provide unprecedented heat dissipation capabilities and thermal coupling optimization, making them the preferred choice for automotive manufacturers seeking comprehensive thermal management and enhanced battery performance. The segment benefits from revolutionary advances in thermal conductivity materials, interface technology, and thermal bonding systems that have created entirely new categories of high-performance thermal interface solutions.

Modern thermal interface materials incorporate sophisticated thermal conductive compounds and advanced interface technologies that enable optimal heat transfer, thermal pathway optimization, and seamless integration with battery cooling systems while ensuring long-term reliability and thermal stability. These innovations have transformed battery thermal management while providing superior heat dissipation capabilities for thermal regulation and battery temperature control through continuous thermal transfer and intelligent thermal coupling. The automotive battery market particularly drives demand for thermal interface solutions, as these applications require high thermal conductivity and reliable thermal bonding to deliver superior battery performance and thermal safety optimization.

Lithium-ion batteries applications are expected to represent 78% of thermal management materials for EV batteries demand in 2025. This dominant share reflects the massive automotive market for lithium-ion battery technology and growing investment in advanced EV battery systems. Lithium-ion battery thermal management materials enable optimal battery performance through sophisticated thermal regulation, thermal safety protection, and comprehensive temperature control systems. The segment benefits from breakthrough advances in lithium-ion battery technology that creates sophisticated thermal management requirements accessible and critical for battery safety and performance optimization.

The global electric vehicle revolution drives significant demand for lithium-ion battery thermal management materials that provide exceptional thermal regulation capabilities and intelligent temperature control for automotive battery systems and energy storage applications. These applications require thermal materials with superior heat management abilities and comprehensive thermal safety integration to ensure reliable battery operation and effective thermal protection capabilities. The segment benefits from growing automotive investment in lithium-ion battery technologies and increasing adoption of advanced battery systems and thermal safety solutions.

Automotive and energy storage sectors contribute substantially to market growth as manufacturers implement thermal management materials in lithium-ion battery systems and comprehensive thermal safety strategies. The growing adoption of electric vehicles creates opportunities for specialized thermal management materials designed for lithium-ion battery protection and comprehensive battery thermal optimization. Additionally, the trend toward battery electrification drives demand for intelligent thermal materials that enable comprehensive lithium-ion battery management through integrated thermal regulation, safety protection, and performance optimization capabilities.

The thermal management materials for EV batteries market is advancing steadily due to revolutionary electric vehicle technology development and unprecedented adoption of advanced battery thermal management across all automotive and energy storage segments. However, the market faces challenges including high material costs, need for robust thermal performance validation, and varying automotive requirements across different battery applications. Automotive safety standards and thermal regulations continue to influence product development and market adoption patterns.

The revolutionary advances in thermal conductivity materials, heat dissipation systems, and thermal interface technologies are enabling unprecedented battery thermal management while maintaining automotive reliability and thermal safety standards. Advanced thermal material architectures and battery-specific thermal systems provide superior heat transfer and thermal regulation capabilities, enabling dynamic thermal management and optimized battery safety protection. These technologies are particularly valuable for automotive applications that require sophisticated thermal control, accurate temperature regulation, and reliable thermal safety management.

Modern thermal management material manufacturers are implementing breakthrough ecosystem integration and comprehensive thermal system development that enables seamless battery thermal integration while supporting holistic battery optimization and thermal safety enhancement. Advanced thermal architectures enable unified thermal management, battery protection, and thermal regulation while ensuring automotive reliability and thermal performance requirements.

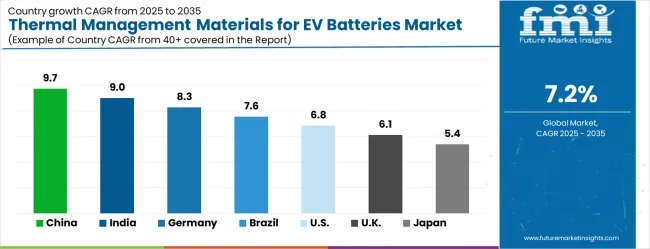

| Country | CAGR (2025-2035) |

|---|---|

| China | 9.7% |

| India | 9.0% |

| Germany | 8.3% |

| Brazil | 7.6% |

| United States | 6.8% |

| United Kingdom | 6.1% |

| Japan | 5.4% |

The thermal management materials for EV batteries market is experiencing strong growth, with China leading at an impressive 9.7% CAGR through 2035, driven by massive electric vehicle production and rapidly expanding battery manufacturing infrastructure. India follows at 9.0%, supported by enormous electric mobility potential and increasing automotive electrification investment. Germany records exceptional growth at 8.3%, emphasizing automotive innovation excellence and advanced thermal technology development. Brazil grows significantly at 7.6%, benefiting from expanding electric vehicle adoption and automotive manufacturing development. The United States shows strong growth at 6.8%, focusing on automotive technology leadership and advanced battery applications. The United Kingdom maintains substantial expansion at 6.1%, supported by automotive innovation advancement. Japan demonstrates steady growth at 5.4%, emphasizing precision thermal technology and automotive excellence.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

Thermal management materials for EV batteries in China is projected to exhibit the highest growth rate with a CAGR of 9.7% through 2035, driven by the country's position as a global electric vehicle manufacturing powerhouse and massive domestic investment in battery production infrastructure. The extensive EV manufacturing capabilities and unprecedented investment in battery thermal technology are creating extraordinary opportunities for thermal management material adoption. Major automotive and battery companies are developing world-leading thermal management capabilities to serve both the enormous domestic EV market and global automotive expansion while establishing leadership in battery thermal management applications.

Thermal management materials for EV batteries in India is expanding at a CAGR of 9.0%, supported by the country's massive electric mobility potential and rapidly accelerating automotive electrification across all vehicle segments and manufacturing operations. The enormous automotive manufacturing growth and increasing electric vehicle adoption are driving extraordinary thermal management material demand potential. Automotive technology companies are leveraging India's vast manufacturing market while developing cost-effective thermal solutions to capture emerging opportunities in electric vehicle production and battery thermal management applications.

Demand for thermal management materials for EV batteries in Germany is projected to grow at a CAGR of 8.3%, supported by the country's leadership in automotive innovation and advanced thermal technology development across automotive, chemical, and materials sectors. German thermal technology companies are implementing sophisticated thermal material development that meets stringent automotive standards and performance requirements while delivering superior thermal properties and system reliability. The market is characterized by focus on automotive innovation, advanced technology integration, and compliance with comprehensive automotive safety and thermal performance regulations.

Thermal management materials for EV batteries in Brazil is growing at a CAGR of 7.6%, driven by expanding electric vehicle adoption and increasing automotive manufacturing development across urban and emerging automotive market segments. The growing electric mobility awareness and increasing automotive production infrastructure are creating substantial opportunities for thermal management market development. Automotive technology companies are adapting thermal materials to support growing electric vehicle demand and automotive manufacturing while maintaining cost accessibility and local market relevance.

Thermal management materials for EV batteries in the United States is expanding at a CAGR of 6.8%, driven by the country's automotive technology leadership and automotive market demand for advanced thermal management products and cutting-edge battery technologies. The sophisticated automotive infrastructure and automotive willingness to invest in advanced thermal systems create enormous demand for high-performance automotive thermal solutions. The market benefits from breakthrough thermal technology research and automotive-grade thermal market segments across automotive, aerospace, and industrial applications.

Demand for thermal management materials for EV batteries in the United Kingdom is projected to grow at a CAGR of 6.1%, supported by ongoing automotive innovation advancement and increasing automotive demand for intelligent thermal products in electric vehicle and automotive applications. Thermal technology companies are investing in automotive thermal development that provides advanced functionality while meeting automotive reliability requirements and regulatory compliance for automotive applications. The market is characterized by focus on automotive innovation, thermal reliability protection, and advanced technology integration across diverse automotive segments.

Automotive innovation advancement and thermal technology innovation programs are supporting adoption of advanced thermal management systems that meet contemporary reliability and functionality standards for automotive applications. Innovation enhancement initiatives and thermal technology excellence programs are creating demand for sophisticated thermal products that provide superior automotive thermal performance and reliability compliance verification.

Thermal management materials for EV batteries in Japan is expanding at a CAGR of 5.4%, driven by the country's emphasis on thermal technology excellence and precision automotive development across automotive, electronics, and materials sectors. Japanese thermal technology companies are developing sophisticated thermal applications that incorporate precision engineering and automotive optimization principles. The market benefits from focus on thermal precision, technology reliability, and continuous innovation in automotive thermal technology and battery thermal management integration.

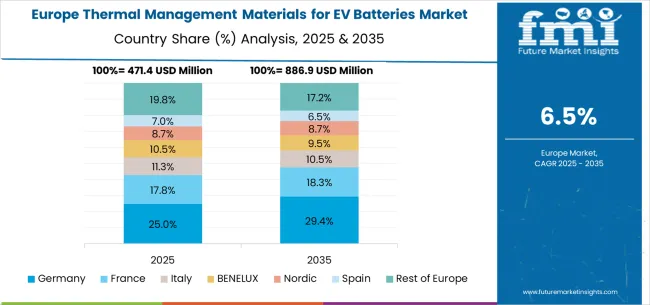

The thermal management materials for EV batteries market in Europe is projected to grow from USD 513.8 million in 2025 to USD 1,030.1 million by 2035, registering a CAGR of 7.2% over the forecast period. Germany is expected to maintain its leadership with a 35.4% share in 2025, supported by its advanced automotive industry and thermal technology excellence. The United Kingdom follows with 24.1% market share, driven by automotive innovation advancement and thermal technology development. France holds 18.2% of the European market, benefiting from automotive technology expansion and thermal materials industry development. Italy and Spain collectively represent 14.3% of regional demand, with growing focus on automotive development and thermal technology applications. The Rest of Europe region accounts for 8.0% of the market, supported by thermal technology development in Eastern European countries and Nordic automotive innovation advancement.

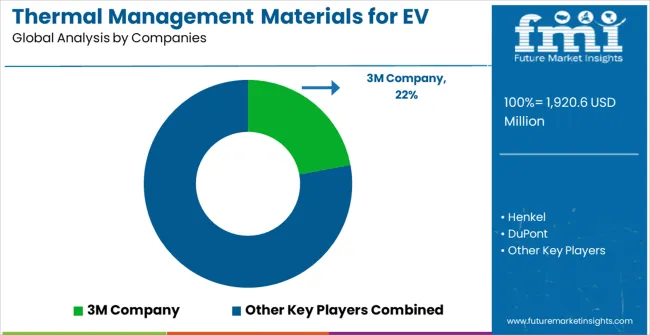

The thermal management materials for EV batteries market is defined by intense competition among materials giants, innovative thermal technology companies, and established automotive suppliers. Companies are investing significantly in thermal materials research and development, advanced product design, thermal performance validation, and automotive ecosystem integration to deliver revolutionary, reliable, and automotive-compatible thermal management products. Strategic partnerships, technological breakthrough, and rapid automotive market expansion are central to achieving market leadership and automotive adoption.

3M Company, operating globally, offers comprehensive thermal management solutions with focus on automotive and industrial applications, thermal performance optimization, and seamless automotive integration across thermal materials, thermal systems, and automotive services applications. Henkel, technology leader, provides advanced thermal materials with emphasis on automotive reliability, thermal performance, and intelligent thermal management capabilities. DuPont delivers innovative thermal materials with focus on comprehensive automotive integration and high-performance thermal applications. Parker Hannifin offers precision thermal systems with advanced thermal management and automotive-grade performance capabilities.

Elkem provides specialized thermal materials with emphasis on automotive and industrial applications. Aspen Aerogels delivers advanced thermal insulation with sophisticated thermal performance and automotive optimization capabilities. Zircotec offers comprehensive thermal barrier solutions with thermal management integration and automotive thermal services. GrafTech provides thermal management materials with advanced thermal integration and automotive thermal systems.

Saint-Gobain, Polymer Science, JBC Technologies, Alpha Engineered Composites, Asahi Kasei, XD Thermal, Hanon Systems, and Valeo offer specialized thermal management expertise, innovative product development, and technical advancement across thermal materials and automotive thermal networks.

The thermal management materials for EV batteries market underpins electric vehicle revolution, automotive safety advancement, battery technology democratization, and automotive thermal optimization evolution. With accelerating EV adoption, automotive thermal technology expansion, and battery safety requirements, the sector faces pressure to balance innovation velocity, automotive thermal protection, and thermal performance validation. Coordinated contributions from governments, industry bodies, OEMs/technology integrators, suppliers, and investors will accelerate the transition toward beneficial, reliable, and universally accessible thermal management material ecosystems.

| Item | Value |

|---|---|

| Quantitative Units | USD 1,920.6 million |

| Material Type | Thermal Interface Materials, Phase Change Materials, Insulating Materials, Fire Retardant Materials |

| Application | Lithium-Ion Batteries, Nickel-Metal Hydride Batteries, Lead-Acid Batteries, Others |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Germany, India, China, United Kingdom, Japan, Brazil, and other 40+ countries |

| Key Companies Profiled | 3M Company, Henkel, DuPont, Parker Hannifin, Elkem, Aspen Aerogels, Zircotec, GrafTech, Saint-Gobain, Polymer Science, JBC Technologies, Alpha Engineered Composites, Asahi Kasei, XD Thermal, Hanon Systems, Valeo |

The global thermal management materials for EV batteries market is estimated to be valued at USD 1,920.6 million in 2025.

The market size for the thermal management materials for EV batteries market is projected to reach USD 3,849.2 million by 2035.

The thermal management materials for EV batteries market is expected to grow at a 7.2% CAGR between 2025 and 2035.

The key product types in thermal management materials for EV batteries market are thermal interface materials, phase change materials, insulating materials and fire retardant materials.

In terms of application, lithium-ion batteries segment to command 78.0% share in the thermal management materials for EV batteries market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Thermal Interface Material Market Size and Share Forecast Outlook 2025 to 2035

Thermal Impulse Sealers Market Size and Share Forecast Outlook 2025 to 2035

Thermal Inkjet Printer Market Size and Share Forecast Outlook 2025 to 2035

Thermal Insulation Material Market Size and Share Forecast Outlook 2025 to 2035

Thermal-Wet Gas Abatement System Market Size and Share Forecast Outlook 2025 to 2035

Thermal Spray Service Market Size and Share Forecast Outlook 2025 to 2035

Thermal Barrier Coatings Market Size and Share Forecast Outlook 2025 to 2035

Thermal Energy Harvesting Market Size and Share Forecast Outlook 2025 to 2035

Thermally Stable Antiscalant Market Size and Share Forecast Outlook 2025 to 2035

Thermal Spa and Wellness Market Size and Share Forecast Outlook 2025 to 2035

Thermal Mixing Valves Market Size and Share Forecast Outlook 2025 to 2035

Thermal Inkjet Inks Market Size and Share Forecast Outlook 2025 to 2035

Thermal Liner Market Analysis Size and Share Forecast Outlook 2025 to 2035

Thermal Insulation Coating Market Size and Share Forecast Outlook 2025 to 2035

Thermal Spray Equipment Market Size and Share Forecast Outlook 2025 to 2035

Thermal Spring Market Size and Share Forecast Outlook 2025 to 2035

Thermal Printing Market Analysis - Size, Share & Forecast 2025 to 2035

Thermal Transfer Roll Market Size and Share Forecast Outlook 2025 to 2035

Thermal Transfer Ribbon Market Growth - Demand & Forecast 2025 to 2035

Thermal Tapes Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA