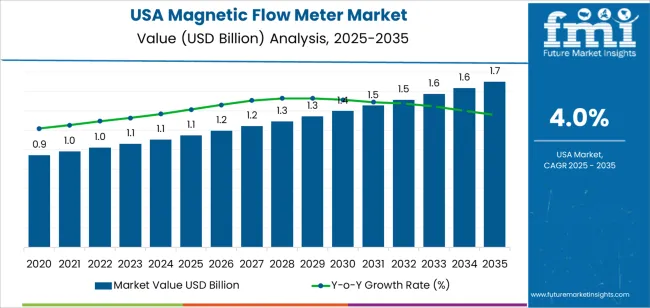

The demand for magnetic flow meter in USA is expected to grow from USD 1.1 billion in 2025 to USD 1.6 billion by 2035, reflecting a CAGR of 4%. The growth in the magnetic flow meter industry is driven by several factors, including the rising focus on regulatory compliance in water treatment facilities, the rising demand for precision measurement in chemical processing plants, and the growing trend of predictive maintenance over traditional reactive maintenance approaches. With industrial operators becoming more efficiency-focused, magnetic flow meter services provide an attractive alternative to mechanical flow measurement systems, allowing facilities to monitor critical processes with electromagnetic technology without the long-term maintenance commitments.

The growth is also driven by advancements in digital communication protocols, increased operator comfort with electromagnetic measurement technologies, and the broadening of applications from basic water monitoring to comprehensive chemical processing applications. Additionally, the rising acceptance of Industry 4.0 integration and the expansion of pharmaceutical manufacturing will further support the sector growth. The rising focus on environmental compliance and cost-efficient measurement among American manufacturers also adds to the demand for magnetic flow meters, which offer both precision and reliability without the environmental impact of mechanical alternatives requiring frequent recalibration.

The sector share erosion or gain analysis for magnetic flow meter in USA reveals that the sector is expected to experience significant sector share gains over the forecast period from 2025 to 2035. The sector will grow from USD 1.1 billion in 2025 to USD 1.6 billion in 2035, reflecting an increase of USD 0.5 billion over the next decade. This growth indicates a strong expansion of the magnetic flow meter sector, with more facilities opting for electromagnetic measurement services rather than traditional mechanical flow measurement purchases.

From 2025 to 2030, the sector will grow from USD 1.1 billion to USD 1.3 billion, contributing USD 0.2 billion in growth. This phase will see an initial gain in sector share as more operators adopt the electromagnetic measurement model, driven by a growing interest in regulatory compliance and cost-effective alternatives to mechanical flow meters. The demand for pharmaceutical-grade flow measurement, particularly for sterile processing applications in biomanufacturing facilities, will contribute significantly to this growth.

From 2030 to 2035, the sector will expand further from USD 1.3 billion to USD 1.6 billion, contributing USD 0.3 billion in growth. This phase will see stronger sector share gains as the model becomes more mainstream, with more facilities choosing to implement electromagnetic flow measurement for everyday process monitoring, chemical processing applications, and environmental compliance requirements. Additionally, with more equipment manufacturers and system integrators adopting the electromagnetic measurement model, the sector is expected to capture a larger share of the overall industrial instrumentation industry, particularly among efficiency-focused and environmentally conscious operators. The strong growth momentum in the latter half of the forecast period reflects the maturation of the sector, where electromagnetic flow measurement services become an integrated part of mainstream industrial operations in USA.

| Metric | Value |

|---|---|

| Industry Sales Value (2025) | USD 1.1 billion |

| Industry Forecast Value (2035) | USD 1.6 billion |

| Industry Forecast CAGR (2025-2035) | 4% |

Demand for magnetic flow meter in USA is rising as industrial operators increasingly adopt precision over convenience, driven by regulatory compliance requirements and the desire for measurement accuracy at lower operational cost. Many facilities, especially in pharmaceutical and chemical processing sectors, prefer implementing electromagnetic measurement for critical processes or continuous monitoring instead of installing instruments that may be used only occasionally or require frequent maintenance. Digital platforms offering condition monitoring capabilities, remote diagnostic systems and integrated measurement solutions support this shift by providing reliability, real-time data access, and operational flexibility. Additionally, equipment manufacturers and system integrators are collaborating with flow measurement services to extend instrument lifecycles and enhance process optimization, which further fuels adoption. Industry data show that the USA magnetic flow meter sector is valued at approximately USD 1.1 billion and is expected to grow steadily.

Another key factor is the convergence of manufacturing trends, technological advancement and the regulatory compliance mindset. Operators increasingly seek to optimize processes, follow lean manufacturing methodologies and minimize measurement uncertainty, which make electromagnetic measurement approaches attractive. Advances in digital communication protocols, condition monitoring systems and intelligent diagnostic platforms reduce complexity in flow measurement processes and improve service reliability, which encourages broader acceptance. Nonetheless, challenges remain: managing installation requirements across multiple pipe configurations, ensuring measurement stability in demanding industrial environments, and maintaining operational profitability amid specialized application requirements and calibration costs. Despite these headwinds, as operator behavior shifts toward precision and reliability, the demand for magnetic flow meter in USA is projected to continue its upward trajectory.

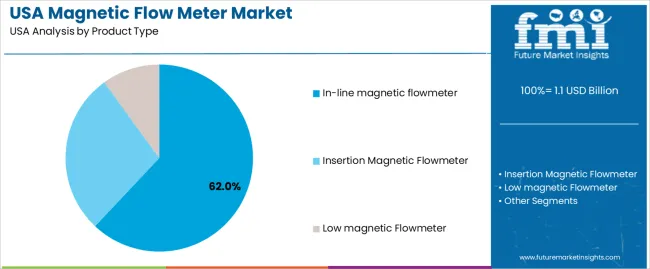

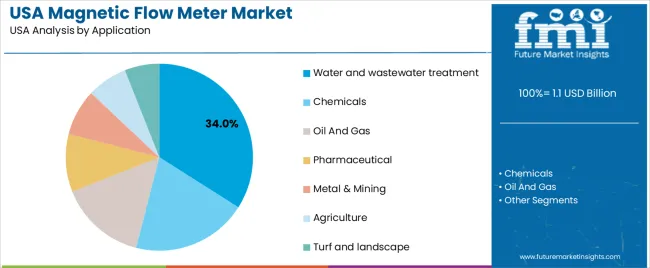

The demand for magnetic flow meter services in USA is primarily driven by product type and application. The leading product type is in-line magnetic flow meters, which holds 62% of the sector share, while water and wastewater is the dominant application segment, accounting for 34% of the demand. Magnetic flow meter has gained significant traction in both the industrial and municipal sectors due to its precision, reliability, and the growing trend of process automation. The electromagnetic measurement approach allows facilities and municipalities to access high-precision, maintenance-free flow monitoring without the need for mechanical components, which appeals to various customer bases.

In-line magnetic flow meters is the leading product type in the magnetic flow meter sector, capturing 62% of the sector share. The rising popularity of integrated measurement solutions for applications such as chemical processing, pharmaceutical manufacturing, and water treatment has driven demand for these devices in the electromagnetic measurement space. Installing in-line magnetic flow meters allows facilities to access high-precision, bidirectional flow measurement for critical processes without the significant cost of installing complex mechanical measurement systems outright.

In USA, where operational efficiency is prominent, electromagnetic measurement services for in-line applications have become an attractive alternative for companies seeking reliable, accurate process monitoring. Installing in-line magnetic flow meters for chemical processing, pharmaceutical manufacturing, or water treatment applications also supports the growing trend of process automation, as these instruments are often integrated only a few times with existing control systems. As operators continue to prioritize precision and reliability in measurement choices, the demand for in-line magnetic flow meter installations is expected to remain strong, positioning it as a dominant category in the electromagnetic measurement sector.

Water and wastewater is the leading application segment for magnetic flow meter in USA, capturing 34% of the sector share. In the municipal and industrial water treatment space, organizations, particularly those in the environmental services sector, are increasingly turning to electromagnetic measurement services for flow monitoring, process control, and regulatory compliance applications. Municipal clients benefit from magnetic flow meter services by ensuring accurate measurement of treatment processes for their operations, without the need for large upfront investments or concerns about mechanical component maintenance.

Electromagnetic measurement services also offer municipalities the flexibility to upgrade or refresh their monitoring capabilities seasonally or for specific regulatory requirements, which can enhance the operational efficiency of their treatment facilities without the financial burden of purchasing and maintaining large inventories of mechanical flow meters. Additionally, the growing focus on environmental compliance and reducing operational waste has driven many organizations to seek electromagnetic measurement solutions, which align with their environmental goals. As the municipal sector continues to adopt flexible, reliable, and precision-focused operational practices, the demand for magnetic flow meter services is expected to grow, further solidifying its position as the dominant segment in the sector.

Demand for magnetic flow meter in the USA is rising as operators increasingly prioritise precision over convenience, driven by regulatory compliance requirements, rapid technological advancement and measurement accuracy enabled industrial platforms. Growth stems from predictive maintenance adoption, continuous process monitoring capabilities and efficiency driven process improvement trends. However, operational challenges like installation complexity, specialized application requirements and operator reluctance to change established practices are restraining expansion. Key trends include interactive condition monitoring capabilities, IoT integrated measurement systems and the shift of electromagnetic measurement services into mainstream industrial applications rather than just specialized or critical process monitoring.

Several factors support growth in the USA sector. First, efficiency-focused generations of plant operators demonstrate strong interest in accuracy, process optimization and cost efficient access to reliable measurement technology, driving electromagnetic measurement demand. Second, the proliferation of digital communication protocols, Industry 4.0 infrastructure and predictive maintenance systems simplifies flow measurement logistics and enhances operational convenience. Third, regulatory compliance imperatives such as reducing process variability and extending equipment lifecycles boost electromagnetic measurement adoption among compliance aware operators. Fourth, environmental monitoring requirements and process optimization initiatives continue to fuel demand for higher precision instruments on an implementation basis rather than purchase basis.

Despite momentum, several restraints inhibit growth. Operator concerns about installation complexity, calibration requirements and performance of electromagnetic instruments may limit adoption among more traditional facilities. The cost structure of electromagnetic measurement approaches, including specialized materials, installation expertise and system integration can reduce attractiveness and raise implementation fees, making the offering less compelling versus mechanical alternatives for some segments. Additionally, the electromagnetic measurement category remains specialized compared to total flow measurement spend, and many operators continue to prefer mechanical solutions. Operational complexity, including pipe modification requirements and electrical infrastructure needs, adds risk for service providers.

Major trends include the move from critical process measurement to broader industrial monitoring services covering everyday applications, chemical processing and environmental compliance. There is rising integration of technology such as condition monitoring, IoT connectivity and predictive diagnostic capabilities, improving user experience and reducing maintenance related service calls. Digital communication protocol adoption is emerging, enabling operators to implement electromagnetic measurement alongside other process instruments and expanding the sector beyond traditional flow monitoring only. Equipment suppliers and measurement service providers are also consolidating with traditional instrumentation companies, offering hybrid mechanical and electromagnetic measurement approaches, and promoting precision measurement credentials to appeal to efficiency conscious operators.

The demand for magnetic flow meter in USA is growing as operators increasingly seek precise, reliable, and maintenance-efficient options for process monitoring. Magnetic flow meter services allow facilities to implement high-accuracy, non-intrusive flow measurement for a fraction of the installation cost, reducing the need for frequent equipment purchases and promoting more efficient operational practices. This model is particularly attractive to operators who want access to a wide variety of measurement technologies without the commitment of long-term equipment ownership. Factors driving this demand include the rise in efficiency-consciousness, the popularity of precision-driven operational practices, and the growing trend of shared instrumentation platforms. Additionally, the rising focus on mechanical measurement systems' maintenance requirements is encouraging operators to seek more reliable alternatives, like electromagnetic measurement.

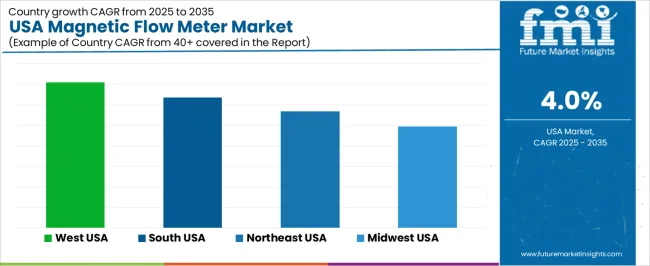

Regional demand varies depending on factors such as industrial concentration, technological advancement, and access to specialized services. The West leads in demand, supported by higher technology adoption rates and efficiency-focused populations, while the South, Northeast, and Midwest show steady adoption driven by shifting operator behavior towards more precise and maintenance-efficient measurement choices. This analysis explores the factors shaping the demand for magnetic flow meter across the USA.

| Region | CAGR (2025-2035) |

|---|---|

| West USA | 7.1% |

| South USA | 6.4% |

| Northeast USA | 5.7% |

| Midwest USA | 4.9% |

The West region leads the USA in the demand for magnetic flow meter with a CAGR of 7.1%. The region's large industrial concentration, particularly in states like California, Washington, and Oregon, is highly attuned to precision measurement trends and process optimization, both of which drive the demand for electromagnetic measurement services. California, known for its technology-conscious operators, is a key area where the demand for reliable and maintenance-efficient flow measurement is growing.

The West also has a higher concentration of technology-focused individuals who are comfortable with digital platforms and precision instrumentation approaches. With the region's focus on operational excellence, magnetic flow meter offers a viable alternative to mechanical measurement systems, enabling operators to access high-precision instruments for various applications without the maintenance cost of traditional equipment acquisition. As the demand for versatile and reliable measurement options continues to rise in the West, the region remains the leading area for electromagnetic measurement services.

The South shows strong demand for magnetic flow meter with a CAGR of 6.4%. The region's rising focus on operational efficiency, combined with a growing interest in process optimization, contributes to the rising adoption of electromagnetic measurement services. States like Texas, Louisiana, and Georgia have large petrochemical and manufacturing populations and emerging precision measurement sectors, making them key drivers of demand for reliable and maintenance-efficient measurement solutions.

The growing industrial population in the South, with its higher operational efficiency focus and rising awareness of the maintenance impact of mechanical measurement systems, further supports the demand for magnetic flow meter. The convenience factor, coupled with the trend toward implementing rather than purchasing, is appealing to many operators in the South. With the rise of precision manufacturing practices and shifting operator preferences, the South is expected to continue to see strong demand for electromagnetic measurement services.

The Northeast demonstrates steady demand for magnetic flow meter with a CAGR of 5.7%. The region, home to major industrial hubs like Boston and Philadelphia, has a high concentration of precision-conscious operators who are increasingly turning to electromagnetic measurement services for high-accuracy, reliable process monitoring. The Northeast's focus on operational efficiency, combined with growing quality awareness, is driving the adoption of precision measurement solutions.

In addition, the operational complexity of major industrial facilities in cities like Boston makes electromagnetic measurement an attractive option for facilities seeking variety in their process monitoring without the hefty maintenance requirements of purchasing expensive mechanical equipment. While growth is steady compared to the West and South, the Northeast's precision-forward industrial population and strong manufacturing infrastructure ensure that the demand for magnetic flow meter remains a key part of the measurement landscape.

The Midwest shows moderate growth in the demand for magnetic flow meter with a CAGR of 4.9%. While the region may not be as technology-focused as the West or Northeast, there is a growing interest in more reliable and maintenance-efficient measurement choices. States like Illinois, Ohio, and Michigan are seeing a rising number of operators turning to electromagnetic measurement services as they seek alternatives to mechanical measurement systems and want to reduce their equipment maintenance requirements.

The Midwest's steady adoption of electromagnetic measurement services is driven by the growing desire for operational convenience and the availability of more measurement platforms that cater to diverse industrial needs. As the awareness of the maintenance benefits of electromagnetic measurement rises and operators seek more reliable, precision measurement solutions, demand for these services will continue to grow in the Midwest, albeit at a slower pace compared to other regions.

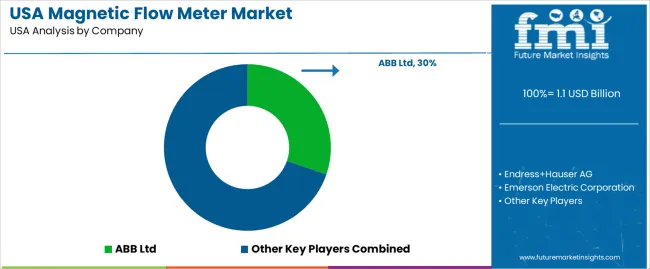

The magnetic flow meter industry in the United States is growing as operators increasingly seek more precise and reliable flow measurement options. Companies such as ABB Ltd (holding approximately 30.3% sector share), Endress+Hauser AG, Emerson Electric Co, Siemens AG, and Yokogawa Electric are key players in this industry, providing facilities with access to high-accuracy, maintenance-free flow measurement technology for process monitoring applications. The rise of process automation, growing efficiency awareness, and the desire for measurement precision without the commitment of mechanical equipment ownership are all driving factors behind the sector's expansion.

Competition in the magnetic flow meter industry is centered around measurement accuracy, operational reliability, and implementation flexibility. Companies focus on offering a wide selection of electromagnetic measurement technologies, from chemical processing applications to water treatment monitoring, and expanding their communication protocol options to cater to a broader facility base. Another competitive advantage is operational convenience, with many companies offering condition monitoring capabilities, predictive maintenance features, and seamless integration options. Some players are also promoting efficiency-focused practices, such as the use of advanced diagnostic capabilities and the promotion of reliable measurement approaches. Implementation materials typically highlight measurement accuracy, convenience of electromagnetic measurement processes, and the reliability of access to high-precision flow monitoring technology. By aligning their offerings with the growing demand for precision, reliability, and operational efficiency, these companies are positioning themselves to lead the USA magnetic flow meter industry.

| Items | Details |

|---|---|

| Quantitative Units | USD Billion |

| Regions Covered | USA |

| Product Type | In-line magnetic flow meters, Insertion magnetic flow meters, Low magnetic flow meters |

| Components | Transmitter, Magnetic coil, Sensing Element, Non-Magnetic |

| Technology | Hart, Modbus, Profibus, Fieldbus |

| Application | Water and Wastewater, Chemicals, Oil and Gas, Pharmacy, Metal and Mining, Agriculture, Turf and Ornamental |

| Key Companies Profiled | ABB Ltd, Endress+Hauser AG, Emerson Electric Co, Siemens AG, Yokogawa Electric |

| Additional Attributes | Dollar sales by product type and application define the sector, with rising USA demand for magnetic flow meter services across industrial and municipal segments, driven by precision measurement needs, reliability, digital communication advances, and evolving electromagnetic monitoring technologies. |

The demand for magnetic flow meter in USA is estimated to be valued at USD 1.1 billion in 2025.

The market size for the magnetic flow meter in USA is projected to reach USD 1.7 billion by 2035.

The demand for magnetic flow meter in USA is expected to grow at a 4.0% CAGR between 2025 and 2035.

The key product types in magnetic flow meter in USA are in-line magnetic flowmeter, insertion magnetic flowmeter and low magnetic flowmeter.

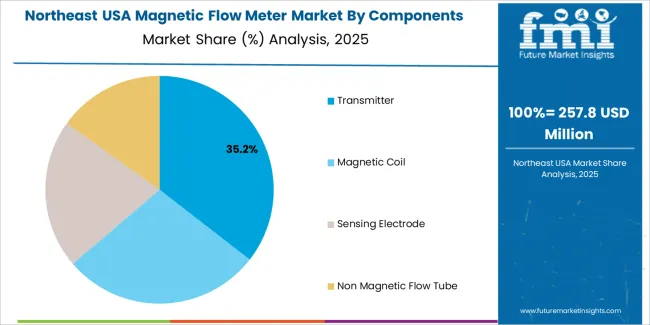

In terms of components, transmitter segment is expected to command 36.0% share in the magnetic flow meter in USA in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Magnetic Flowmeter Market Size and Share Forecast Outlook 2025 to 2035

Magnetic Flow Meter Market Analysis by Product Type, Components, Technology, Application and Region - Trends, Growth & Forecast 2025 to 2035

Flow Meter Devices Market Size, Share, and Forecast 2025 to 2035

Flow Meters Market Growth - Trends & Forecast 2025 to 2035

Flow Cytometer Market

Melt Flow Meter Market Size and Share Forecast Outlook 2025 to 2035

Steam Flow Meter Market

Ultrasonic Flowmeters Market Trends – Growth & Forecast 2025 to 2035

Ultrasonic Flow Meter Market

High Purity Flow Meter Market Size and Share Forecast Outlook 2025 to 2035

Intelligent Flow Meter Market Size and Share Forecast Outlook 2025 to 2035

Automotive Air Flow Meter Market Size and Share Forecast Outlook 2025 to 2035

High Purity Gas Flow Meter Market Size and Share Forecast Outlook 2025 to 2035

Subsea Multiphase Flowmeter Market Size and Share Forecast Outlook 2025 to 2035

Demand for Bone Densitometers in USA Size and Share Forecast Outlook 2025 to 2035

Demand for Open Cross Flow Cooling Tower in USA Size and Share Forecast Outlook 2025 to 2035

Demand for Magnetic Material Magnetization and Testing Equipment in USA Size and Share Forecast Outlook 2025 to 2035

Magnetic Absorption Data Line Market Size and Share Forecast Outlook 2025 to 2035

Magnetic Material Magnetization and Testing Equipment Market Size and Share Forecast Outlook 2025 to 2035

Magnetic Coupler Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA