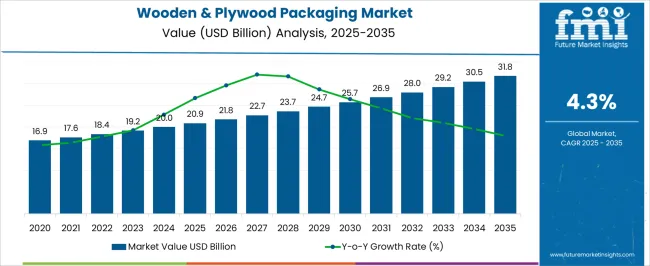

The Wooden & Plywood Packaging Market is estimated to be valued at USD 20.9 billion in 2025 and is projected to reach USD 31.8 billion by 2035, registering a compound annual growth rate (CAGR) of 4.3% over the forecast period.

| Metric | Value |

|---|---|

| Wooden & Plywood Packaging Market Estimated Value in (2025 E) | USD 20.9 billion |

| Wooden & Plywood Packaging Market Forecast Value in (2035 F) | USD 31.8 billion |

| Forecast CAGR (2025 to 2035) | 4.3% |

The wooden and plywood packaging market is progressing steadily, supported by the increasing demand for durable and sustainable packaging solutions across global industries. Industry reports and trade publications have emphasized the importance of wood-based packaging for heavy-duty applications, given its strength, reusability, and recyclability. Rising international trade volumes and logistics expansion have further driven the adoption of wood and plywood packaging, particularly for products requiring stability and protection during transit.

Regulatory frameworks encouraging sustainable and recyclable packaging have strengthened the role of wood-based solutions, while advancements in treatment methods have enhanced resistance to pests and moisture. Food and beverage exports, along with pharmaceutical and industrial goods shipments, have remained key demand drivers.

Looking ahead, growth will be shaped by global supply chain expansion, stricter sustainability standards, and ongoing investments in lightweight yet durable wood and plywood packaging products. Segmental leadership is expected to remain concentrated in hardwood materials, pallets as the dominant product type, and food as the primary end-user category.

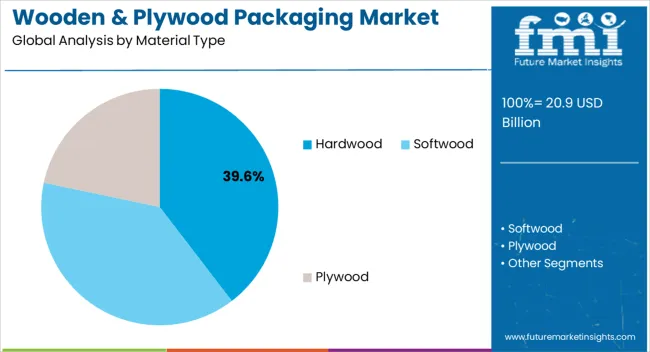

The Hardwood segment is projected to hold 39.6% of the wooden and plywood packaging market revenue in 2025, maintaining its position as the leading material type. Growth has been driven by the superior durability, load-bearing capacity, and long service life offered by hardwood compared to softwood alternatives. Industries engaged in heavy-duty exports and logistics have preferred hardwood packaging for its resilience under mechanical stress and ability to protect high-value goods during transportation.

Additionally, hardwood’s resistance to wear has made it a cost-efficient option for repeated use in global supply chains. International trade regulations requiring strong, pest-resistant packaging have further reinforced the adoption of hardwood.

As export-oriented economies continue to expand, hardwood packaging is expected to remain in demand for sectors requiring robust and compliant transport solutions.

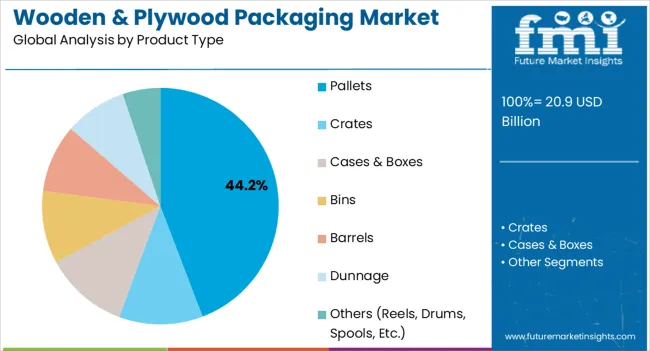

The Pallets segment is forecasted to account for 44.2% of the wooden and plywood packaging market revenue in 2025, leading the product category. The segment’s dominance is supported by the widespread use of wooden pallets in warehousing, logistics, and cross-border trade. Pallets have been preferred for their compatibility with automated handling systems, ability to optimize storage space, and facilitation of efficient loading and unloading processes.

Industry supply chain studies have underscored that wooden pallets provide a cost-effective balance between strength and reusability, driving their adoption in large-scale distribution networks. The standardization of pallet dimensions has further enabled smooth global trade operations.

With increasing e-commerce activity and global trade expansion, the pallets segment is expected to continue as the backbone of wooden packaging, benefiting from its versatility and operational efficiency.

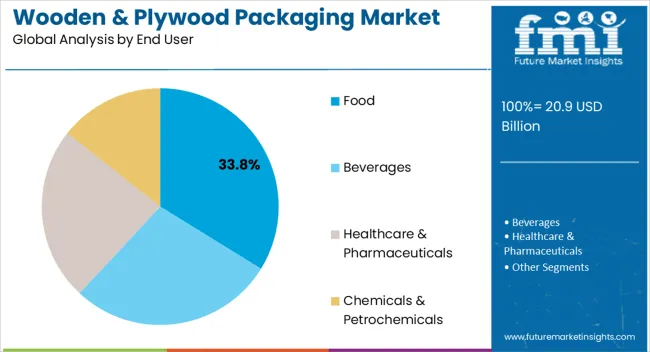

The Food segment is projected to contribute 33.8% of the wooden and plywood packaging market revenue in 2025, making it the largest end-user segment. Demand growth has been driven by the reliance of food exporters on wooden crates and pallets to ensure safe, hygienic, and stable packaging during long-distance transport.

The segment has benefited from rising global consumption of processed and packaged foods, alongside stricter international standards for safe and compliant food transportation. Plywood and hardwood packaging have been valued in the food sector for their ability to withstand variable climatic conditions and safeguard against product spoilage.

Trade data and industry insights indicate that food shipments represent one of the largest uses of wooden packaging in global logistics. As international food exports continue to expand, particularly in fresh produce and processed food categories, the food segment is expected to remain the leading consumer of wooden and plywood packaging solutions.

The global demand for wooden & plywood packaging increased at a CAGR of 2.2% during the forecast period between 2020 and 2025, reaching a total of USD 31.8 billion in 2035.

According to Future Market Insights, a market research and competitive intelligence provider, the wooden & plywood packaging market was valued at USD 20.9 billion in 2025.

The escalating global concern over plastic pollution and its adverse impact on the environment has prompted a widespread movement towards more sustainable and eco-friendly packaging solutions. Wooden and plywood packaging has emerged as a compelling alternative to traditional plastic packaging, offering a range of environmental benefits that resonate with both consumers and businesses.

Plastic packaging has long been associated with environmental challenges, including littering, ocean pollution, and the persistence of plastic waste in natural ecosystems. Wooden and plywood packaging provides a viable alternative that significantly reduces the dependence on plastic materials, helping to mitigate plastic pollution.

Unlike plastic, which can take hundreds of years to break down, wood is a natural material that decomposes relatively quickly. Wooden and plywood packaging are biodegradable, meaning they can be naturally broken down by microorganisms over time, without leaving behind harmful microplastics.

Wood is a renewable resource, as trees can be replanted and harvested sustainably, which contrasts with plastic, which is derived from non-renewable fossil fuels. The use of renewable materials contributes to the conservation of natural resources and reduces the carbon footprint of packaging.

Sustainable Packaging Solutions is Likely to be Beneficial for Market Growth

The emphasis on sustainability and eco-friendliness has become a cornerstone of modern business practices, and the packaging industry is no exception. Brands and manufacturers are seeking packaging solutions that align with these values, as consumers become more environmentally conscious and demand greener products. The shift in consumer behavior and preferences has led to a significant increase in the demand for sustainable packaging solutions, including wooden and plywood packaging.

Wood is a natural and renewable resource. Unlike non-renewable materials like plastic, which are derived from fossil fuels and are finite in supply, wood can be sustainably sourced from responsibly managed forests, which ensures a continuous supply of raw material for wooden and plywood packaging.

One of the critical environmental advantages of wooden and plywood packaging is their biodegradability. The materials break down naturally over time through the action of microorganisms, returning to the earth without leaving behind harmful pollutants or microplastics, which contrasts with plastic, which can persist in the environment for centuries.

The production of wooden and plywood packaging generally has a lower carbon footprint compared to plastic. The energy-intensive processes involved in plastic production, such as polymerization and refining, contribute to higher greenhouse gas emissions. In contrast, wood processing and manufacturing typically require less energy and generate fewer emissions.

Reduced Carbon Footprint to Fuel the Market Growth

The carbon footprint of a product or material refers to the total greenhouse gas emissions generated throughout its lifecycle, from raw material extraction and production to transportation, use, and disposal. Wooden and plywood packaging materials are often touted for their reduced carbon footprint compared to alternatives like plastic or metal.

Wood is a natural and renewable resource. Trees absorb carbon dioxide (CO2) from the atmosphere during their growth, acting as a carbon sink. When wood is harvested and used for packaging, the carbon stored in the wood remains locked away from the atmosphere, reducing net CO2 emissions.

The production of wooden and plywood packaging typically requires less energy compared to the energy-intensive processes involved in plastic or metal production. The reduced energy demand contributes to lower greenhouse gas emissions.

The manufacturing processes for wood and plywood packaging involve fewer emissions of greenhouse gases. For instance, the extraction of raw materials and the processing of wood generally produce fewer emissions than the production of plastics, which involves petrochemical refining.

By material type, plywood segment is estimated to be the leading segment at a CAGR of 4.4% during the forecast period.

Plywood is composed of multiple layers of wood veneers bonded together with adhesive. The layered structure enhances its strength and durability, making it suitable for packaging heavy and fragile items. Plywood packaging provides reliable protection during transportation and handling.

Plywood can be easily cut, shaped, and customized to suit various packaging needs. It can be designed to accommodate products of different shapes and sizes, offering flexibility to packaging designers and manufacturers.

Plywood is often more affordable than solid wood, making it an economical choice for packaging solutions. Its cost-effectiveness is especially important for businesses looking to balance quality packaging with budget constraints.

Plywood is derived from renewable resources, and its manufacturing process generally requires less energy compared to other materials like plastics or metals. The eco-friendly aspect appeals to environmentally conscious consumers and businesses seeking sustainable packaging solutions.

By end user, bakery & confectionery sub-segment of food segment is estimated to be the leading segment at a CAGR of 4.4% during the forecast period.

Bakery and confectionery products are often delicate and prone to breakage. Wooden and plywood packaging provides sturdy protection during transportation and handling, reducing the risk of damage and preserving the quality of the products.

Plywood packaging can be easily customized to fit various bakery and confectionery items, such as cakes, pastries, cookies, and chocolates. Businesses can create unique packaging designs that align with their brand identity and attract consumer attention.

Wooden and plywood packaging adds a touch of rustic elegance to bakery and confectionery products. The natural look and feel of wood enhance the visual appeal of the packaged items, contributing to an enhanced product presentation.

The use of sustainable packaging materials like wood is gaining traction, as consumers become more environmentally conscious. Wooden and plywood packaging align with the demand for eco-friendly packaging solutions, appealing to environmentally conscious consumers.

North America has been witnessing a significant shift towards sustainable and eco-friendly packaging solutions. Wooden and plywood packaging materials align well with this trend, as they are renewable, biodegradable, and have a lower environmental impact compared to conventional packaging materials like plastics.

Government regulations and initiatives aimed at reducing plastic waste and promoting environmentally friendly practices are driving businesses to explore alternative packaging options. Wooden and plywood packaging offer a compliant solution that meets sustainability requirements.

North American consumers appreciate products that convey a natural and authentic feel. Wooden and plywood packaging align with this preference, adding a rustic and organic touch to product presentation, which can resonate well with local consumers.

The rise of e-commerce and online retail in North America has created a need for effective and protective packaging solutions. Wooden and plywood packaging materials provide robust protection during shipping, ensuring products reach customers in optimal condition. The region is expected to hold a CAGR of 4.4% over the analysis period.

The Asia Pacific region is witnessing a surge in e-commerce and online retail, leading to a higher demand for packaging materials that can withstand the rigors of shipping and handling. Wooden and plywood packaging provides robust protection for products during transit, contributing to the growth of the e-commerce sector.

Rapid urbanization and population growth are driving demand for various consumer goods and packaged products. Wooden and plywood packaging materials offer a versatile and customizable option to cater to the diverse packaging needs of a growing population.

Governments and businesses in the Asia Pacific region are increasingly focusing on sustainability and environmentally friendly practices. Wooden and plywood packaging materials align with these initiatives as they are renewable, biodegradable, and have a lower environmental impact compared to traditional packaging materials.

Wooden and plywood packaging materials have cultural significance and are often associated with tradition, authenticity, and craftsmanship in many Asian countries. The aesthetic appeal can enhance the perceived value of products and resonate with consumers. The region is expected to hold a CAGR of 4.3% over the analysis period.

Key players in the wooden & plywood packaging market are strongly focusing on profit generation from their existing product portfolios along while exploring potential new applications. The players are emphasizing on increasing their wooden & plywood packaging production capacities, to cater to the demand from numerous end use industries. Prominent players are also pushing for geographical expansion to decrease the dependency on imported wooden & plywood packaging.

Recent Developments:

| Attribute | Details |

|---|---|

| Forecast Period | 2025 to 2035 |

| Historical Data Available for | 2020 to 2025 |

| Market Analysis | USD Billion for value and Tons for Volume |

| Key Regions Covered | North America; Latin America; Western Europe; Eastern Europe; South Asia & Pacific; East Asia and Middle East & Africa |

| Key Countries Covered | United States, Canada, Brazil, Mexico, Germany, United Kingdom, France, Spain, Italy, Poland, Russia, Czech Republic, Romania, India, Bangladesh, Australia, New Zealand, China, Japan, South Korea, GCC Countries, South Africa, Israel. |

| Key Segments Covered | Material Type, Product Type, End User, and Region |

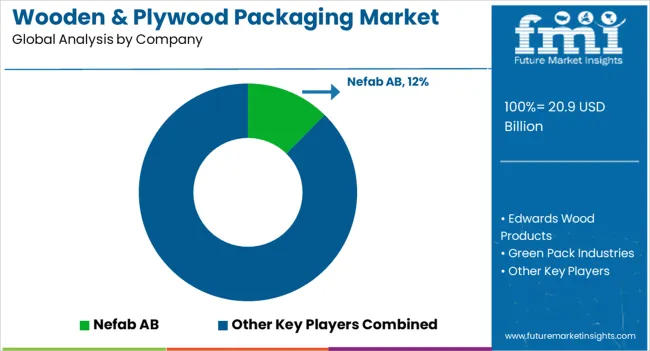

| Key Companies Profiled | Nefab AB; Edwards Wood Products; Inc.; Green Pack Industries; Napa Wooden Box Co.; Ongna Wood Products; Inc.; Shur-way Industries; Inc.; Rowlinson Packaging Ltd; C&K Box Company; Inc.; C Jackson & Sons Ltd.; Bay wood products; Inc.; Arrington Lumber and Pallet Company; LJB Timber Packaging Pty. Ltd. |

| Report Coverage | Market Forecast, brand share analysis, competition intelligence, DROT analysis, Market Dynamics and Challenges, Strategic Growth Initiatives |

| Customization & Pricing | Available upon Request |

The global wooden & plywood packaging market is estimated to be valued at USD 20.9 billion in 2025.

The market size for the wooden & plywood packaging market is projected to reach USD 31.8 billion by 2035.

The wooden & plywood packaging market is expected to grow at a 4.3% CAGR between 2025 and 2035.

The key product types in wooden & plywood packaging market are hardwood, _oak, _teak, _maple, softwood, _pines, _spruces and plywood.

In terms of product type, pallets segment to command 44.2% share in the wooden & plywood packaging market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Wooden Cutlery Market Size and Share Forecast Outlook 2025 to 2035

Wooden Furniture Market Size and Share Forecast Outlook 2025 to 2035

Wooden Interior Door Market Size and Share Forecast Outlook 2025 to 2035

Wooden Decking Market Size, Growth, and Forecast 2025 to 2035

Wooden Barrels Market Growth - Demand & Forecast 2025 to 2035

Market Share Insights of Wooden Crate Providers

Wooden Box Market Demand & Premium Packaging Trends 2024-2034

Wooden Crate Market by Hardwood & Softwood from 2024 to 2034

Wooden Pallets Market

Wooden Pallet Collars Market

R & D Cloud Collaboration Market Size and Share Forecast Outlook 2025 to 2035

US & Canada Sports & Athletic Insoles Market Trends - Growth & Forecast 2024 to 2034

ADC & DAC In Quantum Computing Market Size and Share Forecast Outlook 2025 to 2035

LTE & 5G for Critical Communications Market Size and Share Forecast Outlook 2025 to 2035

Oil & Gas Electrification Market Size and Share Forecast Outlook 2025 to 2035

Oil & Gas Infrastructure Market Size and Share Forecast Outlook 2025 to 2035

Oil & Gas Analytics Market Size and Share Forecast Outlook 2025 to 2035

Oil & Gas Carbon Capture and Storage Market Size and Share Forecast Outlook 2025 to 2035

Cap and Closure Market Trends - Growth & Demand 2025-2035

USA & Canada Pre-painted Steel Roofing and Cladding Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA