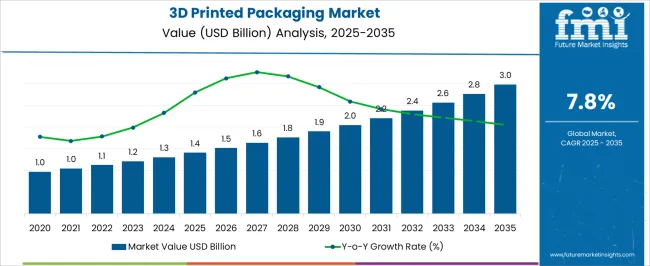

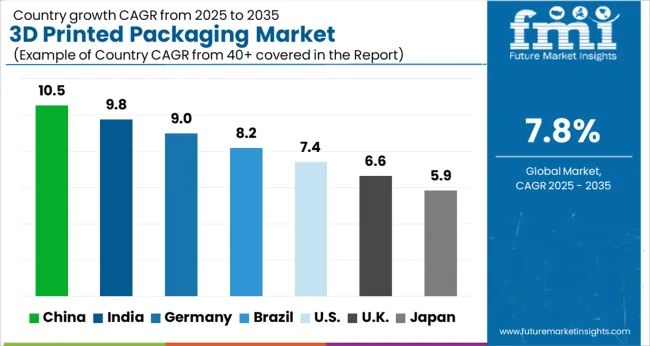

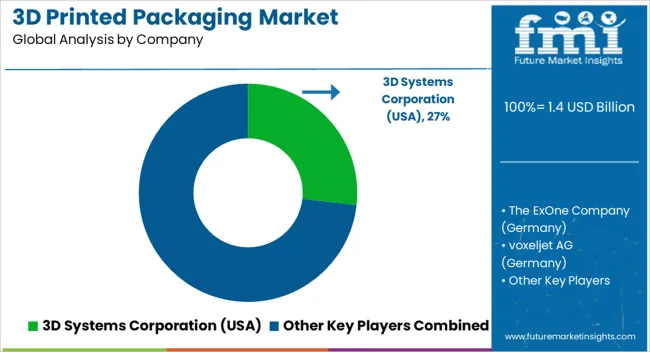

The 3D Printed Packaging Market is estimated to be valued at USD 1.4 billion in 2025 and is projected to reach USD 3.0 billion by 2035, registering a compound annual growth rate (CAGR) of 7.8% over the forecast period.

| Metric | Value |

|---|---|

| 3D Printed Packaging Market Estimated Value in (2025 E) | USD 1.4 billion |

| 3D Printed Packaging Market Forecast Value in (2035 F) | USD 3.0 billion |

| Forecast CAGR (2025 to 2035) | 7.8% |

The 3D printed packaging market is expanding rapidly as industries embrace customization, sustainability, and supply chain efficiency. Growing adoption of additive manufacturing in packaging design is enabling brands to deliver unique, lightweight, and functional solutions that align with consumer demand for eco friendly products.

Advances in material science and digital manufacturing platforms are driving wider applications across food, beverage, cosmetics, and pharmaceutical sectors. The integration of 3D printing technologies allows for rapid prototyping, reduced production waste, and faster time to market.

Regulatory focus on minimizing packaging waste and the increasing pressure for sustainable practices are further accelerating adoption. The future outlook is positive as companies invest in scalable production systems, leveraging 3D printing to achieve cost efficiency, design flexibility, and alignment with circular economy goals.

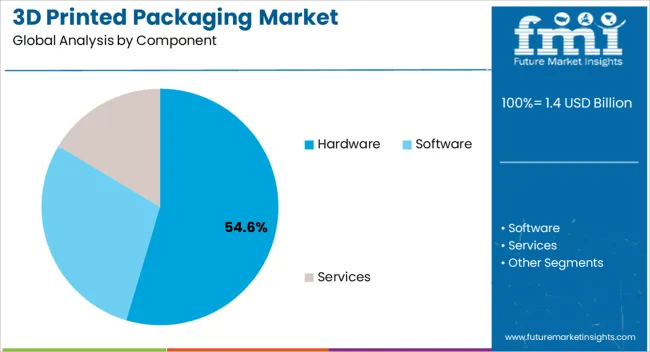

The hardware segment is expected to hold 54.60% of the overall market by 2025 within the component category, making it the leading segment. This dominance is driven by the essential role of 3D printers and related equipment in enabling high precision packaging production.

Hardware investments form the backbone of additive manufacturing ecosystems, as businesses prioritize advanced printers that support a wide range of packaging materials and complex geometries. The ability to ensure reliable output, scalability, and integration with automation systems has reinforced the preference for hardware.

Continuous innovation in high speed and multi material printers has further strengthened its share, positioning hardware as the most critical element of this market.

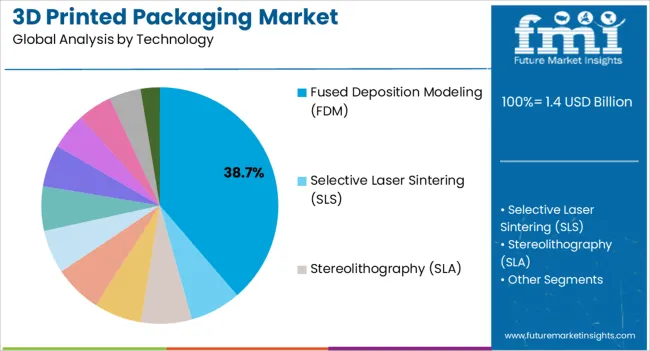

The fused deposition modeling segment is projected to account for 38.70% of the total market by 2025 within the technology category, establishing it as the dominant approach. Its popularity is attributed to cost effectiveness, accessibility, and compatibility with multiple biodegradable and recyclable polymers.

This technology supports efficient prototyping and small batch production, which aligns with the packaging industry’s need for frequent design iterations and customization. The ability to produce lightweight structures with reduced material waste has made FDM highly suitable for sustainable packaging initiatives.

As the industry shifts toward greener alternatives and rapid innovation cycles, FDM technology continues to lead due to its affordability and adaptability.

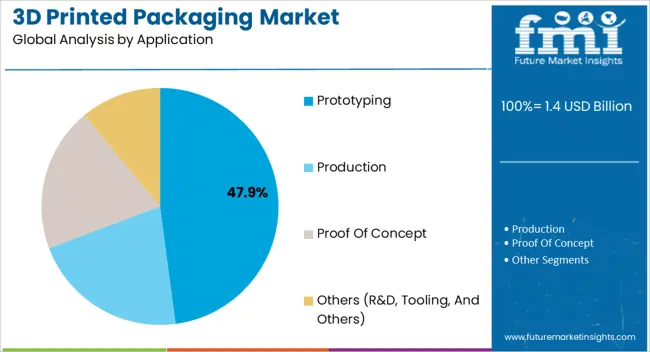

The prototyping segment is projected to generate 47.90% of total revenue by 2025 within the application category, highlighting its leadership position. The prominence of this segment is supported by the increasing requirement for design validation, functional testing, and cost effective iteration before mass production.

Prototyping with 3D printing allows packaging manufacturers and brands to visualize product concepts, optimize ergonomics, and test durability in shorter lead times. This process reduces development risks and enhances innovation cycles, aligning with the fast evolving packaging industry landscape.

As customization and sustainability become central to competitive advantage, the prototyping application segment continues to dominate through its role in bridging design creativity and functional performance.

The 3D printed packaging market has grown significantly in recent years. Owing to the rising demand for customized packaging solutions and advancements in printing technology.

Factors driving the growth of the market include:

Furthermore, 3D printing technology enables the manufacturing of environmentally friendly and sustainable packaging materials. This is usually relevant to both consumers and businesses. Moreover, the growing demand for sustainable packaging solutions is expected to drive market growth in the coming years.

Looking ahead, the future outlook for the market appears promising, with analysts projecting a CAGR of around 7.8% from 2025 to 2035. Investing in the 3D printed packaging industry can help organizations gain a competitive advantage. Increase supply chain efficiency and satisfy sustainability goals. 3D printing technology, with its capacity to manufacture highly customized, on-demand, and cost-effective solutions, is poised to become a game-changer in the packaging sector.

As these trends continue to shape the industry, businesses that invest in 3D printing technology are likely to gain a competitive advantage. Moreover, utilizing the trends can help them meet the evolving needs of their customers.

Design software is mainly used in automotive, aerospace and defense, and construction and engineering industries for constructing object designs to be printed. It acts as a bridge between the object to be printed and the printer's hardware.

In 2025, the hardware category led the market, accounting for more than 64.01% of worldwide sales. The increased importance of quick prototyping and advanced production has benefited the hardware industry substantially.

The rising industrialization and increased penetration of consumer electronic items are the primary drivers of the hardware segment's growth. Additionally, developing civil infrastructure, rapid urbanization, and optimizing labor costs play a key role.

SLA is a 3D printing process that uses a laser to harden a photopolymer resin layer by layer to create a 3D printed item. Stereolithography may retain a considerable market share, particularly in applications requiring great precision and accuracy. Such as the manufacturing of specialized packaging for the medical and dentistry industries.

This is due to the extensive adoption of the prototyping process across several industry verticals. The automotive and aerospace and defense industries use it to design and develop parts, components, and complex systems with precision. Prototyping enables manufacturers to achieve higher accuracy and develop reliable end products. Making it a significant segment in the market and expected to continue leading during the forecast period.

Functional parts, such as smaller joints and metallic hardware connecting components, require high accuracy and precise sizing for developing machinery and systems. This segment is expected to expand at a significant CAGR of 24% from 2025 to 2035. Driven by the increasing demand for designing and building functional parts. Overall, the prototyping segment currently leads the market. Although, both the tooling and functional parts segments are expected to see growth in the coming years.

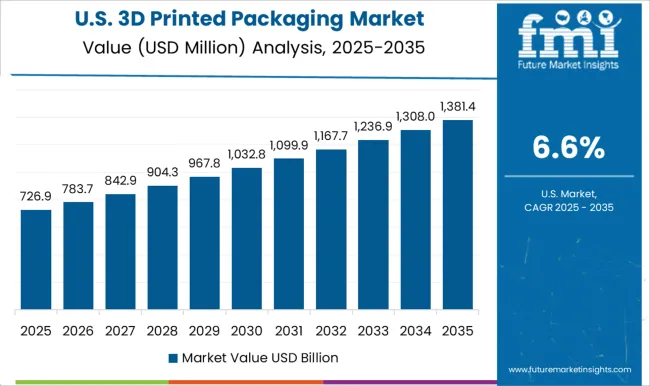

This is due to the increasing use of 3D printing technology in areas such as automotive, aerospace and defense, healthcare, and consumer goods. The region also boasts a well-established and matured 3D printing sector. Numerous significant businesses are present, making it a research and development hub. There is a growing requirement for sustainable and eco-friendly packaging in numerous markets. Similarly, increasing the need for customized packaging solutions are likely to boost the expansion of the 3D printed packaging market in North America.

Europe is a key market for 3D printed packaging, accounting for a sizable portion of the global market. The increasing implementation of printing technology in numerous end-use industries such as automotive, aerospace and defense, and healthcare is driving market expansion. Furthermore, the existence of well-established 3D printing enterprises, research institutions, and favorable government efforts is anticipated to boost market expansion in Europe. The growing need for personalized and sustainable packaging solutions is also predicted to drive the expansion of the region's 3D printed packaging industry.

The implementation of 3D printing technology is increasing in numerous industries. Such as automotive, aerospace and defense, and healthcare can be contributed to the region's market growth. Furthermore, rising disposable incomes and changing consumer tastes are likely to increase demand for customized and sustainable packaging solutions. Ultimately supporting the region's market expansion.

China and Japan are the region's two prominent markets, accounting for a sizable portion of revenue. These countries' market growth can be ascribed to strong manufacturing capabilities, technical advancements, and a well-established industrial base.

The market is dominated by key players such as Stratasys Ltd., 3D Systems Corporation, EOS GmbH, Materialise NV, Arcam AB, and SLM Solutions Group AG, among others. These players have a strong presence in the market, offering a wide range of 3D printing solutions and services.

In recent years, several new players have entered the market, intensifying the competition further. These players are focusing on product innovation, strategic partnerships, and collaborations to expand their market share and strengthen their position in the market. For instance, in 2024, HP Inc. announced a partnership with BASF SE to develop a range of sustainable 3D printing solutions for the packaging industry.

The market is also witnessing increasing consolidation activities such as mergers and acquisitions. These activities are aimed at expanding the product portfolio, enhancing technological capabilities, and expanding the global reach of the companies.

For instance, in 2024, 3D Systems Corporation acquired Oqton Inc., a provider of AI-powered manufacturing software, to strengthen its position in the market.

Imaginarium is a global leader in 3D Printing solutions and innovative manufacturing technology. The company announced the debut of its desktop and industrial 3D printer range in collaboration with 3D printing giant Ultimaker in February 2025.

| Attribute | Details |

|---|---|

| Growth Rate | CAGR of 7.8% from 2025 to 2035 |

| Base Year of Estimation | 2025 |

| Historical Data | 2020 to 2025 |

| Forecast Period | 2025 to 2035 |

| Quantitative Units | Revenue in USD billion and Volume in Units and F-CAGR from 2025 to 2035 |

| Report Coverage | Revenue Forecast, Volume Forecast, Company Ranking, Competitive Landscape, growth factors, Trends, and Pricing Analysis |

| Key Segments Covered | By Component, By Technology, By Application, By End User, By Region |

| Regions Covered | North America; Latin America; Europe; East Asia; South Asia; The Middle East & Africa; Oceania |

| Key Countries Profiled | The United States, Canada, Brazil, Mexico, Germany, Italy, France, The United Kingdom, Spain, Russia, China, Japan, India, GCC Countries, Australia |

| Key Companies Profiled | 3D Systems Corporation (USA); The ExOne Company (Germany); voxeljet AG (Germany); Materialise NV (Belgium); Made in Space, Inc. (USA); Envisiontec, Inc. (Germany); Stratasys Ltd. (USA); HP, Inc. (USA); General Electric Company (GE Additive) (USA); Autodesk Inc. (USA) |

| Customization & Pricing | Available upon Request |

The global 3D printed packaging market is estimated to be valued at USD 1.4 billion in 2025.

The market size for the 3D printed packaging market is projected to reach USD 3.0 billion by 2035.

The 3D printed packaging market is expected to grow at a 7.8% CAGR between 2025 and 2035.

The key product types in 3D printed packaging market are hardware, software and services.

In terms of technology, fused deposition modeling (fdm) segment to command 38.7% share in the 3D printed packaging market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

3D Printed Packaging Kit Market Analysis Size and Share Forecast Outlook 2025 to 2035

Market Share Breakdown of 3D Printed Packaging Manufacturers

3D Printed Dental Brace Market Size and Share Forecast Outlook 2025 to 2035

3D-Printed Prosthetic Implants Market Size and Share Forecast Outlook 2025 to 2035

3D Printed Maxillofacial Implants Market Size and Share Forecast Outlook 2025 to 2035

3D-Printed Personalized Masks Market Size and Share Forecast Outlook 2025 to 2035

3D Printed Clear Dental Aligners Market Size and Share Forecast Outlook 2025 to 2035

3d-Printed Skincare Market Analysis - Size and Share Forecast Outlook 2025 to 2035

3D Printed Prosthetics Market Size and Share Forecast Outlook 2025 to 2035

3D Printed Medical Implants Market Size and Share Forecast Outlook 2025 to 2035

3D Printed Surgical Models Market Analysis - Size, Share, and Forecast 2025 to 2035

3D Printed Hip and Knee Implants Market Size and Share Forecast Outlook 2025 to 2035

3D Printed Wearable Market - by Product Type, Material Type, Technology, Sales Channel, End-User, Application, and Region - Trends, Growth & Forecast 2025 to 2035

3D Printed Medical Devices Market is segmented by drug type, treatment and distribution channel from 2025 to 2035

Market Share Breakdown of 3D-Printed Stickers & Labels Manufacturers

3D Printed Drugs Market Outlook – Growth, Demand & Forecast 2025-2035

3D-Printed Stickers & Labels Market Growth – Trends & Forecast 2024-2034

3D Printed Brain Model Market Analysis – Trends & Forecast 2024-2034

3D Bioprinted Organ Transplants Market Size and Share Forecast Outlook 2025 to 2035

3D Bioprinted Human Tissue Market Analysis - Size, Share, and Forecast 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA