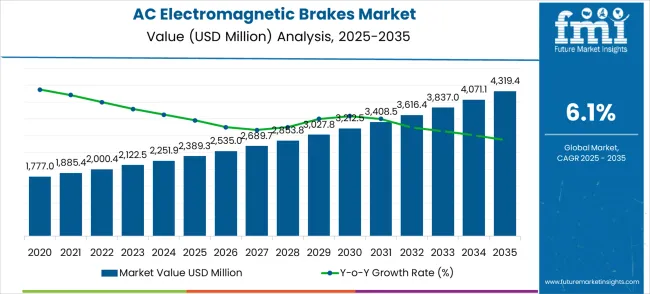

The AC electromagnetic brakes market, valued at USD 2,389.3 million in 2025 and projected to reach USD 4,319.4 million by 2035 at a CAGR of 6.1%, demonstrates a clear early versus late growth curve distinction. Between 2020 and 2027, the market increased gradually from USD 1,777.0 million to USD 2,689.7 million, marking a period of foundational adoption across automotive and manufacturing applications.

This steady build-up signified an early curve characterized by incremental but consistent expansion. By contrast, from 2028 to 2035, the market surged from USD 2,853.8 million to USD 4,319.4 million, illustrating an intensified late-stage growth curve, largely influenced by industrial automation, advanced braking applications, and scaled global adoption, which contributed significantly to overall revenue momentum.

| Metric | Value |

|---|---|

| Market Value (2025) | USD 2,389.3 million |

| Market Forecast Value (2035) | USD 4,319.4 million |

| Forecast CAGR (2025–2035) | 6.1% |

During the early growth phase, the AC electromagnetic brakes market exhibited a controlled expansion, moving from USD 1,777 million in 2020 to USD 2,689.7 million in 2027. This stage represented a steady curve where growth was driven by the gradual introduction of braking technologies in automotive manufacturing and the modernization of industrial machinery. Adoption was influenced by cost-sensitive sectors, which favored gradual integration instead of large-scale deployment. The curve during this period resembled a gentle incline, as adoption was relatively slower due to limited awareness and application scope. The CAGR was modest, with emphasis on establishing product reliability and basic functionality. This foundation laid the groundwork for accelerated momentum in subsequent years, ensuring market readiness for stronger adoption post-2028.

In the late growth stage, the market transitioned into an accelerated trajectory, expanding from USD 2,853.8 million in 2028 to USD 4,319.4 million by 2035. This sharper curve reflected wider application in industrial automation, high-performance automotive systems, and specialized machinery requiring advanced braking precision. Unlike the gradual early phase, this period experienced compounding growth effects, where increased awareness, technological standardization, and reduced implementation costs amplified adoption. The CAGR contribution was stronger, making late-stage growth the dominant driver of overall revenue expansion. The curve steepened as large-scale adoption programs and diversified applications gained traction worldwide.

Market expansion is being supported by the rapid industrial automation across global economies and the corresponding need for reliable braking and safety control systems in automotive, aerospace, and industrial machinery applications. Modern industrial operations require precise braking control and safety management to ensure optimal equipment performance and operational safety. The superior reliability and performance characteristics of AC electromagnetic brakes make them essential components in demanding industrial environments where safety-critical operation and precise control are paramount.

The growing emphasis on equipment safety and regulatory compliance is driving demand for advanced braking technologies from certified manufacturers with proven track records of reliability and performance. Industrial operators are increasingly investing in high-quality braking systems that offer improved safety performance and reduced maintenance requirements over extended service periods. Regulatory requirements and safety standards are establishing performance benchmarks that favor precision-engineered electromagnetic braking solutions with advanced control capabilities.

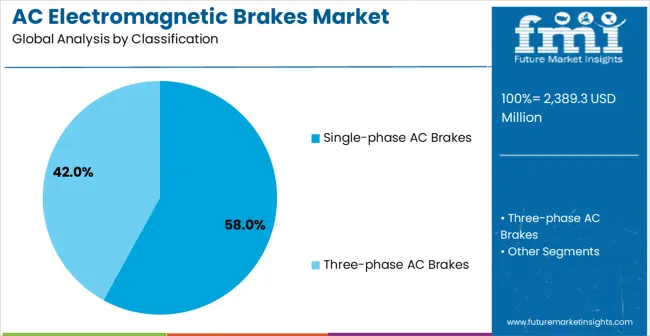

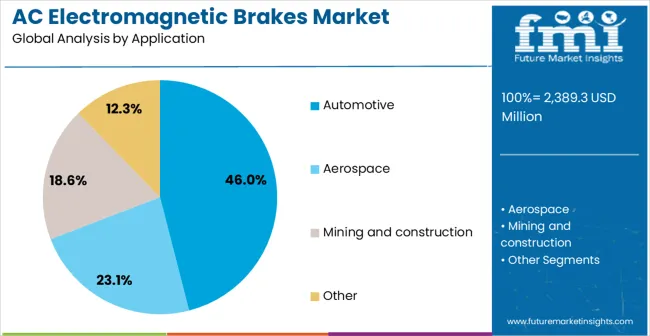

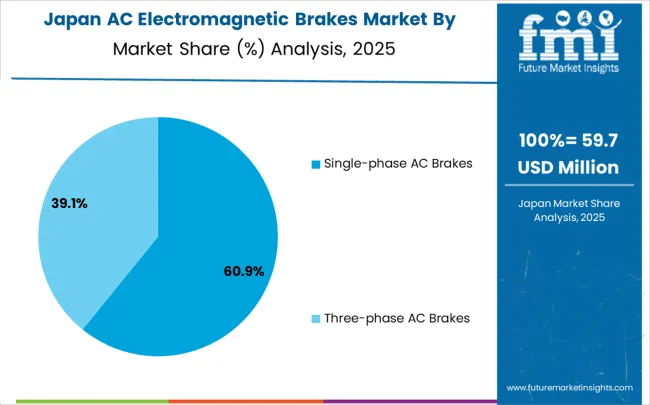

The market is segmented by brake type, application, and region. By brake configuration, the market is divided into single-phase AC brakes and three-phase AC brakes. Based on application, the market is categorized into automotive industry, aerospace industry, mining and construction, and other industrial applications. Regionally, the market is divided into North America, Europe, East Asia, South Asia & Pacific, Latin America, and Middle East & Africa.

Single-phase AC brakes are projected to represent 58% of the AC electromagnetic brakes market in 2025. Their dominance is supported by widespread single-phase power availability and strong adoption in moderate-duty industrial and automotive testing equipment. These brakes offer simplified installation, cost-effectiveness, and improved torque density, making them the first choice in small machinery operations.

Technological enhancements in magnetic circuits, heat dissipation systems, and coil efficiency have extended operational durability while lowering ownership costs. Demand is notably strong from industries requiring compact, reliable braking systems in areas with limited three-phase power access. Adoption is further accelerated by the use of advanced friction materials and optimized magnetic structures, which enhance response time and braking consistency. The market expansion of automotive and industrial facilities in developing regions continues to drive significant preference for single-phase AC brakes.

The automotive industry is projected to account for 46% of AC electromagnetic brakes market demand in 2025. This leading position comes from the vital use of brakes in automotive testing equipment, assembly line machinery, and safety validation processes. Automakers increasingly require precision braking systems capable of handling high-frequency operations under demanding test and production environments. Growth in electric and autonomous vehicles fuels demand for sophisticated brakes used in dynamometers and advanced quality assurance systems

. Regulatory pressures to validate new designs and powertrain technologies create recurring demand for testing and production braking systems. Automotive manufacturing facilities benefit from reliable torque control and enhanced thermal performance, enabling continuous operation without failure risk. The transition toward automation, smart manufacturing, and electrification underscores the need for sensor-equipped brakes with integrated electronic control. Expanding automotive production in Asia-Pacific and Latin America also strengthens the segment’s role in shaping global market growth.

The AC electromagnetic brakes market is advancing rapidly due to increasing industrial automation and growing recognition of advanced braking system importance in safety-critical applications. However, the market faces challenges including higher power consumption compared to DC alternatives, need for specialized AC power control systems, and varying performance characteristics across different voltage and frequency standards. Standardization efforts and efficiency improvement programs continue to influence equipment design and market development patterns.

The growing deployment of variable frequency drives and intelligent control systems is enabling precise speed and torque control capabilities in AC electromagnetic brake installations. Smart control interfaces and automated systems provide continuous monitoring of braking parameters while optimizing energy consumption and extending equipment service life. These technologies are particularly valuable for industrial applications that require precise positioning control and adaptive braking performance across varying operational conditions.

Modern brake manufacturers are incorporating advanced magnetic materials and designs that improve braking performance while reducing energy consumption through optimized magnetic circuits and improved power factor characteristics. Integration of advanced control electronics and sophisticated coil designs enables precise braking control and significant efficiency improvements compared to traditional AC electromagnetic systems. Advanced materials and manufacturing techniques also support development of more compact and lightweight brake components for demanding automotive and aerospace environments.

| Country | CAGR (2025–2035) |

|---|---|

| China | 8.2% |

| India | 7.6% |

| Germany | 7% |

| Brazil | 6.4% |

| United States | 5.8% |

| United Kingdom | 5.2% |

| Japan | 4.6% |

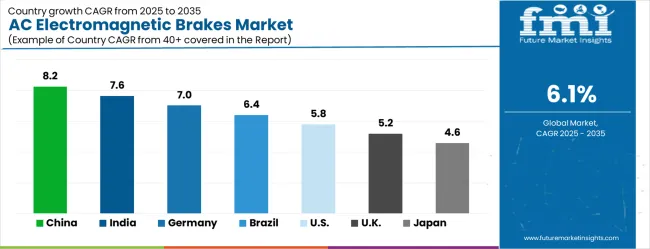

The AC electromagnetic brakes market is growing rapidly, with China leading at an 8.2% CAGR through 2035, driven by massive industrial expansion, automotive production growth, and manufacturing automation programs. India follows at 7.6%, supported by rising industrial development and increasing investments in automotive and aerospace manufacturing facilities. Germany records strong growth at 7%, emphasizing precision engineering, quality standards, and advanced industrial automation capabilities. Brazil grows steadily at 6.4%, integrating braking systems into expanding automotive and mining operations. The United States shows moderate growth at 5.8%, focusing on equipment upgrades and industrial modernization improvements. The United Kingdom maintains steady expansion at 5.2%, supported by aerospace and industrial automation programs. Japan demonstrates stable growth at 4.6%, emphasizing technological innovation and manufacturing excellence.

The report covers an in-depth analysis of 40+ countries top-performing countries are highlighted below.

The AC electromagnetic brakes market in China is projected to grow at a CAGR of 8.2% through 2035, supported by rapid industrial expansion and large-scale automotive production programs. China is exceeding global peers in industrial adoption as advanced braking technologies become integral to automation and manufacturing systems. Global suppliers are competing with rising domestic manufacturers that offer affordable alternatives, driving strong rivalry across the sector. China is also competing with Japan and South Korea in electronics and automotive segments, highlighting regional dynamics. Safety standards and government-backed industrial modernization policies continue to boost demand for high-performance braking systems.

The AC electromagnetic brakes market in India is forecasted to expand at a CAGR of 7.6% from 2025 to 2035, supported by strong growth in automotive, aerospace, and general manufacturing sectors. India is emerging as a cost-competitive manufacturing hub, attracting multinational suppliers that compete with local firms offering tailored braking systems. Market development is further supported by government-backed industrial expansion and infrastructure projects. India is competing with China in cost efficiency and production scale, positioning itself as a strong regional rival. Rising adoption of advanced braking technologies is improving safety compliance and production efficiency across industries, strengthening India’s role in the global market.

The AC electromagnetic brakes market in Germany is expected to grow at a CAGR of 7% through 2035, driven by the country’s strength in precision engineering and automation technology. Germany is growing as a European leader in advanced braking solutions, focusing on accuracy, reliability, and regulatory compliance. Local manufacturers compete with multinational firms that target specialized automotive, aerospace, and robotics applications. Germany is also competing with France and Italy in industrial exports, reinforcing its leadership through innovation-led solutions. High adoption of smart factory concepts and modernization programs continues to drive integration of braking systems into industrial environments.

The AC electromagnetic brakes market in Brazil is projected to expand at a CAGR of 6.4% through 2035, driven by growing demand across automotive and mining industries. Brazil is strengthening its position in Latin America as industries adopt braking systems designed for heavy-duty and safety-critical operations. Global suppliers are entering through partnerships, while domestic manufacturers focus on affordability and durability. Brazil is competing with Mexico in attracting automotive investments, creating regional competition in advanced equipment adoption. Rising industrial safety compliance and modernization efforts are supporting market expansion, making Brazil an important emerging market for braking systems.

The AC electromagnetic brakes market in the United States is projected to grow at a CAGR of 5.8% during 2025–2035, supported by modernization programs and strict safety requirements. The United States is driving large-scale adoption through replacement demand in aerospace, automotive, and defense industries. Global manufacturers dominate with scale and service offerings, while niche domestic players compete through specialization and customization. The United States is competing with Germany and Japan for leadership in aerospace braking technologies, creating international rivalry. Facility upgrade programs and increasing regulatory compliance are further strengthening market opportunities, making the country a strategic hub for advanced braking systems.

The AC electromagnetic brakes market in the United Kingdom is forecasted to expand at a CAGR of 5.2% through 2035, supported by aerospace growth and industrial modernization initiatives. The United Kingdom is advancing its position in Europe by adopting braking systems that ensure reliability, safety, and compliance. Local firms emphasize customization for niche applications, while global companies dominate through established partnerships and service networks. The United Kingdom is competing with Germany in aerospace programs, with rivalry centered on precision equipment adoption. Strong focus on operational safety and regulatory compliance continues to drive industrial adoption across multiple applications.

The AC electromagnetic brakes market in Japan is anticipated to grow at a CAGR of 4.6% through 2035, supported by technological innovation and advanced manufacturing expertise. Japan is building on its leadership in precision equipment by integrating high-performance braking systems across electronics, robotics, and industrial applications. Domestic firms dominate the market, creating high entry barriers for international suppliers. Japan is competing directly with China in electronics and semiconductor braking applications, where quality and reliability differentiate Japanese technologies. Continuous focus on process improvement and advanced design ensures Japan maintains its reputation for excellence in braking systems.

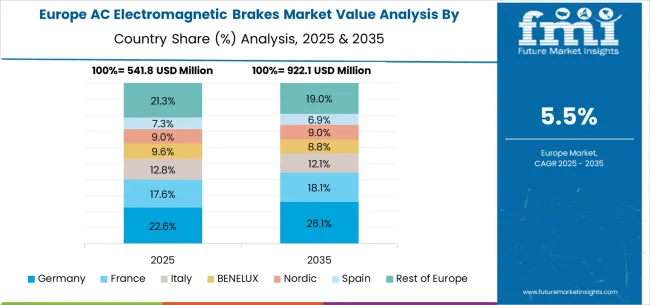

The AC electromagnetic brakes market in Europe is projected to grow from USD 644.6 million in 2025 to USD 1,164.5 million by 2035, registering a CAGR of 6.1% over the forecast period. Germany is expected to maintain its leadership with a 30.8% share in 2025, supported by its strong industrial base and advanced manufacturing infrastructure. The United Kingdom follows with 18.4% market share, driven by ongoing aerospace development and industrial modernization programs. France holds 15.7% of the European market, benefiting from automotive industry expansion and aerospace investments. Italy and Spain collectively represent 21.6% of regional demand, with growing focus on industrial automation and automotive applications. The Rest of Europe region accounts for 13.5% of the market, supported by industrial development in Eastern European countries and Nordic manufacturing sectors.

Companies are investing in advanced electromagnetic technologies, product innovation, standardized safety systems, and technical support capabilities to deliver reliable, efficient, and cost-effective braking solutions. Strategic partnerships, technological advancement, and geographic expansion are central to strengthening product portfolios and market presence. Siemens AG, operating globally, offers comprehensive electromagnetic braking solutions with focus on precision engineering, industrial integration, and technical support services. Lenze SE provides advanced braking systems with emphasis on automation compatibility and digital control capabilities. Kendrion N.V., specialized provider, delivers high-performance braking solutions for industrial applications with focus on reliability and safety. Ogura Industrial Corp. offers comprehensive braking technologies with standardized procedures and global service support.

Stromag (Altra Industrial Motion) provides industrial braking systems with emphasis on heavy-duty applications and technical expertise. Intorq (part of Kendrion) delivers specialized electromagnetic braking equipment with focus on precision applications. Precima Magnettechnik GmbH offers comprehensive braking solutions for demanding industrial environments. Miki Pulley Co., Ltd. provides advanced braking systems with regional manufacturing capabilities. Bonfiglioli Riduttori S.p.A., The Rowland Company offer specialized braking expertise, regional manufacturing capabilities, and technical support across global and regional networks.

The AC electromagnetic brakes market underpins industrial safety, automotive testing, aerospace precision, and eco-efficient manufacturing. With automation mandates, stricter safety requirements, and demand for precision control systems, the sector must balance cost competitiveness, performance reliability, and energy efficiency. Coordinated contributions from governments, industry bodies, OEMs/technology integrators, suppliers, and investors will accelerate the transition toward safety-smart, digitally monitored, and energy-efficient braking systems.

| Item | Value |

|---|---|

| Quantitative Units | USD 2,389.3 million |

| Classification Type | Single-phase AC Brakes, Three-phase AC Brakes |

| Application | Automotive Industry, Aerospace Industry, Mining and Construction, Other |

| Regions Covered | North America, Europe, East Asia, South Asia & Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Germany, India, China, United Kingdom, Japan, Brazil, and other 40+ countries |

| Key Companies Profiled | Siemens AG, Lenze SE, Kendrion N.V., Ogura Industrial Corp., Stromag (Altra Industrial Motion), Intorq (part of Kendrion), Precima Magnettechnik GmbH, Miki Pulley Co., Ltd., Bonfiglioli Riduttori S.p.A., The Rowland Company |

| Additional Attributes | Dollar sales by brake type and application, regional demand trends across North America, Europe, and Asia-Pacific, competitive landscape with established manufacturers and emerging suppliers, buyer preferences for single-phase versus three-phase braking systems, integration with digital automation and control technologies, innovations in magnetic design and thermal management for enhanced performance and reliability, and adoption of smart braking solutions with embedded monitoring and remote control capabilities for improved operational safety and efficiency. |

The global AC electromagnetic brakes market is estimated to be valued at USD 2,389.3 million in 2025.

The market size for the AC electromagnetic brakes market is projected to reach USD 4,319.4 million by 2035.

The AC electromagnetic brakes market is expected to grow at a 6.1% CAGR between 2025 and 2035.

The key product types in AC electromagnetic brakes market are single-phase AC brakes and three-phase AC brakes.

In terms of application, automotive segment to command 46.0% share in the AC electromagnetic brakes market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

DC Electromagnetic Brakes Market Size and Share Forecast Outlook 2025 to 2035

Account Planning Tool Market Size and Share Forecast Outlook 2025 to 2035

Acousto Optical Cavity Dumper Market Size and Share Forecast Outlook 2025 to 2035

Accounting Software Market Size and Share Forecast Outlook 2025 to 2035

Active Wear Market Size and Share Forecast Outlook 2025 to 2035

Acid Resistant Pipe Market Forecast and Outlook 2025 to 2035

AC DC Power Adapter Market Forecast and Outlook 2025 to 2035

Activated Carbon for Sugar Decolorization Market Forecast and Outlook 2025 to 2035

Acrylic Paint Market Forecast and Outlook 2025 to 2035

Acetate Silicone Sealant Market Size and Share Forecast Outlook 2025 to 2035

Active, Smart, and Intelligent Packaging Market Size and Share Forecast Outlook 2025 to 2035

Acetone Market Size and Share Forecast Outlook 2025 to 2035

Activated Alumina Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Fibre Market Size and Share Forecast Outlook 2025 to 2035

Acetoacetanilide Market Size and Share Forecast Outlook 2025 to 2035

Acetylacetone Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Emulsions Market Size and Share Forecast Outlook 2025 to 2035

AC Electric Motor Market Size and Share Forecast Outlook 2025 to 2035

AC Power Source Market Size and Share Forecast Outlook 2025 to 2035

Acrylic Polymer Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA