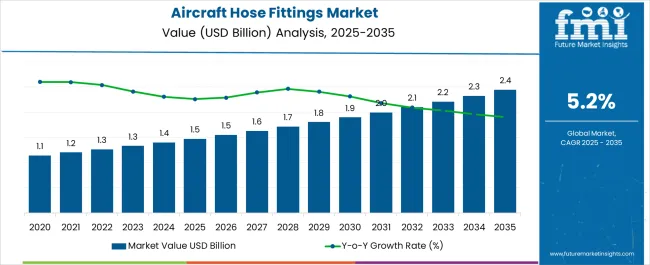

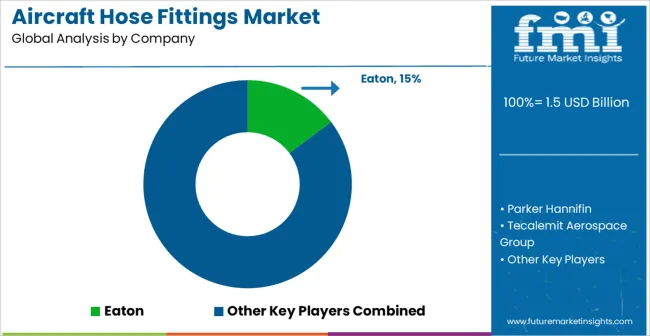

The Aircraft Hose Fittings Market is estimated to be valued at USD 1.5 billion in 2025 and is projected to reach USD 2.4 billion by 2035, registering a compound annual growth rate (CAGR) of 5.2% over the forecast period.

| Metric | Value |

|---|---|

| Aircraft Hose Fittings Market Estimated Value in (2025 E) | USD 1.5 billion |

| Aircraft Hose Fittings Market Forecast Value in (2035 F) | USD 2.4 billion |

| Forecast CAGR (2025 to 2035) | 5.2% |

The Aircraft Hose Fittings market is experiencing significant growth, driven by increasing demand for reliable fluid transfer systems across the aerospace sector. Adoption is being fueled by the need for high-performance components that ensure safety, efficiency, and durability in commercial, military, and private aircraft operations. Technological advancements in materials, precision manufacturing, and design optimization are enhancing the performance and longevity of hose fittings, supporting their widespread deployment.

The integration of lightweight, corrosion-resistant materials such as PTFE and advanced alloys is reducing maintenance requirements and operational costs, further driving adoption. Increasing investments in new aircraft production, fleet modernization programs, and rising global air traffic are contributing to higher demand for hose fittings.

Strict regulatory compliance for safety, quality, and environmental standards continues to shape market dynamics, reinforcing the importance of certified and high-quality components As aircraft manufacturers and maintenance providers prioritize reliability, efficiency, and regulatory adherence, the Aircraft Hose Fittings market is expected to sustain steady growth, with innovations in parts, materials, and applications expanding its reach across the aerospace ecosystem.

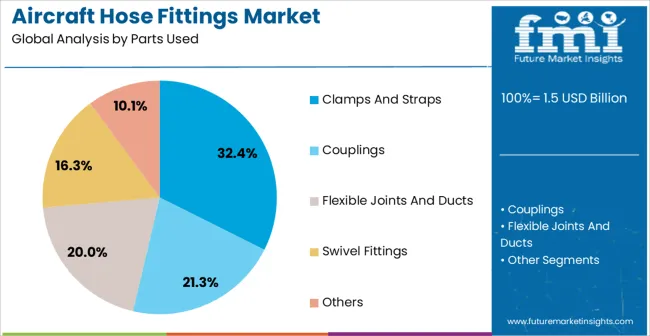

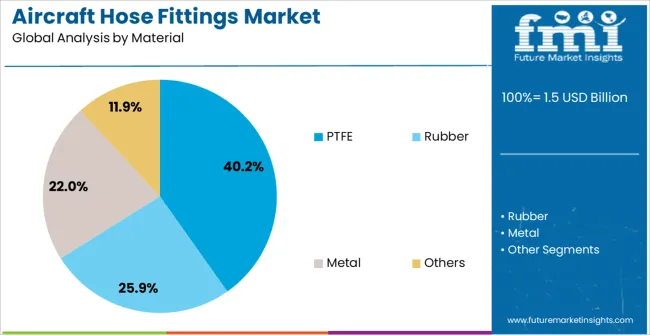

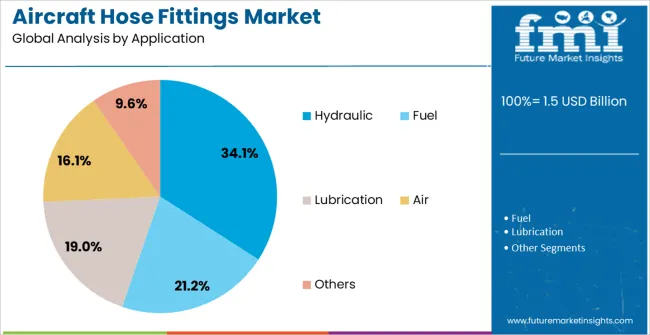

The aircraft hose fittings market is segmented by parts used, material, application, flexibility, type of aircraft, and geographic regions. By parts used, aircraft hose fittings market is divided into Clamps And Straps, Couplings, Flexible Joints And Ducts, Swivel Fittings, and Others. In terms of material, aircraft hose fittings market is classified into PTFE, Rubber, Metal, and Others. Based on application, aircraft hose fittings market is segmented into Hydraulic, Fuel, Lubrication, Air, and Others. By flexibility, aircraft hose fittings market is segmented into Flexible and Non Flexible. By type of aircraft, aircraft hose fittings market is segmented into Commercial Airlines, Military, Industrial, General Aviation, and Others. Regionally, the aircraft hose fittings industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The clamps and straps segment is projected to hold 32.4% of the market revenue in 2025, making it the leading parts used category. Growth in this segment is being driven by the critical role these components play in securing hose assemblies, ensuring leak-free connections, and maintaining system integrity under high pressure and vibration conditions. The ability of clamps and straps to provide adjustable, reliable fastening solutions across various hose diameters and materials enhances their adoption.

Lightweight and corrosion-resistant designs reduce maintenance needs while contributing to overall aircraft efficiency. Compatibility with different hose materials, including PTFE, stainless steel, and composite hoses, reinforces their versatility in both hydraulic and fuel systems.

As aerospace manufacturers continue to prioritize safety, operational reliability, and performance optimization, clamps and straps are expected to maintain their market leadership Ongoing design innovations, improved material strength, and ease of installation are further strengthening their adoption across commercial and military aircraft fleets.

The PTFE material segment is anticipated to account for 40.2% of the market revenue in 2025, establishing it as the leading material type. Growth is being driven by PTFE’s superior chemical resistance, high thermal stability, low friction, and durability under extreme operating conditions. These properties make PTFE ideal for aircraft hose applications, particularly in hydraulic, fuel, and pneumatic systems.

Its non-reactive nature ensures compatibility with a wide range of fluids, minimizing the risk of contamination and maintaining system reliability. The lightweight characteristic of PTFE contributes to overall aircraft efficiency and fuel savings, which is increasingly valued by manufacturers.

Continued improvements in PTFE formulations, including enhanced mechanical strength and flexibility, have expanded its applicability in aerospace hose fittings With rising demand for high-performance, low-maintenance, and long-lasting materials, PTFE is expected to maintain its leading position, supported by its unique combination of durability, chemical resistance, and operational efficiency in aerospace applications.

The hydraulic application segment is projected to hold 34.1% of the market revenue in 2025, making it the leading application area. Growth is being driven by the essential role of hydraulic systems in aircraft operations, including flight control, landing gear actuation, and braking systems. Hose fittings used in hydraulic applications must ensure leak-proof connections, withstand high pressures, and operate reliably under varying temperature and vibration conditions.

The adoption of advanced materials like PTFE and optimized component designs is enhancing system safety and performance. Increasing investments in new aircraft production, fleet upgrades, and modernized hydraulic systems are fueling demand for high-quality hose fittings.

Regulatory requirements for aerospace safety, quality standards, and performance reliability are reinforcing the importance of certified fittings As aircraft manufacturers and maintenance providers continue to prioritize hydraulic system efficiency, reliability, and compliance, the hydraulic application segment is expected to maintain its leadership, supported by ongoing innovations in materials, design, and manufacturing processes.

Over the past 10 years, the airline industry has seen a number of changes, such as the increased market share of low cost airlines (LCCs) as well as an increase in air passenger traffic. This increase in the number of passengers has in turn resulted in an increased in the number of flights, which eventually is spurring the demand for the automotive hose fitting market.

Generally, two types of housing are used in aircraft: flexible and non-flexible. Flexible hoses are used with moving parts or where the hose is subject to considerable vibration. Flexible hoses are used in aircraft fluid systems to connect moving parts with stationery parts in locations, which are subject to vibrations or where a great amount of flexibility is needed.

Most manufacturers use Buna-N, neoprene, butyl and ethylene propylene diene rubber (EPDM) to manufacture flexible hoses. These hoses are suitable for use in coolant, oil, fuel and hydraulic systems. The hose can also be designed according to the dash number as per the size. The dash number is stenciled on the side of the hose and indicates the size tubing with which the hose is compatible.

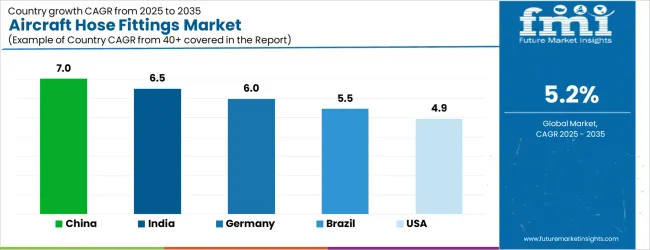

| Country | CAGR |

|---|---|

| China | 7.0% |

| India | 6.5% |

| Germany | 6.0% |

| Brazil | 5.5% |

| USA | 4.9% |

| UK | 4.4% |

| Japan | 3.9% |

The Aircraft Hose Fittings Market is expected to register a CAGR of 5.2% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 7.0%, followed by India at 6.5%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 3.9%, yet still underscores a broadly positive trajectory for the global Aircraft Hose Fittings Market.

In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 6.0%. The USA Aircraft Hose Fittings Market is estimated to be valued at USD 518.1 million in 2025 and is anticipated to reach a valuation of USD 518.1 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 66.3 million and USD 41.4 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.5 Billion |

| Parts Used | Clamps And Straps, Couplings, Flexible Joints And Ducts, Swivel Fittings, and Others |

| Material | PTFE, Rubber, Metal, and Others |

| Application | Hydraulic, Fuel, Lubrication, Air, and Others |

| Flexibility | Flexible and Non Flexible |

| Type Of Aircraft | Commercial Airlines, Military, Industrial, General Aviation, and Others |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Eaton, Parker Hannifin, Tecalemit Aerospace Group, Titeflex, Hy-Lok USA, Chief Aircraft, SHV, Delafield, Specialty Hose, Precision Hose Technology, Flexfab, and Aircraft Spruce |

The global aircraft hose fittings market is estimated to be valued at USD 1.5 billion in 2025.

The market size for the aircraft hose fittings market is projected to reach USD 2.4 billion by 2035.

The aircraft hose fittings market is expected to grow at a 5.2% CAGR between 2025 and 2035.

The key product types in aircraft hose fittings market are clamps and straps, couplings, flexible joints and ducts, swivel fittings and others.

In terms of material, ptfe segment to command 40.2% share in the aircraft hose fittings market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Aircraft Refueling Hose Market

Aircraft Cabin Environment Sensor Market Forecast and Outlook 2025 to 2035

Aircraft Flight Control System Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Electric Motor Market Forecast Outlook 2025 to 2035

Aircraft Cooling Turbines Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Smoke Detection and Fire Extinguishing System Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Cabin Interior Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Galley Systems Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Interior Lighting Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Battery Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Floor Panels Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Fuel Systems Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Lubricant Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Seat Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Ground Support Equipment Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Maintenance, Repair and Overhaul Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Actuators Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Elevator Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Weapons Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Lighting Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA