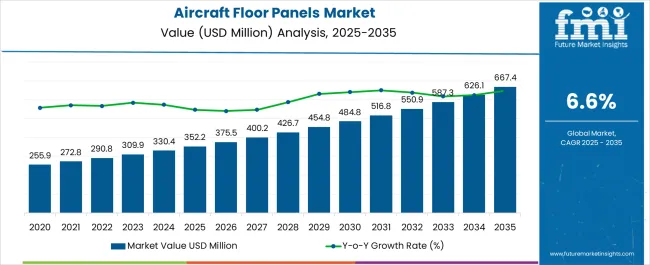

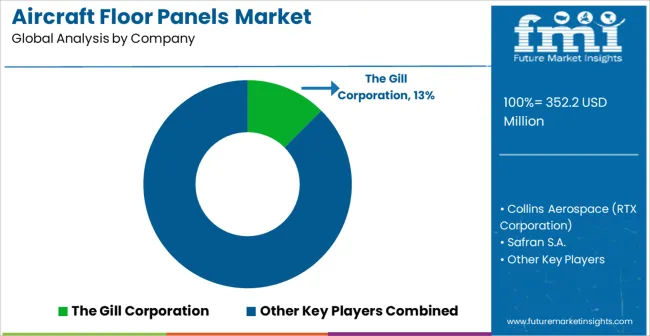

The Aircraft Floor Panels Market is estimated to be valued at USD 352.2 million in 2025 and is projected to reach USD 667.4 million by 2035, registering a compound annual growth rate (CAGR) of 6.6% over the forecast period.

| Metric | Value |

|---|---|

| Aircraft Floor Panels Market Estimated Value in (2025 E) | USD 352.2 million |

| Aircraft Floor Panels Market Forecast Value in (2035 F) | USD 667.4 million |

| Forecast CAGR (2025 to 2035) | 6.6% |

The Aircraft Floor Panels market is witnessing substantial growth, driven by the increasing demand for lightweight, high-strength components to improve fuel efficiency and overall aircraft performance. Rising air travel and fleet expansions across commercial airlines are further boosting the adoption of advanced floor panel solutions. Manufacturers are increasingly focusing on materials that provide high structural integrity while reducing weight, such as aluminum honeycomb and composite-based panels.

These panels are designed to meet stringent safety and regulatory standards, ensuring durability under high load and operational stress conditions. Technological advancements in material engineering, manufacturing precision, and modular assembly processes are enabling better performance and easier maintenance.

Growing emphasis on cost reduction, operational efficiency, and environmental sustainability is accelerating the replacement of traditional flooring materials with lightweight and high-performance alternatives As airlines continue to prioritize fuel savings, passenger comfort, and regulatory compliance, the Aircraft Floor Panels market is expected to sustain long-term growth, with innovations in material technology and design flexibility shaping future opportunities.

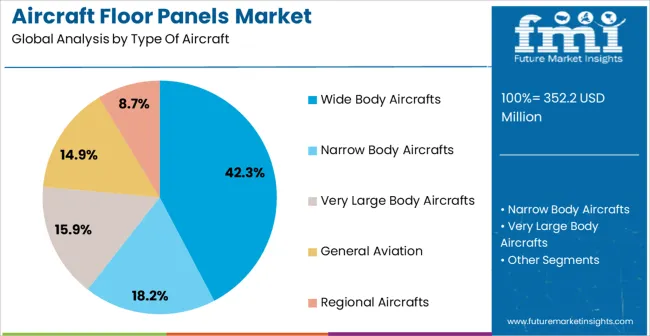

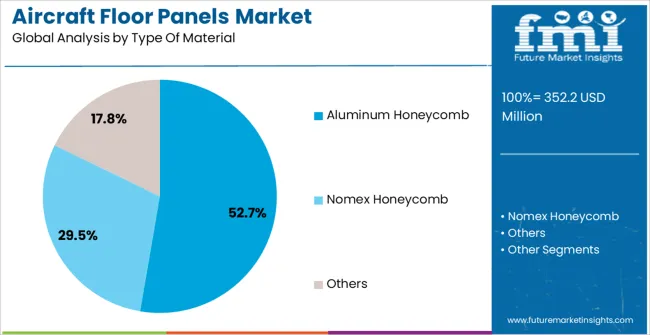

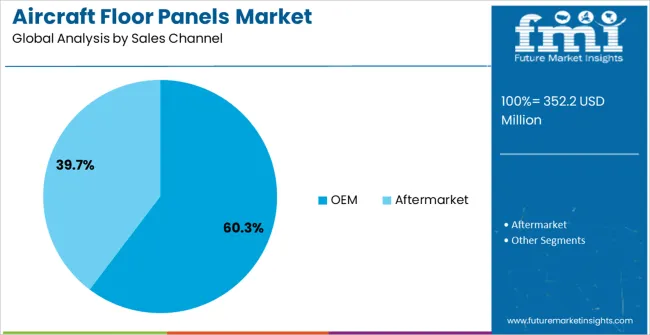

The aircraft floor panels market is segmented by type of aircraft, type of material, sales channel, and geographic regions. By type of aircraft, aircraft floor panels market is divided into Wide Body Aircrafts, Narrow Body Aircrafts, Very Large Body Aircrafts, General Aviation, and Regional Aircrafts. In terms of type of material, aircraft floor panels market is classified into Aluminum Honeycomb, Nomex Honeycomb, and Others. Based on sales channel, aircraft floor panels market is segmented into OEM and Aftermarket. Regionally, the aircraft floor panels industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The wide body aircrafts segment is projected to hold 42.3% of the market revenue in 2025, establishing it as the leading aircraft type. Growth in this segment is being driven by the increasing production of wide body jets to meet the rising demand for long-haul air travel. Wide body aircrafts require larger floor areas and higher load-bearing capacity, which has increased the demand for high-strength, lightweight floor panels.

The integration of advanced materials and modular floor structures improves aircraft efficiency, reduces fuel consumption, and supports operational reliability. Airlines are increasingly investing in retrofitting and upgrading existing fleets with modern floor panels to comply with evolving safety and performance standards.

Technological advancements in panel design, such as better load distribution and corrosion resistance, have strengthened adoption The wide body aircrafts segment is expected to maintain its leading position, driven by fleet expansion, long-haul air travel growth, and the need for durable and lightweight flooring solutions.

The aluminum honeycomb segment is anticipated to account for 52.7% of the market revenue in 2025, making it the leading material type. Its dominance is attributed to the material’s high strength-to-weight ratio, excellent durability, and resistance to fatigue and corrosion. Aluminum honeycomb panels provide enhanced energy absorption and load distribution, which are critical for aircraft safety and performance.

The material also allows for easy integration into modular floor structures, reducing maintenance costs and improving lifecycle performance. Advancements in manufacturing processes, such as precision bonding and extrusion, have enhanced the material’s reliability and scalability.

Airlines and aircraft manufacturers are increasingly adopting aluminum honeycomb due to its ability to reduce overall aircraft weight, contributing to lower fuel consumption and operational costs As demand for lightweight and high-performance aircraft components continues to rise, aluminum honeycomb is expected to retain its leading share, supported by technological innovation and stringent aerospace safety standards.

The OEM sales channel segment is expected to hold 60.3% of the market revenue in 2025, positioning it as the leading distribution route. Growth in this segment is driven by the direct procurement of floor panels by aircraft manufacturers to ensure quality, compatibility, and compliance with design specifications. OEM-supplied panels provide consistent performance, reliability, and integration efficiency, which are critical in large-scale aircraft production.

Strong partnerships between material suppliers and aircraft manufacturers facilitate advanced product development, streamlined supply chains, and timely delivery. Direct engagement with OEMs also ensures adherence to regulatory standards, quality certifications, and maintenance requirements, reducing operational risks.

The adoption of OEM channels is further supported by increasing aircraft production rates, fleet expansions, and upgrades in commercial and business aviation As manufacturers prioritize efficiency, safety, and regulatory compliance, OEM remains the preferred channel, reinforcing its leading revenue share in the Aircraft Floor Panels market.

Increasing demand of lightweight aircraft interiors provide ample growth opportunities for the augmentation of aircraft floor panels market over the assessment period. Aircraft floor panels are integral part of aircraft interiors, which are usually constructed with advanced composite structures. The aircraft floor panel are generally made by the honeycomb structure.

A honeycomb structure is built up from a core material resembling a honeycomb which is sandwiched between thin sheets. A floor panel made from the honeycomb structure is very strong. Manufacturers are focusing on manufacturing lightweight floor panels. Moreover, aircraft floor panels are designed and manufactured in such a way that they have properties such as durability, high strength and stiffness.

Furthermore, for obtaining the desired properties the aircraft floor panels are generally made of advanced materials and systems, such as epoxy resin system and unidirectional fiberglass or carbon containing aircraft floor panels. Few manufacturers have also developed heated floor panels, which provide heat in the cabin areas susceptible to cold for passengers and crew comfort.

The aircraft floor panels can be fabricated by using adhesives in between the thin layers or by press curving. The type of aircraft floor panels differ according to the type of aircrafts and are an important consideration, for the improved safety and comfort of passengers.

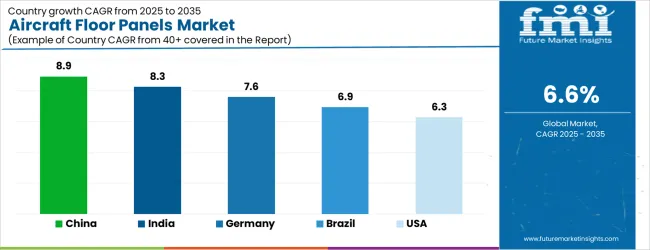

| Country | CAGR |

|---|---|

| China | 8.9% |

| India | 8.3% |

| Germany | 7.6% |

| Brazil | 6.9% |

| USA | 6.3% |

| UK | 5.6% |

| Japan | 5.0% |

The Aircraft Floor Panels Market is expected to register a CAGR of 6.6% during the forecast period, exhibiting varied country level momentum. China leads with the highest CAGR of 8.9%, followed by India at 8.3%. Developed markets such as Germany, France, and the UK continue to expand steadily, while the USA is likely to grow at consistent rates. Japan posts the lowest CAGR at 5.0%, yet still underscores a broadly positive trajectory for the global Aircraft Floor Panels Market. In 2024, Germany held a dominant revenue in the Western Europe market and is expected to grow with a CAGR of 7.6%. The USA Aircraft Floor Panels Market is estimated to be valued at USD 121.3 million in 2025 and is anticipated to reach a valuation of USD 121.3 million by 2035. Sales are projected to rise at a CAGR of 0.0% over the forecast period between 2025 and 2035. While Japan and South Korea markets are estimated to be valued at USD 19.4 million and USD 11.5 million respectively in 2025.

| Item | Value |

|---|---|

| Quantitative Units | USD 352.2 Million |

| Type Of Aircraft | Wide Body Aircrafts, Narrow Body Aircrafts, Very Large Body Aircrafts, General Aviation, and Regional Aircrafts |

| Type Of Material | Aluminum Honeycomb, Nomex Honeycomb, and Others |

| Sales Channel | OEM and Aftermarket |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | The Gill Corporation, Collins Aerospace (RTX Corporation), Safran S.A., Triumph Group Inc., Singapore Technologies Engineering Ltd., LATECOERE, Aeropair Ltd., Elbe Flugzeugwerke GmbH, VINCORION Advanced Systems GmbH, Satair (Airbus SE), Lufthansa Technik AG, Hexcel Corporation, Jamco Corporation, and Diab Group |

The global aircraft floor panels market is estimated to be valued at USD 352.2 million in 2025.

The market size for the aircraft floor panels market is projected to reach USD 667.4 million by 2035.

The aircraft floor panels market is expected to grow at a 6.6% CAGR between 2025 and 2035.

The key product types in aircraft floor panels market are wide body aircrafts, narrow body aircrafts, very large body aircrafts, general aviation and regional aircrafts.

In terms of type of material, aluminum honeycomb segment to command 52.7% share in the aircraft floor panels market in 2025.

Our Research Products

The "Full Research Suite" delivers actionable market intel, deep dives on markets or technologies, so clients act faster, cut risk, and unlock growth.

The Leaderboard benchmarks and ranks top vendors, classifying them as Established Leaders, Leading Challengers, or Disruptors & Challengers.

Locates where complements amplify value and substitutes erode it, forecasting net impact by horizon

We deliver granular, decision-grade intel: market sizing, 5-year forecasts, pricing, adoption, usage, revenue, and operational KPIs—plus competitor tracking, regulation, and value chains—across 60 countries broadly.

Spot the shifts before they hit your P&L. We track inflection points, adoption curves, pricing moves, and ecosystem plays to show where demand is heading, why it is changing, and what to do next across high-growth markets and disruptive tech

Real-time reads of user behavior. We track shifting priorities, perceptions of today’s and next-gen services, and provider experience, then pace how fast tech moves from trial to adoption, blending buyer, consumer, and channel inputs with social signals (#WhySwitch, #UX).

Partner with our analyst team to build a custom report designed around your business priorities. From analysing market trends to assessing competitors or crafting bespoke datasets, we tailor insights to your needs.

Supplier Intelligence

Discovery & Profiling

Capacity & Footprint

Performance & Risk

Compliance & Governance

Commercial Readiness

Who Supplies Whom

Scorecards & Shortlists

Playbooks & Docs

Category Intelligence

Definition & Scope

Demand & Use Cases

Cost Drivers

Market Structure

Supply Chain Map

Trade & Policy

Operating Norms

Deliverables

Buyer Intelligence

Account Basics

Spend & Scope

Procurement Model

Vendor Requirements

Terms & Policies

Entry Strategy

Pain Points & Triggers

Outputs

Pricing Analysis

Benchmarks

Trends

Should-Cost

Indexation

Landed Cost

Commercial Terms

Deliverables

Brand Analysis

Positioning & Value Prop

Share & Presence

Customer Evidence

Go-to-Market

Digital & Reputation

Compliance & Trust

KPIs & Gaps

Outputs

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Aircraft Cabin Environment Sensor Market Forecast and Outlook 2025 to 2035

Aircraft Flight Control System Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Electric Motor Market Forecast Outlook 2025 to 2035

Aircraft Cooling Turbines Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Smoke Detection and Fire Extinguishing System Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Hose Fittings Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Cabin Interior Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Galley Systems Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Interior Lighting Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Battery Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Fuel Systems Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Lubricant Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Seat Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Ground Support Equipment Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Maintenance, Repair and Overhaul Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Actuators Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Elevator Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Weapons Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Lighting Market Size and Share Forecast Outlook 2025 to 2035

Aircraft Micro Turbine Engines Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA