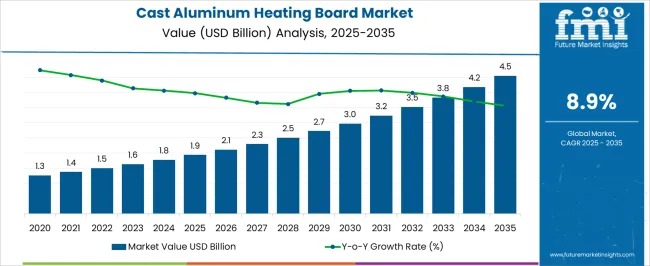

The cast aluminum heating board market is estimated to be valued at USD 1.9 billion in 2025 and is projected to reach USD 4.5 billion by 2035, registering a compound annual growth rate (CAGR) of 8.9% over the forecast period.

The cast aluminum heating board market is valued at USD 1.9 billion in 2025 and is expected to grow to USD 4.5 billion by 2035, with a CAGR of 8.9%. Between 2021 and 2025, the market grows steadily from USD 1.3 billion to USD 1.9 billion, with values passing through USD 1.4 billion, 1.5 billion, 1.6 billion, and 1.8 billion. This initial growth phase is driven by the increasing demand for energy-efficient and durable heating solutions across sectors such as automotive, electronics, and construction, where cast aluminum is favored for its heat conductivity and lightweight properties.

Between 2026 and 2030, the market continues to expand from USD 1.9 billion to USD 3.2 billion, with values progressing through USD 2.1 billion, 2.3 billion, 2.5 billion, and 2.7 billion. This period sees stronger adoption in energy-efficient heating systems and high-performance applications, spurred by growing awareness of sustainability and cost-effectiveness. The acceleration in demand is also fueled by innovations in aluminum alloy compositions that enhance performance and reliability in extreme environments.

From 2031 to 2035, the market grows further, reaching USD 4.5 billion, passing through USD 3.5 billion, 3.8 billion, and 4.2 billion. The compound absolute growth during this phase reflects a mature and expanding market, driven by widespread use in industrial heating solutions, electric vehicles, and emerging technologies, solidifying cast aluminum heating boards as a preferred choice for advanced applications.

| Metric | Value |

|---|---|

| Cast Aluminum Heating Board Market Estimated Value in (2025 E) | USD 1.9 billion |

| Cast Aluminum Heating Board Market Forecast Value in (2035 F) | USD 4.5 billion |

| Forecast CAGR (2025 to 2035) | 8.9% |

The heating equipment market is a major driver, accounting for around 30-35%, as cast aluminum heating boards are commonly used in various heating systems, including electric radiators, convection heaters, and underfloor heating systems, where their efficient heat transfer and durability are crucial. The home appliances market also plays a significant role, contributing approximately 25-30%, as cast aluminum heating boards are widely used in household heating devices like space heaters, baseboard heaters, and electric stoves, driven by the demand for energy-efficient and long-lasting home heating solutions. The industrial heating equipment market contributes about 15-20%, as these heating boards are used in industrial applications such as ovens, furnaces, and drying equipment, where their ability to withstand high temperatures and distribute heat efficiently is essential.

The automotive and electric vehicles (EV) market contributes around 10-12%, as cast aluminum heating boards are used in vehicle heating systems, including cabin heaters, seat heaters, and battery heating in electric vehicles, all of which require efficient thermal management for optimal performance. Lastly, the renewable energy market accounts for approximately 8-10%, as these heating boards are used in solar thermal systems and other renewable heating applications, where their thermal conductivity is essential for efficient heat transfer. These parent markets highlight the diverse applications and growing demand for cast aluminum heating boards across various industries.

The cast aluminum heating board market is advancing steadily, driven by the growing need for uniform and efficient thermal management across industrial, commercial, and scientific applications. The market’s growth trajectory is shaped by the increasing use of high-precision heating systems in sectors such as packaging, electronics, plastics, and laboratory equipment. Cast aluminum boards offer high durability, uniform heat distribution, corrosion resistance, and customizable design, which make them ideal for temperature-sensitive operations.

Advancements in manufacturing technologies are enabling integration of embedded heating elements, improving energy transfer and operational consistency. As industries continue to demand efficient, long-lasting, and compact heating solutions, the versatility and reliability of cast aluminum boards are gaining traction. Regulatory emphasis on energy-efficient heating systems is also contributing to their adoption across global markets.

With rising demand for precision-controlled thermal systems in both emerging and developed economies, the market is expected to expand further Manufacturers are increasingly focusing on developing embedded heating technologies and tailored temperature ranges to meet the evolving needs of next-generation industrial heating applications.

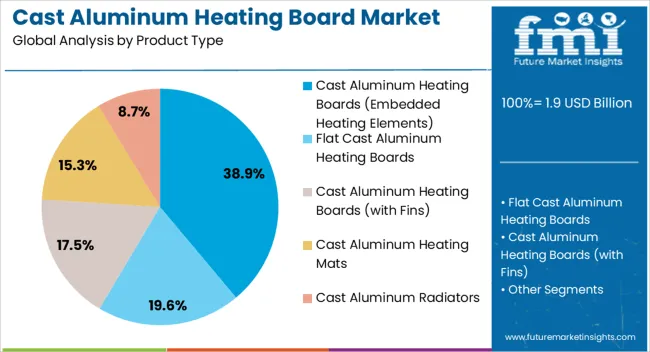

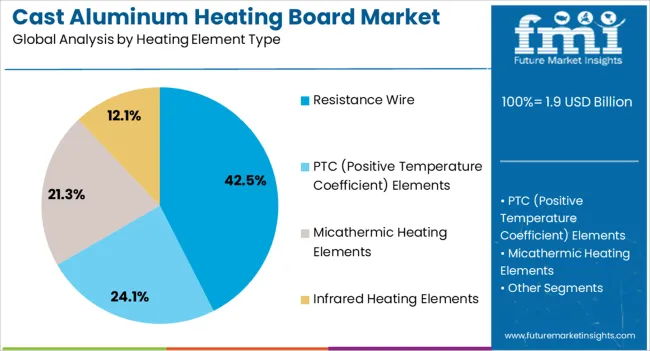

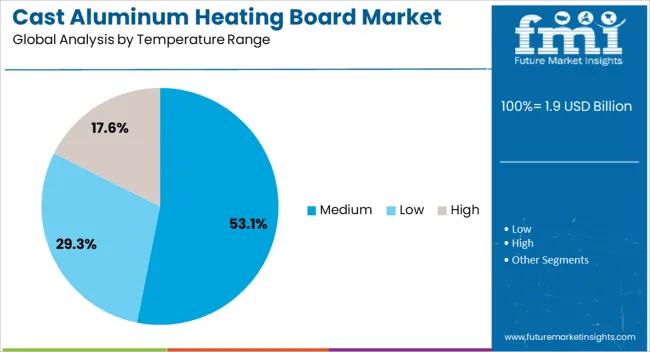

The cast aluminum heating board market is segmented by product type, heating element type, temperature range, application, end use, distribution channel, and geographic regions. By product type, cast aluminum heating board market is divided into cast aluminum heating boards (embedded heating elements), flat cast aluminum heating boards, cast aluminum heating boards (with fins), cast aluminum heating mats, and cast aluminum radiators. In terms of heating element type, cast aluminum heating board market is classified into resistance wire, PTC (positive temperature coefficient) elements, micathermic heating elements, and infrared heating elements. Based on temperature range, cast aluminum heating board market is segmented into medium, low, and high. By application, cast aluminum heating board market is segmented into industrial heating, commercial heating, and residential heating. By end use, cast aluminum heating board market is segmented into electronics manufacturing, food processing, automotive, aerospace, healthcare, chemical processing, oil and gas, textiles, and construction. By distribution channel, cast aluminum heating board market is segmented into distributors and wholesalers, direct sales, online retail, and B2B sales. Regionally, the cast aluminum heating board industry is classified into North America, Latin America, Western Europe, Eastern Europe, Balkan & Baltic Countries, Russia & Belarus, Central Asia, East Asia, South Asia & Pacific, and the Middle East & Africa.

The cast aluminum heating boards with embedded heating elements segment is projected to account for 38.9% of the cast aluminum heating board market revenue share in 2025, emerging as the leading product type. This leadership is attributed to the segment’s ability to offer superior thermal uniformity, extended lifespan, and high structural integrity. Embedded heating elements allow heat to be evenly distributed across the board surface, resulting in improved thermal efficiency and reduced energy losses during operation.

These boards are being widely adopted in applications that demand consistent temperature control under varying environmental conditions. The robust performance of embedded systems reduces maintenance frequency, improving overall operational productivity. The capability to design custom-shaped boards with integrated elements tailored for specific applications has enhanced versatility and broadened market acceptance.

As industries continue to prioritize space-saving solutions with embedded efficiency, this product type is expected to maintain its dominant position The added benefits of safety, clean operation, and reduced downtime are further supporting its continued expansion across high-demand industrial sectors.

The resistance wire heating element segment is expected to capture 42.5% of the cast aluminum heating board market revenue share in 2025, making it the leading heating element type. This dominance is being driven by the proven efficiency, cost-effectiveness, and adaptability of resistance wire technology in delivering rapid and consistent heat output. Resistance wires are capable of achieving high temperatures quickly and are suitable for a wide variety of heating environments, including those requiring precise temperature control and prolonged heat exposure.

Their integration into cast aluminum heating boards ensures reliable conductivity and stable performance, even under intensive use. The segment’s growth is also supported by the availability of different resistance wire materials such as nichrome and Kanthal, allowing manufacturers to tailor performance characteristics for diverse industrial applications.

Ease of installation, simple replacement, and long operational life contribute to its widespread adoption As industries continue to seek robust and efficient heating components, resistance wire technology is expected to retain its strong presence in the market.

The medium temperature range segment is projected to hold 53.1% of the cast aluminum heating board market revenue share in 2025, establishing itself as the dominant temperature category. Its leadership is being supported by the wide applicability of medium-range heating systems in industries such as packaging, plastics, food processing, and laboratory equipment. This temperature range offers an ideal balance between energy efficiency and operational effectiveness, making it suitable for applications requiring consistent thermal output without the risks associated with high-temperature exposure.

The segment benefits from compatibility with a broad spectrum of embedded heating elements and control systems, enhancing precision and user flexibility. Manufacturers are focusing on medium-range boards due to their high demand across both standard and custom-engineered heating solutions.

The operational safety, lower energy consumption, and longer component life associated with this temperature range are further reinforcing its appeal As energy-conscious industries prioritize equipment that performs reliably within moderate thermal limits, the medium temperature segment is expected to remain the most widely utilized category in the market.

Cast aluminum heating boards are widely used in a range of industries such as electronics, automotive, and industrial heating, due to their excellent heat conductivity, corrosion resistance, and long-lasting performance. The market is driven by increasing demand for energy-efficient heating systems, especially in applications where precise temperature control and fast heat dissipation are required. Challenges in the market include the high cost of raw materials, especially aluminum, and the need for consistent product quality.

Opportunities lie in the development of more compact, lightweight, and energy-efficient cast aluminum heating boards that offer enhanced performance. Trends in the market point to increasing adoption of aluminum heating solutions in the automotive sector, particularly in electric vehicles (EVs), as well as growing interest in smart, connected heating systems for industrial applications. Suppliers that can offer high-performance, cost-effective, and environmentally friendly solutions are well-positioned for growth.

The cast aluminum heating board market is being driven by the growing demand for energy-efficient and durable heating solutions. As industries seek to reduce energy consumption and operating costs, cast aluminum heating boards, known for their excellent heat conductivity and long lifespan, are gaining popularity in a variety of applications. These boards are particularly valuable in heating systems where precise temperature control and fast heat dissipation are crucial, such as in industrial heating, electronics, and HVAC systems. The increasing adoption of energy-efficient technologies in both commercial and residential sectors is further boosting the market. In addition, as electric vehicles (EVs) gain market share, the automotive industry is becoming a key driver for cast aluminum heating boards, especially for battery heating applications in EVs.

The cast aluminum heating board market faces several challenges related to raw material costs, particularly for aluminum, which can fluctuate based on global supply and demand. These price fluctuations can significantly impact the production cost of heating boards. Additionally, ensuring consistent product quality in terms of heat conductivity, durability, and finish is crucial for maintaining market competitiveness. Regulatory constraints, particularly in terms of product safety and environmental compliance, are also important considerations.

Manufacturers must ensure that their products meet international safety standards while adhering to environmental guidelines regarding emissions and material usage. Technical constraints related to the design of compact, high-performance heating boards that offer energy efficiency without compromising heat dissipation remain a key challenge. Overcoming these obstacles requires continuous innovation and investment in research and development.

Opportunities in the cast aluminum heating board market are particularly strong in the automotive sector, especially with the rise of electric vehicles (EVs). Cast aluminum heating boards are increasingly being used for battery heating applications in EVs, where efficient and uniform heat distribution is critical for battery performance and longevity. Additionally, there is growing interest in smart, connected heating systems for industrial applications, where real-time monitoring and temperature control are essential.

Manufacturers are also exploring opportunities in the development of more compact, lightweight, and energy-efficient cast aluminum heating boards that can be integrated into a wider range of applications. As industries continue to prioritize energy efficiency, automation, and sustainability, demand for advanced, high-performance heating solutions is expected to rise, presenting substantial growth potential for suppliers offering innovative and reliable products.

The cast aluminum heating board market is trending toward the integration of smart technologies, energy-efficient solutions, and compact designs. The growing demand for connected devices and smart heating systems is driving manufacturers to develop heating boards that can be monitored and controlled remotely, providing real-time data on performance, temperature, and energy consumption. In parallel, there is a significant shift towards the development of energy-efficient heating solutions that reduce power consumption while maintaining high levels of heat conductivity.

Compact designs are also gaining traction, as manufacturers look to create smaller, more versatile heating boards that can be integrated into a wide range of devices, from household appliances to industrial machinery. These trends are shaping the future of the market, with innovation in energy efficiency, connectivity, and design leading the way.

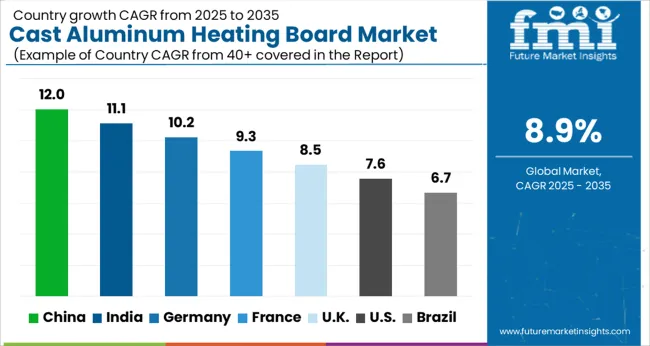

| Country | CAGR |

|---|---|

| China | 12.0% |

| India | 11.1% |

| Germany | 10.2% |

| France | 9.3% |

| UK | 8.5% |

| USA | 7.6% |

| Brazil | 6.7% |

The global cast aluminum heating board market is expected to grow at a CAGR of 8.5% from 2025 to 2035. China leads with a CAGR of 12.0%, followed by India at 11.1% and Germany at 10.2%. The UK and USA have more moderate growth rates of 8.5% and 7.6%, respectively. The demand for these products is driven by the increasing need for energy-efficient heating solutions across residential, commercial, and industrial sectors. Government policies focused on reducing carbon emissions, the growing adoption of smart home technologies, and the rise of sustainable living trends are expected to further accelerate market growth. The analysis spans over 40+ countries, with the leading markets shown below

The cast aluminum heating board market in China is expected to grow at a CAGR of 12.0% from 2025 to 2035, leading the global market. The country's rapid industrialization and expanding manufacturing sectors are key drivers of this growth. China’s increasing adoption of energy-efficient heating solutions in industries such as automotive, construction, and residential buildings is contributing to the rising demand for cast aluminum heating boards.

As a major producer of aluminum products, China benefits from its strong supply chain, ensuring cost-effective production of high-quality heating boards. The growing focus on reducing carbon footprints and improving energy efficiency has further accelerated the use of cast aluminum heating boards in commercial and residential heating systems. China’s commitment to upgrading its infrastructure and expanding smart home technology is driving the market.

The cast aluminum heating board market in India is projected to grow at a CAGR of 11.1% from 2025 to 2035. The market is being driven by India’s rising demand for efficient and cost-effective heating solutions, especially in the residential and industrial sectors. As urbanization accelerates and more people transition to modern homes, the need for reliable and energy-efficient heating systems is increasing, which boosts the demand for cast aluminum heating boards.

India’s growing industrial and manufacturing sectors also require these heating boards for use in equipment and machinery. With the government’s push for green building initiatives and energy-efficient solutions, the demand for aluminum-based products is further rising. The growth of the real estate sector and increasing disposable income are expected to boost the market for cast aluminum heating systems in India. The affordability and durability of these products make them attractive to both consumers and businesses, further accelerating their adoption.

The cast aluminum heating board market is projected to grow at a CAGR of 10.2% from 2025 to 2035. As one of Europe’s largest manufacturing hubs, Germany is witnessing strong demand for energy-efficient solutions, particularly in residential, commercial, and industrial sectors. The government’s commitment to sustainable energy policies and building regulations is driving the adoption of environmentally friendly heating solutions. Cast aluminum heating boards are becoming increasingly popular due to their high efficiency, durability, and relatively low cost compared to other heating solutions.

The automotive and manufacturing industries, which rely on precision heating systems, are also significant consumers of these products. Germany’s growing emphasis on smart home technologies and intelligent heating solutions is contributing to the increased demand for cast aluminum heating boards. With its strong technological infrastructure and focus on sustainability, Germany is poised to remain a key market for these heating solutions.

The UK cast aluminum heating board market is expected to grow at a CAGR of 8.5% from 2025 to 2035. The demand for cast aluminum heating boards in the UK is being driven by the increasing need for energy-efficient solutions, particularly in the residential sector. With rising energy costs, consumers are looking for affordable and reliable heating alternatives, and cast aluminum heating boards are emerging as a popular choice. Additionally, the UK government’s focus on reducing carbon emissions and promoting green energy solutions is boosting the adoption of energy-efficient heating technologies in both commercial and residential buildings.

The increasing popularity of modern housing and renovations, along with the rise of smart home systems, further drives the demand for high-performance heating products. The UK also benefits from a growing manufacturing sector, which requires energy-efficient heating systems for equipment and machinery.

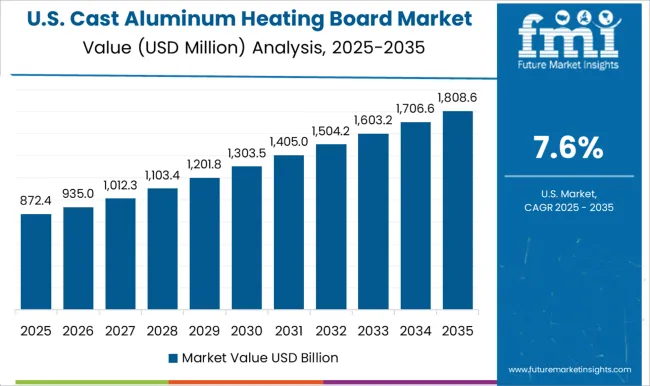

The USA cast aluminum heating board market is projected to grow at a CAGR of 7.6% from 2025 to 2035. As the USA continues to expand its residential, commercial, and industrial infrastructure, the demand for cost-effective and energy-efficient heating solutions is rising. The construction of new homes, along with renovations in existing buildings, is fueling the need for durable and high-performance heating systems, particularly cast aluminum heating boards.

The USA government’s commitment to reducing energy consumption and supporting green initiatives is further boosting the market for energy-efficient heating solutions. The demand is also driven by the growing adoption of smart homes and automation systems, which require advanced heating products. With the rise of sustainable living trends, consumers are increasingly opting for environmentally friendly products, and cast aluminum heating boards offer a viable solution. The industrial sector in the USA continues to expand, increasing the demand for efficient heating systems in manufacturing and other sectors.

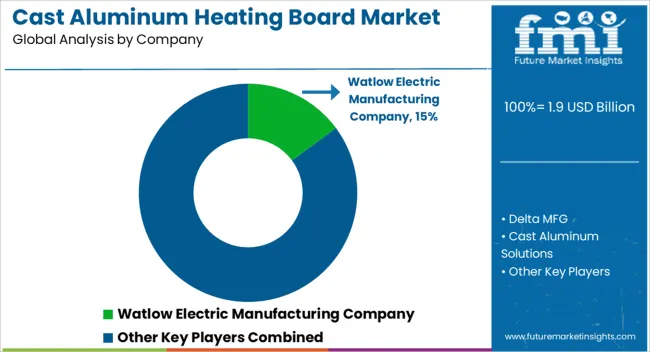

The cast aluminum heating board market is competitive, with key players providing high-performance solutions across diverse industries, including automotive, electronics, industrial heating, and HVAC. Watlow Electric Manufacturing Company is a dominant force, offering a range of cast aluminum heating boards designed for process heating and temperature control applications. Their solutions are known for durability, energy efficiency, and customization, catering to industries that require reliable thermal management.

Delta MFG competes by providing high-quality cast aluminum heating boards that excel in heat conductivity and resistance to thermal stress, making them ideal for applications in industrial heating systems and equipment. Cast Aluminum Solutions also plays a significant role, offering solutions designed for extreme temperatures and high thermal efficiency. Their products are used in demanding sectors such as aerospace and automotive, where precision and reliability are paramount.

Hotwatt, Inc. specializes in cast aluminum heating elements used in laboratory, industrial, and HVAC systems. The company emphasizes energy efficiency and precision heat distribution, providing solutions that are reliable and cost-effective. Tutco-Farnam’s offerings are focused on providing fast heat-up times, energy savings, and long-term performance, making them a popular choice in industrial applications. Dalton Electric Heating Co., Inc. provides robust cast aluminum heating boards for industrial furnaces and ovens, ensuring uniform heat distribution and long-term durability. Backer Marathon, Inc. and Durex Industries offer similar high-performance heating solutions, focusing on product reliability and the ability to withstand extreme conditions.

Tempco Electric Heater Corporation and Pelonis Technologies, Inc. provide energy-efficient heating solutions suitable for a wide range of applications. Companies like Warren Electric Corporation, Temp-Pro Inc., and Chromalox, Inc. are also significant players, offering tailored, high-performance products for specialized industrial needs. The competitive strategies in this market revolve around offering customized solutions that maximize energy efficiency, ensure safety, and meet the demanding specifications of industries that require reliable and long-lasting thermal management systems. Product brochures from these companies highlight key attributes such as high thermal conductivity, corrosion resistance, and ease of integration into existing systems.

| Item | Value |

|---|---|

| Quantitative Units | USD 1.9 billion |

| Product Type | Cast Aluminum Heating Boards (Embedded Heating Elements), Flat Cast Aluminum Heating Boards, Cast Aluminum Heating Boards (with Fins), Cast Aluminum Heating Mats, and Cast Aluminum Radiators |

| Heating Element Type | Resistance Wire, PTC (Positive Temperature Coefficient) Elements, Micathermic Heating Elements, and Infrared Heating Elements |

| Temperature Range | Medium, Low, and High |

| Application | Industrial heating, Commercial heating, and Residential heating |

| End Use | Electronics Manufacturing, Food Processing, Automotive, Aerospace, Healthcare, Chemical Processing, Oil and Gas, Textiles, and Construction |

| Distribution Channel | Distributors and Wholesalers, Direct Sales, Online Retail, and B2B Sales |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

| Country Covered | United States, Canada, Germany, France, United Kingdom, China, Japan, India, Brazil, South Africa |

| Key Companies Profiled | Watlow Electric Manufacturing Company, Delta MFG, Cast Aluminum Solutions, Hotwatt, Inc., Tutco-Farnam, Dalton Electric Heating Co., Inc., Backer Marathon, Inc., Durex Industries, Industrial Heating Elements, Tempco Electric Heater Corporation, Pelonis Technologies, Inc., Warren Electric Corporation, Temp-Pro Inc., and Chromalox, Inc. |

| Additional Attributes | Dollar sales by product type, application, and energy efficiency are rising, driven by demand for energy-efficient, durable heating solutions, with strong growth in North America, Europe, and Asia-Pacific, fueled by industrial automation investments |

The global cast aluminum heating board market is estimated to be valued at USD 1.9 billion in 2025.

The market size for the cast aluminum heating board market is projected to reach USD 4.5 billion by 2035.

The cast aluminum heating board market is expected to grow at a 8.9% CAGR between 2025 and 2035.

The key product types in cast aluminum heating board market are cast aluminum heating boards (embedded heating elements), flat cast aluminum heating boards, cast aluminum heating boards (with fins), cast aluminum heating mats and cast aluminum radiators.

In terms of heating element type, resistance wire segment to command 42.5% share in the cast aluminum heating board market in 2025.

Full Research Suite comprises of:

Market outlook & trends analysis

Interviews & case studies

Strategic recommendations

Vendor profiles & capabilities analysis

5-year forecasts

8 regions and 60+ country-level data splits

Market segment data splits

12 months of continuous data updates

DELIVERED AS:

PDF EXCEL ONLINE

Casting Mold Market Size and Share Forecast Outlook 2025 to 2035

Cast Stretch Films Market Size and Share Forecast Outlook 2025 to 2035

Casted Automotive Components Market Size and Share Forecast Outlook 2025 to 2035

Casting Multi-stage Centrifugal Blower Market Size and Share Forecast Outlook 2025 to 2035

Castor Oil Polyol Market Size and Share Forecast Outlook 2025 to 2035

Cast Polymers Market Size and Share Forecast Outlook 2025 to 2035

Cast Resin Transformer Market Size and Share Forecast Outlook 2025 to 2035

Casters Market Size and Share Forecast Outlook 2025 to 2035

Castor Oil-Based Biopolymer Market Size and Share Forecast Outlook 2025 to 2035

Cast Acrylic Sheets Market Size and Share Forecast Outlook 2025 to 2035

Castor Oil Market Growth – Trends & Forecast 2025 to 2035

Castration-Resistant Prostate Cancer (CRPC) Treatment Market Insights - Demand, Size & Industry Trends 2025 to 2035

Castor Oil Derivatives Market Growth - Trends & Forecast 2025 to 2035

Precast Concrete Market Size and Share Forecast Outlook 2025 to 2035

Podcasting Market Size and Share Forecast Outlook 2025 to 2035

Die Cast Toys Market Size and Share Forecast Outlook 2025 to 2035

Die Casting Services Market Analysis - Growth & Forecast 2025 to 2035

Gray Cast Iron Rod Market Size and Share Forecast Outlook 2025 to 2035

Grid Casting Machine Market Size and Share Forecast Outlook 2025 to 2035

Broadcast Switchers Market Size and Share Forecast Outlook 2025 to 2035

Thank you!

You will receive an email from our Business Development Manager. Please be sure to check your SPAM/JUNK folder too.

Chat With

MaRIA